Ti-13V-11Cr-3Al, also referred to as Ti-13-11-3, Ti-13V-11Cr-3Al beta titanium, Ti-13V-11Cr-3Al alloy, and Ti-13-11-3 alloy, is a metastable beta titanium alloy designed for high strength, good hardenability, and useful formability in the solution-treated condition. After the initial introduction of these variants, this article will consistently use Ti-13V-11Cr-3Al or Ti-13-11-3 as the main name.

This alloy is widely used in aerospace and high-performance engineering for structural components that demand high specific strength, good fatigue resistance, and acceptable corrosion performance. The following content provides a comprehensive and systematic description of Ti-13V-11Cr-3Al, including its composition, microstructure, mechanical properties, heat treatment strategies, processing characteristics, machinability, and common application considerations.

Alloy Classification and Typical Composition

Ti-13V-11Cr-3Al belongs to the family of metastable beta titanium alloys. These alloys are characterized by a beta phase stabilized at room temperature by the addition of beta stabilizing alloying elements. The presence of vanadium and chromium in Ti-13V-11Cr-3Al ensures that the beta phase can be retained after rapid cooling from the solutionizing temperature and adjusted through subsequent aging treatments.

Nominal composition by weight percent is:

- Titanium (Ti): balance

- Vanadium (V): approximately 13 wt%

- Chromium (Cr): approximately 11 wt%

- Aluminum (Al): approximately 3 wt%

In practice, industrial specifications define composition ranges with strict limits on impurities such as oxygen, nitrogen, hydrogen, iron, and carbon. Common impurity limits include:

- Oxygen: typically ≤ 0.12 wt% (exact limit depends on product specification)

- Nitrogen: typically ≤ 0.03 wt%

- Hydrogen: typically ≤ 0.015 wt%

- Iron: typically ≤ 0.25 wt%

- Carbon: typically ≤ 0.05 wt%

Vanadium and chromium are strong beta stabilizers, while aluminum is a primary alpha stabilizer in titanium alloys. Their combined effect defines a metastable beta matrix capable of transformation to alpha and alpha prime phases during controlled thermal processing.

Phase Constitution and Microstructural Features

The performance of Ti-13V-11Cr-3Al is heavily governed by its phase constitution and microstructural morphology, which depend on heat treatment and thermo-mechanical history.

Key phases and microstructural constituents include:

- Beta (β) phase: body-centered cubic (bcc) matrix, stable at high temperature and metastable at room temperature when sufficient beta stabilizers are present.

- Alpha (α) phase: hexagonal close-packed (hcp) phase that can precipitate during aging or slow cooling from the beta field.

- Omega (ω) phase (if present): can form as a metastable intermediate under certain aging conditions in some beta alloys, influencing hardness and toughness.

- Alpha prime (α′) or alpha double prime (α″) martensite (if formed): depending on quench severity and composition, though in Ti-13V-11Cr-3Al the aim is often to retain β followed by controlled α precipitation.

Typical microstructures for Ti-13V-11Cr-3Al include:

1) Solution-treated and quenched (single-phase β structure):

- Predominantly equiaxed or slightly elongated β grains.

- Minimal α precipitation if quenching is sufficiently rapid.

- Good formability and relatively lower strength compared with aged conditions.

2) Solution-treated and aged (β + α):

- Fine α precipitates within the β matrix (intra-granular) and/or at grain boundaries depending on treatment parameters.

- Enhanced strength and hardness with balanced ductility and toughness when aging conditions are optimized.

3) Thermo-mechanically processed (forged and aged):

- Refined β grains and controlled α morphology (e.g., fine dispersion) to improve fatigue and fracture performance.

By adjusting solution treatment temperature, cooling rate, and aging parameters, engineers can tailor the morphology and fraction of α and β phases to achieve required property combinations for specific applications.

