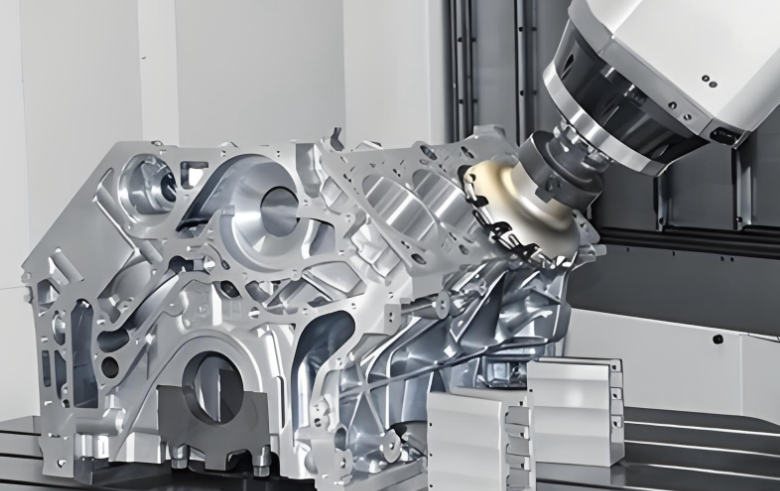

5-axis CNC machining services provide high-precision manufacturing for complex parts across the full product lifecycle, from initial prototypes to validated production runs. By enabling cutting tools to move along five different axes simultaneously, 5-axis machines can produce intricate geometries, maintain tight tolerances, and reduce setup times for a wide range of metals and plastics. This article explains the principles, capabilities, parameters, and application considerations for using 5-axis CNC machining as a complete solution from concept to mass production.

What Is 5-Axis CNC Machining

5-axis CNC machining is a computer-controlled subtractive manufacturing process in which the cutting tool and/or the workpiece can move along five different axes during machining. In addition to the conventional X, Y, and Z linear axes, 5-axis machines incorporate two rotational axes, typically denoted as A, B, or C, depending on the machine configuration.

The main feature of 5-axis machining is the ability to position and orient the tool so that complex surfaces and multiple features can be machined in a single setup. This improves dimensional accuracy, reduces cumulative error from repeated repositioning, and increases overall throughput.

Key 5-Axis Machine Configurations

There are several common configurations of 5-axis CNC machines. Each configuration offers different advantages for specific part shapes, sizes, and tolerances. The most typical configurations include:

- Swivel-rotary (trunnion) table machines

- Table-table machines

- Head-table machines

- Head-head machines

The following table summarizes typical characteristics of the primary configurations.

| Configuration | Rotational Axes Location | Typical Applications | Key Characteristics |

|---|---|---|---|

| Trunnion (swivel-rotary table) | A and C axes on tilting/rotary table | Complex prismatic parts, manifolds, housings | Good for heavy workpieces, excellent chip evacuation |

| Table-Table | A and C axes both on table | General precision components, molds | High rigidity, good accuracy, large work envelope |

| Head-Table | One axis in spindle head, one in table | Mixed geometry parts, aerospace brackets | Flexible orientation, good access to complex features |

| Head-Head | Both rotational axes in spindle head | Large parts clamped stationary, impellers | Ideal for bulky workpieces, reduced table motion |

In all configurations, the main objective is to keep the tool optimally oriented to the workpiece surface while maintaining rigidity and minimizing tool deflection.

From Prototype to Production with 5-Axis Machining

5-axis CNC machining supports every stage of product development, allowing a seamless transition from one-off prototypes to validated production volumes. The fundamental process steps remain the same, but the focus and priorities change as the part moves through its lifecycle.

Prototype Stage

In the prototype stage, the primary objectives are design validation, functional testing, and fast iteration. 5-axis machining is particularly useful here because it allows:

- Rapid production of complex geometries without dedicated tooling

- Short lead times with minimal setup changes

- Close approximation of final production materials and tolerances

For prototypes, programming is often optimized for flexibility, with toolpaths that can be quickly adjusted as the design evolves. Surface finish requirements may be relaxed in some areas to reduce machining time while maintaining critical features to specified tolerances.

