CNC turning is one of the most widely used subtractive manufacturing processes for cylindrical parts, but estimating its cost accurately can be complex. A precise cost breakdown needs to consider machine time, setup and programming, materials, tooling, quality requirements, and overheads. This guide explains each cost driver in detail and shows how they combine into a predictable pricing model.

Fundamentals of CNC Turning Cost Structure

CNC turning costs are typically structured around three main components:

- Direct costs: machine time, labor, raw material, and consumables

- Indirect costs: overheads, maintenance, facility and administrative expenses

- Margin: profit added to ensure sustainable operation of the machining business

Most machine shops convert these components into an hourly shop rate for the CNC lathe and then multiply by the time needed to produce the parts, while adding material and other itemized charges. Understanding what is inside that hourly rate and how time is calculated is essential for both buyers and manufacturers.

Key Cost Drivers in CNC Turning

Several factors influence CNC turning pricing, even for parts that look similar. The most influential cost drivers are:

- Machine type and hourly rate

- Part geometry and complexity

- Tolerances and surface finish requirements

- Material type, size, and availability

- Production volume and batch size

- Setup and programming time

- Tooling and tool life

- Inspection and quality control requirements

Each of these drivers can change the cycle time, scrap risk, tooling wear, or the amount of engineering and quality assurance effort required. A systematic estimate quantifies each item rather than relying only on experience or rules of thumb.

Machine Hourly Rate and Its Components

The machine hourly rate is the backbone of CNC turning cost estimation. It converts time into cost and is usually expressed as cost per machine hour or cost per spindle hour. Typical rates vary widely depending on region, machine capability, and overhead structure.

Key elements embedded in a CNC lathe hourly rate include:

1. Machine acquisition and depreciation

The purchase price of a CNC lathe is amortized over its useful life. A simple model is:

Annual machine cost = (Purchase price − Residual value) / Useful years of service

Dividing annual machine cost by the number of available machine hours per year yields the depreciation component of the hourly rate.

2. Facility and overhead costs

Overheads include:

- Factory rent or building ownership costs

- Electricity, compressed air, heating, and lighting

- Insurance, administrative staff, and management costs

- Maintenance, calibration, and auxiliary equipment costs

These costs are allocated to each machine and then to the hourly rate based on utilization.

3. Labor and support costs

Operator wages, benefits, and indirect labor (such as setup personnel, quality engineers, and programmers) affect the effective hourly rate. Some shops separate programming and setup labor from the basic machine rate, while others include them within a blended rate.

Setup Time and Programming Costs

Setup and programming costs become significant when the part quantity is low or when the part requires complex operations. They are usually treated as one-time costs and then spread across the batch size.

Setup operations

Setup time includes:

- Loading and aligning chucks, collets, or custom fixtures

- Mounting tools in the turret or toolholders and measuring offsets

- Loading programs into the machine

- Running first article parts and making adjustments

Setup can range from less than 30 minutes for a simple recurring job to several hours for complex parts requiring multiple operations and custom tooling. Setup cost is usually:

Setup cost = Setup time (hours) × Setup labor rate

Per-part setup cost is then obtained by dividing this amount by the number of parts in the batch.

Programming activities

Programming cost covers creating the CNC program using CAM software or manual programming. This includes:

- Importing and checking CAD models or 2D drawings

- Selecting cutting tools and defining toolpaths

- Simulating toolpaths to avoid collisions and verify machining sequence

- Post-processing to generate machine-specific code

Programming time depends on part complexity, the number of operations, and whether a similar program can be reused. Programming cost is often calculated as:

Programming cost = Programming time (hours) × Programmer hourly rate

For large production runs, programming cost per part is small, but for prototypes and small batches, it can be a major component of the quoted price.

Cycle Time and Machining Time Calculation

Cycle time is the actual machining time per part on the CNC lathe. It directly determines the machining cost, since most pricing models multiply cycle time by the machine rate. Cycle time consists of:

- Cutting time: time during which tools are removing material

- Non-cutting time: tool changes, rapid traverses, part loading/unloading, and indexing

Elements of cutting time

For turning operations, cutting time is influenced by:

- Spindle speed (rpm)

- Feed rate (mm/rev or in/rev)

- Depth of cut

- Length of cut and number of passes

- Material machinability and tool limitations

Typical turning time calculations consider the length of each pass and the feed rate. Boring, grooving, threading, and parting-off operations add to the total cutting time.