Physical and Thermal Properties

Ti-13V-11Cr-3Al exhibits physical and thermal properties characteristic of titanium alloys, with some variation due to the high beta-stabilizing alloy content. Typical room-temperature values are summarized below; actual values depend on product form and specific specification.

| Property | Typical Value (Approximate) | Notes |

|---|---|---|

| Density | ~4.75–4.85 g/cm³ | Lower than steels, slightly higher than some alpha-beta Ti alloys due to alloying |

| Melting range | ~1600–1700 °C | Varies with precise composition |

| Elastic modulus (E) | ~110–120 GPa | Lower than steels (~210 GPa), typical for beta titanium |

| Thermal conductivity | ~7–10 W/m·K | Relatively low, affects machining heat removal |

| Specific heat | ~0.5–0.6 kJ/kg·K | Near room temperature |

| Coefficient of thermal expansion | ~8.5–9.5 × 10⁻⁶ /K | Between that of aluminum and steels |

These properties contribute to the high specific strength of Ti-13V-11Cr-3Al and influence process planning, particularly in machining, heat treatment, and joining.

Mechanical Properties and Performance Characteristics

The mechanical performance of Ti-13V-11Cr-3Al depends strongly on heat treatment and product form. As a metastable beta alloy, it can reach very high strength levels after aging while maintaining useful ductility.

Typical mechanical properties at room temperature for wrought products (such as bars or forgings) are outlined below. The values are indicative ranges; actual specification limits depend on standards and customer requirements.

| Condition | Yield Strength 0.2% (MPa) | Tensile Strength (MPa) | Elongation (%) | Reduction of Area (%) | Hardness (HRC, approx.) |

|---|---|---|---|---|---|

| Solution-treated (β) and quenched | ~900–1100 | ~1000–1200 | ~10–18 | ~25–40 | ~30–36 |

| Solution-treated and aged (high strength) | ~1200–1400 | ~1300–1500 | ~6–12 | ~15–30 | ~38–46 |

| Optimized toughness condition | ~1100–1250 | ~1200–1400 | ~8–15 | ~20–35 | ~34–42 |

Key performance characteristics include:

- High specific strength: combination of low density and high tensile strength yields high strength-to-weight ratio, particularly attractive for aerospace components.

- Good hardenability: large cross-sections can be through-hardened via solution treatment and relatively slow quenching compared with alpha-beta alloys.

- Good fatigue resistance: when processed with refined microstructure and controlled surface integrity, Ti-13V-11Cr-3Al offers strong fatigue performance under high-cycle and low-cycle regimes.

- Moderate fracture toughness: toughness depends on microstructure, presence of α at grain boundaries, and cleanliness. Optimized heat treatments are required for critical fracture-control applications.

- Reasonable creep resistance at moderate temperatures: suitable for applications up to intermediate service temperatures (exact limits specified by application and design standards).

Corrosion and Environmental Resistance

Ti-13V-11Cr-3Al benefits from the passive oxide film typical of titanium alloys, offering good corrosion resistance in many environments, particularly:

- Atmospheric and marine environments: good resistance to general corrosion due to stable TiO₂ surface film.

- Neutral and mildly oxidizing aqueous media: stable passive behavior under many service conditions.

- Many industrial environments: good resistance to chloride-bearing solutions compared with many steels, although pitting and crevice corrosion must still be considered at elevated temperatures or high chloride concentrations.

However, as with many titanium alloys, certain environments require careful control:

- Strong reducing acids and certain high-temperature chemical environments can degrade the passive film.

- Hydrogen uptake in certain environments may lead to hydride formation and embrittlement if not controlled.

- At elevated temperatures in air or oxygen-rich environments, oxidation rates increase and surface degradation can occur if exposure is prolonged.

Correct surface preparation, avoidance of contamination, and control of service environment are important considerations for long-term reliability.

Heat Treatment Principles for Ti-13V-11Cr-3Al

Heat treatment is the primary means of tailoring the microstructure and mechanical properties of Ti-13V-11Cr-3Al. Typical heat treatment sequences involve solution treatment in the beta or alpha-beta field, quenching, and subsequent aging.

Beta Transus and Solution Treatment Range

The beta transus temperature (Tβ) is the temperature above which the alloy exists entirely as β phase under equilibrium. For Ti-13V-11Cr-3Al, beta transus is generally in the approximate range of 750–800 °C, depending on precise chemistry and prior processing.

Two main types of solution treatment are commonly used:

- Beta solution treatment (above Tβ): produces fully β microstructure prior to quenching. Typical temperatures are slightly above the beta transus (for example, Tβ + 10–30 °C).

