Cost is often the decisive factor when choosing between CNC machining and 3D printing. Both processes can produce functional parts, but their cost structures, scaling behavior, and economic suitability differ substantially. This guide explains those differences in a systematic and data-driven way so that engineers, buyers, and manufacturing planners can make informed decisions.

Definitions and Scope of Cost Comparison

To compare machining costs between CNC and 3D printing, it is important to define the scope and boundaries of the analysis. Costs can be considered at multiple levels, from per-part variable cost to lifecycle investment.

This article focuses on:

- Per-part manufacturing cost for prototypes, small batches, and medium-volume production

- Cost drivers such as material, machine time, labor, and overhead

- Economic break-even points between CNC and 3D printing for different scenarios

The comparison excludes highly specialized cases such as ultra-large-format additive systems or multi-axis mill-turn systems with integrated automation cells. The emphasis is on typical industrial CNC machining centers and commonly used 3D printing technologies for engineering components.

Cost Components of CNC Machining

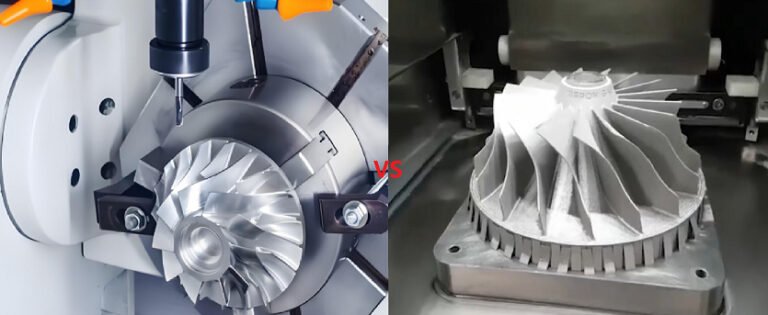

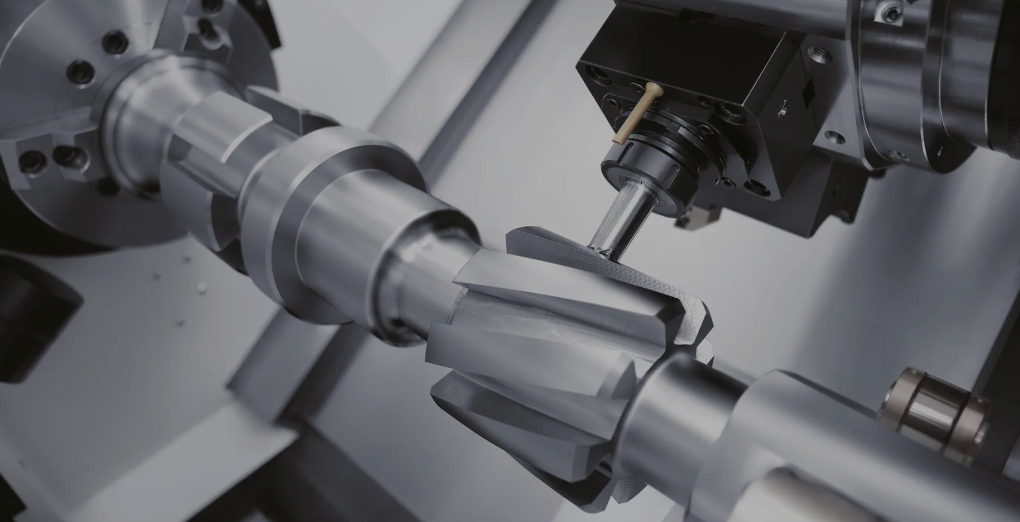

CNC machining is a subtractive manufacturing process where material is removed from a solid block (workpiece) using cutting tools driven by computer-controlled machines. The cost of CNC machining consists of several clearly identifiable elements.

Machine Hourly Rate

The machine hourly rate aggregates the cost of ownership and operation of the CNC equipment. It typically includes:

- Depreciation of the machine tool over its useful life

- Facilities and utilities (electricity, compressed air, floor space)

- Maintenance, service contracts, and spare parts

- Indirect overhead allocation (administration, quality, management)

Typical indicative ranges (values vary by region, year, and shop size):

3-axis vertical machining center: approximately USD 35–75 per machine hour.

5-axis machining center: approximately USD 60–120 per machine hour.

High-precision equipment or specialized machines may exceed these ranges.

