CNC machines can cut steel effectively and with high precision, provided the right machine type, tooling, process parameters, and workholding are used. From mild steel to hardened tool steel, modern CNC milling, turning, and drilling centers routinely process steel in both prototyping and high-volume production. This article explains how CNC machines cut steel in a systematic, technical, and comprehensive way.

Fundamentals of CNC Steel Machining

Computer Numerical Control (CNC) machining uses programmed toolpaths to remove material from a workpiece. When applied to steel, the same principles as other metals apply, but stiffness, power, heat management, tooling, and cutting parameters become more critical due to steel’s higher strength and hardness compared with aluminum or plastics.

Key aspects determining whether a CNC machine can cut a specific steel include:

- Machine rigidity and spindle power

- Steel grade, hardness, and heat treatment condition

- Tool material, geometry, and coating

- Cutting speed, feed rate, and depth of cut

- Coolant delivery, lubrication, and chip evacuation

As long as these factors are appropriately matched, CNC machining of steel can achieve repeatable tolerances, good surface finish, and reliable tool life.

Types of CNC Machines Used for Steel

Different CNC machine architectures handle steel cutting tasks in different ways. The most frequently used types are milling machines, lathes (turning centers), and machining centers with both milling and turning capabilities.

CNC Milling Machines

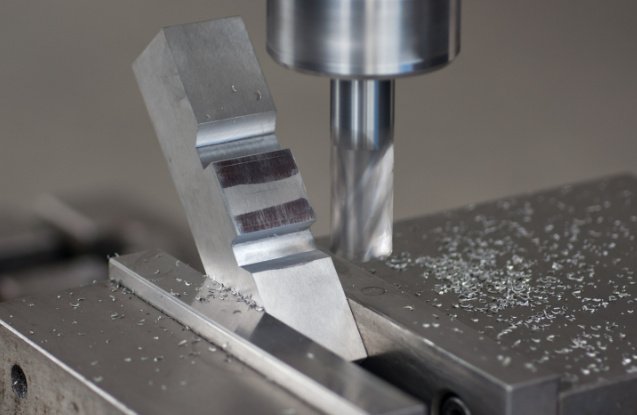

CNC milling machines use rotating cutting tools to remove steel from a stationary or moving workpiece. Vertical machining centers (VMCs) and horizontal machining centers (HMCs) are both widely used for steel machining.

Important attributes of a steel-capable CNC mill include:

- Rigid machine frame and linear guideways or box ways

- Sufficient spindle power (commonly 7.5 kW–30 kW for general industrial use)

- High-torque spindle at lower RPM for heavy cuts in steel

- Efficient coolant delivery and chip evacuation

CNC milling is suitable for cavities, pockets, complex 3D surfaces, and prismatic parts made from steel plates, blocks, or forgings.

CNC Turning Centers

CNC lathes or turning centers are used to cut steel bars, shafts, bushings, and other rotational components. The workpiece rotates, and stationary or powered tools remove material.

Features that support steel machining on turning centers include:

- Robust spindle bearings to withstand radial and axial loads

- High-torque spindle motors for larger diameters

- Turret tooling with rigid clamping and quick-change inserts

- Optional Y-axis and live tooling for milling features on turned parts

Multi-Axis and Mill-Turn Machines

Multi-axis machining centers (such as 4-axis and 5-axis mills, or combined mill-turn machines) can cut steel in more complex orientations. These machines are used for parts with intricate geometry where multiple setups on simple 3-axis machines would be inefficient or less accurate.

