Choosing a 5-axis machining supplier is a critical decision that directly affects part accuracy, functional reliability, delivery performance, and total project cost. This guide explains the technical, operational, and commercial factors you should evaluate in a systematic way so you can identify suppliers capable of delivering consistent, high-precision 5-axis CNC components for your specific application.

About 5-Axis Machining Capabilities

Before evaluating suppliers, it is essential to understand what 5-axis machining is and what capabilities it can provide. This ensures that your expectations align with what a supplier can realistically deliver.

In 5-axis CNC machining, the tool or the part can move along three linear axes (X, Y, Z) and two additional rotational axes (typically A and B, or B and C). This enables machining complex geometries in a single setup, minimizing repositioning and improving accuracy.

Key aspects of 5-axis machining capabilities include:

- Simultaneous vs. indexed 5-axis machining

- Maximum workpiece size and weight

- Achievable dimensional and geometric tolerances

- Supported materials and material thickness

- Surface finishing and feature complexity

Simultaneous 5-axis machining allows all five axes to move at the same time, enabling complex free-form surfaces and high-speed machining with optimized tool orientation. Indexed (or 3+2) machining repositions the part using the rotary axes but machines with only three axes at a time; it is suitable for multi-face machining but less capable for continuous contoured surfaces.

Defining Your Technical Requirements

A precise definition of your requirements is the foundation for supplier selection. Without clearly stated technical parameters, you cannot properly evaluate a supplier’s suitability or obtain comparable quotations.

Critical dimensional and geometric tolerances

Specify realistic and measurable tolerances for your parts. Common considerations include:

- Linear tolerances on critical dimensions (for example ±0.005 mm, ±0.01 mm, ±0.02 mm)

- Geometric tolerances such as position, flatness, straightness, circularity, cylindricity, parallelism, and perpendicularity

- Runout requirements for mating features such as shafts and bores

- True position requirements for hole patterns and interface locations

State how these tolerances are to be verified (for example, CMM, air gauge, optical measurement) to ensure alignment with the supplier’s inspection capabilities.

Material specifications

Define the exact material requirements, including:

- Material grade and standard (for example, 6061-T6 per ASTM B209, 17-4PH condition H900 per ASTM A564, Ti-6Al-4V per ASTM B348)

- Required mechanical properties (yield strength, ultimate tensile strength, hardness)

- Heat treatment condition and post-machining heat treatment, if any

- Corrosion resistance or biocompatibility requirements

- Material traceability requirements (for example, mill certificates, lot traceability)

Ensure that the supplier has experience machining your specified materials, particularly if your design uses hard alloys, high-temperature alloys, or materials with poor machinability.

Surface finish and cosmetic requirements

Clearly state surface finish requirements in terms of roughness parameters (for example, Ra, Rz) and any cosmetic expectations:

- Functional surfaces may need Ra ≤ 0.4 µm, 0.8 µm, 1.6 µm, or other specified values

- Non-critical surfaces may allow rougher finishes to optimize cost and cycle time

- Cosmetic surfaces may require uniform machining marks, no visible tool chatter, or controlled lay direction

- Requirements for deburring, edge rounding, and removal of sharp edges (for example, break edges 0.2–0.5 mm)

Production volume and lifecycle

Specify the expected demand profile:

- Prototype quantities (1–20 pieces)

- Pilot or pre-series (20–200 pieces)

- Series production (>200 pieces per batch or per year)

- Estimated annual volume and product lifecycle (for example, 5 years, 10 years)

This information helps you evaluate whether the supplier’s capacity, automation level, and manufacturing strategy are compatible with your needs.

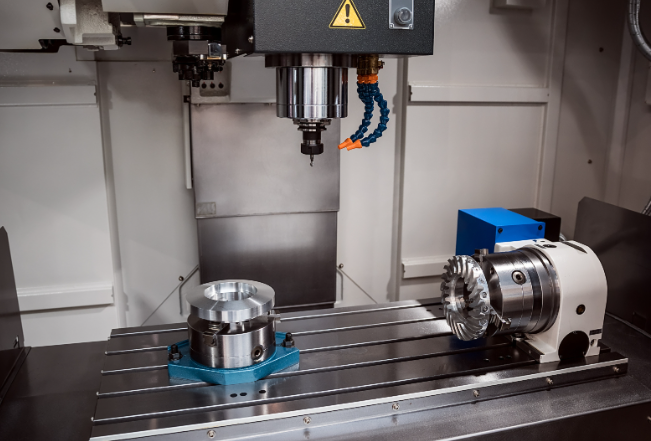

Assessing Machine Tools and Equipment

The performance of a 5-axis machining supplier is heavily determined by the machine tools and auxiliary equipment they use. When evaluating suppliers, examine the capability and condition of their equipment rather than relying solely on brand names.