Programming and Setup Time

CNC machining requires CAM programming and machine setup before the first part is produced. Relevant cost elements include:

- CAM programming time (toolpaths, strategies, simulations)

- Fixturing design and preparation

- Tool selection and tool length measurement

- First article inspection and adjustments

Hourly labor rates for skilled CNC programmers and setup operators are commonly higher than general machine operator rates. For a simple prismatic part, programming and setup might require 0.5–2 hours, while complex 5-axis parts can require several hours. This cost is distributed over the production quantity, which makes setup cost a dominant factor for one-off and low-volume parts.

Cutting Time and Tooling Cost

Once the machine is setup, the variable cost per part is driven by cutting time and tool wear.

Key factors affecting cutting time:

- Material machinability (aluminum vs stainless steel vs titanium)

- Volume of material to be removed (stock size vs final geometry)

- Required tolerances and surface finish

- Machine dynamics and toolpath strategy

Tooling cost includes cutting tools (end mills, drills, inserts), toolholders, and periodic replacement. For many jobs, tooling cost per part is modest, but in hard-to-machine materials or abrasive composites, tooling can become a substantial cost driver.

Material Cost and Buy-to-Fly Ratio

Material cost in CNC machining is influenced by the buy-to-fly ratio, which is the ratio between the mass of the purchased stock and the final part mass. A high buy-to-fly ratio indicates significant material waste.

Consider an example:

Final aluminum part mass: 0.8 kg.

Required stock block: 2.5 kg.

Buy-to-fly ratio: 2.5 / 0.8 ≈ 3.1.

If aluminum cost is USD 6/kg, the raw stock cost is 2.5 × 6 = USD 15. The effective material used in the part is only USD 4.8, with the remainder converted into chips. Recyclability of chips can offset some cost, but the machining process still handles the full mass of the stock.

Inspection and Finishing Processes

Post-machining processes add to the total cost. They may include:

- Deburring and edge finishing

- Surface finishing (polishing, bead blasting)

- Coating and plating (anodizing, hard chrome, nickel)

- Dimensional inspection (CMM, gauging)

The level of quality control needed (e.g., 100% inspection vs sampling) influences total cost. Tight tolerances and critical safety components often require more extensive inspection and documentation, increasing cost per part.

Cost Components of 3D Printing

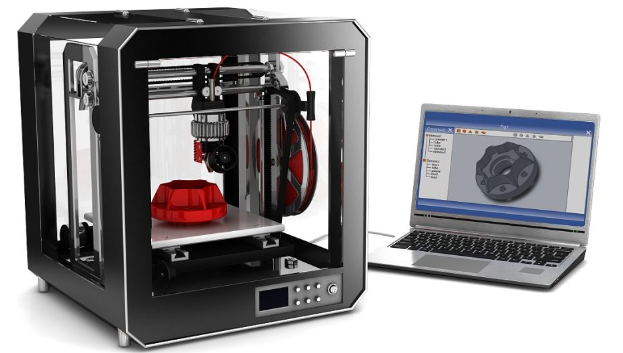

3D printing, or additive manufacturing, builds parts layer by layer from digital models. It has a different cost structure compared to CNC machining, with less emphasis on setup and fixturing and more on material and machine time.

Machine Hourly Rate and Build Time

For 3D printing, the machine hourly rate also includes depreciation, utilities, maintenance, and overhead. However, additive systems often have higher capital costs per machine, and in some technologies, build rates are slower, which can raise the effective hourly rate.

Indicative ranges:

FDM/FFF industrial printer: approximately USD 10–40 per machine hour.

SLA/DLP resin printer: approximately USD 15–50 per machine hour.

SLS (polymer) system: approximately USD 40–90 per machine hour.

Metal powder bed fusion: approximately USD 80–200 per machine hour or more, depending on system size and configuration.

Build time depends on layer thickness, part height, infill density, and the number of parts in the build. Part geometry influences build time differently from CNC: tall parts and fine layers increase build time significantly even when the part volume remains unchanged.

Material Cost in Additive Manufacturing

3D printing materials are typically more expensive per kilogram than bulk stock for machining. However, the buy-to-fly ratio is close to 1 for many additive processes, especially in polymer systems, because there is minimal scrap.

Typical indicative material price ranges:

- Industrial FDM engineering thermoplastics (e.g., ABS, PC, PA): approximately USD 40–200 per kg.

- Photopolymer resins (SLA/DLP): approximately USD 80–300 per kg.

- Polymer powders (SLS/HP MJF): approximately USD 60–200 per kg.

- Metal powders (laser powder bed fusion): approximately USD 150–600 per kg, depending on alloy.