In steel machining, multi-axis capability is often exploited for:

- Complex aerospace brackets and structural components

- Automotive powertrain parts

- Molds and dies with contoured surfaces

Steel Types Commonly Machined on CNC

Steel is a broad family of iron-carbon alloys with different alloying elements, heat treatments, and mechanical properties. Machinability varies significantly across grades. Not all CNC machines or setups are suitable for all steels, especially for very hard or abrasive alloys.

| Steel Category | Example Grades | Approx. Hardness Range (HB or HRC) | Machinability Characteristics |

|---|---|---|---|

| Low carbon (mild) steel | ASTM A36, 1018, 1020 | ~120–180 HB | Generally easy to machine, moderate strength, common for structural parts. |

| Free-machining steel | 12L14, 11L17 | ~150–200 HB | Enhanced machinability due to added sulfur/lead; good chip control and tool life. |

| Medium carbon steel | 1045, 1144 | ~180–260 HB (normalized) | Higher strength than mild steel, requires more robust tooling and parameters. |

| Alloy steel | 4140, 4340, 8620 | ~200–350 HB (annealed); up to ~45–50 HRC when quenched and tempered | Widely used in machinery; machining becomes more demanding with hardness increase. |

| Stainless steel (austenitic) | 304, 316 | ~150–220 HB | Tough and work-hardening; requires sharp tools, lower surface speeds, effective coolant. |

| Stainless steel (martensitic) | 410, 420 | Up to ~50 HRC after hardening | Relatively hard and abrasive in heat-treated state; often requires carbide or CBN tooling. |

| Tool steel (annealed) | D2, O1, H13 (annealed) | ~200–260 HB | Machinable in annealed condition with carbide tools and controlled parameters. |

| Tool steel (hardened) | D2, H13, A2 (~50–62 HRC) | ~50–62 HRC | Requires advanced tooling (CBN, ceramic) and specialized finishing strategies. |

The machinability index (relative to a reference steel such as AISI 1112) is commonly used in industry to compare cutting performance, but actual performance depends on the specific combination of machines, tools, and cutting data.

Key Machine Capabilities for Cutting Steel

Not every CNC machine is optimized for steel. The ability to cut steel reliably depends on several machine-related parameters and design features.

Rigidity and Structural Design

High rigidity minimizes deflection under cutting forces, which is critical for steel due to the higher loads compared with softer materials. Relevant aspects include:

- Cast iron or mineral cast machine base and column

- Box ways or preloaded linear guides with substantial cross-section

- Short overhangs in tooling and workholding

- Robust spindle and toolholder systems (e.g., BT, CAT, HSK with appropriate taper size)

Rigidity directly influences achievable surface finish, dimensional accuracy, and permissible depth of cut.

Spindle Power and Torque

Cutting steel requires more power and torque than cutting aluminum for comparable removal rates. While even small CNC machines can cut mild steel in light passes, industrial users typically rely on spindles with several kilowatts of power and significant torque at moderate speeds.

Typical characteristics of steel-capable spindles include:

- Power range commonly from 7.5 kW to over 30 kW

- Maximum speed moderate compared with aluminum-focused machines (often 8,000–15,000 rpm for general-purpose steel machining)

- Strong torque in the lower to mid-speed range (e.g., 1,000–4,000 rpm) for larger cutters

Motion Control and Accuracy

High-precision motion control enables accurate steel cutting at specific tolerances. Essential elements are:

- High-resolution encoders on all axes

- Backlash compensation and preloaded ball screws or linear motors

- Thermal compensation for long machining cycles

For most steel components in general industry, tolerances in the range of ±0.01 mm are common and achievable with standard CNC machining practices. Tighter tolerances are possible with refined setups and controlled environments.

Coolant and Chip Management

Steel cutting generates substantial heat and continuous or segmented chips. An effective coolant and chip management system is essential to maintain tool life and dimensional stability.

Key features include:

- Flood coolant with sufficient flow rate for general steel machining

- Through-spindle coolant for deep-hole drilling and high-speed milling of steel

- Chip conveyors, augers, or flush systems to prevent chip accumulation

Tooling for CNC Steel Cutting

Tool material, geometry, and coatings significantly affect the success of cutting steel on a CNC machine. Proper selection ensures a balance between tool life, surface finish, and productivity.