Bridge and Pre-Production Stage

In the bridge or pre-production stage, the goal is to validate manufacturability and refine process parameters. At this stage, 5-axis machining is used to:

- Confirm stable cutting parameters for the selected material

- Verify fixture concepts and clamping strategies

- Establish inspection procedures and gauge points

Typical activities include machining small batches, performing dimensional analysis, and adjusting toolpaths to minimize cycle time while maintaining the required accuracy.

Production Stage

In the production stage, the emphasis shifts to repeatability, throughput, and cost control. 5-axis machines enable efficient production by:

- Reducing the number of setups required for each part

- Combining multiple operations into a single machine cycle

- Utilizing advanced CAM strategies for high material removal rates

Process control becomes critical. Tool wear monitoring, consistent tool presetting, documented setup sheets, and standardized inspection routines help maintain stable quality throughout the production run.

Typical 5-Axis Machining Capabilities and Tolerances

While specific capabilities depend on the machine model, tooling, and shop expertise, 5-axis CNC services commonly achieve the following performance ranges for metals and engineering plastics:

| Parameter | Typical Range | Notes |

|---|---|---|

| Maximum part size | Up to approx. 800 mm x 800 mm x 600 mm | Larger sizes possible on specialized machines |

| Minimum feature size | Down to approx. 0.5 mm | Dependent on tool diameter and material |

| Dimensional tolerance | ±0.005 mm to ±0.02 mm | Tighter tolerances may be possible for local features |

| Positional tolerance | ±0.01 mm to ±0.05 mm | Varies with work envelope and measurement basis |

| Surface roughness (Ra) | 0.4 µm to 3.2 µm | Improved finish achievable with finishing passes or polishing |

| Production volumes | 1 piece to several thousand pieces | Depending on part complexity and cycle time |

When very tight tolerances are required on critical features, it is important to specify the tolerance zones and datum references clearly in technical drawings or 3D models. This allows the machining provider to allocate appropriate cutting strategies, tools, and inspection methods.

Materials Suitable for 5-Axis CNC Machining

5-axis CNC machines can process a wide range of metals and plastics. Material selection is usually driven by mechanical properties, operating environment, weight constraints, and cost. Below are common material categories used with 5-axis machining.

Aluminum Alloys

Aluminum is widely used due to its good machinability, favorable strength-to-weight ratio, and corrosion resistance. Common grades include:

- 6061-T6: General-purpose structural parts, fixtures, and housings

- 7075-T6: High-strength components, aerospace and motorsport parts

- 2024: Aerospace structures and critical load-bearing components

Aluminum is well suited to high-speed 5-axis machining, enabling efficient production of complex lightweight structures.

Steel and Stainless Steel

Steel offers high strength and wear resistance but requires appropriate tooling and cutting parameters. Common grades include:

- Mild steel (e.g., 1018, S235): General mechanical parts, brackets, and frames

- Tool steels (e.g., D2, H13): Dies, molds, and wear-resistant components

- Stainless steels (e.g., 304, 316, 17-4PH): Corrosion-resistant parts, medical and food processing components

5-axis machining can manage complex steel parts where multiple orientations are needed, such as mold cavities, cores, and precision mechanical assemblies.

Titanium and High-Temperature Alloys

Titanium and nickel-based superalloys are popular in aerospace, medical, and energy sectors. Typical materials include:

- Titanium Grade 5 (Ti-6Al-4V): Implants, aerospace brackets, and structural components

- Inconel and other nickel alloys: High-temperature turbine and exhaust components

These materials require controlled cutting parameters and toolpath strategies to manage heat and tool wear. 5-axis capability allows optimum tool engagement and efficient chip evacuation, which is important for these materials.

Copper, Brass, and Bronze

Non-ferrous alloys like copper, brass, and bronze are used for electrical components, heat exchangers, and decorative parts. 5-axis machining enables precise features such as channels, contact surfaces, and complex contours that may be required in conductive or wear-resistant applications.

