3 axis and 5 axis CNC machines are core equipment in modern manufacturing. Choosing between them requires a clear understanding of machine kinematics, achievable geometries, tolerances, productivity, and cost structure. This guide explains the technical differences and practical implications so that engineers, machinists, and buyers can make an informed selection.

Fundamental Concepts of CNC Axes

In CNC machining, an axis is a direction in which the cutting tool or the workpiece can move relative to each other under numerical control. The number of controlled axes determines the complexity of parts that can be produced in a single setup.

Linear and Rotational Axes

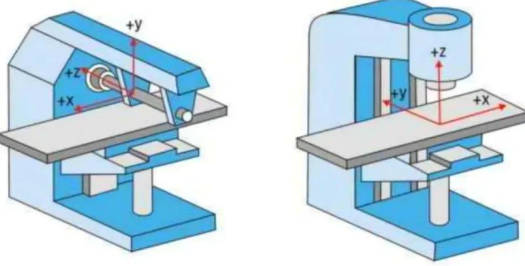

Most machining centers define axes as follows:

- X axis: horizontal movement left–right

- Y axis: horizontal movement front–back

- Z axis: vertical movement up–down

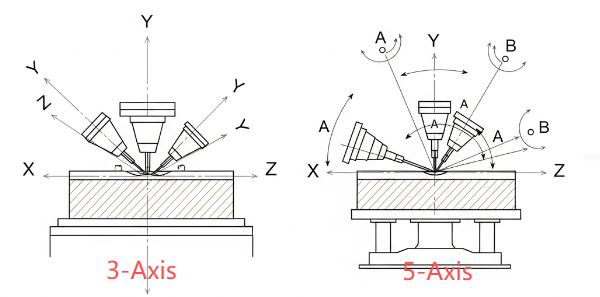

Beyond these three linear axes, rotational axes are added:

- A axis: rotation around the X axis

- B axis: rotation around the Y axis

- C axis: rotation around the Z axis

A 3 axis CNC machine controls X, Y, and Z only. A 5 axis CNC machine controls five axes simultaneously, typically X, Y, Z plus two of the rotational axes (commonly A and C or B and C).

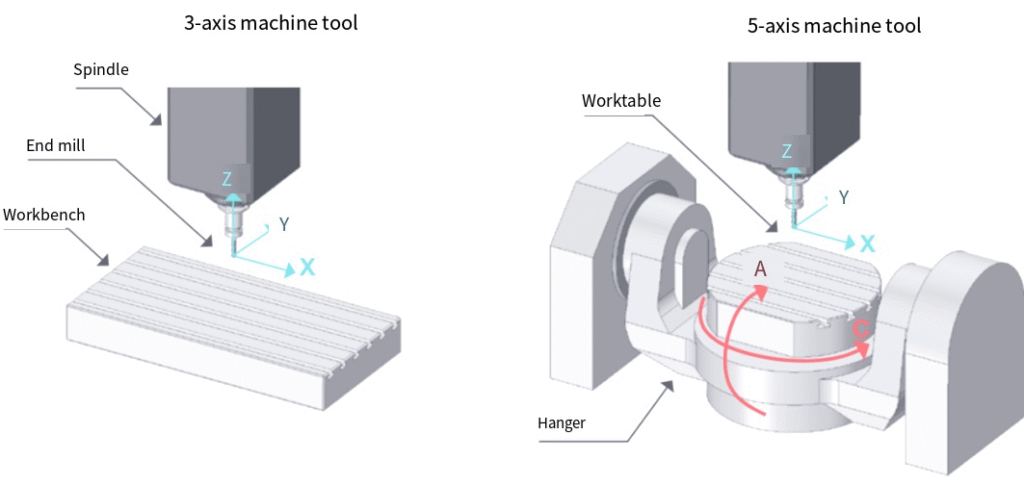

What Is 3 Axis CNC Machining

3 axis CNC machining uses three linear movements (X, Y, Z) to remove material from a stationary workpiece. The cutting tool approaches the part mainly from a single direction, usually perpendicular to the workpiece surface.

Machine Configuration

Common 3 axis configurations include:

- Vertical machining center: spindle oriented vertically, most widely used type

- Horizontal machining center: spindle oriented horizontally, suitable for certain chip evacuation and fixture arrangements

- 3 axis CNC router: often used for wood, plastics, and soft metals with high-speed spindles

In all cases, motion is limited to linear interpolation in three dimensions. Complex shapes can be produced but often require multiple setups and re-fixturing to access different sides of the workpiece.

