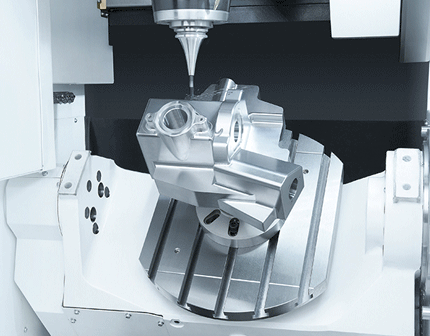

5-axis CNC machining has become a primary solution for manufacturing complex, high-precision parts while controlling cost and lead time. By allowing the tool or workpiece to move in five directions simultaneously, it enables more operations to be completed in a single setup, reduces manual intervention, and improves dimensional accuracy. This article explains in a systematic and technical way how 5-axis machining delivers cost and time savings, what drives those savings, and how to apply 5-axis capabilities effectively in industrial environments.

Fundamentals of 5-Axis CNC Machining

Understanding the fundamentals of 5-axis machining is essential for evaluating its economic impact. Unlike traditional 3-axis machining, which moves the cutting tool linearly in X, Y, and Z axes, 5-axis machining adds two rotary axes that allow the tool or table to tilt and rotate. This additional freedom of movement enables the tool to approach the workpiece from virtually any direction within machine limits.

Axis Configurations and Motion Types

5-axis machines are generally categorized by how they achieve the additional two degrees of freedom. Common configurations include:

- Table-table: Both additional axes are on the table (e.g., tilting and rotating table).

- Head-head: Both additional axes are in the spindle head (e.g., tilting and swiveling spindle).

- Head-table: One rotary axis in the head and one on the table.

Two main motion strategies are used:

Indexed 5-axis (3+2 machining) – The rotary axes are positioned to a fixed angle, then locked, while cutting is performed using X, Y, and Z. This is useful for accessing multiple faces without full simultaneous motion.

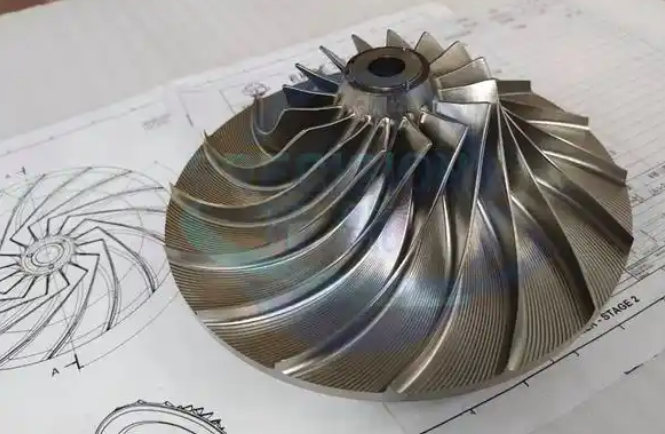

Simultaneous 5-axis – All five axes can move at the same time. This allows continuous tool orientation changes during cutting and is crucial for freeform surfaces, impellers, and turbine blades.

Key Hardware and Control Elements

For cost and lead time performance, several hardware and control aspects are important:

- High-rigidity mechanical structure (cast iron, advanced damping materials).

- Linear and rotary axis drives with sufficient torque and acceleration.

- High-speed spindles, often 12,000–30,000 rpm for aluminum and smaller tools.

- High-resolution encoders on rotary axes (often 0.0001° or finer).

- CNC control with look-ahead capability and optimized 5-axis interpolation.

These features support stable high-feed machining, maintain accuracy across complex motion paths, and directly influence cycle time and quality.

Cost and Lead Time Drivers in Complex Part Machining

Before explaining how 5-axis machining reduces cost and lead time, it is useful to identify what typically drives cost and schedule in complex part production. The most influential factors are:

1) Number of setups required to complete the part.

2) Total cutting time (cycle time) and machine utilization.

3) Manual operations including handling, repositioning, deburring, and polishing.

4) Scrap rate and rework due to dimensional or geometric inaccuracies.

5) Fixture design, manufacturing time, and validation.

6) Programming complexity and CAM processing time.

7) Inspection and quality assurance requirements.

For parts with multiple faces, complex contours, freeform surfaces, or undercuts, 3-axis machines often require many setups and specialized fixtures. Each additional setup adds indirect labor, schedule risk, and cumulative positioning errors. 5-axis machining addresses these drivers in a direct and quantifiable way.

Single-Setup Machining and Setup Cost Reduction

One of the most direct ways 5-axis machining reduces cost and lead time is by minimizing the number of setups needed to complete a part. With the ability to tilt and rotate the workpiece or spindle, the machine can access multiple faces and angles without removing the part from the fixture.