Types and configuration of 5-axis machines

Different machine configurations offer distinct advantages. Understanding these helps you match your part geometry with the right supplier setup.

| Configuration | Characteristics | Best suited for |

|---|---|---|

| Swivel head (tilting spindle) | Rotary axes in the spindle head; fixed table or one rotary axis in table; good access to complex surfaces. | Large parts, complex contours, aerospace structures. |

| Trunnion table (tilting rotary table) | Rotary axes in the table; compact design; strong workholding; good for small to medium parts. | High-precision components, prismatic parts, multi-face machining. |

| Table-table or head-table | Combination of rotary axes in both head and table; high flexibility; often high-end systems. | Very complex geometries, high-mix precision work. |

Ask suppliers for information such as machine model, year of manufacture, travels (X/Y/Z), rotary axis ranges, and maximum spindle speed.

Spindle specifications

Spindle characteristics determine the supplier’s ability to handle different materials and cutting strategies:

- Spindle power (kW or HP): higher power is beneficial for heavy cuts and hard materials.

- Maximum spindle speed (rpm): high-speed spindles are suitable for small tools and fine finishing operations.

- Spindle taper (for example, HSK, BT, CAT) and tool interface: can influence tool rigidity and precision.

- Cooling method (air, oil, coolant through spindle) and thermal control: impacts dimensional stability and tolerance holding.

Tool changers, pallet systems, and automation

Evaluate the supplier’s capability to support efficient production and quick changeovers:

- Automatic tool changer capacity (for example, 30, 60, 120 tools): large capacity supports complex jobs and reduces setup changes.

- Availability of pallet changers or flexible manufacturing systems: important for higher volume and lights-out machining.

- Probing systems for tool length, tool breakage, and part alignment: critical for reducing human error and maintaining consistency.

- Use of standardized workholding systems and zero-point clamping: reduces setup time and improves repeatability.

Auxiliary equipment and inspection tools

The supporting equipment is equally important:

- Coordinate Measuring Machines (CMM) with sufficient volume and accuracy ratings

- Surface roughness testers, height gauges, and bore gauges

- Optical or vision inspection systems for small features

- In-machine or offline balancing for high-speed tools

- Equipment for deburring, cleaning, passivation, or other post-processing operations

Evaluating Precision, Tolerance, and Stability

For many applications such as aerospace, medical, optics, and precision mechanical assemblies, the ability to repeatedly meet tight tolerances is a decisive factor in supplier selection.

Dimensional and geometric accuracy

Ask potential suppliers to clearly state their typical and maximum achievable tolerances under production conditions, not just under ideal or laboratory conditions. Pay attention to:

- Typical milling tolerances for small parts (for example, ±0.005 mm to ±0.02 mm depending on size and material)

- Tolerance capability for deep pockets, thin walls, and long overhangs

- Geometric tolerances they can regularly meet for true position, flatness, and perpendicularity

- Capability to control cumulative tolerances in assemblies

Request sample measurement reports or capability studies (for example, process capability indices such as Cp, Cpk) for similar parts if available.

Thermal and process stability

Consistency over time is vital. Discuss how the supplier manages factors that can cause dimensional variation:

- Machine warm-up procedures and temperature stabilization

- Shop environment control (for example, ambient temperature ranges, humidity)

- Scheduled calibration and maintenance intervals for machines and measuring equipment

- Use of in-process probing to compensate for thermal drift or setup variations

Inspection strategy and measurement traceability

A reliable 5-axis machining supplier will have a structured inspection strategy that corresponds to the complexity and risk level of your parts:

- Incoming inspection for raw materials, including verification against certificates

- In-process inspection at defined checkpoints for critical features

- Final inspection and full dimensional reports for first articles and production lots

- Measurement systems traceable to national or international standards

- Gauge Repeatability and Reproducibility (GR&R) studies for key measuring instruments

Checking Experience in Target Industries and Applications

Industry-specific experience greatly increases the probability that a supplier understands your requirements and hidden constraints. Examine which sectors the supplier routinely serves and what types of parts they produce.