Typical Capabilities

3 axis CNC machines are well suited for:

- Flat or prismatic parts with features such as pockets, slots, holes, and 2.5D contours

- Parts that can be fully machined from one or two main directions

- Simple 3D surfaces that do not require undercuts or complex multi-face access

Many general engineering components, jigs, fixtures, and housings are efficiently produced on 3 axis machines.

Accuracy and Tolerances

Accuracy of a 3 axis machine depends on build quality, ballscrews or linear motors, guideways, temperature stability, and maintenance.

Typical values for industrial-grade 3 axis machining centers:

- Positioning accuracy: about ±0.005 to ±0.02 mm over the working envelope

- Repeatability: about ±0.002 to ±0.01 mm

- Surface roughness (milled finish): Ra commonly between 0.8 and 3.2 µm, depending on cutting conditions and tool type

These ranges are general indications; high-precision machines can achieve better figures, and light-duty equipment may be less accurate.

What Is 5 Axis CNC Machining

5 axis CNC machining adds two controlled rotational movements to the three linear axes, allowing the tool or workpiece to be oriented at various angles during machining. This enables machining from multiple directions in a single setup, including complex surfaces and undercuts.

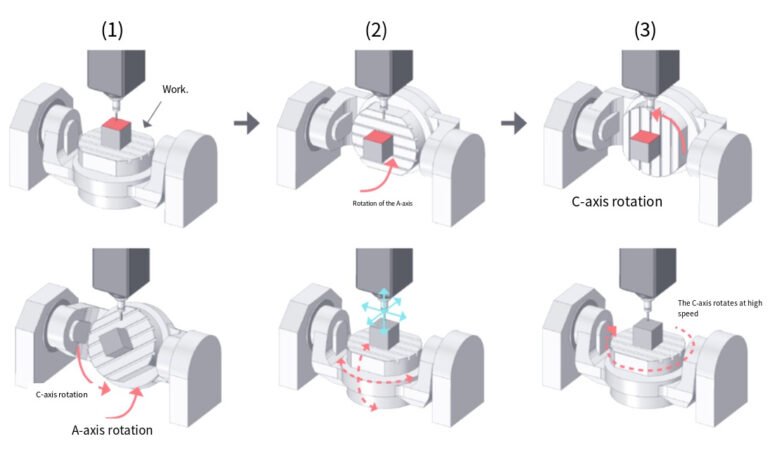

Machine Configuration Types

Main 5 axis configurations include:

- Trunnion type: the workpiece is mounted on a tilting and rotating table. The table usually provides A axis tilt and C axis rotation while X, Y, Z remain on the machine structure.

- Swivel head type: the spindle head tilts and rotates, providing B and C or A and C axes. The workpiece remains on a simpler table.

- Mixed architectures: combinations where one rotational axis is in the table and the other in the head.

Each configuration has specific strengths regarding working volume, rigidity, tool access, and fixture design, but all provide simultaneous 5 axis interpolation for complex tool paths.

Typical Capabilities

5 axis machines can perform operations that are difficult or impossible on 3 axis equipment, such as:

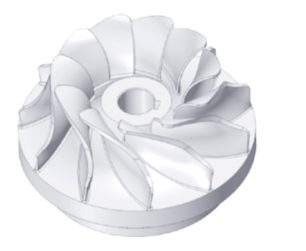

- Machining freeform surfaces with continuous tool orientation control

- Producing parts with deep cavities and features oriented at compound angles

- Creating undercuts and features that require tool access from multiple directions

- Performing multi-face machining of a prismatic part in one clamping

Industries such as aerospace, medical, energy, high-end automotive, and precision tooling rely heavily on 5 axis machining for complex components.

Accuracy and Tolerances

5 axis machines can achieve very high accuracy, but the total system error includes both linear and rotary axes. Typical industrial values:

- Linear positioning accuracy: roughly comparable to quality 3 axis machines, about ±0.005 to ±0.02 mm

- Rotary axis positioning accuracy: often within a few arc-seconds to a few arc-minutes, depending on build quality

- Multiaxis volumetric accuracy: controlled through machine calibration; achievable part tolerances in the range of ±0.01 to ±0.05 mm for complex 3D forms are common on well-maintained machines

Because the tool can be kept oriented optimally, improved surface finish and dimensional consistency on inclined and curved surfaces can be obtained compared with 3 axis machining that requires multiple setups.