Engineering Plastics

Many engineering plastics are machined on 5-axis equipment, including:

- POM (Delrin, acetal): Precision gears, bushings, and mechanical components

- PEEK: High-performance parts in aerospace, medical, and chemical environments

- Nylon, ABS, PC, and others: Functional prototypes, enclosures, and structural parts

For plastics, considerations such as thermal expansion, dimensional stability, and clamping pressure must be addressed in the machining strategy.

Design Considerations for 5-Axis Machined Parts

To leverage 5-axis machining effectively from prototype to production, it is important to design parts with manufacturability in mind. The following considerations help improve quality, reduce cycle time, and control costs.

Tool Access and Reach

Although 5-axis machines permit advanced tool orientations, tools still have practical reach limits. Designers should:

- Avoid extremely deep cavities relative to tool diameter

- Provide adequate clearance for tool approach and retraction

- Consider fillets and radii that match typical tool sizes

Excessive reach increases tool deflection, negatively affecting tolerances and surface finish.

Wall Thickness and Rigidity

Thin walls or slender features can vibrate or deform during machining. As a guideline:

- Maintain wall thickness proportional to part size and loading conditions

- Use ribs or stiffening features where possible

- Consider machining thin walls in multiple passes to reduce distortion

For critical thin-wall components, prototypes can be used to validate behavior under actual machining conditions before committing to full production.

Fillets, Radii, and Corner Geometry

Fillets and radii should be chosen based on readily available tool diameters. Internal sharp corners are difficult to achieve due to tool geometry, so it is advisable to:

- Use internal corner radii at least equal to the tool radius

- Avoid specifying zero-radius internal corners unless absolutely necessary

- Coordinate with the machining provider to match tool sizes to design radii

Appropriate corner geometry improves chip evacuation and extends tool life.

Tolerances and GD&T

Tolerances should be applied selectively, with tight tolerances reserved for features that genuinely require high accuracy. When defining tolerances and geometric dimensioning and tolerancing (GD&T):

- Identify critical dimensions and their functional purpose

- Specify datums that reflect actual assembly or functional relationships

- Provide clear tolerances for position, flatness, perpendicularity, and concentricity where needed

Overly tight or ambiguous tolerances increase machining and inspection time without necessarily improving functional performance.

Material and Surface Finish Requirements

Material and finish specifications should align with application needs. Designers should:

- Indicate the exact material grade and temper or hardness if applicable

- Specify required surface roughness values for functional areas

- Define any post-machining treatments, such as coating, anodizing, or passivation

Clarity in these specifications helps the machining provider plan the full process sequence, including finishing operations.

CAM Programming and Toolpath Strategies

Computer-aided manufacturing (CAM) software is essential for generating 5-axis toolpaths. Effective CAM programming ensures precise motion control, efficient material removal, and safe tool orientation throughout the machining cycle.

Simultaneous vs. Positional 5-Axis

5-axis machining can be performed in two basic modes:

- Positional (3+2) machining: The two rotational axes are used to orient the workpiece or tool, and cutting is then performed using standard 3-axis motion. This is useful for multi-sided machining with fewer setups.

- Simultaneous 5-axis machining: All five axes can move at the same time during cutting, which is essential for free-form surfaces, impellers, and complex contours.

Many parts use a combination of both approaches, optimizing for quality and efficiency.

Toolpath Types

Common 5-axis toolpath strategies include:

- Contour machining for curved surfaces and profiles

- Swarf cutting where the side of the tool is used to machine walls

- Multi-axis roughing for efficient bulk material removal

- Finishing passes with small stepovers for fine surface quality

The choice of toolpath affects cycle time, surface finish, and tool life, and is often refined between prototype and production stages.

Collision Avoidance and Verification

Collision avoidance is critical in 5-axis machining because the tool, spindle head, and machine structures can approach the workpiece from many angles. CAM systems typically offer:

- Machine simulation with virtual models of the machine, fixtures, and tools

- Collision detection and clearance checks for all tool orientations

- Optimization of tool tilt angles to avoid interference and minimize overtravel

Verification and simulation are particularly important before running production batches to avoid machine downtime or part damage.

Workholding and Fixturing for 5-Axis Machining

Workholding is a key factor in 5-axis machining because the workpiece must remain accessible from multiple directions while being rigidly clamped.

