Choosing a CNC machining supplier in China requires more than comparing prices. It involves systematic evaluation of technical capability, quality management, communication, and long-term sustainability. This guide provides a complete and technical framework you can apply step by step.

Clarify Your CNC Machining Requirements First

Before contacting suppliers, define your requirements with enough technical detail so Chinese machine shops can quote accurately and manufacture consistently.

Part and Application Definition

- Application and function: load cases, operating temperature, environment (indoor, outdoor, corrosive, medical, food-contact).

- Annual and batch volume: prototyping, pre-series, mass production; expected ramp-up plan.

- Lifecycle: one-off project, repeat orders, or long-term serial production.

Technical Documentation Package

Prepare a complete package to minimize ambiguity:

- 2D drawings with dimensions, tolerances, GD&T symbols, datums, and surface finish callouts.

- 3D models (STEP/IGES/Parasolid) as geometry reference but not a substitute for 2D drawings.

- Material specifications with standards (e.g., ASTM, DIN, GB) and temper/condition.

- Heat treatment requirements (e.g., HRC values, case depth, solution treatment).

- Surface treatment and coatings (anodizing type and color, plating thickness, powder coating system).

- Special requirements: cleanliness class, burr standards, edge treatment (e.g., break sharp edges 0.2–0.5 mm).

Tolerance and Quality Requirements

Define realistic tolerances and acceptance criteria to avoid under- or over-specification:

Typical machining tolerances ranges (actual capability depends on machine, setup, and process):

| Feature / Parameter | Standard Capability Range | Notes |

|---|---|---|

| General linear dimensions | ±0.05 mm to ±0.10 mm | Standard production tolerance for many CNC shops. |

| Precision linear dimensions | ±0.01 mm to ±0.02 mm | Requires stable process, high-quality machines, and controlled environment. |

| Very high precision (selected features) | ±0.005 mm or better | Only for critical features; may require grinding or honing. |

| Hole diameters (reamed/ground) | H7–H9 fits commonly achievable | Specify ISO fit classes if functional fits are needed. |

| Flatness / parallelism | 0.02–0.05 mm per 100 mm | Depends strongly on material, part size, and clamping. |

| Surface roughness Ra (milled/turned) | Ra 1.6–3.2 μm | Standard machined surface; finer finish requires extra operations. |

| Surface roughness Ra (fine machining) | Ra 0.4–0.8 μm | Requires fine inserts, small stepovers, optimized parameters. |

In addition, define inspection level and acceptance criteria, such as:

- Sampling plan (e.g., ISO 2859-1 AQL levels) or 100% inspection for critical features.

- PPAP/FAI requirements for automotive, aerospace, or regulated industries.

- Documentation you expect with shipments (e.g., material certificates, CMM reports).

Evaluate Core Technical Capabilities

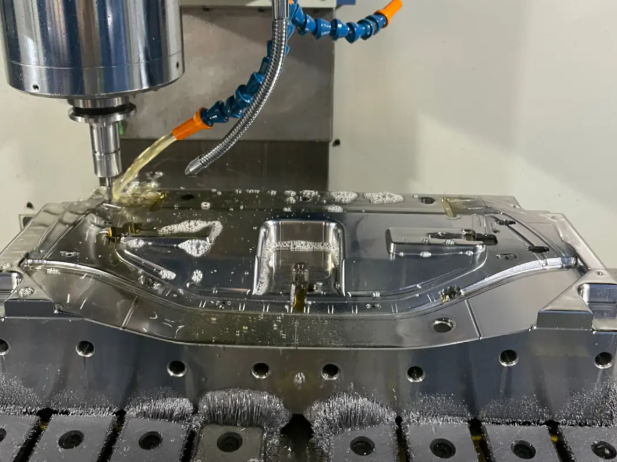

Technical capability determines whether a supplier can meet your tolerances, lead times, and machining cost targets. Review their equipment, process scope, and engineering capacity in detail.