Aerospace and defense

For aerospace components, typical expectations include:

- Compliance with aerospace quality systems and documentation

- Experience machining high-strength aluminum alloys, titanium alloys, nickel-based superalloys

- Familiarity with tight tolerance stack-ups and critical safety-related features

- Control of surface integrity, including residual stresses and avoidance of burrs in critical areas

- Ability to manage special processes (for example, shot peening, non-destructive testing) via approved partners

Medical and dental

Medical applications impose strict requirements on material traceability, cleanliness, and surface condition:

- Experience with implant-grade titanium, stainless steels, and cobalt-chrome alloys

- Knowledge of relevant standards for implants and instruments

- Controlled handling and cleaning to minimize contamination

- Capability to achieve fine surface finishes suitable for human contact or tissue integration

- Documentation and lot traceability for every batch and serial number

Automotive, energy, and general engineering

In these sectors, cost efficiency, repeatability, and delivery performance are typically critical:

- Ability to handle moderate to high volumes with stable cycle times

- Use of standardization, fixtures, and automation to reduce variation

- Optimization of tool life and machining strategies for cost-effective production

- Experience with castings, forgings, and near-net-shape parts for machining

Reviewing Quality Management Systems

A robust quality management system (QMS) provides the framework for controlled, repeatable manufacturing. Assess whether the supplier has implemented and actually uses formal quality procedures.

Certifications and compliance

Check for relevant certifications and their status:

- ISO 9001: baseline quality management system for many industries

- AS9100: widely adopted in aerospace and defense

- ISO 13485: common in medical device manufacturing

- Other sector-specific requirements as applicable

Verify the validity of certificates and ensure they cover the actual scope of 5-axis machining services.

Documented processes and work instructions

Investigate how the supplier controls and documents their processes:

- Standard operating procedures for setup, machining, inspection, and handling

- Work instructions with clear reference to drawings, 3D models, and revision levels

- Control of NC programs, including approval, revision, and backup

- System for non-conformance handling, corrective actions, and continuous improvement

Traceability and record retention

For critical applications, traceability is not optional. Confirm the supplier’s ability to:

- Link each part or batch to raw material certificates, machining parameters, and inspection records

- Maintain controlled identification and labeling during all process stages

- Store manufacturing and inspection records over defined retention periods

- Provide detailed documentation on request, including first article inspection reports and process histories

Engineering and DFM Support

5-axis machining suppliers with strong engineering capabilities can add substantial value by optimizing your designs for manufacturability and cost without compromising functionality.

Design for manufacturability (DFM) review

Assess whether the supplier can review your CAD models and technical drawings and provide specific, technically justified suggestions on:

- Adjustments to wall thicknesses, fillets, and corner radii for better tool access

- Reduction of unnecessary tight tolerances, especially on non-functional surfaces

- Optimization of datum schemes to simplify inspection and assembly

- Consolidation of multiple parts into single machined components where appropriate

- Alternative design features that reduce setups or tool changes

CAM programming and simulation capabilities

High-quality 5-axis machining requires advanced computer-aided manufacturing (CAM) capabilities:

- Use of recognized CAM software capable of true 5-axis toolpaths and collision checking

- Experience with strategies such as swarf cutting, multi-axis contouring, and rest machining

- Verification of NC programs using simulation to avoid collisions and over-travel

- Standardized post-processors for each machine type, validated and maintained

Prototyping and iterative development

Many projects require iterative prototype phases before full production. Evaluate whether the supplier can:

- Rapidly produce prototype parts with short lead times

- Provide detailed feedback on manufacturability issues discovered during prototyping

- Implement design changes efficiently, including quick updates to CAM programs and workholding

- Maintain configuration control between prototype revisions and pre-series builds

Capacity, Lead Time, and Flexibility

The best technical capability is of limited value if the supplier cannot meet your delivery expectations. Analyze their capacity, typical lead times, and flexibility in managing varying demand patterns.