Tool Materials

The main categories of cutting tool materials for steel are:

| Tool Material | Typical Application in Steel | Key Advantages | Considerations |

|---|---|---|---|

| High-Speed Steel (HSS) | Drills, taps, reamers, end mills for mild and medium carbon steels | Good toughness, less brittle than carbide, tolerant of interrupted cuts | Lower cutting speeds, more limited tool life in harder steels |

| Cemented Carbide | Inserts for turning, milling, drilling; solid carbide end mills | High hardness and wear resistance, higher cutting speeds than HSS | More brittle, requires rigid setup; grade selection important for steel types |

| Cermet | Finishing operations on steels with stable conditions | Excellent wear resistance and good surface finish | Less tolerant of interruptions and impacts |

| Cubic Boron Nitride (CBN) | Hard turning of hardened steels (typically > 45 HRC) | Excellent performance in hardened steel, high cutting speeds | High cost, best for finishing and high-value parts |

| Ceramic | High-speed finishing of hardened steels and cast irons | Very high heat resistance and speed capability | Requires stable conditions, sensitive to shock and vibration |

Tool Geometry

Geometry affects chip formation, cutting forces, and heat generation. In steel machining, tool geometry is selected to balance sharp cutting edges with edge strength.

Important geometric parameters include:

- Rake angle: positive rake reduces cutting force but weakens the edge; negative or small positive rake is common in steel milling and turning.

- Relief angle: ensures clearance behind the cutting edge to prevent rubbing.

- Nose radius (in inserts): smaller radii for fine finishing and tight corners, larger radii for heavier loads and improved surface finish in roughing.

- Helix angle (in end mills): moderate to high helix angles improve chip evacuation, but very high helix can potentially increase deflection in aggressive steel cuts.

Tool Coatings

Coatings improve wear resistance, reduce friction, and help control heat in steel cutting. Common coatings include:

- TiN (Titanium Nitride): general-purpose coating with improved wear resistance over uncoated tools.

- TiCN (Titanium Carbonitride): better hardness and wear resistance than TiN, suitable for many steels.

- TiAlN / AlTiN (Titanium Aluminum Nitride): excellent heat resistance, effective in high-speed steel cutting and dry machining conditions.

- Multi-layer advanced coatings: tailored to specific steel grades and applications, combining layers for abrasion and thermal resistance.

Coating selection depends on steel grade, cooling strategy (wet or dry), and cutting intensity.

Cutting Parameters for Steel on CNC Machines

Feeds and speeds must be set appropriately for steel to avoid tool failure or poor surface finish. While precise values depend on many factors, general ranges can be discussed.

Cutting Speed (Surface Speed)

Cutting speed for steel is often specified as surface speed (m/min or ft/min). For a given tool diameter, the spindle speed (rpm) is derived from this value. Typical ranges include:

- Mild steel with HSS tools: approximately 20–40 m/min

- Mild steel with carbide tools: approximately 100–200 m/min

- Alloy steel with carbide: approximately 80–180 m/min depending on hardness

- Stainless steel with carbide: approximately 60–150 m/min

- Hardened tool steel with CBN: substantially higher speeds are possible, but must follow tool manufacturer recommendations

These ranges are indicative. Specific values should follow tooling catalogs and be adjusted based on actual machine rigidity, coolant flow, and desired tool life.

Feed Rate and Chip Load

Feed rate determines chip thickness and cutting forces. For milling, feed per tooth is often used; for turning, feed per revolution. Proper chip load is essential to avoid both rubbing (too low load) and overloading the tool (too high load).

- For carbide milling cutters in mild steel, feed per tooth might range from roughly 0.02–0.12 mm/tooth depending on diameter and operation (finishing vs. roughing).

- For turning inserts in steel, feed per revolution might range from roughly 0.05–0.4 mm/rev based on insert geometry and depth of cut.