Machinery and Equipment

Key points to verify:

- Machine types: 3-axis, 4-axis, 5-axis machining centers; CNC lathes; mill-turn centers; grinders.

- Machine brands and age: well-known brands (e.g., Mazak, DMG Mori, Haas, Okuma, FANUC-based Chinese machines) typically offer better stability.

- Spindle speed and power: suitability for your material (high-speed spindles for aluminum, high-torque for steels).

- Work envelope: maximum X/Y/Z travel and turning diameter/length relative to your part sizes.

- Auxiliary equipment: CMMs, optical projectors, profilometers, hardness testers, tool presetters, and specialized fixtures.

Process Range and Vertical Integration

Identify what the supplier can do in-house versus outsourced services:

| Process Category | Common In-House Capabilities | Common Outsourced Services |

|---|---|---|

| Core machining | CNC milling, CNC turning, drilling, tapping, boring | High-precision grinding, gear hobbing for complex gears |

| Heat treatment | Basic stress relief (some shops) | Carburizing, nitriding, induction hardening, vacuum hardening |

| Surface treatment | Deburring, polishing, basic bead blasting | Anodizing, plating (Zn, Ni, Cr), black oxide, powder coating |

| Finishing and assembly | Sub-assembly, simple press-fit operations | Complex assembly, testing, and packaging to retail standards |

Outsourcing is not necessarily negative, but verify the control over subcontractors, additional lead time, and risk of process variation.

Engineering and DFM Support

A reliable Chinese CNC supplier typically offers engineering support, including:

- DFM (Design for Manufacturability) review to optimize part geometry for machining.

- Material substitution proposals referencing equivalent Chinese standards (e.g., GB/T) with clear mapping.

- Tolerance optimization suggestions based on functional requirements.

- Fixture and tooling design capability for stable and repeatable production.

Ask for examples where the supplier has improved manufacturability, reduced cost, or enhanced performance via engineering input.

Assess Quality Management and Certification

Quality management systems and the actual implementation on the shop floor are critical in selecting a reliable supplier.

Quality System and Certifications

Key certifications to verify:

- ISO 9001 for general quality management.

- IATF 16949 for automotive parts, if relevant.

- ISO 13485 for medical device components.

- AS9100 for aerospace applications.

Request copies of certificates and verify their validity through the issuing body when possible. However, certification alone is not sufficient; it must be supported by robust procedures and records.

Incoming, In-Process, and Final Inspection

Evaluate how the supplier controls quality across the value chain:

- Incoming inspection: verification of raw material certificates, hardness tests, and dimensional spot checks.

- In-process inspection: first article inspection for each setup, patrol inspection frequency, and use of control charts for critical dimensions.

- Final inspection: CMM or manual inspection based on detailed control plans, with traceable reports.

Request sample inspection records, control plans, and gauge calibration logs to see how these practices are implemented.

Metrology Capability

Check that metrology capability matches your tolerance requirements:

- Availability of CMMs (bridge or gantry type) with suitable measurement ranges and accuracy.

- Use of calibrated gauges and measurement tools (micrometers, bore gauges, height gauges, pin gauges).

- Environmental control for inspection rooms (temperature, humidity) when tight tolerances are involved.

Ask the supplier to demonstrate how they measure your critical features and what uncertainty is associated with those measurements.

Traceability and Documentation

Reliable suppliers maintain traceable records, including:

- Batch-level traceability linking raw material heat numbers to finished parts.

- Serialized part traceability if required by your industry.

- Archiving of inspection reports, non-conformance reports (NCRs), and corrective actions.

This is particularly important for safety-critical components, regulated industries, and long service life products.

Verify Materials and Surface Treatment Capabilities

Material and surface treatment capabilities significantly influence performance, cost, and reliability of CNC machined parts.

Material Expertise

Confirm experience with your material categories and specific alloys:

- Aluminum alloys: e.g., 6061, 6082, 7075, 2024.

