Not all plastics can be reliably or economically processed by CNC milling, turning, drilling or routing. Some polymers exhibit excessive melting, tearing, warping, cracking, or chemical degradation under cutting conditions, making them unsuitable or only marginally suitable for CNC machining. This guide provides a systematic overview of plastics that are generally not recommended for CNC machining, their underlying limitations, common issues in real production, and practical alternatives.

Why Certain Plastics Are Poor Candidates for CNC Machining

CNC machining applies concentrated mechanical and thermal loads to a workpiece. Plastics with unfavorable combinations of melting temperature, glass transition temperature, hardness, toughness, thermal conductivity, and chemical stability can respond poorly. Typical failure modes include softening and smearing instead of cutting, melting and resolidification, edge chipping, stress cracking, and dimensional instability.

Key material-related reasons a plastic may be unsuitable include:

- Low heat resistance leading to melting or severe softening under cutting temperatures

- Extreme elasticity or softness causing part deflection, poor tolerances, and surface tearing

- High brittleness or glassy behavior causing cracking and chipping under tool load

- Very low glass transition temperature causing creep and relaxation during machining

- High thermal expansion and low stiffness causing distortion and warpage as heat builds

- Chemical sensitivity to coolants, lubricants, or ambient moisture

Many of these factors interact: a plastic that is soft and thermally sensitive, for instance, will deflect away from the tool while simultaneously smearing and melting at the surface, making precise CNC machining impractical.

Typical CNC Machining Requirements for Plastics

Understanding baseline machining requirements clarifies why some plastics fail in practice. CNC machining of plastics assumes that the material can retain sufficient dimensional stability and structural integrity while being cut at specific spindle speeds, feed rates, and depth of cut. Important physical and mechanical properties include:

- Glass transition temperature (Tg) and melting temperature (Tm)

- Elastic modulus and flexural modulus

- Heat deflection temperature (HDT)

- Thermal expansion coefficient

- Hardness and impact strength

- Thermal conductivity

Plastics that fall far outside practical ranges (for instance, very low Tg combined with low modulus) are inherently difficult to fixture, cut, and hold tolerances. Highly anisotropic or heavily foamed materials further complicate tool engagement, chip formation, and surface quality, often making CNC machining technically feasible only under extreme restrictions or not feasible at all.

Amorphous and Low-Temperature Plastics That Deform and Smear

Amorphous plastics and low-temperature thermoplastics with very low softening temperatures frequently smear instead of forming clean chips. Typical issues include heavy burrs, melted edges, dimensional drift, and inconsistent surface finish, especially when tools heat up during extended cutting. The following groups are common examples.

Vinyl and Flexible PVC Compounds

Soft or flexible PVC (polyvinyl chloride) formulations used for cable jackets, soft tubing, gaskets, and similar products are usually not suitable for CNC machining in solid block form. While rigid PVC sheets and rods can be machined with tailored parameters, plasticized PVC grades present several limitations:

Representative characteristics (ranges are approximate and formulation dependent):

| Property | Flexible PVC | Implication for CNC Machining |

|---|---|---|

| Shore hardness | ~60A–95A | Soft, elastomeric response; deflects away from the cutter |

| Glass transition (Tg) | Well below 0 °C (plasticized) | Rubbery at room temperature; poor chip formation |

| Heat deflection temperature | Low (grade dependent) | Softens under cutting heat; edges smear and deform |

| Elastic modulus | Very low (tens to hundreds of MPa) | Part bending and vibration; poor tolerances |

Typical machining issues are:

- Elastic recovery: material springs back after tool passage, eliminating sharp features

- Smearing instead of cutting: edges are dragged and torn rather than cleanly sheared

- Tool fouling: softened material adheres to cutting edges, worsening heat buildup

- Difficulty clamping: the workpiece compresses in the fixture, causing distortion when released

For parts made from soft PVC, extrusion, molding, or die cutting are more practical than CNC machining from solid stock.