- Alpha-beta solution treatment (sub-transus): leads to a mixture of α and β at the solution temperature with different resultant microstructures after cooling and aging.

The choice between these methods is guided by property requirements, component geometry, and dimensional stability needs.

Solution Treatment and Quenching

Typical solution treatment steps for Ti-13V-11Cr-3Al include:

- Heating to selected solution temperature (e.g., near or above beta transus) under protective atmosphere or vacuum to prevent oxidation.

- Holding time sufficient to homogenize temperature and dissolve undesired phases; hold times depend on section thickness, often ranging from tens of minutes to several hours for large components.

- Quenching to retain metastable β or controlled α+β microstructure. Common quench media include water, polymer quenchant, or forced air, selected based on required cooling rate and distortion considerations.

Water quenching provides the highest cooling rate and maximizes β retention but may increase residual stresses and distortion. Polymer solutions and agitated air quench offer intermediate cooling rates with improved dimensional control.

Aging Heat Treatment

Aging of Ti-13V-11Cr-3Al is used to induce controlled precipitation of fine α particles within the β matrix, increasing strength and hardness. Typical aging practice involves:

- Aging temperature: commonly in the range of approximately 425–600 °C depending on desired strength-ductility balance.

- Aging time: typically from 2 to 24 hours, with longer times at lower temperatures or shorter times at higher temperatures.

- Cooling from aging temperature: usually air cooling is sufficient; properties are less sensitive to cooling rate after aging compared with solution treatment.

Lower aging temperatures, for example near 450 °C, can produce higher strength and hardness but may reduce ductility and toughness. Higher temperatures, such as 550–600 °C, produce coarser precipitates and slightly lower strength but improved toughness and ductility. Precise optimization is application-specific.

Stress Relieving and Distortion Control

After heavy machining, forming, or welding, stress relieving treatments can be applied to Ti-13V-11Cr-3Al to reduce residual stresses without significantly altering mechanical properties. Typical stress-relief temperatures are below aging temperatures, often in the region of 350–450 °C for a few hours, followed by air cooling. Care is taken to avoid overaging effects or undesirable phase changes.

Hot Working and Forging Practices

As a beta titanium alloy, Ti-13V-11Cr-3Al is generally processed by hot working in the beta or alpha-beta temperature range. Proper control of temperature and strain rate is essential to achieve desirable microstructures and avoid cracking or excessive grain growth.

Forging Temperature Range

Typical forging practices for Ti-13V-11Cr-3Al include:

- Forging in the beta field: temperatures above beta transus, for example 780–900 °C, depending on specific transus and forging practice. Forging in this region produces equiaxed or slightly elongated β grains which can be transformed to fine α+β structures through subsequent heat treatment.

- Forging in the alpha-beta region: slightly below beta transus, which can help refine microstructure and improve mechanical property balance.

Overheating significantly above the recommended forging range can cause excessive grain growth, leading to decreased toughness and poor fatigue performance. Underheating may result in insufficient ductility and difficulties in deformation.

Deformation and Cooling Considerations

Key considerations during hot working of Ti-13V-11Cr-3Al include:

- Preheating of dies and tools to reduce thermal gradients and surface chilling.

- Control of strain rate: typically moderate to low strain rates to avoid flow localization and cracking.

- Reduction schedule: multiple forging passes with intermediate reheats to maintain appropriate temperature.

- Post-forging cooling: controlled cooling, often air cooling, followed by solution treatment and aging to set final properties.

Appropriate lubrication and protection from air exposure at high temperature help limit surface contamination and alpha case formation.

Cold Working and Formability

Ti-13V-11Cr-3Al exhibits good formability in the solution-treated, metastable β condition. This characteristic is exploited to form complex shapes before final aging. Typical aspects of cold working include:

- Forming condition: solution-treated and quenched β condition, where dislocation mobility is higher and strength is lower than in the aged state.

- Cold-working methods: rolling, drawing, bending, and other deformation processes can be used, provided adequate tooling and lubrication are employed.

- Work hardening: as deformation proceeds, the alloy work-hardens; intermediate anneals or partial stress-relief treatments may be implemented for substantial plastic deformation.