- Carbon and alloy steels: e.g., 1045, 4140, 4340, 40Cr.

- Stainless steels: e.g., 304, 316, 410, 420, 17-4PH.

- Copper and brass: e.g., C3604, C1100, H62.

- Tool steels and hardened materials: e.g., D2, H13.

- Engineering plastics: e.g., POM, PA, PEEK, PTFE.

Each material requires proper tooling, cutting parameters, and coolant strategies to achieve stable quality and tool life. Ask for reference parts in the same material class and similar tolerance range.

Heat Treatment and Hardness Control

If your parts require heat treatment, verify how the supplier manages:

- Selection and control of heat treatment subcontractors if not in-house.

- Hardness inspection (Rockwell, Brinell, Vickers) before and after machining if necessary.

- Distortion management for tight-tolerance parts (machining before and after heat treatment, stress relief).

Surface Treatments and Cosmetic Requirements

Surface treatments can affect both aesthetics and technical performance (corrosion resistance, wear resistance, electrical properties). Confirm experience in:

- Anodizing of aluminum (Type II, Type III hard anodizing, color consistency across batches).

- Electroplating: zinc, nickel, chrome with controlled thickness and adhesion.

- Chemical conversion coatings, black oxide, passivation.

- Painting and powder coating: color matching, gloss level, and adhesion tests.

For cosmetic-critical parts, request samples showing the typical appearance and variation range. Define acceptable cosmetic criteria using photos, samples, or grading systems.

Review Production Capacity and Scalability

A good technical fit is not enough if the supplier cannot match your volume and lead time requirements.

Capacity and Load Planning

Discuss the following aspects:

- Number of machines available for your product type and shift patterns (1, 2, or 3 shifts).

- Typical daily and monthly output for parts similar to yours.

- Ability to adjust capacity in response to demand changes, including subcontracting strategy.

Request realistic lead time estimates for prototype, pilot run, and mass production batches, and confirm what buffers are built into those lead times.

Scaling from Prototype to Mass Production

Many CNC machining projects start with prototypes and transition to series production. Verify that the supplier can handle:

- Quick-turn prototypes with flexible setups and manual programming if necessary.

- Process industrialization: fixture standardization, CNC program optimization, and batch-level quality planning.

- Documentation of process parameters, tooling lists, and setup sheets to ensure repeatability.

Ask for case studies where they have successfully scaled similar products from small batches to larger volumes.

Analyze Cost Structure and Quoting Practices

Cost is often a main driver for sourcing in China, but the focus should be on total cost of ownership, not just unit price.

Quotation Transparency

Prefer suppliers that can explain how the price is built, including:

- Material cost and sourcing strategy.

- Machining time and setup time assumptions.

- Tooling and fixture costs, including amortization for series production.

- Surface treatment, heat treatment, and inspection costs.

- Packaging, shipping, and any additional handling charges.

Transparent quotations indicate the supplier understands the process and is less likely to cut corners later to protect their margins.

Balancing Price, Quality, and Risk

When comparing suppliers, consider:

- Unit price differences relative to defect risk and rework cost.

- Impact of lead time differences on your inventory and time-to-market.

- Costs of quality issues: returns, sorting, field failures, and brand impact.

In many cases, selecting a slightly higher-priced but more reliable supplier leads to lower overall cost over the project lifecycle.

Evaluate Communication, Language, and Project Management

Good communication is essential to avoid misunderstanding technical details and delivery commitments.

Language and Responsiveness

Check that your contact person can handle technical English effectively, including:

- Understanding GD&T, tolerance notations, and process terminology.

- Writing clear emails, meeting minutes, and technical clarifications.

- Responding within agreed time frames, especially for urgent issues.

You can gauge this during RFQ and sample stages. Frequent, precise communication is a positive indicator.