Low-Density and Linear Low-Density Polyethylene (LDPE, LLDPE)

Polyethylene exists in several forms; some are reasonably machinable, others are not. LDPE and LLDPE have lower modulus and lower softening points than high-density polyethylene (HDPE), resulting in poor machining behavior:

General characteristics:

- Low hardness, waxy surface feel

- Very low friction and high ductility

- Low melting point (Tm typically around 110–125 °C)

- Low heat deflection temperature

When subjected to CNC machining, LDPE and LLDPE often exhibit:

Smearing and stringing rather than chip formation, dimensional instability in thin features, rapid temperature increase and localized melting, and difficulty achieving tight tolerances or fine surface detail. Although very simple features in thick sections can sometimes be machined with very sharp tools and conservative parameters, LDPE and LLDPE are generally considered poor candidates for precision CNC machining.

Thermoplastic Elastomers (TPE, TPU, TPR, SEBS Blends)

Thermoplastic elastomers combine rubber-like elasticity with thermoplastic processing. Many grades of TPE, TPU (thermoplastic polyurethane), TPR, and SEBS-based compounds are unsuitable for CNC machining in solid bar or block form due to:

- Extremely low modulus and high elongation at break (often >300%)

- Pronounced elastic recovery and deformation under cutting forces

- Surface smearing, tearing, and inconsistent material removal

Common machining outcomes include unstable dimensions, poor edge definition, rough or “torn” surfaces especially on drilled holes, and difficulty drilling and tapping because the elastomer closes behind the tool. In most engineering contexts, such materials are formed through injection molding, extrusion, or die cutting rather than CNC machining from stock.

Highly Ductile, Low-Stiffness Plastics with Poor Dimensional Stability

Beyond low-temperature behavior, some plastics are simply too soft or flexible to maintain shape during CNC machining. Even if they do not melt excessively, they deform under relatively small clamping or cutting loads.

Soft Polyolefin Foams and Expanded Plastics

Foamed polymers such as soft polyethylene foam, some expanded polyolefins, and low-density flexible foams contain a high volume fraction of gas-filled cells. These materials are designed for cushioning and thermal insulation, not for precision machining. Typical characteristics include very low density, low compressive strength, and high compressibility.

When CNC machining is attempted, the following issues arise:

- Severe compression under clamp force, leading to unpredictable thickness after release

- Irregular cutting because the tool alternates between solid polymer and voids

- Cell tearing and ragged edges instead of smooth surfaces

- Difficulty maintaining uniform depth or flatness

Die cutting, waterjet cutting, and hot-wire cutting (for certain foams) are typically more suited to these materials than conventional CNC milling or turning.