In powder-based processes, a portion of unused powder can be recycled into subsequent builds. The effective powder consumption rate depends on refresh ratios and part packing density.

Preparation, Support, and Post-processing

3D printing requires digital preparation (build orientation, support generation, slicing) but the time investment per part is usually lower than full CNC programming, especially for simple parts.

Cost components include:

- Pre-processing: nesting of parts, orientation, support structure design

- Support material consumption and removal labor

- Post-processing: depowdering, support removal, surface finishing, heat treatment

Support removal can be labor-intensive in some technologies, particularly for complex metal parts with internal support structures. Post-processing steps for metal 3D printing may include stress relief, hot isostatic pressing (HIP), machining of mating surfaces, and surface finishing. These steps can contribute significantly to the total cost, sometimes exceeding the primary printing cost.

Labor Input and Operator Time

In many additive processes, once a build is started, the machine runs largely unattended. The labor cost per part often consists of:

- Preparation and machine setup time before starting the build

- Operator oversight for powder handling and safety procedures (in metal systems)

- Post-processing activities (support removal, cleaning, finishing)

For polymer additive processes, labor can be relatively low per part, especially when multiple parts are printed in a single build. Metal systems require more specialized handling and safety procedures, which increases labor costs per job.

Direct Comparison of Cost Structure

The cost structure between CNC machining and 3D printing differs in how fixed and variable costs are distributed. The table below summarizes the main cost components for each process in a qualitative way.

| Cost Driver | CNC Machining | 3D Printing |

|---|---|---|

| Machine hourly rate | Moderate to high; varies with machine type and axis count | Low to very high; metal systems often highest |

| Programming / setup | Significant for new parts; intensive for complex geometries | Generally lower; mainly orientation, support, and slicing |

| Material cost per kg | Relatively low; standard industrial stock pricing | High to very high, especially metal powders and resins |

| Material utilization | Buy-to-fly often >2; significant chip waste | Near net-shape; low waste in many processes |

| Labor per part | Moderate: setup, loading, unloading, in-process checks | Low to moderate: preparation and post-processing dominate |

| Cost sensitivity to geometry | Strongly affected by complexity and access for tools | Primarily affected by volume, height, and support requirements |

| Economy of scale | Strong; cost per part decreases significantly with quantity | Moderate; less reduction per part with higher quantities |

Part Geometry and Its Impact on Cost

Geometry is a central factor in the cost comparison because it influences both machining time and printing time, as well as support structures, material utilization, and post-processing.

Simple Prismatic Parts

Simple prismatic parts with 2.5D features (pockets, holes, bosses) and accessible surfaces are typically more economical to manufacture with CNC machining, especially in medium to high volumes.

For example:

- Material: Aluminum 6061.

- Dimensions: 120 × 80 × 20 mm block with pockets and through-holes.

- Tolerances: ±0.05 mm on critical features.

CNC machining can often produce such a part with short setup and high material removal rates, resulting in low cycle time and low per-part cost. 3D printing the same part may involve unnecessary build time and higher material cost, without taking advantage of design freedoms that favor additive manufacturing.

Complex Organic and Lattice Structures

For complex freeform geometries, internal channels, or lattice structures, CNC machining may require multiple setups, specialized tooling, or complex fixturing. In some cases, the geometry may not be machinable at all due to tool access limitations.

3D printing can often produce such geometries in a single build, with cost mainly dependent on volume, orientation, and support. In these cases, additive manufacturing may provide a lower total cost even at higher material prices, especially when consolidating multiple components into a single printed part.

Thin Walls and Small Features

Thin-walled structures and small features present cost implications for both processes:

- CNC: Thin walls can lead to chatter, deflection, and reduced cutting parameters, increasing cycle time and scrap risk.

- 3D printing: Thin walls can be limited by minimum wall thickness constraints and may require fine layers and slower print parameters.

The cost outcome depends on specific design requirements, tolerance levels, and the chosen technology for 3D printing. In many cases, hybrid approaches are used: 3D printing near-net-shape followed by CNC machining of critical interfaces and surfaces.

Volume, Batch Size, and Break-even Considerations

One of the most important aspects in cost comparison is the production quantity. CNC machining and 3D printing scale differently with volume because their fixed and variable costs behave differently.