Fixture Concepts

Typical fixturing methods include:

- Modular vise systems with multi-axis accessibility

- Zero-point clamping systems for fast changeover and repeatability

- Custom fixtures designed for specific parts or families of parts

- Rotary fixtures for parts that benefit from continuous rotation

Fixtures must be designed to support the part without obstructing tool access. For production runs, dedicated fixtures can significantly reduce changeover times and improve positional consistency.

Datums and Repeatability

Clearly defined datums are necessary for both machining and inspection. Good practice includes:

- Using stable geometric references such as flat surfaces, holes, or pins

- Maintaining consistent datum schemes between design, machining, and inspection

- Incorporating features into fixtures that align with part datums for repeatable loading

For ongoing production, repeatable fixturing allows interchangeable use of multiple machines or shifts with minimal setup changes.

Surface Finishes and Post-Machining Treatments

Surface quality and appearance can be tailored through both machining parameters and post-processing treatments. Different applications may prioritize functional surfaces, corrosion resistance, or visual consistency.

Machined Surface Quality

The achieved surface finish depends on factors such as tool geometry, feed rate, spindle speed, step-over, and toolpath pattern. Common practice includes:

- Roughing operations with larger tools and higher material removal rates

- Semi-finishing passes to stabilize surface geometry

- Finishing passes using small step-overs and optimized cutting conditions

For critical surfaces, additional polishing or lapping can further reduce roughness and improve dimensional accuracy.

Heat Treatment and Hardening

For many steels and certain alloys, heat treatment is used to achieve target hardness and mechanical properties. Process sequences may include:

- Machining in the annealed or pre-hardened state, followed by final finishing after heat treatment where necessary

- Partial machining before heat treatment, with final machining of critical surfaces after hardening

5-axis machining is suitable for hardened materials using appropriate tooling such as carbide or coated inserts.

Protective and Decorative Coatings

Surface treatments provide corrosion resistance, wear resistance, or specific aesthetic properties. Common treatments include:

- Anodizing for aluminum parts (clear or colored)

- Conversion coatings such as chromate or phosphate

- Powder coating or liquid painting

- Electroplating (e.g., nickel, chrome)

When specifying coatings, it is important to consider impact on final dimensions, as coating thickness can influence clearances and fits.

Quality Control and Inspection in 5-Axis Machining

Quality control ensures that machined parts meet the defined specifications and remain consistent throughout the production run. Because 5-axis machining is often used for high-precision components, appropriate inspection methods are essential.

Measurement Tools and Techniques

Common inspection tools include:

- Coordinate Measuring Machines (CMM) for high-accuracy dimensional checks

- Optical measurement systems for complex surfaces and profiles

- Hand tools such as calipers, micrometers, and height gauges for routine checks

- Surface roughness testers for critical functional surfaces

For complex free-form geometries, 3D scanning combined with comparison against the CAD model is frequently used.

In-Process and Final Inspection

Inspection activities can be divided into in-process checks and final verification:

- In-process inspection may involve probing on the machine to verify critical dimensions and adjust tool offsets if needed.

- Final inspection typically occurs in a controlled environment, confirming all specified dimensions and tolerances.

For production, statistical methods such as sampling plans and process capability assessments can be implemented to ensure ongoing quality.

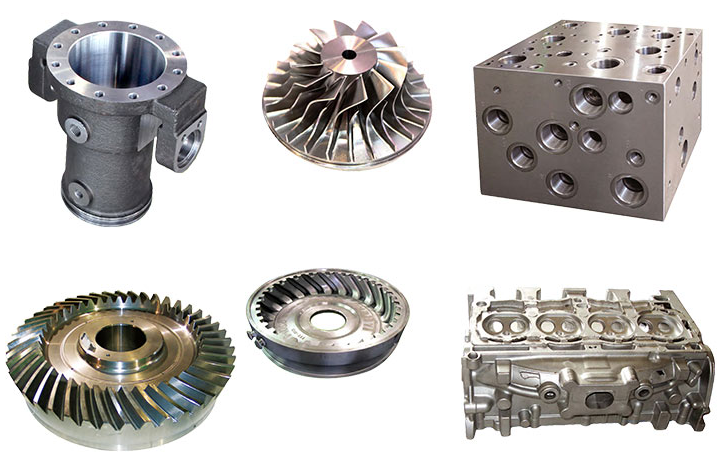

Industries and Typical Applications

5-axis CNC machining is used in many industries where high precision and complex geometries are required. Common sectors include:

- Aerospace: Structural components, brackets, engine parts, and turbine blades

- Automotive and motorsport: Engine components, suspension parts, and lightweight structural elements

- Medical: Implants, surgical instruments, and diagnostic equipment parts

- Industrial machinery: Precision housings, manifolds, and complex mechanical components

- Electronics: Heat sinks, enclosures, and high-precision connectors

Across these industries, 5-axis machining enables the production of complex components with consistent quality from initial prototypes through full-scale manufacturing.

Selecting a 5-Axis CNC Machining Service Provider

Choosing the right machining partner is important for achieving reliable results at each stage of product development. Key aspects to evaluate include:

Technical Capability

Technical capability covers the machine types, control systems, and tooling available. Points to consider:

- Availability of modern 5-axis machining centers with suitable work envelopes

- Experience with the specific materials and part types required

- CAM programming expertise for simultaneous 5-axis operations

- Access to inspection equipment such as CMMs

A provider with a broad range of equipment can support both small prototypes and larger production volumes with consistent quality.

Process Control and Documentation

Robust process control is essential for production. Important elements include:

- Documented workflows for setup, machining, and inspection

- Tool management and replacement schedules

- Traceability of materials and process parameters where necessary

For regulated industries such as aerospace or medical, adherence to formal quality standards and documentation is often mandatory.

Lead Time and Production Flexibility

A suitable provider should be able to handle varying quantities and respond to schedule changes. Consider:

- Typical lead times for prototypes, bridge runs, and production batches

- Capacity for concurrent projects or multiple part numbers

- Ability to scale from low-volume to higher-volume production

This flexibility is important when design changes occur or when demand for parts increases faster than originally forecast.

Communication and Engineering Support

Effective communication between design and manufacturing teams helps avoid errors and reduces iteration cycles. Engineering support may include:

- Design for manufacturability feedback during early stages

- Suggestions on material options and surface finish selection

- Clarification of tolerances and GD&T to align with achievable machining performance

Cooperation at this level is especially valuable when refining prototypes into production-ready designs.

Cost Factors in 5-Axis CNC Machining

The cost of 5-axis machined parts is influenced by several technical and logistical parameters. Understanding these factors helps in optimizing designs and selecting appropriate manufacturing strategies.

Part Complexity and Cycle Time

Complex geometries requiring multiple passes, tool changes, and intricate toolpaths increase cycle time, which directly impacts cost. Features such as deep cavities, very tight tolerances, or intricate free-form surfaces require additional machining and inspection effort.

Material Selection and Tool Wear

Different materials affect cost through raw material price, machinability, and tool life. Hard or heat-resistant alloys often require slower cutting speeds and more frequent tool changes, leading to higher machining costs compared to aluminum or softer plastics.

Quantity and Setup Costs

Setup costs are incurred in programming, fixturing, and machine preparation. For small quantities, setup costs represent a larger portion of the unit price. As quantity increases, the setup cost is distributed over more pieces, reducing the per-part cost. 5-axis machining can reduce the number of setups, which helps to control these costs.

Inspection and Quality Requirements

Extensive inspection, especially for parts with comprehensive GD&T and documentation requirements, adds time and cost. Coordinating with the machining provider to define appropriate inspection levels for different stages (prototype vs. production) helps align quality needs with cost targets.

Integrating 5-Axis Machining into the Product Lifecycle

When planned systematically, 5-axis CNC machining can serve as a consistent manufacturing platform throughout the product lifecycle.

Early-Stage Collaboration

Involving the machining provider early in the design stage allows potential manufacturing issues to be addressed before finalizing the design. This includes reviewing:

- Tool access for all features

- Feasible tolerances and surface finishes

- Material and thickness choices

Such collaboration supports faster transitions from design to functional prototypes.