Production capacity and scalability

Discuss their production structure in realistic terms:

- Number of 5-axis machining centers and their availability

- Operating shifts per day and days per week

- Percentage of capacity already committed to existing customers

- Ability to add shifts or reallocate machines in response to increased demand

- Use of scheduling systems to manage multiple projects and priorities

Typical and expedited lead times

Request information about typical lead times for different project types:

- Quotation response time

- Prototype lead time (for example, 5–15 working days depending on complexity)

- Pre-series and production lead times (for example, 3–8 weeks depending on batch size and processes)

- Availability of expedited options for urgent requirements, including associated cost impact

Handling demand variability

If your demand is not constant, confirm how the supplier manages variability:

- Processes for demand forecasting and capacity planning

- Policies for minimum order quantities or framework agreements

- Ability to build and manage safety stock or buffer inventories when justified

- Mechanisms for communicating and implementing schedule changes

Cost Structure and Quotation Analysis

Price is always a factor, but it should be evaluated alongside technical capability, quality, and delivery performance. A low initial unit cost may lead to higher overall project cost if quality or reliability is poor.

Understanding cost drivers in 5-axis machining

Key contributors to total cost include:

- Machining time, determined by toolpaths, part complexity, and cutting parameters

- Setup time, including fixturing and programming time allocation

- Tooling cost, especially for specialized cutters and wear-intensive operations

- Material cost and material utilization (for example, bar stock vs. billet vs. near-net shape preforms)

- Inspection and documentation level (for example, basic inspection versus 100% measurement with detailed reports)

Comparing quotations

When you receive multiple quotations, consider the following:

- Are the suppliers quoting based on the same technical requirements and revision level?

- Are special requirements (for example, certificates, reports, packaging, surface treatments) clearly itemized?

- Is the cost breakdown transparent enough to understand major cost elements?

- Are there hidden costs such as programming fees, tooling charges, or setup fees that apply to future orders?

Total cost of ownership perspective

Evaluate cost over the entire lifecycle rather than per-piece price alone:

- Scrap and rework risk due to inadequate capability

- Costs associated with delays, missed deadlines, or supply interruptions

- Administrative overhead due to poor communication or lack of documentation

- Potential savings from process optimization by technically competent suppliers

Communication, Project Management, and Technical Support

Effective communication ensures that requirements are understood, risks are managed, and changes are implemented without errors. Examine how the supplier handles information flow, project control, and ongoing technical support.

Single point of contact and response times

Ideally, you should have a dedicated project or account manager responsible for your projects. Evaluate their:

- Responsiveness to technical and commercial inquiries

- Ability to coordinate internally between engineering, production, and quality departments

- Familiarity with your industry and standards

- Willingness to discuss risks, uncertainties, and open issues in detail

Document and revision control

Miscommunication about drawing or model revisions is a common source of problems. Assess the supplier’s controls for:

- Managing and distributing up-to-date drawings and 3D models

- Documenting any deviations or concessions and obtaining your approval

- Maintaining change histories and ensuring obsolete data are not used

- Communicating engineering changes clearly and promptly

Technical support during production

Check whether the supplier can support you beyond simply delivering parts:

- Root cause analysis and corrective actions in case of non-conformities

- Proposals for cost reduction through process improvements or design adjustments

- Support for qualification activities, including test pieces and documentation

- Collaboration on long-term improvement of part performance and manufacturability

Supply Chain, Secondary Processes, and Logistics

5-axis machining is often only one stage in a broader supply chain that may include heat treatment, coating, assembly, and testing. Ensure the supplier can manage or coordinate these stages effectively.

In-house vs. outsourced secondary processes

Identify which processes are performed in-house and which are outsourced:

- Heat treatment (for example, hardening, tempering, solution treatment, aging)

- Surface treatments (for example, anodizing, plating, passivation, coating)

- Grinding, honing, lapping, or other high-precision finishing operations

- Assembly of sub-components and functional testing

For outsourced processes, confirm that the supplier has approved partners and clear quality agreements in place.

Packaging, labeling, and preservation

Especially for precision and cosmetic parts, packaging and handling are critical:

- Use of protective caps, foam, or custom trays to prevent impact damage

- Corrosion protection methods (for example, VCI bags, oils, desiccants) when required

- Individual or batch labeling to maintain traceability

- Cleanliness control to avoid contamination that may affect downstream processes

Logistics and shipping

Discuss the logistics model for your deliveries:

- Incoterms and transport responsibilities

- Typical shipping methods and transit times

- Availability of tracking and delivery notifications

- Capability to support consignment stock, vendor-managed inventory, or scheduled deliveries

On-Site Audits and Sample Evaluation

For critical or long-term projects, an on-site audit and evaluation of sample parts can provide deeper insight than documents and quotations alone.