Setup Reduction Mechanism

In a typical 3-axis environment, a complex part may require:

- 4–8 separate setups for different faces and angles.

- Multiple dedicated fixtures or soft jaws for each setup.

- Manual inspection and realignment steps between operations.

In contrast, a 5-axis machine can often complete the same part in one or two setups. The reduction in setups yields:

- Lower non-cutting labor cost: Fewer operator interventions to load, unload, and realign the part.

- Shorter cumulative setup time: Typical single-setup preparation may be 30–90 minutes, compared to several hours for multiple fixtures.

- Reduced fixture inventory and management overhead.

Impact on Positioning Accuracy and Scrap

Every time a part is removed from a fixture and re-clamped, there is a risk of positional error. Even with precision fixtures, small deviations accumulate across multiple setups. This can lead to:

- Misaligned features between faces.

- Out-of-tolerance hole positions.

- Geometric mismatches on intersecting surfaces.

5-axis single-setup machining uses one fixture and one coordinate system, dramatically improving relative position accuracy between features. This reduces the risk of scrap and rework, particularly for parts where tight true position, profile, or concentricity tolerances are required between features located on different faces.

Tool Access, Shorter Tools, and Higher Material Removal Rates

Tool length and access angle have a significant impact on both machining time and stability. 5-axis capabilities allow the tool to be oriented optimally relative to the surface, enabling shorter tools and more aggressive cutting parameters.

Effect of Tool Length on Stability

Long tool overhang causes increased deflection and vibration, which forces conservative feeds and speeds to maintain surface quality and dimensional accuracy. By tilting the workpiece or tool, 5-axis machining can often reduce the required tool length by 30–60% compared to 3-axis setups.

This directly affects:

- Maximum allowable feed rate before chatter occurs.

- Depth of cut and width of cut for roughing operations.

- Surface finish and dimensional accuracy on slender features.

Higher Material Removal Rates (MRR)

Shorter, stiffer tools allow higher material removal rates. For example:

- Roughing aluminum with a 16 mm end mill on a 3-axis machine may require conservative parameters due to tool reach constraints.

- The same operation on a 5-axis machine using a shorter tool can often run at higher radial engagement and feed rate.

Although exact gains depend on machine rigidity and workpiece material, it is common to see significant reductions in roughing time when 5-axis orientation is used to maintain a favorable engagement and tool length.

Reduced Fixturing Complexity and Cost

Fixturing is a major cost and lead time contributor for complex parts. Specialized multi-face fixtures require design effort, machining time, and validation, especially when precision location is needed for each face.

Simplified Fixtures through Rotary Motion

Because 5-axis machines can access multiple faces with one clamping, fixture design can be simplified to focus on secure, repeatable clamping of the raw stock or near-net shape. Typical advantages include:

- Use of standardized modular fixturing systems instead of extensive custom fixtures.

- Reduced need for complex multi-station tombstones and indexing fixtures.

- Easier fixture validation and maintenance.

Quantitative Impact on Fixture Costs

For a new complex part family, fixture-related tasks may include CAD design, CAM for fixture machining, material procurement, machining of fixture components, assembly, and testing. By eliminating several part orientations, 5-axis machining can reduce:

- Number of fixtures required per part.

- Engineering hours for fixture design.

- Machine time allocated to fixture manufacturing.

In many production environments, the cumulative fixture cost across a project can be reduced substantially, while also shortening the time from design release to first article completion.

Cycle Time Reduction through Simultaneous 5-Axis Strategies

Beyond setup and fixturing savings, 5-axis machining enables specific toolpath strategies that reduce cycle time directly. These strategies rely on continuous tool orientation control to maintain constant engagement, optimize cutting conditions, and reduce air cutting.

Continuous Tool Orientation for Freeform Surfaces

When machining freeform surfaces such as turbine blades, blisks, molds, or orthopedic implants, simultaneous 5-axis machining allows the tool to remain normal or near-normal to the surface. This yields:

- Consistent chip thickness and improved tool life.

- Uniform surface finish across complex curvature.

- Reduced number of passes due to effective stepover control.

By avoiding extreme tool tilts or unfavorable cutting directions that are common in 3-axis approximation strategies, the programmer can choose higher feeds and maintain stable cutting conditions across the entire surface.