Cold-working after aging is more limited due to increased strength and reduced ductility. When extensive cold forming is required, the usual sequence is to form in solution-treated condition and then apply aging heat treatment to reach target mechanical properties.

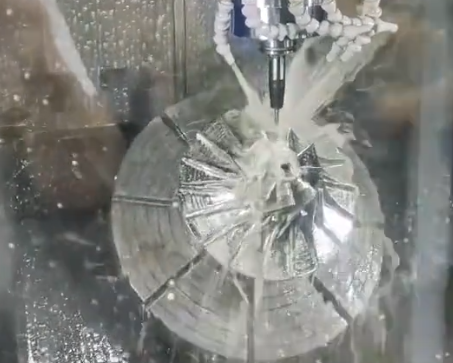

Machinability of Ti-13V-11Cr-3Al

Ti-13V-11Cr-3Al, like many titanium alloys, is generally considered challenging to machine compared with conventional steels and aluminum alloys. The combination of low thermal conductivity, high strength, and chemical reactivity at elevated temperatures can lead to tool wear, built-up edge, and surface integrity issues if not properly managed.

Key Factors Affecting Machinability

Several intrinsic characteristics affect the machinability of Ti-13V-11Cr-3Al:

- Low thermal conductivity: heat generated at the cutting zone is poorly conducted away from the tool–chip interface, resulting in high cutting temperatures.

- High hot strength: the alloy retains significant strength at elevated temperatures, requiring higher cutting forces and contributing to accelerated tool wear.

- Chemical affinity for tool materials: titanium alloys may react with common tool materials at high temperatures, promoting diffusion wear and crater formation.

- Tendency to work harden: near-surface plastic deformation can increase hardness in the machined layer, particularly if cutting parameters are not optimal.

These factors must be addressed by appropriate selection of tools, cutting parameters, and coolant strategies.

Recommended Machining Practices

Effective machining of Ti-13V-11Cr-3Al typically involves:

- Tool materials: preference for high-quality carbide tools with suitable coatings (e.g., TiAlN, AlTiN) or cermet and ceramic tools for specific operations. Uncoated carbides with optimized geometry can also be used when carefully controlled.

- Tool geometry: positive rake angles to reduce cutting forces, optimized clearance angles to minimize rubbing, and robust edge preparation to improve tool life.

- Cutting speed: moderate cutting speeds in comparison with steels. Speeds are kept relatively low for roughing operations to control temperature and wear, with slightly higher speeds possible for finishing when depth of cut is small.

- Feed rate and depth of cut: sufficient feed and depth of cut to maintain stable chip formation and minimize rubbing, avoiding extremely light cuts which can exacerbate work hardening and tool wear.

- Coolant: high-pressure, copious application of cutting fluid (commonly water-based emulsions or synthetic coolants) to enhance heat removal and chip evacuation. In some precision operations, minimum quantity lubrication or specialized techniques may be employed depending on tool and operation.

Tool wear monitoring and regular replacement are essential to maintain dimensional accuracy and surface quality, particularly for critical aerospace components.

Pain Points and Mitigation in Machining

Typical machining-related difficulties and mitigation approaches for Ti-13V-11Cr-3Al include:

- Rapid flank and crater wear: mitigated by selecting wear-resistant tool materials and coatings, optimizing speed–feed–depth combinations, and ensuring continuous coolant delivery.

- Built-up edge and poor surface finish: minimized by using sharp tools with positive rake, avoiding very low cutting speeds, and maintaining consistent feed.

- Dimensional instability from residual stresses: reduced by employing appropriate heat treatment (stress relief) before finish machining, and by using stable clamping and moderate depths of cut in finishing passes.

- Chip control issues: addressed by using chip-breaking geometries, suitable feed rates, and effective coolant to promote chip breakage and evacuation.

By systematically implementing these measures, machinability challenges can be brought under control and reliable production machining of Ti-13V-11Cr-3Al components can be achieved.

Weldability and Joining Techniques

Ti-13V-11Cr-3Al can be joined by several fusion and solid-state processes when correct procedures are followed. As with other titanium alloys, the main considerations during welding and joining are protection from atmospheric contamination and control of microstructure in the heat-affected zone (HAZ).