Project Management Approach

For multi-part projects or complex assemblies, verify the project management structure:

- Assigned project manager or key account manager.

- Use of project timelines, milestones, and regular progress updates.

- Change management process for drawing revisions and engineering changes (ECNs).

Ask how they handle version control of drawings and CNC programs when you issue design changes.

Check Intellectual Property and Data Security Practices

Protection of intellectual property and sensitive data is important when working with overseas suppliers.

Contractual Protection

Work with legal counsel to implement:

- NDA (Non-Disclosure Agreement) covering drawings, models, and process documents.

- Manufacturing agreement outlining ownership of tooling, fixtures, and design rights.

- Restrictions on sub-contracting and use of your parts or designs for third parties.

Make sure contracts are enforceable in the relevant jurisdiction and clearly state consequences for violations.

Practical IP Safeguards

Consider practical measures such as:

- Splitting manufacturing across suppliers for highly sensitive parts or assemblies.

- Providing only necessary drawing details to subcontracted processes.

- Using controlled marking or coding strategies to track parts and detect unauthorized copies.

Discuss how the supplier manages data access internally and how they protect electronic files (e.g., controlled access servers, document control systems).

Perform Supplier Due Diligence and Audits

On-site or remote audits provide evidence beyond certificates and sales presentations.

Pre-Audit Desk Review

Before an audit, collect and analyze:

- Company registration documents and basic financial information when available.

- Organization chart and key personnel profiles.

- List of main customers and reference industries.

- Quality manual and example procedures.

This helps focus your audit on critical areas such as process control, quality management, and capacity.

On-Site Audit Checklist

During an on-site audit, systematically evaluate:

- Shop floor organization: cleanliness, material flow, labeling, and WIP management.

- Machine condition: maintenance schedules, visible wear, and breakdown handling.

- Process documentation at machines: work instructions, setup sheets, inspection checklists.

- Material storage: separation of different batches, FIFO (First-In-First-Out) practices.

- Quality department: calibration records, inspection reports, and corrective action logs.

If on-site visits are not possible, consider video audits with live demonstrations of machines, inspections, and warehouses, though this is less comprehensive.

Use Samples and Pilot Runs to Validate Capability

Sample production and pilot runs provide tangible proof of capability under realistic conditions.

First Article Samples

Request first article samples with complete documentation:

- Dimensional inspection report showing all critical and major dimensions.

- Material certificates from the mill or verified third-party test reports.

- Surface treatment reports if applicable.

Compare the results against your drawings and specifications. Verify that deviations, if any, are analyzed and corrected with documented actions.

Pilot or Trial Production Runs

For series production, organize a pilot run to check:

- Process stability across larger quantities (e.g., 50–500 pieces depending on your volume).

- Cycle time versus estimate and potential bottlenecks.

- Consistency of surface finish, color, and cosmetic aspects over the batch.

Use this phase to finalize control plans, packaging methods, and shipping documents.

Define Logistics, Shipping, and Packaging Requirements

International logistics and packaging strongly affect overall reliability, especially for precision machined parts.

Incoterms and Shipping Modes

Clarify Incoterms at the quotation stage (e.g., EXW, FOB, CIF, DAP) and how shipping responsibilities are split. Discuss shipping modes:

- Air freight for prototypes and urgent deliveries.

- Sea freight for larger, regular batches to optimize cost.

- Courier express for very small batches or spare parts.

Confirm the supplier’s export experience, including customs documentation, HS code allocation, and compliance with destination country requirements.

Packaging and Corrosion Protection

For CNC machined parts, proper packaging avoids damage and corrosion:

- Individual or partitioned packing to avoid metal-to-metal contact.

- Use of VCI bag or paper, desiccants, and sealed cartons for sea shipments.

- Custom foam, trays, or fixtures for delicate or high-value parts.

Agree on packaging standards and labeling (part number, batch number, quantity, and manufacturing date) and document them with photos.