Conducting an on-site audit

During an audit, observe and verify:

- Overall organization and cleanliness of the shop floor

- Condition of machines and measuring equipment

- Implementation of safety practices and equipment handling

- Availability and use of work instructions at the machines

- How operators set up parts, manage tools, and record data

First article and sample part evaluation

Before full production, request first article samples and detailed inspection reports:

- Verify that critical dimensions and features fully meet specifications

- Check that surface finish and cosmetic appearance are acceptable

- Confirm that material certificates and traceability match requirements

- Assess packaging and labeling as they will appear in standard deliveries

Performance monitoring over initial batches

Based on the first several production lots, monitor:

- Dimensional stability and rejection rates

- On-time delivery performance versus agreed schedules

- Responsiveness to any issues or required adjustments

- Consistency of documentation and communication quality

Risk Management and Contractual Considerations

A structured approach to risk management helps avoid unexpected interruptions or quality problems over the long term.

Single-source vs. dual-source strategy

Determine whether your parts should be produced by one or multiple suppliers:

- Single-source can simplify communication and process control but increases dependency on one supplier.

- Dual-source can improve supply security but requires more coordination and harmonized specifications.

- For highly specialized 5-axis work, maintaining at least a backup plan is often advisable.

Agreements, NDAs, and intellectual property

For sensitive designs or proprietary processes, ensure appropriate legal safeguards:

- Non-disclosure agreements covering drawings, models, specifications, and production know-how

- Clear ownership of NC programs and fixturing concepts, especially if you may transfer work later

- Clauses regarding data security and controlled access within the supplier’s organization

Performance metrics and review mechanisms

Define measurable expectations and review processes, such as:

- Quality performance targets (for example, maximum reject rate or PPM levels)

- On-time delivery targets and acceptable deviation thresholds

- Response times for corrective actions and problem resolution

- Regular technical and commercial review meetings to evaluate performance and plan improvements

Common Issues When Selecting 5-Axis Machining Suppliers

When choosing a 5-axis machining supplier, certain recurring issues can lead to delays, quality problems, or unnecessary costs if not properly addressed.

| Issue | Potential impact | Preventive action |

|---|---|---|

| Unclear technical specifications | Inconsistent quotations, quality disputes, unexpected rework. | Provide complete drawings, models, tolerances, and material standards; confirm mutual understanding. |

| Overemphasis on lowest price | Higher total cost due to quality issues and delays. | Evaluate suppliers on capability, quality, and delivery, not only unit price. |

| Insufficient check of quality systems | Unstable quality, inadequate traceability. | Verify certifications, procedures, and example inspection reports. |

| Lack of alignment on lead times | Missed project milestones, supply shortages. | Discuss realistic lead times and capacity; formalize in agreements. |

| No trial phase before large orders | High-volume non-conformities, costly corrections. | Implement first article inspection and pilot lots before ramp-up. |

Summary: Building a Reliable 5-Axis Machining Partnership

Selecting the right 5-axis machining supplier is not a one-dimensional decision based solely on price or location. It involves assessing technical capabilities, equipment, process stability, quality systems, engineering support, capacity, and communication practices in a structured way.

By clearly defining your technical requirements, evaluating machine and inspection capabilities, verifying industry experience and certifications, and analyzing cost within a total cost of ownership perspective, you can systematically identify suppliers that are well suited to your application. Combining initial audits, sample evaluations, and performance monitoring over early batches further reduces risk and lays the foundation for a long-term, reliable partnership.

Investing time and effort in a thorough selection process will help ensure that your 5-axis machined components meet functional expectations, arrive on time, and support the overall success of your products and projects.

XCM - Your reliable partner for 5-axis machining services

With advanced equipment, strict quality control, and an experienced engineering team, we deliver complex parts with tight tolerances and excellent surface finish. From single prototypes to small and medium batch production, XCM supports your project with fast response, stable lead times, and competitive pricing. Whether you’re in aerospace, automotive, medical, or industrial automation, our 5-axis machining solutions help you shorten development cycles, reduce costs, and bring better products to market faster.