Feed settings must be coordinated with depth of cut and machine rigidity. CNC controls allow precise programming of feeds to maintain consistent chip load even during complex toolpaths.

Depth of Cut and Width of Cut

Depth of cut (axial) and width of cut (radial) define material removal volume. In steel, they must be moderate enough to control cutting forces and vibration, while still supporting productivity.

Common strategies include:

- Conventional roughing: moderate depth and width of cut, stable engagement.

- High-efficiency machining (HEM): larger axial depth and smaller radial width to maintain constant tool engagement and manage heat.

- Finishing passes: small depths (e.g., 0.1–0.5 mm) and fine feeds to achieve the desired surface finish and dimensional accuracy.

Coolant, Lubrication, and Chip Control

The interaction between tool, workpiece, chips, and coolant is critical in steel cutting. Managing heat and chip flow improves tool life and surface integrity.

Coolant Types and Delivery

Coolant for steel machining is typically water-based cutting fluid with additives for corrosion protection and lubrication. For tapping and other high-friction operations, higher lubricity fluids may be used.

Coolant delivery methods include:

- Flood cooling: nozzles direct large volumes of fluid onto the cutting area for general milling and turning.

- Through-tool coolant: high-pressure streams delivered through internal channels in drills, end mills, and turning tools, improving chip evacuation in deep pockets or holes.

- Mist or minimum quantity lubrication (MQL): small amounts of lubricant with compressed air, more common where lower coolant use is desired and cutting conditions allow.

Chip Formation and Evacuation

Steel chips can be long and stringy or short and broken depending on material and tool geometry. Excessively long chips can wrap around tools or workpieces, causing surface damage or machine stoppages. Chip-breaking geometries on inserts and appropriate feeds and speeds are used to control chip shape.

Effective chip evacuation is achieved by:

- Optimized chipbreaker design and feed rate to promote chip curling and breaking.

- Coolant and air jets to move chips away from the cutting zone.

- Machine features such as chip conveyors and properly sloped enclosures.

Workholding and Fixturing for Steel

Steel’s higher cutting forces require strong and rigid workholding to prevent part movement, vibration, and dimensional inaccuracies.

Clamping Devices

Common workholding methods for steel include:

- Vise clamping: used for rectangular blocks and plates; must ensure sufficient clamping force.

- Chucks: three-jaw or four-jaw chucks on lathes to hold round stock or irregular shapes; hydraulic or pneumatic chucks provide repeatable clamping forces.

- Fixtures and jigs: custom or modular fixtures for complex geometries or repeat production, designed to resist cutting forces in multiple directions.

Proper clamping avoids part distortion and maintains accurate positioning across multiple operations.

Location and Support

The workpiece must be accurately located and supported to maintain tolerances. Techniques include:

- Use of locating pins and surfaces to define reference datums.

- Support of overhanging features using rest pads or tailstocks in turning.

- Minimizing unsupported spans to reduce vibration during heavy steel cutting.

Surface Finish and Tolerance in Steel Machining

CNC machines can achieve fine surface finishes and tight dimensional tolerances on steel when appropriate tooling and parameters are used.

Surface Roughness

Surface roughness in steel machining depends strongly on feed, tool geometry, machine rigidity, and vibrations. Finishing operations can achieve:

- Roughness average (Ra) values of 0.8–1.6 µm with standard finishing passes.

- Lower Ra values (below 0.4 µm) using optimized tooling, fine feeds, and possibly specialized finishing tools.

For applications requiring higher surface integrity (e.g., sealing surfaces), further processes such as grinding or honing are sometimes applied after CNC machining.

Dimensional Tolerance

Steel components produced on CNC machines commonly achieve tolerances like ±0.01–0.05 mm depending on part size and function. Tighter tolerances are attainable with:

- Stable temperature conditions

- Tool wear compensation strategies

- In-process probing and measurement

Machine manufacturers often specify position accuracy and repeatability values, and these guide achievable tolerances in production environments.