One-off and Very Low Volume Production

For single prototypes or very small batches (1–10 pieces), 3D printing often offers economic advantages, especially when:

- Geometry is complex or not easily machinable

- Lead time is critical and design changes are expected

- Material waste in machining would be high

CNC machining must recover programming and setup costs over a small number of parts, which can make the per-part cost relatively high. 3D printing, with lower setup cost, can offer a lower total cost even if per-hour machine rates and materials are more expensive.

Small to Medium Batches

In the range of approximately 10–500 pieces (depending on part size and complexity), both processes can be competitive. The break-even point is influenced by:

- CNC setup and programming cost

- CNC cycle time per part

- 3D printing build time per batch

- Material costs for both processes

For relatively simple parts, CNC machining tends to become more economical as the batch size increases, because setup costs are amortized and cycle times are optimized. For complex geometries, 3D printing can remain competitive across wider volume ranges, especially for small parts that can be nested densely in a build.

Higher Volume Production

For higher volumes (hundreds to thousands of parts), CNC machining usually gains a strong cost advantage over 3D printing, particularly when combined with:

- Optimized fixtures and multi-part setups

- Automation such as pallet changers and robotic loading

- Process standardization and improved throughput

3D printing is constrained by build volume and build time. Scaling production often requires multiple machines or long build durations, which can increase capital and operating costs. For standardized parts, CNC machining, and in some cases casting plus machining of critical features, is often the more economical choice.

Material Type and Cost Implications

Material selection strongly influences cost dynamics, because material price, machinability, and compatibility with 3D printing technologies vary significantly.

Metals

Metal parts represent a common comparison point, especially for aerospace, automotive, and industrial applications.

CNC machining of metals:

- Material costs: relatively moderate for aluminum and steels; higher for titanium and nickel alloys

- Tool wear: more severe for hard or difficult-to-machine alloys

- Cycle times: longer for tough materials, increasing machine cost per part

Metal 3D printing (e.g., laser powder bed fusion):

- Material costs: significantly higher per kg than bar or plate stock

- Near-net-shape capability reduces waste for high buy-to-fly parts

- Post-processing often necessary to reach dimensional and surface requirements

For parts with a buy-to-fly ratio above approximately 5–10, metal 3D printing can be economically competitive because it reduces raw material consumption and enables geometry-driven weight reduction. For simple metal parts with accessible geometries, CNC machining typically remains cost-effective.

Polymers

For polymer components, a wider variety of 3D printing processes is available, and material costs are generally lower than metal. CNC machining of plastics is often straightforward but may suffer from issues such as burrs, heat generation, and material clamping.

Cost influences for polymer parts:

- CNC plastic machining: low raw material cost, moderate machine and labor cost

- Polymer 3D printing: higher material cost but high design flexibility and low setup effort

For functional prototypes, housings, and complex internal features, polymer 3D printing often offers a good balance between cost and lead time at low and medium volumes. For simple shapes or recurring production, CNC machining can be less expensive per part.

Tolerance, Surface Finish, and Cost Impact

Required tolerances and surface quality have a direct cost impact because they determine process parameters and post-processing steps.

CNC Machining Dimensional Capabilities

Standard CNC machining can routinely achieve tolerances in the range of ±0.01–0.05 mm on many features, depending on machine condition, setup, and measurement strategy. Finer tolerances often require additional operations, precision fixtures, or environmental control.

In cost terms:

- Tighter tolerances can increase machining time (slower passes, finishing cuts)

- Additional inspection (CMM, gauge blocks) may be required

- Scrap and rework risk increases, influencing quoted prices

3D Printing Dimensional Capabilities

3D printing dimensional tolerances depend on the technology and process parameters. As a general indication:

- Polymer FDM: typical tolerances ≈ ±0.2–0.3 mm or ±0.5% of dimension

- Polymer SLS: typical tolerances ≈ ±0.1–0.3 mm

- Metal powder bed fusion: typical tolerances ≈ ±0.05–0.1 mm before machining

To achieve tighter tolerances or specific surface finishes, post-machining or polishing is often required. This adds cost that must be considered when comparing 3D printing to pure CNC machining.

Lead Time and Cost Interactions

Lead time is not a direct cost component but influences cost through machine utilization, rush order premiums, and supply chain decisions.

CNC machining lead time may be influenced by:

- Queue time in busy job shops

- Availability of material and tooling

- Programming workload and fixture fabrication

3D printing lead time may be influenced by:

- Printer build queues and batch planning

- Build duration for large components

- Post-processing capacity

When compressed lead times are required, some suppliers apply rush charges or priority pricing. 3D printing can sometimes compress overall lead time by eliminating tooling and reducing setup effort, which may offset higher per-part manufacturing cost. This is relevant in situations where the cost of delayed product launch or development iteration is substantial.