Shorter Toolpaths and Reduced Air Cutting

5-axis CAM strategies allow the tool to follow the shortest viable path while maintaining proper orientation. This reduces air cutting segments where the tool is moving but not removing material. Particularly for parts with deep pockets, enclosed cavities, or complex multi-faceted geometry, this can significantly reduce total cycle time.

| Contributor | Description | Impact on Time |

|---|---|---|

| Continuous tool orientation | Maintains optimal cutting angle on freeform surfaces | Shorter finishing passes, higher feed rates |

| Reduced repositioning | Eliminates intermediate moves between multiple setups | Less non-cutting machine motion |

| Shorter tools | Improved stiffness allows more aggressive parameters | Higher material removal rates in roughing and semi-finishing |

| Optimized access paths | Direct access to features without complex approach moves | Lower air cutting time |

Improved Geometric Accuracy and Reduced Rework

Geometric tolerance requirements are a common source of rework, inspection iteration, and delivery delays. 5-axis machining improves the ability to achieve tight geometric and positional tolerances on complex components.

Accuracy Benefits from Single Coordinate System

With 5-axis machining, most critical features can be aligned and cut within a single coordinate system. This ensures precise relationships between faces, holes, slots, and freeform surfaces. When combined with modern probing systems, the machine can:

- Automatically locate the raw stock or pre-machined reference surfaces.

- Compensate for small misalignments in the clamping.

- Update toolpaths or work offsets based on in-process measurements.

This reduces the need for manual adjustments and rework and increases first-pass yield.

Tool Tilt to Control Surface Quality and Dimensional Error

By tilting the tool, 5-axis machining can keep the effective cutting edge in contact with the surface under favorable conditions. This helps to:

- Minimize cusp height for a given stepover in finishing operations.

- Avoid cutting with less effective tool regions (e.g., the center of a ballnose end mill).

- Reduce scallop variations across complex curvature.

Improved consistency in surface quality and feature definition translates into lower post-machining adjustment and finishing time, which directly shortens lead time.

Eliminating or Reducing Secondary Operations

5-axis machining can integrate operations that would otherwise be performed in separate setups or even on different machines. By consolidating operations, shops can reduce part handling, queue time, and coordination effort across multiple processes.

Multi-Side Drilling, Tapping, and Milling

Common secondary operations for 3-axis workflows include drilling and tapping holes on multiple faces, milling chamfers, or adding side features. A 5-axis machine can orient the part so that these features are machined in the same cycle as the primary operations. This consolidation:

- Reduces the number of machine tools needed in the process chain.

- Decreases WIP (work in progress) inventory between operations.

- Simplifies scheduling and logistics.

Surface Finishing and Blending Reduction

Because 5-axis machining can produce better surface continuity on complex geometry, manual finishing steps like hand blending, polishing, or re-contouring are often reduced. For example, turbine blades or complex mold surfaces can be finished to near-final surface quality directly on the machine, leaving only minimal manual work for critical zones if required.

Design for Manufacturability with 5-Axis Capabilities

To fully realize the cost and lead time benefits of 5-axis machining, part designs should leverage the strengths and capabilities of 5-axis processes. Design for manufacturability (DFM) in a 5-axis context focuses on geometry, tolerancing, and material considerations that align with 5-axis machine capabilities.

Geometry Considerations

5-axis machining is particularly well-suited for:

- Parts with multiple angled features or intersecting faces.

- Freeform surfaces that require continuous curvature and tight surface profile control.

- Internal features accessible only through tilted or angled toolpaths.

Designers can often simplify or integrate features knowing that tools can be oriented freely, reducing the need for separate components or assembly steps.

Tolerance and Datum Strategy

When designing for 5-axis machining, it is beneficial to:

- Define datums that can be probed and aligned in one clamping.

- Group tight tolerances among features that can be machined in the same setup.

- Use geometric tolerancing to reflect functional requirements rather than overly tight defaults.

This approach aligns inspection and machining processes, reduces unnecessary precision on non-critical features, and ensures that 5-axis capability is directed toward features where it provides the most value.

Material and Industry Applications Influencing Cost and Lead Time

The cost and lead time advantages of 5-axis machining become more pronounced in certain materials and industries where part complexity and tolerance requirements are high.

Aerospace Components

Aerospace parts often have complex 3D geometries, thin walls, and tight tolerances, frequently in materials like titanium and high-strength aluminum alloys. In this context, 5-axis machining provides:

- Optimized tool engagement to maintain stable cutting in difficult materials.

- Reduced setups for multi-face parts such as structural brackets, frames, and housings.

- Efficient machining of blisks, impellers, and turbine components that require continuous freeform surfaces.

The reduction of setups and improved accuracy minimize scrap, which is especially important for high-value aerospace materials and long raw material lead times.

Medical Implants and Instruments

Medical components such as orthopedic implants, dental implants, and surgical instruments often require complex organic shapes and high surface quality. 5-axis machining supports:

- Accurate reproduction of anatomical geometries.

- Uniform surface finishes suitable for coatings or direct implantation.

- Consolidated machining of multi-face features like bone screw threads and flanges.