Process Validation and Qualification

Before entering full production, it is common to perform process validation. This stage may include:

- Producing small qualification batches

- Measuring critical dimensions and analyzing results

- Adjusting toolpaths, cutting parameters, or fixturing as needed

Validated processes provide a stable foundation for serial production with predictable outcomes.

Ongoing Production and Continuous Improvement

During production, process monitoring and feedback from assembled products can guide incremental improvements. Examples include:

- Refined toolpaths to reduce cycle time

- Alternate tooling strategies to extend tool life

- Adjustments to tolerances based on practical functional requirements

These refinements help optimize the overall cost and reliability of the manufacturing process over time.

Practical Considerations for Ordering 5-Axis CNC Parts

To ensure accurate quotations and smooth execution, certain information should be prepared when requesting 5-axis CNC machining services.

Technical Data to Provide

Essential data include:

- 3D CAD models in a neutral format (e.g., STEP, IGES) and, if available, native CAD files

- 2D technical drawings with dimensions, tolerances, and surface finish indications

- Material specification, including grade and condition

- Required quantity, delivery schedule, and any special packaging needs

If certain features are more important than others, they should be clearly identified as critical characteristics.

Defining Inspection and Documentation Needs

Customers should specify the level of inspection and documentation required, such as:

- Basic dimensional checks and delivery of inspection reports

- Full dimensional inspection with detailed CMM reports

- Certificates of material compliance or heat treatment records

Defining these requirements in advance helps the machining provider allocate the appropriate inspection methods and report formats.

Clarifying Surface Treatments and Assembly Requirements

If the parts will undergo additional processes or assembly, details should be provided, including:

- Planned coatings, anodizing, or surface treatments

- Mating components and fit requirements

- Any assembly operations to be performed by the machining provider

This information ensures that dimensions and finishes are aligned with the complete manufacturing and assembly sequence.

Conclusion

5-axis CNC machining services provide a robust and flexible solution for manufacturing complex parts from prototype to production. By allowing multi-axis tool orientation, these machines can produce intricate geometries with high accuracy and reduced setups. Understanding the capabilities, design considerations, materials, and process parameters involved helps designers and engineers make effective use of 5-axis machining across the entire product lifecycle.

With appropriate planning, collaboration, and process control, 5-axis CNC machining can support rapid prototyping, bridge production, and long-term serial manufacturing while delivering consistent quality and reliable performance for demanding applications.

XCM 5-Axis Precision Machining Service

With high-rigidity, high-speed equipment and an experienced engineering team, we can complete multi-face and complex surface machining in a single setup, significantly improving accuracy and yield. From aerospace components and medical molds to precision automation parts and custom automotive pieces, we consistently achieve micron-level tolerances and near-mirror surface finishes.

We support everything from small-batch prototyping to mass production, with fast material changeover for aluminum alloys, stainless steel, titanium and more. Our team also provides early DFM (design for manufacturability) review and machining optimization suggestions, helping bring your ideas into reality faster while reducing overall costs.

Frequently Asked Questions About 5-Axis CNC Machining

What is 5-axis CNC machining?

5-axis CNC machining is a manufacturing process in which cutting tools move along five different axes simultaneously. This allows complex parts to be machined in a single setup with greater precision and efficiency.

How is 5-axis machining different from 3-axis machining?

Unlike 3-axis machining, which moves along the X, Y, and Z axes only, 5-axis machining adds two rotational axes. This enables better access to complex geometries, reduced repositioning, and improved surface finishes.

Is 5-axis CNC machining more expensive?

While the hourly machine cost may be higher, overall project costs can be lower due to reduced setup time, fewer fixtures, faster production, and less manual intervention.

What are the main advantages of 5-axis CNC machining?

Key benefits include higher accuracy, shorter production time, fewer setups, improved surface quality, and the ability to machine complex and highly detailed parts.

When should I choose 5-axis CNC machining?

5-axis machining is recommended when parts require complex geometry, high precision, superior surface finish, or when reducing lead time and setup complexity is critical.