Ultra-Soft Silicone Elastomers

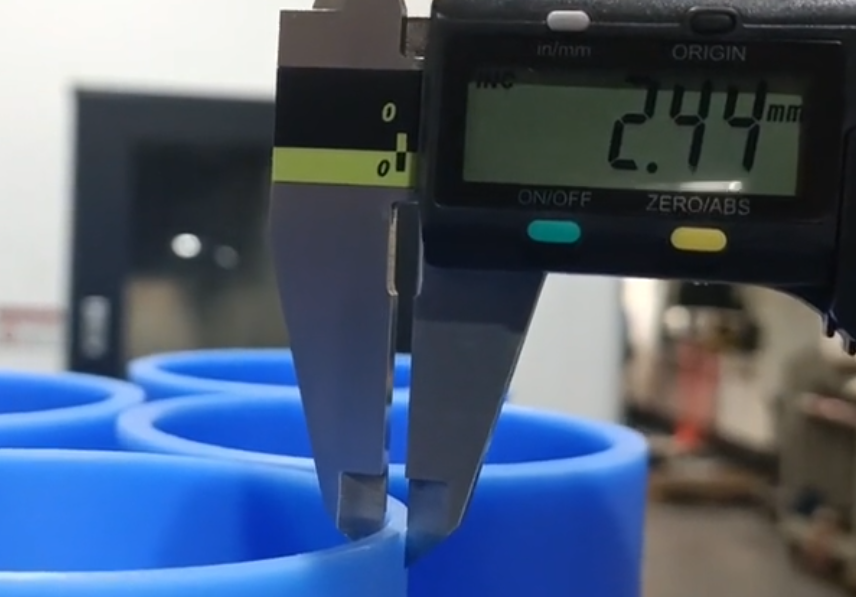

Room-temperature vulcanizing (RTV) silicone rubbers and very soft silicone elastomers, especially those in the low Shore A range or softer (including gel-like silicones), show an almost gel-like response under machining tools. Because of their high elasticity and very low modulus, they do not generate conventional chips and cannot maintain dimensional integrity.

Practical problems include extreme deflection under tools and fixtures, inability to hold tolerances or sharp geometries, difficulty cutting threads, and surface distortion and drag marks. Components in soft silicone are more effectively produced by molding, casting into tools, or die cutting thin sheets instead of CNC machining from bulk blocks.

Brittle, Glassy, and Highly Filled Plastics Prone to Cracking

At the opposite end of the spectrum, very brittle or heavily glass-filled plastics can crack, chip, or delaminate under the stresses generated by CNC machining. Even if they do not melt, they may fracture under tool engagement, particularly at sharp internal corners or thin sections.

Polystyrene (GPPS) and Some Styrenic Copolymers

General-purpose polystyrene (GPPS) is a transparent, rigid, but brittle thermoplastic. It has a relatively high glass transition temperature (around 90–100 °C), but its low impact strength and propensity for stress cracking make it poorly suited to CNC machining.

Common behaviors in machining include brittle fracture along tool paths, edge chipping and micro-cracks, surface crazing, and high risk of cracking during drilling and tapping. Because of these issues, polystyrene is better formed through injection molding, vacuum forming (as sheet), or cutting with finely controlled saws or lasers for non-critical applications rather than precision CNC machining.

Highly Mineral-Filled or Glass-Reinforced Plastics

Glass fiber reinforced plastics (GFRP) and highly mineral-filled compounds can sometimes be machined with specialized tools and parameters, but certain formulations are effectively impractical for precision CNC machining from solid plastic stock, especially when reinforcement content is very high or the matrix itself is brittle.

Typical issues include rapid abrasive wear of cutting tools, fiber pull-out and rough surfaces, edge chipping and micro-delamination along fiber directions, dust and fine particulate generation that requires specialized extraction, and anisotropic mechanical behavior causing unpredictable stresses and deformation. For many applications involving heavy reinforcement, composite-specific machining strategies and tools or near-net-shape molding processes are preferred over general-purpose CNC machining of solid plastic bars.

Plastics with Very Low Heat Resistance or Narrow Processing Windows

CNC machining generates frictional heat at the cutting zone. Plastics with very low heat resistance or extremely narrow temperature ranges between softening and thermal degradation are at risk of deforming or burning during machining.

Some Biodegradable Plastics (Certain PLA, PHA, Starch Blends)

Biodegradable polymers such as polylactic acid (PLA), certain polyhydroxyalkanoates (PHA), and starch-based blends vary widely in composition. While some PLA grades can be machined with care, many biodegradables exhibit limited heat resistance and relatively low softening temperatures.

Observed problems may include localized melting and sticking to tools, discoloration and surface degradation when overheated, brittleness leading to chipping in thin sections, and dimensional instability if residual stresses relax during machining or subsequent conditioning. Given the sensitivity of these materials, near-net-shape molding or additive manufacturing is often more effective than machining from solid plate or rod.

Very Low Softening Temperature Copolymers and Blends

Certain specialty copolymers and blends are formulated for flexibility or processability at low temperatures. While useful for films, overmolding, or adhesive layers, their low softening points and low glass transition temperatures hinder precise CNC operations.

Potential consequences include severe smearing of features with small tools, deformation of thin walls and fine ribs as soon as the tool warms the material, and surface rippling and waviness instead of smooth, sharp features. In many cases, these plastics are handled via roll-to-roll processes, thermoforming, or molding rather than subtractive machining.

