CNC turning services are essential for producing cylindrical and rotationally symmetrical components with consistent accuracy and repeatability. Choosing the right supplier directly affects part quality, project timelines, and total manufacturing cost. This guide explains CNC turning fundamentals, key evaluation criteria, technical parameters, and practical steps to select a supplier that fits your requirements.

About CNC Turning Services

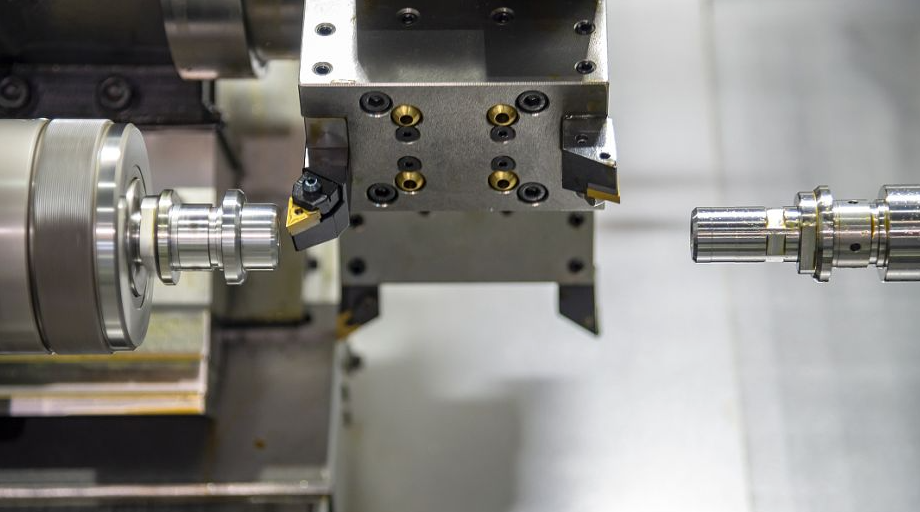

CNC turning is a subtractive machining process in which a cutting tool removes material from a rotating workpiece. It is typically carried out on CNC lathes or turning centers, which are controlled by computer numerical control to follow programmed toolpaths.

CNC turning is widely used for:

- Shafts, pins, spacers, bushings, and sleeves

- Fittings, connectors, and couplings

- Housings, caps, and threaded components

- Hydraulic and pneumatic components

Common CNC turning operations include:

- Facing: Creating a flat surface at the end of the workpiece

- External and internal turning: Reducing diameter or enlarging bores

- Grooving and parting: Cutting grooves and separating parts

- Threading: Producing internal or external threads

- Boring: Enlarging and finishing internal diameters

- Drilling and tapping: Producing holes and internal threads

Many modern turning centers integrate live tooling and sub-spindles, allowing milling, drilling, and secondary operations in a single setup. This reduces handling and improves dimensional consistency.

Key Criteria for Selecting a CNC Turning Supplier

Evaluating a CNC turning supplier involves more than comparing prices. Technical capability, quality systems, process control, and communication all influence the outcome. The following criteria help structure the selection process.

1. Technical Capability and Equipment

The supplier’s machine tools define the types of parts they can produce efficiently and accurately. When assessing a supplier, review:

Types of machines:

- 2-axis CNC lathes for straightforward turning

- Multi-axis turning centers (e.g., Y-axis, B-axis) for complex geometries

- Swiss-type (sliding-head) lathes for slender and small-diameter parts

- Turn-mill centers with live tooling and sub-spindle for complete machining

Important machine parameters include:

- Maximum turning diameter and length

- Spindle speed range

- Spindle bore size (bar capacity)

- Tool turret capacity and live tool speed

- Chuck size and workholding options

A supplier with a broad mix of machines can handle both simple and complex parts, different sizes, and varying production volumes with more flexibility.

2. Tolerances and Dimensional Capability

Different industries and components demand different levels of precision. Before committing to a supplier, check:

- Standard tolerances they routinely achieve (for example, ±0.01 mm, ±0.02 mm)

- Capability for tight tolerances on critical features

- Roundness, cylindricity, and runout control capabilities

- Surface finish capabilities for turned surfaces and bores

Request sample inspection reports or capability studies (such as process capability indices for key dimensions) to confirm the supplier’s ability to meet your drawing requirements consistently.