Application Examples of CNC Steel Cutting

CNC steel machining is used across multiple industries for parts requiring strength, wear resistance, and predictable mechanical behavior.

Automotive and Transportation Components

Typical steel parts produced by CNC for automotive and transportation include:

- Axles, shafts, and gears from alloy steels

- Engine components such as crankshafts, connecting rods, and housings

- Structural brackets and suspension parts

These parts often use medium carbon and alloy steels treated to achieve specific strength and fatigue properties.

Mold and Die Components

Mold and die industries use tool steels and alloy steels for high wear resistance and dimensional stability. CNC machines perform tasks such as:

- Rough milling of cavities in annealed tool steel blocks

- Semi-finishing and finishing of contoured surfaces

- Machining of hardened tool steels using high-performance tools and strategies

Industrial Machinery and Equipment

Machine components, fixtures, and tooling rely heavily on steel. CNC machining provides precision and repeatability for parts like:

- Spindles, bearing housings, and gearboxes

- Machine frames and structural components

- Toolholders and clamps

Considerations and Practical Issues When Cutting Steel on CNC

While CNC machines can cut steel effectively, certain practical issues must be considered for consistent results and economical operation.

Tool Wear and Tool Life

Steel causes more wear on cutting tools than softer metals. Tool wear mechanisms include abrasion, adhesion, diffusion, and chipping. To manage tool wear:

- Select tool materials and coatings suitable for the steel grade and hardness.

- Use recommended cutting speeds and feeds from tooling catalogs, adjusting for desired tool life.

- Monitor tool condition through tool life counters or in-process inspection.

Heat and Thermal Expansion

Heat generated during steel cutting can cause tool softening, surface alterations, and dimensional changes due to thermal expansion. Using appropriate coolant, avoiding excessive cutting parameters, and planning operations to minimize heat accumulation contribute to dimensional stability.

Machine Selection and Load Limits

Lightweight or hobby-level CNC machines may be able to cut mild steel but are typically limited to shallow depths of cut, low feed rates, and small tools. Industrial CNC machines with higher rigidity and power accommodate heavier steel machining tasks, higher material removal rates, and harder alloys.

FAQ About CNC Machines Cutting Steel

Can a small CNC machine cut steel?

Small CNC machines can cut mild steel in limited conditions, using light cuts, conservative feeds and speeds, and high-quality tooling. However, due to lower rigidity and spindle power, material removal rates are modest, and machining harder steels or deep cuts is constrained. For continuous industrial steel machining, more robust machines are generally preferred.

What is the best tool material for cutting hardened steel on CNC?

For hardened steels above approximately 45 HRC, cubic boron nitride (CBN) and certain ceramic tools are commonly used, particularly for finishing operations. Carbide can still be used for some hardened steels at reduced speeds and with specialized grades, but tool life is usually shorter compared with CBN in high-hardness applications.

Do CNC machines need coolant for machining steel?

Coolant is highly recommended for most CNC steel machining because it helps dissipate heat, lubricates the cutting zone, and assists chip evacuation. Some specialized operations use dry cutting or minimum quantity lubrication with appropriate tools and coatings, but for general-purpose steel machining, flood or through-tool coolant is commonly applied.

What tolerances can CNC machining achieve in steel?

Standard CNC machines routinely achieve dimensional tolerances in steel parts on the order of ±0.01–0.05 mm, depending on part size and setup. With high-quality machines, controlled environments, proper fixturing, and in-process measurement, even tighter tolerances are possible for critical features.

Can CNC machines cut stainless steel as easily as mild steel?

CNC machines can cut stainless steel, but the process is usually more demanding than machining mild steel. Austenitic stainless steels such as 304 and 316 tend to work-harden and are tougher, requiring sharper tools, lower cutting speeds, higher-quality coatings, and effective coolant to maintain tool life and surface quality.