Foams and Cellular Plastics: Structural Weakness and Surface Quality Issues

Foams and cellular plastics pose unique problems for CNC machining because of their non-homogeneous microstructure. Material density and strength vary from point to point, and the interface between solid cell walls and voids reacts inconsistently to cutting forces.

Soft Polyurethane Foam and Flexible Cellular Materials

Soft polyurethane foams, flexible microcellular elastomer foams, and similar materials offer cushioning and acoustic damping but lack the structural integrity necessary for precision machining. While rigid urethane modeling boards are specifically designed for machining, flexible foams are not.

Key issues include tearing of cell walls rather than controlled cutting, highly irregular edge profiles and fuzziness, substantial compression under tool and clamp forces leading to unpredictable final dimensions, and inability to maintain sharp internal corners or small feature sizes. Cutting methods such as waterjet cutting, oscillating knife cutting, or hot-wire cutting (for appropriate foams) deliver more consistent results than CNC milling.

Expanded Polystyrene (EPS) and Some Low-Density Insulation Foams

Expanded polystyrene (EPS) insulation boards and similar bead foams consist of fused beads with interfaces that are mechanically weak relative to the beads themselves. Conventional CNC toolpaths can cause bead separation and crumbling, especially near edges and contours.

Typical machining behavior includes bead pull-out and cratering, substantial dust and small particles, poor dimensional accuracy because the material crushes under the tool, and highly variable surface finish. Specialized hot-wire cutting or low-force routing designed specifically for EPS is usually preferred to standard CNC machining approaches.

Chemically Sensitive Plastics and Coolant Compatibility

CNC machining of plastics frequently uses coolants, lubricants, or compressed air to control heat and chip evacuation. Some polymers are chemically sensitive and can craze, crack, or swell upon exposure to common coolants, making them unsuitable or risky for conventional CNC setups.

Stress-Crack-Prone Plastics in the Presence of Coolants

Certain clear, amorphous plastics such as some grades of polycarbonate, acrylic (PMMA), and styrenics are known to be susceptible to environmental stress cracking when exposed to specific chemicals. If the machining process introduces internal stresses and the material contacts a non-compatible coolant or cleaning agent, delayed cracking can occur.

Although some of these materials can be machined with very controlled parameters and compatible coolants, specific grades or formulations may effectively be unsuitable for CNC machining in typical shop environments where standard coolant chemistries are used. In such cases, alternative manufacturing methods or strict coolant control measures are required to avoid failures.

Plastics Swelling or Softening in Contact with Oils and Cutting Fluids

Some elastomeric or highly plasticized materials absorb oils or certain cutting fluid components, resulting in swelling, softening, or loss of mechanical properties. If such plastics are machined, contact with typical shop fluids may cause parts to lose dimensional accuracy or mechanical integrity after machining.

In environments where dry machining or air-only cooling is not feasible, these plastics are operationally unsuitable for CNC machining because the mandatory process fluids conflict with the material’s chemical resistance profile.

Common Machining Problems with Non-Suitable Plastics

Across the various categories of plastics that are not suitable for CNC machining, many recurring problems can be observed. Recognizing these issues helps identify when a material-to-process mismatch is present.

| Observed Problem | Typical Material Characteristics | Impact on Parts |

|---|---|---|

| Smearing and melting at edges | Low softening temperature, low thermal conductivity | Poor surface finish, loss of feature sharpness, rework or scrap |

| Excessive burr formation | Ductile, low-stiffness polymers | Additional deburring steps, risk of dimensional changes during cleanup |

| Chipping and cracking | Brittle or highly filled plastics | Functional defects, micro-cracks, reduced strength, part rejection |

| Part deflection and vibration | Very low modulus, elastomeric response | Loss of tolerance, inconsistent wall thickness, misalignment |

| Warping and distortion after machining | High thermal expansion, residual stresses, low stiffness | Assembly issues, dimensional non-conformance over time |

| Tool clogging or fouling | Softening, tacky chip formation | Unstable cutting, increased heat, accelerated tool wear |

| Dust and particle generation | Brittle or foamed plastics | Contamination, additional cleaning, possible health and safety concerns |