Shorter lead times are critical for product introduction and customization, and 5-axis machining enables flexible, precise manufacturing of small to medium batches.

Mold and Die Manufacturing

Molds and dies typically feature complex cavity surfaces and require high dimensional stability. 5-axis machining enables:

- Single-setup machining of deep cavities with tilted tools.

- Reduced polishing and blending due to improved surface continuity.

- Better access to undercuts and intricate features without complex EDM setups.

The ability to finish cavities in fewer setups shortens overall mold build time and brings tools into production faster, which directly improves time-to-market for molded products.

Programming, CAM, and Data Considerations

The economic performance of 5-axis machining also depends on the efficiency of programming and CAM processes. Modern CAM software provides advanced 5-axis toolpath generation, verification, and simulation functions that help reduce lead time from design to first article.

Toolpath Strategies and Templates

Programming time can be reduced by using standardized 5-axis toolpath templates for common part families. Examples include:

- Blade and impeller templates for turbomachinery components.

- Surface finishing templates for molds and freeform surfaces.

- Automatic feature-based machining for holes, slots, and pockets on multiple faces.

Once these strategies are validated, they can be reused, which decreases programming effort for similar parts and shortens the overall engineering phase.

Simulation and Collision Avoidance

5-axis machining introduces additional possibilities for collision between the tool, holder, spindle, and workpiece. Detailed CAM simulation with accurate machine, fixture, and tool models helps ensure that toolpaths are safe and optimized before release to the shop floor. This:

- Reduces the risk of machine damage and unplanned downtime.

- Minimizes on-machine trial and error.

- Improves confidence in unattended or lightly attended machining.

By identifying issues early in the digital environment, shops avoid delays during setup and prove-out, thereby shortening time to stable production.

Quantifying Cost and Lead Time Savings

The specific numerical savings from 5-axis machining vary by part, industry, and production volume, but general patterns can be observed in areas such as setup time, cycle time, and scrap rate. Conceptually, cost and lead time effects can be compared between 3-axis and 5-axis workflows.

| Aspect | Typical 3-Axis Workflow | 5-Axis Workflow |

|---|---|---|

| Number of setups | Multiple (4–8 or more for complex parts) | Often 1–2 setups |

| Fixture complexity | High, multiple dedicated fixtures | Simplified, often modular fixturing |

| Tool length | Longer tools, higher deflection | Shorter tools, higher stiffness |

| Cycle time | Longer due to conservative parameters and air cutting | Shorter due to higher MRR and efficient toolpaths |

| Scrap and rework | Higher due to multi-setup alignment errors | Lower due to single coordinate system machining |

| Lead time to first article | Longer due to fixture build and multi-machine routing | Shorter due to operation consolidation |

By analyzing these aspects for specific part families, manufacturers can estimate payback time for 5-axis investments and identify where 5-axis capacity will yield the highest economic benefit.

Practical Considerations for Implementing 5-Axis Machining

Successfully leveraging 5-axis machining for cost and lead time reduction requires more than acquiring machines. Several practical considerations influence the realized benefits.

Part Selection and Prioritization

Not all parts justify 5-axis machining. Parts with simple prismatic geometry and minimal side features may be more economical on 3-axis equipment. 5-axis capacity should be prioritized for:

- Parts with multiple angled faces and complex surfaces.

- High-value parts where scrap is particularly costly.

- Parts requiring frequent design changes or short lead times.

A structured selection process ensures that 5-axis machines are used where they provide maximum cost and lead time advantages.

Process Standardization

Consistent process standards help compress lead time across multiple jobs. Standardization efforts may include:

- Common fixture bases and locating schemes.

- Standard tool libraries and holders for 5-axis work.

- Documented programming templates and machining parameters for typical materials and geometries.

This reduces variability, shortens setup and programming time, and improves repeatability across shift changes and different operators.

Summary of Cost and Lead Time Benefits

5-axis CNC machining offers a comprehensive set of mechanisms that directly reduce cost and lead time for complex parts:

- Single-setup machining decreases setup labor, reduces fixture count, and improves positional accuracy.

- Optimized tool orientation enables shorter tools, higher material removal rates, and reduced cycle time.

- Simplified fixturing cuts engineering and manufacturing time for fixtures.

- Improved geometric accuracy and surface quality reduce rework, scrap, and finishing operations.

- Consolidation of multi-face and secondary operations on one machine shortens the overall process chain.

- Effective use of CAM and simulation accelerates programming and reduces prove-out time.

When integrated thoughtfully into part design, process planning, and production workflows, 5-axis machining becomes an effective method for controlling manufacturing cost and meeting tight delivery schedules on demanding, complex components across multiple industries.