3. Materials and Size Range

Not every supplier is equally experienced with all materials or sizes. Discuss with potential suppliers:

- Metals: carbon steel, alloy steel, stainless steel, aluminum, brass, copper, titanium, tool steels

- Plastics: POM, PEEK, PTFE, nylon, polycarbonate, ABS, and engineering plastics

- Difficult-to-machine materials: high-temperature alloys, hardened steels

Confirm the maximum and minimum dimensions they can handle, including:

- Turning diameter range (e.g., from a few millimeters to several hundred millimeters)

- Maximum turning length between centers

- Bar feeding capacity for high-volume production

4. Production Volume and Flexibility

Production volume influences tooling strategy, machine selection, setup planning, and pricing. Suppliers typically specialize in one or more of the following:

- Prototypes and small batches: emphasis on quick setup and flexibility

- Medium batches: balanced approach to cost and responsiveness

- High-volume production: optimized cycle times, bar-fed lathes, and automated loading

Verify whether the supplier can ramp from prototype to series production if your project will scale. Also ask about minimum order quantities and their approach to engineering changes during early stages.

5. Quality Management and Certifications

A structured quality management system supports stable and repeatable output. Important aspects include:

- Formal certification such as ISO 9001 for general quality management

- Industry-specific certifications (e.g., IATF 16949 for automotive, AS9100 for aerospace, ISO 13485 for medical)

- Documented procedures for process control, nonconforming product, and corrective actions

- Calibration system for gauging and measuring equipment

Ask for sample documentation such as control plans, inspection checklists, and process flow diagrams to understand how quality is embedded in daily operations.

6. Inspection and Measurement Capabilities

Inspection capability must match the precision demands of the parts. Key elements include:

- CMM (coordinate measuring machine) for complex geometries

- Roundness testers, surface roughness testers, and contour measuring instruments

- Optical measuring systems for small parts and threads

- Thread gauges, plug gauges, ring gauges, micrometers, and bore gauges

Confirm whether the supplier can provide inspection reports such as first article inspection, statistical process control charts on critical dimensions, and final inspection records according to your format.

7. Lead Time and Capacity

Lead time depends on machine availability, scheduling, setup effort, material procurement, and secondary operations. During supplier evaluation, clarify:

- Typical lead times for prototypes, small batches, and series production

- Current capacity utilization and ability to handle urgent orders

- Approach to capacity planning and scheduling during demand fluctuations

Suppliers with adequate machine capacity and flexible scheduling can reduce delivery risk for time-sensitive projects.

8. Cost Structure and Pricing Transparency

Price is important but should be evaluated together with quality, reliability, and service. Transparent pricing helps compare suppliers fairly. Ask potential suppliers to explain:

- Setup cost and how it scales with batch size

- Cycle time and machine hourly rate assumptions

- Material cost sourcing and markups

- Tooling cost (special tools, fixtures, gauges) and ownership

- Packaging, logistics, and additional handling costs

A clear quotation that itemizes these elements makes it possible to identify cost drivers and optimization opportunities.

9. Engineering Support and DFM

Engineering support is critical in CNC turning, especially when parts have tight tolerances, complex geometries, or critical functions. Evaluate whether the supplier:

- Reviews drawings and models for manufacturability and cost efficiency

- Provides feedback on tolerances, surface finishes, undercuts, and blending radii

- Suggests alternative features (e.g., replacing sharp internal corners with radii) to suit turning operations

- Collaborates on prototype iterations and design changes

Such involvement can prevent production issues and reduce overall project cost.

10. Communication, Documentation, and Project Management

Effective communication reduces misunderstandings and prevents delays. Important aspects include:

- Responsiveness to RFQs, technical questions, and design changes

- Use of standardized documentation (drawings, 3D models, specifications, inspection forms)

- Clear order confirmations, schedules, and progress updates

- Defined contact persons for technical and commercial topics

A supplier with structured project management practices can better align with your internal processes and timelines.