Fusion Welding

Gas tungsten arc welding (GTAW/TIG) and electron beam welding (EBW) are commonly used for titanium alloys and are applicable to Ti-13V-11Cr-3Al. Key aspects include:

- Shielding: high-purity inert gas (usually argon, sometimes helium or argon–helium mixtures) must protect the molten pool, arc, and adjacent heated areas. Back purging and trailing shields are typically required.

- Cleanliness: strict control of joint cleanliness, including removal of oils, grease, oxides, and surface contaminants, is essential.

- Heat input: controlled, moderate heat input to manage HAZ width and microstructural changes. Excessive heat can coarsen microstructure and reduce mechanical properties.

- Filler metals: matching or compatible filler wire for Ti-13V-11Cr-3Al is selected according to required joint properties and design codes.

Post-weld heat treatment is often applied to restore or optimize mechanical properties and relieve residual stresses. Procedures depend on component geometry and performance requirements.

Solid-State Joining

For critical applications, solid-state processes such as diffusion bonding and friction welding can be employed. Their advantages include:

- Reduced or absence of fusion defects such as porosity or solidification cracking.

- Fine, well-controlled microstructures in the joint region.

- Potentially superior fatigue performance when executed correctly.

As with fusion welding, careful control of atmosphere, surface preparation, and process parameters is necessary to obtain reliable joints.

Surface Treatments and Finishing

Surface condition has a direct influence on fatigue performance, corrosion resistance, and compatibility with subsequent processes such as bonding or coating. Treatment options for Ti-13V-11Cr-3Al include:

Mechanical Finishing

Common operations include grinding, polishing, and shot peening. Grinding must be performed with appropriate abrasives and coolant to avoid overheating and surface damage. Shot peening can enhance fatigue performance by introducing compressive residual stresses at the surface, but parameters must be optimized to avoid surface roughness that could act as crack initiation sites.

Chemical and Electrochemical Treatments

Chemical milling, pickling, and etching processes are used to remove alpha case and contaminated surface layers produced during high-temperature operations. Typically, mixtures of acids (such as nitric and hydrofluoric) under controlled conditions are used; processing parameters are selected to control metal removal rate and surface finish.

Anodizing and other electrochemical processes can also be applied for identification, surface modification, or improved corrosion behavior under certain conditions. Process selections must be compatible with design and environmental requirements.

Typical Applications and Design Considerations

Ti-13V-11Cr-3Al is primarily used in applications where a high strength-to-weight ratio and good mechanical performance are required. Typical application areas include:

- Aerospace structural components: such as airframe parts, landing gear elements, and highly loaded structural fittings where high strength is needed.

- Rotating components: where balance among strength, fatigue resistance, and density is critical.

- High-performance mechanical systems: including components in high-stress environments, mechanical linkages, and fasteners where specific strength and reliability are prioritized.

When designing with Ti-13V-11Cr-3Al, several considerations are important:

- Heat treatment strategy: must be integrated into design and manufacturing planning to achieve required strength and toughness.

- Component geometry and section thickness: influence cooling rates during heat treatment and thus microstructure and properties.

- Machining allowances: tooling, setup, and machining allowances should account for machining difficulty and potential distortion during heat treatment.

- Inspection and quality control: non-destructive testing methods, such as ultrasonic inspection and dye penetrant testing, are typically specified to ensure the integrity of critical components.

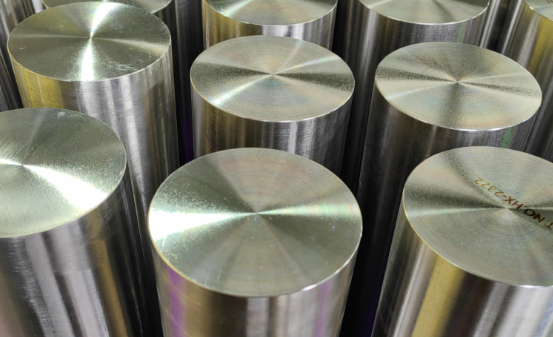

Material Standards and Supply Forms

Ti-13V-11Cr-3Al is supplied in various wrought forms, including bar, plate, sheet, forgings, and sometimes tubing, depending on producer capability and market demand. Each product form is typically covered by relevant standards or customer-specific specifications that define:

- Chemical composition limits.