When a Plastic Is Only Marginally Machinable

Some plastics sit on the boundary: CNC machining is not technically impossible, but produces limitations that may be unacceptable for many applications. These borderline cases share common characteristics:

- Acceptable results only in thick, simple geometries with generous tolerances

- Need for very low cutting speeds, extremely sharp tools, and light depths of cut

- Inability to reliably machine small features, thin walls, or fine threads

- High scrap or rework rates due to variability in surface finish and dimensions

When a material behaves this way, it is often more effective to select a different plastic with better machining behavior, or to use an alternative manufacturing process for that material.

Alternative Manufacturing Processes for Non-Machinable Plastics

When a chosen plastic is not suitable for CNC machining, alternative processes can provide consistent, economical results while preserving desired material properties such as flexibility, optical clarity, or biodegradability.

Injection Molding and Compression Molding

Many soft, brittle, or chemically sensitive plastics are best shaped by molding. Injection molding and compression molding allow the polymer to be processed in a controlled thermal and flow environment, eliminating the localized mechanical and thermal loads associated with CNC cutting. Complex geometries, thin walls, and elastic components are often more reliably produced by molding than by machining.

Extrusion, Thermoforming, and Die Cutting

For films, sheets, tubing, and flexible profiles, extrusion followed by thermoforming or die cutting is commonly used. Materials such as flexible PVC, TPE, and certain specialty copolymers are routinely processed in this way. Thermoforming allows heat-softened sheets to be shaped over molds, and die cutting can produce 2D shapes in foams and elastomer sheets without inducing the concentrated stresses typical of milling tools.

Additive Manufacturing for Complex or Sensitive Materials

Some biodegradable plastics and low-temperature polymers are available in filament or powder forms for additive manufacturing. Layer-by-layer processes can build complex geometries without the high cutting forces and tool-interface heat of CNC machining. For small batches and prototypes, this is often preferable to attempting precision machining of such materials from solid stock.

Material Selection Guidelines to Avoid Non-Suitable Plastics

To minimize problems, early-stage material selection should consider not only functional performance in service but also compatibility with CNC machining. Key guidelines include:

- Check whether the plastic is typically supplied as machinable stock (sheet, plate, rod) intended for subtractive manufacturing

- Review material datasheets for properties related to machining: modulus, heat deflection temperature, glass transition temperature, hardness, and recommended processing methods

- Avoid very low modulus, highly elastic materials for tight-tolerance CNC parts

- Be cautious with highly filled, brittle, or foam materials when fine feature accuracy is required

When the datasheet or supplier documentation emphasizes molding, extrusion, or casting and provides no guidance on machining, the material is often a poor candidate for CNC processes.

FAQ on Plastics Not Suitable for CNC Machining

What types of plastics are not suitable for CNC machining?

Plastics that are too soft, highly flexible, extremely brittle, or have very low melting temperatures are generally not suitable for CNC machining. These materials tend to deform, melt, or crack during cutting.

Why are soft plastics difficult to CNC machine?

Soft plastics often deform under cutting forces instead of producing clean chips. This can result in poor dimensional accuracy, rough surface finishes, and difficulty maintaining tight tolerances.

Which low-melting-point plastics are problematic for CNC machining?

Plastics such as polyethylene (PE), polypropylene (PP), and some low-grade PVC can melt or smear when exposed to cutting heat, leading to poor surface quality and tool clogging.

Are brittle plastics unsuitable for CNC machining?

Yes. Brittle plastics like acrylic (PMMA) or certain polystyrenes may crack or chip during machining, especially if improper tooling or cutting parameters are used.

Why are highly flexible plastics not ideal for CNC machining?

Highly flexible plastics, such as rubber-like materials or soft elastomers, lack sufficient rigidity. They can bend or vibrate during machining, making it difficult to achieve precision or consistent results.