Typical CNC Turning Capabilities and Parameters

To match your parts with a supplier’s capability, it is useful to understand common CNC turning parameters and what they mean in practical terms. While exact figures vary by machine and process setup, the ranges below illustrate typical values you can use as a reference during discussions with suppliers.

| Capability Aspect | Typical Range | Notes |

|---|---|---|

| Turning diameter | Ø2 mm to Ø400 mm (larger on heavy lathes) | Small parts via bar feed; large via chucking |

| Turning length | Up to 1,000 mm or more | Long parts may require steady rests or support |

| Bar capacity | Ø5 mm to Ø80 mm typical | Defines feasible sizes for bar-fed high-volume work |

| General dimensional tolerance | ±0.02 mm to ±0.05 mm | Common for non-critical features |

| Tight dimensional tolerance | ±0.005 mm to ±0.01 mm | Requires optimized setups, stable environment |

| Surface roughness (Ra) | 0.4 µm to 3.2 µm | Dependent on tool, speed, feed, and material |

| Thread types | Metric, UNC/UNF, BSP, NPT, internal/external | Check with supplier for special thread standards |

| Production volume | Single pieces to tens of thousands | Depends on automation level and machine mix |

These values are indicative. When you evaluate suppliers, compare their stated capabilities against the maximum dimensions, tolerances, and surface finish requirements in your drawings.

Material and Surface Finish Options in CNC Turning

Material selection and surface finishing have direct influence on performance, life, cost, and appearance of turned components. A competent CNC turning supplier should support a wide range of materials and finishing processes or work with reliable sub-contractors.

1. Common Metals for CNC Turning

Frequently used metals include:

- Aluminum alloys (e.g., 6061, 6082, 7075): good machinability, low weight, moderate strength

- Carbon steels (e.g., C45, 1045): robust, cost-effective for structural and mechanical parts

- Alloy steels (e.g., 4140, 4340): improved mechanical properties for shafts and high-load components

- Stainless steels (e.g., 304, 316, 17-4PH): corrosion resistance for food, medical, and outdoor applications

- Brass and copper alloys: good machinability, conductivity, and appearance for fittings and connectors

- Titanium alloys (e.g., Ti-6Al-4V): high strength-to-weight ratio and corrosion resistance

Different materials demand different cutting speeds, feeds, tooling, and cooling strategies. Suppliers with experience in your chosen material will be better positioned to achieve stable quality and reasonable cycle times.

2. Plastics and Engineering Polymers

Many CNC turning applications use plastics where low weight, chemical resistance, or electrical insulation are required. Common options include:

- POM (acetal), nylon, and UHMWPE for wear parts and bushings

- PEEK and PTFE for high temperature and chemically resistant components

- Polycarbonate and ABS for housings, covers, and non-load-bearing parts

Plastics require careful management of clamping force, tool geometry, and cutting parameters to avoid deformation and surface damage. Verify that the supplier understands these aspects and has experience with similar components.

3. Heat Treatment and Hard Turning

Some turned parts require heat treatment to achieve target hardness or mechanical properties, such as induction hardening, through hardening, or case hardening. In such cases, machining may be performed before and after heat treatment, or in one stage using hard turning techniques. Discuss with potential suppliers:

- Whether they manage heat treatment internally or via approved partners

- Hardness ranges they can handle with hard turning processes

- Sequence of operations (turning, heat treatment, grinding if needed)

Clear agreement on the process chain avoids dimensional drift and ensures that final properties match specifications.

4. Surface Finishing and Coatings

Depending on the application, surface finishing may be required for corrosion protection, wear resistance, or appearance. Typical options for turned parts include:

- Anodizing (clear or colored) for aluminum components

- Electroplating (zinc, nickel, chrome) for steel and brass parts

- Black oxide coating for steel components

- Passivation for stainless steel parts

- Shot blasting or bead blasting to obtain uniform matte surfaces

- Polishing for functional sealing surfaces and aesthetic areas

Ask suppliers to specify achievable thickness, adhesion quality, and dimensional impact of coatings, especially when tight tolerances apply after finishing.

Quality Control and Process Assurance in CNC Turning

Robust quality control ensures that turned parts meet specifications consistently and repeatably. When choosing a supplier, review their entire quality assurance framework rather than only final inspection.