- Mechanical property requirements in specific heat-treated conditions.

- Permissible defect levels and inspection requirements.

- Surface condition and dimensional tolerances.

Users select grades and tempers according to design requirements and manufacturing processes, ensuring that final properties match those specified for the intended application.

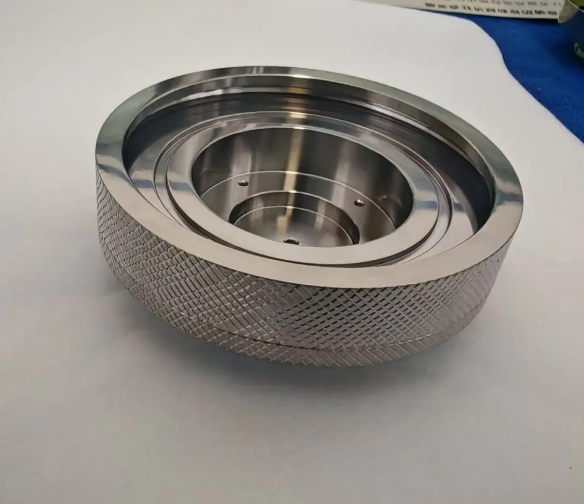

XCM Precision Machining for Ti-13V-11Cr-3Al

XCM specializes in CNC machining of high-performance titanium alloy Ti-13V-11Cr-3Al (Ti-13-11-3), providing tight-tolerance, lightweight components for aerospace, motorsport and other demanding industries. With 5-axis machining, optimized cutting strategies and strict process control tailored to this difficult-to-machine alloy, we help customers turn complex 3D designs into stable, repeatable parts – from rapid prototypes to low-volume production – while offering DFM support to reduce cost, improve manufacturability and accelerate time to market.

FAQ about Ti-13V-11Cr-3Al (Ti-13-11-3)

Is Ti-13V-11Cr-3Al easier to form before or after aging?

Ti-13V-11Cr-3Al is significantly easier to form in the solution-treated and quenched metastable β condition, before aging. In this state, strength is lower and ductility is higher, facilitating cold forming and complex shaping. After aging, the formation of fine α precipitates increases strength and hardness, which reduces formability. Therefore, the recommended practice is to perform most forming operations prior to aging and then apply the final aging treatment to achieve the required mechanical properties.

How does Ti-13V-11Cr-3Al compare with alpha-beta titanium alloys in machining?

Compared with many alpha-beta titanium alloys, Ti-13V-11Cr-3Al can be more demanding to machine, especially in high-strength aged conditions. Its higher alloy content and strong beta stabilization contribute to high strength at cutting temperatures and increase tool wear. However, with modern carbide tooling, optimized cutting parameters, and adequate coolant application, productive machining is achievable. In general, cutting speeds are kept somewhat lower than for common alpha-beta alloys like Ti-6Al-4V, and tool wear monitoring is more critical to maintain dimensional accuracy and surface quality.

Can Ti-13V-11Cr-3Al be welded without losing high strength?

Yes, Ti-13V-11Cr-3Al can be welded using appropriate procedures, and high joint strength can be maintained. Successful welding requires strict inert gas shielding, high cleanliness, controlled heat input, and suitable filler materials. Post-weld heat treatment is often employed to restore or optimize mechanical properties and relieve residual stresses. When properly executed and qualified, welded joints can achieve strength levels comparable to the base material, though detailed procedure qualification and testing are typically required for critical aerospace applications.

What is the typical heat treatment sequence for aerospace components made from Ti-13V-11Cr-3Al?

A common sequence for aerospace components is: hot forging in the beta or alpha-beta range, followed by beta or sub-transus solution treatment, quenching (often water or polymer quench), and then aging at an intermediate temperature to precipitate fine α within the β matrix. Parameters are selected according to component size and design requirements to achieve a balance of high strength, adequate ductility, and good fatigue performance. Stress-relief treatments may be added after major machining operations to reduce residual stresses without significantly changing the aged microstructure.