Non-cutting time and handling

Non-cutting time includes:

- Automatic tool changes and turret indexing

- Spindle ramp-up and deceleration

- Part clamping and unclamping

- Chip evacuation and periodic checks

For high-volume production, shops often invest in bar feeders, parts catchers, and automation to reduce handling time and lower per-part cost.

Material Selection and Raw Stock Cost

Material cost in CNC turning is not limited to the price per kilogram or per bar; it also depends on yield, stock dimension, and waste. Turned parts commonly start from round bars, tubes, or forgings.

Material type and price

Different materials have different price ranges and machinability characteristics. Common groups include carbon steel, alloy steel, stainless steel, aluminum alloys, copper alloys, titanium alloys, and engineering plastics. The base material price is obtained from suppliers and multiplied by the required quantity, including a suitable allowance for waste.

Stock dimension and material yield

For a cylindrical part, the bar diameter must exceed the largest part diameter plus some machining allowance. The part length determines the bar length consumed per piece, including allowances for parting-off and chucking. Poor material yield, large diameters, or long parts can significantly increase material cost per piece.

| Factor | Impact on Material Cost |

|---|---|

| Material grade (e.g., carbon steel vs. titanium) | Higher-grade or difficult-to-machine materials usually have higher unit price and may require more stock due to scrap risk. |

| Bar diameter and length | Oversized bars increase waste; too small bars may be impossible to safely grip or may not provide enough machining allowance. |

| Bar form (solid vs. tube vs. forging) | Forgings or near-net shapes can reduce cycle time and waste but usually have higher purchase cost. |

| Order quantity | Larger material purchases can reduce per-unit material price through volume discounts. |

| Material yield and scrap rate | Poor yield or high scrap rate increases effective material cost per good part. |

Tooling, Inserts, and Consumables

Tooling costs cover cutting inserts, toolholders, boring bars, drills, taps, and other consumables. In CNC turning, the most frequently replaced items are carbide inserts. Tooling cost is generally treated as a consumable cost that is either:

- Included within the machine hourly rate, or

- Calculated separately based on estimated tool life per part

Tool life and per-part tooling cost

Tool life depends on cutting speed, feed, depth of cut, material hardness, coolant configuration, and chip control. A typical estimation approach is:

Per-part tooling cost = (Insert cost / Parts per insert edge) + Cost of other consumables divided by expected usage

For hard materials or tight tolerances requiring reduced tool wear, the number of parts per insert edge will be lower, raising the per-part tooling cost. Shops may choose conservative tool life assumptions to avoid unexpected tool failures and scrap.

Tolerances, Surface Finish, and Their Cost Impact

Tight tolerances and demanding surface finish requirements have a direct impact on CNC turning pricing. They can increase machining time, tool wear, inspection effort, and scrap risk.

Tolerance considerations

Effects of tighter dimensional tolerances include:

- Need for reduced cutting parameters and lighter finishing passes

- Potential need for additional operations such as grinding or honing

- More frequent inspection during production

- Higher scrap rate if process capability is marginal

As tolerances approach the limits of the machine capability, the cost typically increases sharply, even if the geometric shape of the part remains simple.

Surface finish requirements

Surface roughness requirements (for example, Ra values) affect choice of cutting tools, nose radii, inserts, and cutting conditions. Finer finishes may require:

- Reduced feed rates and additional finishing passes

- High-quality inserts or wiper geometries

- Post-machining operations such as polishing or superfinishing

These factors extend cycle time and can add secondary process costs, all of which must be reflected in the final price.