1. Incoming Material Control

Quality starts with material. Suppliers should have processes to verify:

- Material certificates detailing composition and mechanical properties

- Correct material grade and dimensions upon receipt

- Traceability from finished parts back to material batches

Effective incoming inspection reduces the risk of mixing incorrect materials in production.

2. In-Process Control and Monitoring

In-process controls help detect deviations early. Common measures include:

- First piece inspection after setup and parameter confirmation

- Periodic checks for critical dimensions during production

- Tool wear monitoring and scheduled tool changes

- Use of control charts for critical or high-risk features

Ask suppliers how they record and store in-process inspection results and how they react to deviations.

3. Final Inspection and Documentation

Before shipment, parts should undergo final inspection steps defined by customer requirements and internal standards. These may include:

- Dimensional checks against drawings

- Visual inspection for burrs, scratches, and surface defects

- Functional tests such as thread gauges and fit checks

- Documentation of results in inspection reports or certificates of conformity

For safety-critical or high-precision parts, consider requiring a first article inspection report when starting production or after design or process changes.

Comparing Suppliers: A Structured Evaluation Approach

A structured approach supports objective comparison between CNC turning suppliers. This can reduce the risk of overlooking important factors while focusing only on price.

| Criteria Group | Specific Points to Review |

|---|---|

| Technical capability | Machine types, axes, size range, live tooling, bar feeding, complex geometry handling |

| Quality and inspection | Certifications, inspection equipment, process controls, traceability, documentation |

| Materials and processes | Experience with required metals and plastics, heat treatment, surface finishing |

| Lead time and capacity | Typical lead times, capacity buffer, response to urgent orders, scalability |

| Cost and transparency | Quotation clarity, cost breakdown, tooling charges, logistics cost handling |

| Engineering support | DFM reviews, prototype support, feedback quality, problem-solving approach |

| Communication | Responsiveness, language skills, documentation standards, project updates |

| Experience and references | Track record in similar parts or industries, customer references, sample parts |

Assigning relative importance to each group based on your project needs can help you score and rank suppliers in a consistent way.

Pain Points When Choosing CNC Turning Services

When selecting CNC turning services, buyers may encounter several practical difficulties. Understanding these pain points can guide better questions and decisions.

1. Misalignment Between Drawings and Capability

One common issue arises when drawings specify extremely tight tolerances or features that are difficult to machine via turning, such as sharp internal corners or deep narrow grooves. If the supplier accepts the order without highlighting these constraints, the result may be delayed deliveries, higher scrap rates, or dimensionally unstable parts.

To avoid this, share 3D models and detailed drawings early, and encourage suppliers to signal any features that may require design adaptation or additional processes such as grinding.

2. Incomplete Specification of Requirements

Another frequent problem is insufficient detail in specifications. Lack of information on surface finishes, thread standards, geometric tolerances, material condition, or post-processing can cause interpretation differences between customer and supplier.

Using standardized drawing practices and specifying standards for threads, tolerances, and finishing helps align expectations and reduce the risk of rework or dispute.

3. Variability in Quality Between Batches

Inconsistent quality between batches can occur when process conditions, tools, or material suppliers change without adequate control. This leads to dimensional variation, surface quality shifts, or unexpected functional issues during assembly.

Address this by discussing with suppliers how they maintain process settings, document machine programs, and control tool and material changes between production runs.

4. Insufficient Communication on Delivery Status

Delays in production or logistics may happen, but if the supplier does not communicate promptly, scheduling and downstream operations may be disrupted. Transparent and early communication allows rescheduling and mitigation measures.

Clarify reporting routines, such as weekly status updates, and escalation paths for any issues that could impact delivery dates.

Practical Steps to Qualify a CNC Turning Supplier

To reduce risk and build a cooperative relationship, follow a staged approach when qualifying a CNC turning supplier.