Economic Use Cases Favoring CNC Machining

CNC machining is economically favorable in multiple scenarios where its characteristics align with project requirements.

Standardized and Repeat Production

When the same part is manufactured repeatedly over time in stable volumes, the upfront investment in CNC programming, fixtures, and optimization can be amortized over large quantities. The result is a low per-part cost and high consistency.

Examples:

- Production of mechanical brackets, blocks, and flanges in aluminum or steel

- Machined housings for electronics in standardized sizes

- Hydraulic manifolds with recurring designs

In such cases, 3D printing would usually not offer a lower cost per part, because its strengths (low setup, geometry freedom) are less relevant while its higher material cost remains.

High Material Removal Rates with Cheap Stock

When the final part geometry corresponds closely to standard stock shapes (bars, plates) and material is inexpensive, CNC machining can remove material quickly with minimal waste. High material removal rates lead to short cycle times and low machine cost per part.

Examples include structural aluminum parts, steel plates with drilled and milled features, and simple turned shafts produced from bar stock.

High-precision Interfaces and Critical Tolerances

Even when 3D printing is used, many functional parts require CNC machining for critical interfaces such as bearing seats, sealing surfaces, and precision threads. For parts dominated by these features, machining the entire part is often more economical than combining additive with extensive subtractive finishing.

Economic Use Cases Favoring 3D Printing

3D printing becomes economically attractive when its characteristics align with geometry, volume, and product requirements.

Complex Geometry and Part Consolidation

In many applications, 3D printing enables combining multiple components into a single part, reducing assembly operations, fasteners, and leak paths. The cost benefits can include:

- Elimination of fixtures and assembly labor

- Reduction of part count and supply chain complexity

- Weight reduction that may impact system-level cost (e.g., fuel or energy consumption)

When assessing economic viability, the cost of separate machined parts plus assembly should be compared with a single printed part plus limited finishing. In such cases, the total system cost may favor 3D printing even if the per-part manufacturing cost appears higher in isolation.

Rapid Design Iteration and Development

During product development, design changes are common. 3D printing allows fast iteration with minimal setup modification, which can reduce the cost associated with multiple design cycles.

Economic benefits include:

- No need to modify fixtures or re-program complex toolpaths for small design changes

- Ability to produce prototypes for testing within short time frames

- Reduced engineering time for one-off or evolving designs

When the cost of engineering effort and project delay is incorporated, 3D printing may offer a lower effective cost for early-stage and pre-production phases.

High Buy-to-Fly Metal Parts

For metal components where the final part mass is only a small fraction of the stock needed for machining, 3D printing can reduce material and machining costs.

Examples include:

- Lightweight aerospace brackets and mounts with internal cavities

- Topology-optimized structural parts

- Complex fluid manifolds with curved internal channels

By producing near-net-shape parts and optimizing internal geometry, 3D printing can reduce both material consumption and downstream machining, leading to favorable cost structures despite higher per-kg material prices.

Hybrid Strategies and Combined Cost Approaches

In practice, many cost-optimized solutions use both CNC machining and 3D printing. This hybrid approach can balance strengths and weaknesses of each process.

Printing Near-Net-Shape Followed by Machining

A common strategy is to print a near-net-shape blank and then machine critical features. Cost benefits can include:

- Reduced material waste compared to machining from solid stock

- Preservation of complex internal features impossible to machine

- Accurate interfaces and surface finishes from CNC finishing passes

This approach is widely used in metal additive manufacturing for high-value components. The cost model includes additive build cost, heat treatment, and machining cost. When optimized, this can outperform either pure machining with high waste or pure printing with extensive finishing.

Printed Tooling, Jigs, and Fixtures for CNC

3D printing can also reduce CNC machining cost indirectly by providing low-cost fixtures, soft jaws, and custom workholding solutions. These printed tools can:

- Shorten fixture design and manufacturing time

- Improve accessibility for tools, reducing cycle time

- Enable better clamping of complex parts

In this case, 3D printing is not replacing machining but enhancing its cost efficiency by reducing setup and changeover costs.