Key Technical Differences Between 3 Axis and 5 Axis CNC

3 axis and 5 axis CNC machines differ not only in the number of axes but also in the kinds of geometry they can efficiently and accurately produce, the programming complexity, and the typical production workflow.

| Aspect | 3 Axis CNC | 5 Axis CNC |

|---|---|---|

| Axes controlled | X, Y, Z linear | X, Y, Z plus two rotational (A/B/C) |

| Tool approach directions | Primarily from one main direction | Multiple directions and angles in one setup |

| Geometry complexity | Simple to moderately complex 2D/2.5D and some 3D | Highly complex 3D surfaces and multi-face parts |

| Setups per part | Often several setups | Often single setup for full part |

| Programming difficulty | Lower, many standard cycles | Higher, requires advanced CAM and verification |

| Machine cost | Lower purchase and maintenance cost | Higher purchase and maintenance cost |

| Cycle time on complex parts | Longer due to multiple setups and handling | Shorter due to simultaneous machining and fewer setups |

| Operator skill requirement | Standard CNC operation skills | Higher skills for setup, probing, and collision avoidance |

Workpiece Geometry and Design Considerations

The most critical factor in choosing between 3 axis and 5 axis CNC is the required part geometry.

Parts Suitable for 3 Axis CNC

3 axis machining is generally appropriate when:

- The part is prismatic, with features aligned to a small number of orthogonal directions.

- All features can be accessed by repositioning the part a few times at right angles.

- There are no significant undercuts or complex freeform surfaces that need continuous angular tool orientation.

- Tolerances across different faces can tolerate potential alignment errors from multiple setups.

Parts that Benefit from 5 Axis CNC

5 axis machining becomes advantageous when parts include:

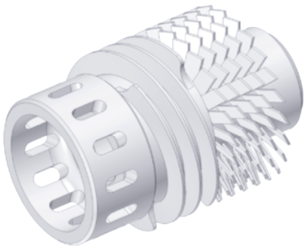

- Complex freeform surfaces, such as turbine blades, impellers, orthopedic implants, and aerodynamic profiles.

- Features oriented at non-orthogonal angles that would require special fixtures or multiple operations on 3 axis machines.

- Deep cavities or areas where tool length on a 3 axis machine would need to be very long, causing deflection and chatter.

- High-density feature layouts on multiple faces of a part, where alignment between faces is critical.

Tool Orientation and Cutting Performance

Tool orientation control is one of the main differences between 3 axis and 5 axis machining.

Tool Orientation in 3 Axis CNC

In 3 axis machining, the tool is normally fixed in orientation relative to the part during cutting, aligned with the machine’s Z axis. To reach different faces, the part must be reoriented in the fixture. As a result:

- The effective cutting angle relative to the surface is limited.

- Certain surfaces may require ball nose tools and fine stepovers, which can increase machining time.

- Accessibility issues may arise in deep cavities or steep side walls, leading to longer tools, reduced rigidity, and possible vibration.

Tool Orientation in 5 Axis CNC

With 5 axis machining, the tool orientation can be adjusted continuously:

- The tool can be tilted to maintain optimal contact with the surface, improving cutting conditions.

- Shorter tools can be used because the head or table tilts instead of relying on long tool overhangs.

- Surface finish can be improved because the cutter can be oriented to minimize cusp height and maintain a more consistent cutting speed.

- Machining time can be reduced by using larger stepovers while keeping acceptable surface quality.

Setup, Fixturing, and Workholding

Fixturing requirements differ significantly between 3 axis and 5 axis machining and directly affect accuracy and cost.

Setup on 3 Axis CNC

Typical 3 axis workflow:

- Multiple setups are needed to reach all faces of a part. Each setup requires locating, clamping, and re-zeroing.

- Custom fixtures or vises with soft jaws are often designed for specific parts or part families.

- Cumulative error can occur between setups, especially for tight tolerances between features on different faces.

For some production environments, multiple 3 axis machines with dedicated fixtures are used to process different sides of the same part in a flow line.

Setup on 5 Axis CNC

In 5 axis machining:

- The part can often be clamped once in a centered position, and all sides are accessed by rotating and tilting.

- Fixtures can be simplified to focus mainly on secure clamping and minimal obstruction; the machine handles orientation changes.

- On-machine probing is commonly used to refine part location, adjust work coordinates, and verify alignment.