Plan for Long-Term Cooperation and Performance Monitoring

Selecting a supplier is the beginning of a long-term relationship. Define how you will monitor their performance.

Key Performance Indicators (KPIs)

Common KPIs for CNC machining suppliers include:

- On-time delivery rate.

- Incoming defect rate (PPM or %).

- Response time for quotation, technical questions, and corrective actions.

- Cost improvement over time through joint optimization.

Review these KPIs regularly with the supplier and include them in business review meetings.

Continuous Improvement Collaboration

Encourage continuous improvement by:

- Sharing forecast and demand plans to support capacity optimization.

- Discussing design changes that can reduce machining time or scrap.

- Supporting training or joint workshops when needed for specialized processes.

A structured performance and improvement process ensures the supplier remains a reliable partner as your business evolves.

Typical Issues When Sourcing CNC Machining in China

There are recurring issues that buyers may encounter when sourcing CNC machining in China. Understanding them helps you set preventive measures.

Dimensional Inconsistency Between Batches

Causes can include different operators, tool wear, and adjustments not fully documented. Mitigation includes robust control plans, first-piece approval for each batch, and clearly documented setup sheets.

Surface Finish and Cosmetic Variations

Variations may arise from tool condition, cutting parameters, and surface treatment differences. Define measurable criteria (Ra values, visual standards) and use sample references to align expectations.

Misinterpretation of Drawings and Specifications

Differences in standards or symbols can cause errors if not clarified. Use internationally recognized standards for drawings, avoid ambiguous tolerances, and confirm critical features via technical discussions before production.

Conclusion

Choosing a reliable CNC machining supplier in China requires systematic evaluation of technical capability, quality management, materials and surface treatments, capacity, cost structure, communication, IP protection, logistics, and long-term performance. By following a structured approach and validating claims through audits, samples, and pilot runs, you can build a stable supply base that supports both current needs and future growth.

Why Choose XCM for CNC Machining in China

XCM is a trusted CNC machining brand in China, dedicated to delivering high-precision custom parts with consistent quality and reliable lead times. Backed by advanced CNC equipment, strict quality control systems, and an experienced engineering team, XCM supports customers from rapid prototyping to mass production. We focus on clear communication, competitive pricing, and international manufacturing standards, helping global clients reduce sourcing risks while achieving superior machining results. With XCM, you gain a long-term manufacturing partner committed to precision, efficiency, and trust.

FAQ

How can I verify the reliability of a CNC machining supplier in China?

You can verify reliability by checking the supplier’s business license, factory certifications (such as ISO 9001), years of experience, customer reviews, and past project samples. Factory audits and video calls are also effective ways to confirm legitimacy.

What certifications should a reliable CNC machining supplier have?

A trustworthy supplier typically holds ISO 9001 for quality management. Depending on your industry, additional certifications such as ISO 13485 (medical), IATF 16949 (automotive), or AS9100 (aerospace) may be required.

How can I evaluate a supplier’s machining capabilities?

Ask about their CNC equipment, machining tolerances, materials they work with, surface finishing options, and quality inspection processes. Request sample parts or case studies to assess their technical capability.

What should I consider regarding pricing and quotations?

Be cautious of prices that are significantly lower than the market average. A professional supplier provides transparent quotations that include material costs, machining, surface treatment, quality control, and lead time.

How many suppliers should I evaluate before selecting one?

For most projects, evaluating 3–5 qualified CNC machining suppliers is practical. This allows comparison of technical capability, quotation structure, and communication style without overwhelming your resources. Shortlist based on initial RFQ responses, then perform deeper audits and sample trials with the top candidates.

Is it necessary to visit the CNC machining supplier in China?

A physical visit is not strictly necessary but is highly beneficial, especially for critical or long-term projects. On-site audits provide a much clearer view of real capacity, process control, and shop-floor practices than documents alone. If travel is not possible, detailed video audits and third-party inspection services can partially substitute.