1. Initial Screening

During the initial stage, focus on high-level fit:

- Check basic capabilities against your size, material, and tolerance requirements

- Review certifications and quality management information

- Request reference parts or photos that resemble your components

- Assess responsiveness to your initial inquiry

2. Technical and Commercial Review

If the initial screening is positive, proceed with a detailed review:

- Send drawings and 3D models for technical analysis

- Ask for preliminary DFM feedback and suggestions for cost reduction

- Request a detailed quotation with breakdown of costs and lead times

- Clarify terms of delivery, payment, and packaging

3. Trial Order and First Article Inspection

Before awarding larger volumes, place a trial order:

- Define a limited quantity that still reflects production conditions

- Request a first article inspection report for key dimensions and characteristics

- Evaluate part quality, documentation, and delivery performance

4. Ongoing Performance Monitoring

After approval of the first articles and start of regular production:

- Track on-time delivery rate and rejection rate

- Establish a feedback loop to address any deviations

- Perform periodic reviews to discuss improvement opportunities

This systematic approach helps identify reliable suppliers and maintain stable collaboration over time.

How to Communicate Requirements to Your CNC Turning Supplier

Clear communication of requirements is vital for successful CNC turning projects. Ambiguities can lead to misinterpretation, rework, and additional costs. The following information is typically necessary:

1. Technical Documentation

Provide comprehensive and consistent documentation, including:

- 2D drawings with dimensions, tolerances, surface finishes, and notes

- 3D models in widely used formats for CAM programming and verification

- Material specification including grade, condition, and standards

- Heat treatment and surface treatment requirements if applicable

2. Functional and Critical Features

Highlight functional requirements and critical characteristics that significantly affect fit, performance, or safety, for example:

- Sealing surfaces and mating diameters

- Threaded connections and tolerances affecting assembly

- Features related to rotational balance or dynamic performance

Marking these features as critical helps the supplier prioritize inspection and control resources.

3. Packaging, Labelling, and Traceability

Define how parts should be packaged and labeled to prevent damage and ensure correct identification. Consider:

- Protection against scratches, corrosion, or contamination

- Batch labels with part number, revision, quantity, and material

- Traceability tags linking to inspection records and material certificates

4. Revision and Change Management

When design or requirement changes occur, it is important to manage them in a controlled manner:

- Use clear revision numbers on drawings and models

- Communicate changes in writing with revised documents attached

- Agree on disposition of work-in-progress and finished stock

- Update any control plans or inspection documents as needed

Structured change management keeps both parties aligned and reduces the risk of mixing different revisions.

Conclusion

Selecting the right CNC turning services supplier has a direct impact on the quality, cost, and reliability of your turned components. By examining technical capabilities, tolerances, materials, quality systems, inspection resources, lead time, cost structure, engineering support, and communication practices, you can make an informed choice aligned with your project objectives.

A structured evaluation process, supported by clear documentation and open technical dialogue, is the most effective way to establish a long-term partnership with a CNC turning supplier that consistently delivers parts matching your specifications.

XCM CNC Turning Service – Let Precision Speak for Your Brand

Looking for a machining partner that’s fast, stable, and highly accurate?

XCM CNC Turning Service delivers a one-stop solution with high precision, high efficiency, and consistent quality.

- Advanced CNC equipment & experienced engineers

- Flexible for both small prototypes and large-volume production

- Strict quality control with full process traceability

- Short lead times to help you launch products faster

Leave the complexity to us and let the market prove your quality.

Choose XCM – where every part is made to “showcase” standards.

FAQs

What information should I send to get an accurate CNC turning quote?

To receive an accurate CNC turning quotation, provide a complete 2D drawing with all dimensions, tolerances, and surface finish requirements; 3D model files where available; clear material specification including grade and any required standards; information on heat treatment and surface finishing; target quantities and potential annual volume; required delivery time; and any special requirements such as packaging, documentation, or inspection reports. The more precise and complete your information, the more accurate and comparable the quotations will be.

How can I verify a CNC turning supplier’s quality level before large orders?

Before placing large CNC turning orders, verify quality by reviewing the supplier’s certifications and quality manual, checking sample inspection reports and process documents, requesting reference parts similar to your components, and conducting a trial order combined with a first article inspection. If possible, perform an on-site or remote audit to observe their machines, inspection equipment, and process control methods. Evaluating their performance on a smaller order allows you to confirm dimensional accuracy, documentation quality, and on-time delivery before committing to higher volumes.