This approach significantly reduces manual handling and positioning errors and shortens overall setup time for complex jobs.

Programming, CAM, and Control Systems

The number of axes directly affects the complexity of CNC programming and the requirements for software and control hardware.

Programming 3 Axis CNC

3 axis programs are typically generated by CAM systems using well-understood 2D and 3D strategies. Characteristics include:

- Simpler tool path strategies such as contouring, pocketing, drilling patterns, and basic 3D surfacing.

- G-code is shorter and easier to interpret manually if needed.

- Standard post-processors are widely available and straightforward.

Program verification is important but collision scenarios are relatively limited because only three linear axes are moving.

Programming 5 Axis CNC

5 axis programming requires more advanced CAM capabilities:

- Simultaneous 5 axis tool paths with continuous tool orientation calculation.

- Tool axis control strategies such as normal-to-surface, lead/lag angles, and side tilt angles.

- Complex transition and linking moves to avoid collisions with fixtures and machine components.

Comprehensive simulation is highly recommended to detect collisions and over-travel before running the program on the machine.

Control System Capabilities

5 axis controls must handle:

- Higher data processing rates due to more complex, dense tool paths.

- Inverse kinematics for converting tool center point commands into axis movements.

- Rotary axis synchronization and feed rate management to maintain consistent cutting speeds on complex paths.

Many high-end controls provide functions such as tool center point control, dynamic collision monitoring, and advanced smoothing algorithms for better surface quality and machine motion.

Accuracy, Repeatability, and Quality Impacts

Both 3 axis and 5 axis machines can produce high-quality parts, but their effect on accuracy and repeatability depends on how the part is machined.

Impacts of Multiple Setups vs Single Setup

In 3 axis machining with multiple setups:

- Each re-clamping can introduce small location deviations, even with precise fixtures.

- Rotating the part manually between vises or fixtures may result in angular errors that affect relationships between faces.

- For some precision parts, additional inspection and rework may be needed to correct accumulated errors.

In 5 axis machining with a single setup:

- Datums and feature relationships are maintained by the machine kinematics instead of manual repositioning.

- Geometric relationships between features on different faces are generally more consistent.

- The risk of misalignment between operations is reduced, which can be critical for mating parts or assemblies.

Surface Finish and Tool Path Smoothness

On complex surfaces:

- 3 axis machining often uses ball nose cutters with small stepovers and constant Z-level passes, which can leave visible scallops and require long machining times.

- 5 axis machining enables the cutter to be kept at a more favorable angle and orientation, reducing scallop height and yielding a smoother finish for the same or even larger stepovers.

Leveraging 5 axis motion can therefore increase both surface quality and productivity for freeform shapes.

Cycle Time, Throughput, and Productivity

Productivity is influenced by machining time, setup time, and non-cutting time such as loading and unloading.

3 Axis CNC Productivity

3 axis machines can be highly productive for suitable parts:

- Simple parts with limited sides can be machined quickly with standard operations.

- Tool paths are shorter and easier to compute, enabling rapid job preparation.

- For larger batch sizes, dedicated fixtures and standardized setups can minimize downtime.

However, for complex multi-face parts, cumulative setup time and handling can become a significant portion of total production time.

5 Axis CNC Productivity

5 axis machines often improve productivity for complex parts because:

- Many operations are combined into one setup, reducing idle time and manual intervention.

- Tool paths can be optimized for constant engagement and better chip removal.

- Access to multiple faces allows simultaneous machining of different features.

For parts that fit well within the machine’s work envelope, these factors can yield shorter lead times and higher overall throughput, despite potentially longer CAM programming times.

Cost Structure and Investment Considerations

Cost analysis should consider both capital expenditure and operating costs, as well as the type and volume of work.

Machine and Infrastructure Cost

3 axis CNC machines:

- Lower purchase price due to simpler mechanics and controls.

- Lower cost for foundation, installation, and basic peripherals.

- Commonly available from a wide range of manufacturers, including entry-level models.

5 axis CNC machines:

- Higher purchase cost because of more complex mechanical assemblies, rotary axes, and advanced control systems.

- May require more robust foundations to maintain stability during multidirectional motion.

- Often need additional peripherals such as automatic probing and advanced coolant and chip management systems for complex parts.

Operating and Maintenance Costs

Operating costs include energy consumption, tooling, maintenance, and programming time.

3 axis:

- Lower training requirements for operators and programmers.