Part Complexity, Features, and Operation Count

Part geometry strongly influences CNC turning cost beyond simple diameter and length data. Features that increase complexity include:

- Multiple diameters and shoulders

- Deep grooves, undercuts, and reliefs

- Internal and external threads

- Thin walls or slender shafts susceptible to deflection

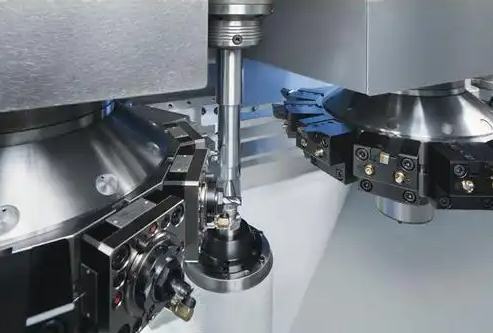

- Combination parts requiring turning and milling in one setup

More complex parts often require additional operations, custom tooling, careful programming, and lower machining parameters to maintain dimensional stability.

Single-operation vs. multi-operation parts

Some parts can be completed in one chucking and one machine. Others need:

- Multiple chuckings (for example, machining both ends separately)

- Transfer between machines, such as from a lathe to a machining center

- Sub-spindle operations or Y-axis milling on mill-turn centers

Each new operation or setup introduces setup time, handling, alignment checks, and additional risk of error, all of which increase the overall cost.

Batch Size, Production Volume, and Economies of Scale

Production volume is one of the most visible influences on CNC turning pricing. Small batches bear a larger share of setup and programming cost per part, whereas large production runs allow these fixed costs to be spread over many parts.

Effect of batch size on unit cost

Per-part cost typically consists of:

- Variable cost: machining time, material, per-part tooling, and direct labor

- Fixed cost per batch: setup, programming, and sometimes fixture cost

Unit cost decreases as batch size increases, until the fixed costs become negligible compared to variable costs. However, very large batches may require dedicated fixtures, more robust process control, and higher quality assurance effort, which may partly offset the economies of scale.

Quality Control, Inspection, and Metrology Costs

Inspection and quality control are essential to ensure that turned parts meet specifications. Depending on requirements, quality-related costs can range from basic dimensional checks to extensive sampling and documentation.

Inspection scope

Cost factors related to inspection include:

- Number of dimensions to be measured and their tolerance levels

- Frequency of in-process and final inspections

- Use of advanced equipment such as CMMs (coordinate measuring machines)

- Measurement of form, roundness, concentricity, and runout

- Creation of inspection reports, certificates of conformity, and traceability records

Parts for sectors with stringent quality requirements often incur additional inspection costs, which can be itemized or integrated into the machine rate and overhead.

Overhead, Administration, and Indirect Cost Allocation

Indirect costs are those not directly attributable to a single part but necessary for operating the machining business. These include administration, sales, engineering support, IT, inventory management, and facility maintenance.

Methods of overhead allocation

Common methods for distributing overhead costs include:

- Percentage markup on direct labor or machine time

- Shop rate method, where machine hourly rates incorporate an overhead factor

- Activity-based costing, linking overhead to specific activities such as programming, inspection, or logistics

An accurate allocation model ensures that all parts bear a fair share of indirect costs, maintaining financial sustainability while avoiding hidden subsidies between different jobs or customers.

Additional Services and Hidden Cost Elements

Beyond basic CNC turning, many quotations include optional or required services that contribute to the final price. These can be easily overlooked if the cost model only focuses on machine time and material.

Typical additional cost elements

Examples of additional cost items include:

- Heat treatment (hardening, tempering, case hardening)

- Surface treatments and coatings (anodizing, plating, nitriding)

- Deburring, cleaning, and protective packaging

- Assembly or sub-assembly operations

- Special certifications or documentation

Each of these may be provided in-house or outsourced, and they carry their own cost structure and lead time implications.