Quantitative Cost Modeling Considerations

To make an informed process choice for a specific part, it is useful to build a basic cost model that compares CNC machining and 3D printing. An example simplified model might include the following terms:

| Cost Element | CNC Machining | 3D Printing |

|---|---|---|

| Setup and programming cost (USD) | CNC_setup_cost | AM_preparation_cost |

| Machine time per part (hours) | CNC_time_per_part | AM_time_per_part |

| Machine hourly rate (USD/hour) | CNC_rate | AM_rate |

| Material cost per part (USD) | CNC_material_cost | AM_material_cost |

| Post-processing cost per part (USD) | CNC_post_cost | AM_post_cost |

| Labor cost per part (USD) | CNC_labor_cost | AM_labor_cost |

For a given quantity Q, the total cost per part can be expressed in a simplified form as:

Total_CNC_cost_per_part = (CNC_setup_cost / Q) + (CNC_time_per_part × CNC_rate) + CNC_material_cost + CNC_post_cost + CNC_labor_cost

Total_AM_cost_per_part = (AM_preparation_cost / Q) + (AM_time_per_part × AM_rate) + AM_material_cost + AM_post_cost + AM_labor_cost

By estimating these parameters based on supplier data or internal manufacturing records, it is possible to identify the quantity at which both totals are equal. That quantity represents a break-even point between CNC machining and 3D printing for the particular part.

Pain Points and Practical Cost Considerations

In real projects, several practical aspects affect cost beyond the basic technical parameters.

Cost of Design for Manufacturability

Designing parts for CNC manufacturing may require adjustments such as increasing radii in internal corners, avoiding deep narrow pockets, or simplifying undercuts. These changes can reduce machining cost but require engineering effort and may affect performance.

Designing for 3D printing often involves different rules: ensuring adequate support, avoiding trapped powder areas, and maintaining minimum wall thicknesses. Violations of these rules can lead to print failures and scrap. The time and expertise required for design adaptation are indirect cost components that influence overall project economics.

Scrap Risk and Rework

Scrap occurs when parts fail to meet requirements. It is a hidden cost factor that depends on process capability, quality control, and operator experience.

- CNC: Scrap may result from tool breakage, setup errors, or dimensional deviations. Individual part loss can be isolated, but time and material are lost.

- 3D printing: In some technologies, a failed build can scrap all parts in the build volume, which concentrates risk. However, when builds succeed, multiple parts are produced simultaneously, improving consistency.

When scrap rates are high, actual cost per part exceeds the nominal cost. Process choice should consider historical performance and quality stability, especially for complex geometries or new materials.

Supply Chain and Outsourcing Considerations

Many companies outsource some or all of their CNC machining and 3D printing. Supplier availability, geographic location, and logistics influence total cost through:

- Shipping costs for raw material and finished parts

- Customs and taxes for cross-border sourcing

- Variation in hourly rates and material prices by region

Access to reliable 3D printing services can make additive solutions economically accessible without capital investment. At the same time, trusted machining suppliers can provide competitive pricing through optimized setups and economies of scale.

Summary of Cost Comparison: CNC vs 3D Printing

CNC machining and 3D printing are complementary technologies with distinct cost structures. CNC machining generally excels in:

- Medium to high-volume production of simple to moderately complex geometries

- Parts requiring tight tolerances and high surface quality directly from the machine

- Situations where material is inexpensive and buy-to-fly ratios are low

3D printing tends to be cost-effective for:

- Low-volume and prototype production with frequent design changes

- Complex geometries, internal channels, and part consolidation opportunities

- High buy-to-fly metal parts where material savings are significant

The most economical solution for a specific part is determined by a combination of design, material, quantity, tolerance requirements, and lead-time constraints. Evaluating both processes using a structured cost model and realistic production assumptions allows engineers and purchasing managers to select the most cost-efficient manufacturing route.

FAQ: CNC Machining vs 3D Printing Cost

What is the main cost difference between CNC machining and 3D printing?

CNC machining generally has higher setup and tooling costs but lower per-part cost for large runs. 3D printing has low initial setup costs but can be more expensive per part for larger or high-strength components.

How does material cost affect CNC machining vs 3D printing?

CNC machining: Wastes material (chips, offcuts), increasing cost, especially for expensive metals.

3D printing: Material usage is often optimized, but high-performance polymers or metal powders can be costly.

Are there cost differences based on part complexity?

CNC machining: Complex parts may require multiple setups, special tooling, or multi-axis machines, increasing cost.

3D printing: Complexity has little impact on cost, as the machine builds intricate geometries layer by layer.

How do labor and expertise affect cost?

CNC machining requires skilled operators and programmers, contributing to higher labor costs. 3D printing is often more automated, reducing labor cost, but complex materials or high-performance prints still need expertise.