- Maintenance is simpler with fewer moving axes and fewer high-precision rotary components.

- Spare parts are generally more affordable and widely available.

5 axis:

- Requires personnel skilled in multiaxis programming, setup, and verification.

- Rotary axes and advanced control hardware can be more expensive to maintain and repair.

- Unexpected collisions can be more costly, as more complex components may be affected.

Material Compatibility and Application Fields

Both 3 axis and 5 axis CNC machines can process a wide range of materials such as aluminum, steel, stainless steel, titanium, nickel alloys, plastics, composites, and others. The choice of machine is more influenced by geometry than by basic material type, but some tendencies exist.

3 Axis CNC Applications

Common application areas include:

- General mechanical components: brackets, plates, blocks with drilled and tapped holes.

- Jigs and fixtures: locating plates, clamping elements, simple nest details.

- Molds and dies with less complex geometries or where electrodes are manufactured separately.

- Woodworking and plastic fabrication for panels, signs, and 2.5D shapes (often on CNC routers).

5 Axis CNC Applications

Typical uses for 5 axis machines:

- Aerospace components: blades, blisks, structural parts with pockets and complex interfaces.

- Medical devices: joint implants, surgical instruments, anatomical models.

- High-performance automotive components: cylinder heads, intake manifolds, turbocharger impellers.

- Precision tooling: complex cavity molds, multi-angle electrodes, and dies.

Inspection, Metrology, and Quality Control

Inspection methods and the relationship to machine capability should be considered during process planning.

Inspection for 3 Axis Machined Parts

For 3 axis machining with multiple setups:

- Coordinate measuring machines (CMMs) or optical measurement systems are often used to verify relationships between features from different setups.

- Additional datums may be required for each setup, which increases complexity in measurement programs.

- If misalignment is found after machining, rework may involve partially re-fixturing and re-machining certain surfaces.

Inspection for 5 Axis Machined Parts

5 axis machining with a single setup can simplify inspection:

- The part coordinate system often remains consistent for all features, easing CMM program creation.

- On-machine probing can measure critical dimensions during machining and adjust tool offsets or work coordinates as needed.

- For complex surfaces, scanning probes or structured light scanners can compare the part to CAD data, taking advantage of the single-setup approach for consistent reference.

Typical Pain Points When Choosing Between 3 Axis and 5 Axis

Manufacturing teams often encounter decision points when evaluating whether 3 axis or 5 axis CNC is more appropriate for a project or investment. Some recurring pain points include:

- Difficulty estimating total cost per part when accounting for setup, fixture design, and inspection.

- Uncertainty about whether current or future part geometries justify the investment in 5 axis capability.

- Balancing machine utilization across a workshop that may have both 3 axis and 5 axis equipment.

- Ensuring that available programming and operating skills match the complexity of planned 5 axis work.

Clear analysis of parts, production volume, tolerance requirements, and available resources is essential to minimize these issues.

Practical Selection Guidelines

Some practical guidelines can help determine whether a 3 axis or 5 axis solution is more appropriate for a given situation.

| Requirement or Condition | More Suitable Choice |

|---|---|

| Simple prismatic parts, few sides | 3 axis CNC |

| High proportion of multi-face parts with tight inter-face tolerances | 5 axis CNC |

| Complex freeform surfaces or undercuts | 5 axis CNC |

| Limited budget, general-purpose machining | 3 axis CNC |

| High-value parts where fewer setups reduce risk | 5 axis CNC |

| Limited multiaxis programming expertise | 3 axis CNC (or gradual introduction of 5 axis) |

| Need to consolidate multiple operations into one machine | 5 axis CNC |

Summary: When to Choose 3 Axis vs 5 Axis CNC

Both 3 axis and 5 axis CNC machines are essential tools in manufacturing. The choice should be driven by part geometry, required accuracy, production volume, and total cost considerations.

- 3 axis CNC is the practical choice for many standard parts, offering lower investment, simpler programming, and straightforward operation. It excels at machining prismatic geometries and parts where multiple setups do not severely impact accuracy or cost.

- 5 axis CNC provides expanded capability for complex 3D shapes, multi-face machining in one setup, and better control of tool orientation. It can reduce setups, shorten lead times, and improve dimensional consistency for intricate components, at the cost of higher machine and skill requirements.

A balanced manufacturing environment often uses both types of machines, assigning each part to the equipment that best fits its geometric and economic characteristics.