Typical Cost Breakdown Example for a Turned Part

The following simplified example illustrates how different cost components can be combined to estimate the price of one CNC turned part. Values are illustrative and not tied to a specific currency.

| Cost Element | Basis | Estimated Cost (per part) |

|---|---|---|

| Material | Bar stock required per piece, including waste | 2.40 |

| Machining time | Cycle time × Machine hourly rate | 3.10 |

| Setup and programming | Total setup and CAM time distributed over batch | 0.90 |

| Tooling and consumables | Estimated tool wear and coolant usage per part | 0.35 |

| Inspection and quality | Allocated based on inspection time and overhead | 0.45 |

| Overhead allocation | Share of facility and administrative costs | 0.80 |

| Manufacturing cost subtotal | Sum of all manufacturing elements | 8.00 |

| Margin | Profit added as percentage of manufacturing cost | 1.60 |

| Total part price | Manufacturing cost + Margin | 9.60 |

This example demonstrates how per-part price is built from multiple components rather than a single parameter. Adjusting any of these items, such as reducing setup time with standard tooling or improving cycle time with optimized feeds and speeds, directly affects total cost.

Practical Considerations When Requesting CNC Turning Quotes

Accurate and comparable quotes require clear and complete technical information. Incomplete specifications often lead to assumptions that may not match the buyer’s expectations or may result in conservative pricing.

Information to include in an RFQ

When requesting a CNC turning quotation, it is helpful to provide:

- Detailed 2D drawings and, if available, 3D CAD models

- Material specification, including grade and any approved alternatives

- Tolerances, surface finish requirements, and any geometric dimensioning and tolerancing (GD&T)

- Heat treatment, coating, or special processing requirements

- Expected annual and batch quantities

- Inspection and certification requirements

- Packaging, labeling, and delivery details

Providing this information upfront helps the machine shop create a realistic cost breakdown and minimizes the need for later adjustments due to missing requirements.

Common Issues Affecting CNC Turning Cost Accuracy

Several issues can cause a gap between estimated and actual CNC turning costs. Recognizing these factors helps create more reliable cost models and reduces the risk of unexpected overruns.

Typical cost-related issues

- Underestimating setup and programming time for complex parts

- Ignoring the effect of tight tolerances on cycle time and scrap rates

- Assuming optimistic tool life that is not achievable in production

- Overlooking secondary operations such as deburring or special cleaning

- Using outdated material prices or not accounting for minimum order quantities

- Not including inspection and documentation requirements in the cost model

Systematically checking each of these issues against the part specifications and shop capabilities leads to more robust price estimates.

Summary

CNC turning cost calculation is a structured process that integrates machine time, setup and programming, material, tooling, quality control, overhead, and margin. Understanding each component enables both buyers and manufacturers to:

- Estimate part prices more accurately

- Compare quotations on a consistent basis

- Identify which technical or process changes have the largest cost impact

Instead of treating CNC turning as a single hourly charge, a transparent cost breakdown makes it clear how product design, material selection, tolerances, batch size, and quality requirements influence the final price.

FAQ: CNC Turning Cost and Pricing

How do I roughly estimate the cost of a CNC turned part?

A practical first approximation is to estimate the cycle time per part, multiply by an estimated machine hourly rate, and add material and a margin for setup and tooling. For example, if a part takes 5 minutes (0.083 hours), and the machine rate is 60 per hour, the machining portion is about 5. Then add material cost per part, share of setup and programming, expected tooling cost per part, and overhead or margin. This approach does not replace a detailed quote, but it helps you determine whether a design is likely to be cost-effective.

Why do small CNC turning batches cost more per part?

Small batches have higher per-part cost because fixed costs such as setup and programming are spread across fewer pieces. For example, if setup and programming take three hours, that cost is minor when divided over thousands of parts but substantial when applied to a batch of ten. Additionally, small batches may not justify specialized tooling or process optimization that would reduce unit cost in larger runs.

Which design features most strongly increase CNC turning cost?

Features that significantly increase cost include deep or narrow grooves, internal threads, thin-walled sections, tight concentricity and runout tolerances, very smooth surface finish requirements, and geometries that require multiple setups or transfer between machines. Each of these features can add operations, increase cycle time, raise scrap risk, or require additional inspection, all of which contribute to a higher overall price.

How does material selection affect CNC turning pricing?

Material choice affects both the raw material cost and the machining cost. Higher-cost alloys, such as some stainless steels or titanium, increase the material portion of the price. At the same time, lower machinability materials may require reduced cutting parameters and more frequent tool changes, increasing cycle time and tooling costs. Selecting a material with good machinability that still meets performance requirements can significantly reduce overall part cost.