40CrMoV5 / H13 is a chromium-molybdenum-vanadium hot work tool steel widely used for die casting, hot forging, extrusion tooling and other thermally stressed tools. It combines high tempering resistance, good hot strength, and adequate toughness, making it a standard choice for many hot work applications.

Chemical Composition of 40CrMoV5 / H13

40CrMoV5 / H13 is a medium-carbon alloy tool steel with chromium, molybdenum and vanadium as key alloying elements. The typical composition range follows major tool steel standards and is designed to provide high temper resistance, secondary hardening and resistance to thermal fatigue.

| Element | Typical Content (wt.%) | Function in Alloy |

|---|---|---|

| C | 0.36 – 0.42 | Base hardness, strength and wear resistance |

| Si | 0.20 – 1.00 | Deoxidation, improves temper resistance, enhances strength |

| Mn | 0.25 – 0.80 | Improves hardenability and strength, assists deoxidation |

| Cr | 4.80 – 5.50 | Hardenability, high-temperature strength, oxidation and wear resistance |

| Mo | 1.10 – 1.50 | Reduces tempering softening, improves hot strength and creep resistance |

| V | 0.80 – 1.20 | Carbide formation, secondary hardening, improves wear resistance and toughness |

| P | ≤ 0.030 | Impurity, controlled to preserve toughness |

| S | ≤ 0.030 | Impurity, controlled; affects machinability and toughness |

Some grades specified as 40CrMoV5-1 or similar designations may include tighter composition ranges or additional quality requirements (e.g., purity, microcleanliness, guaranteed hardenability band).

Standards, Designations and Equivalents

40CrMoV5 / H13 is part of the hot work tool steel family defined in European and international standards. It is closely related to several widely known grades.

Typical corresponding or similar designations include:

- DIN / EN: 40CrMoV5-1, W.-Nr. 1.2344

- ISO / generic: X40CrMoV5-1 (nomenclature indicating ~0.40% C, ~5% Cr, with Mo, V)

- ASTM / AISI: Similar to H13 hot work tool steel (not always identical but closely comparable)

The exact match depends on national standards and supplier specifications. When replacing an existing grade, a detailed comparison of chemical composition, heat treatment condition and mechanical properties is necessary.

Material Delivery Conditions and Typical Forms

40CrMoV5 / H13 is supplied in various product forms and delivery conditions to meet toolmaking and engineering requirements.

Common product forms:

- Round bars (peeled, turned, ground or as-rolled)

- Flat bars and plates (for die blocks and inserts)

- Square bars and forged blocks

- Pre-machined plates and near-net-shape forged pieces

Typical delivery conditions:

40CrMoV5 / H13 is often delivered in soft annealed condition for CNC machining. Some suppliers also offer pre-hardened or quenched and tempered variants at defined hardness levels for specific applications.

Microstructure Characteristics

In annealed condition, 40CrMoV5 / H13 exhibits a fine, uniformly distributed carbide structure in a ferritic-pearlitic or spheroidized matrix, depending on the annealing route. After quenching and tempering, the microstructure is predominantly tempered martensite with fine alloy carbides (mainly Cr, Mo, V carbides) contributing to secondary hardening and hot strength.

Key microstructural features:

Fine carbidic distribution and controlled grain size are essential for achieving good toughness and resistance to thermal fatigue cracking. High cleanliness (low non-metallic inclusions) improves fatigue performance and polishability, important for die casting and plastic molds when the same steel type is used.

Mechanical Properties and Performance

The mechanical properties of 40CrMoV5 / H13 depend strongly on the heat treatment condition, hardness level, and section size. The following values are indicative for properly heat-treated material.

| Property | Typical Value Range | Notes |

|---|---|---|

| Hardness (HRC) | 44 – 52 HRC | Common working range for hot work tools |

| Tensile strength Rm | ~ 1400 – 1900 MPa | Depending on hardness and section size |

| Yield strength Rp0.2 | ~ 1100 – 1500 MPa | Correlated with hardness |

| Elongation A5 | ~ 8 – 14 % | Measured on standard test specimens |

| Charpy V-notch impact toughness | Typically 20 – 40 J at room temperature | Can vary with quality and tempering temperature |

At elevated temperatures, 40CrMoV5 / H13 retains strength better than many general-purpose alloy steels. Good hot hardness and high-temperature tensile properties are crucial for tools that operate in continuous thermal cycling, such as die casting dies. While specific elevated-temperature data varies by source, the alloy is known for stable properties up to typical hot work operating temperatures when correctly tempered.

Physical Properties

Physical properties are relatively consistent among hot work tool steels of this type. Typical values at room temperature are:

Density: approximately 7.80 – 7.85 g/cm³

Thermal conductivity: around 25 – 30 W/m·K (specific values depend on temperature)

Specific heat capacity: approximately 460 – 500 J/kg·K

Coefficient of thermal expansion (20–200 °C): roughly 11 – 12 × 10⁻⁶ /K

These properties influence heat transfer within the tool and thermal stress distribution. Adequate thermal conductivity is important for cooling channel design and temperature control in die casting and forging tooling.

Heat Treatment of 40CrMoV5 / H13

Heat treatment is a critical factor for achieving the desired balance of hardness, strength, toughness and thermal fatigue resistance. The exact parameters can vary with part size, furnace type and quenching medium, but general guidelines are well established.

Soft Annealing

Soft annealing is used to reduce hardness for machinability and to homogenize microstructure before final hardening.

Typical procedure:

Heat to approximately 800 – 860 °C, hold for sufficient time for uniform heating, then cool slowly in the furnace (e.g., at 10 – 20 °C per hour) down to around 600 °C, followed by air cooling. The resulting hardness is usually around 180 – 220 HB.

Stress Relieving

Stress relieving is applied after heavy machining or roughing to minimize distortion during final hardening.

Typical procedure:

Heat to about 600 – 650 °C, hold long enough to equalize temperature (often 1–2 h depending on section size), then cool in still air. The hardness remains nearly unchanged while internal stresses are reduced.

Hardening (Austenitizing and Quenching)

Hardening is carried out to form martensite and dissolve alloy carbides to the extent needed for subsequent secondary hardening during tempering.

Typical hardening steps:

- Preheating: often in two stages, e.g., 450 – 550 °C and then 800 – 850 °C, to reduce thermal shock.

- Austenitizing: usually around 1000 – 1040 °C (values around 1020 – 1030 °C are common). Hold time depends on section size and furnace conditions.

- Quenching: typically in air, forced air, or oil, with appropriate agitation. Salt baths or gas quenching furnaces can also be used.

The choice of quenching medium aims to ensure adequate hardness and through-hardening while limiting distortion and cracking. Larger sections may require more intensive quenching or adjusted austenitizing parameters.

Tempering

Tempering is essential to achieve service hardness and to develop hot work properties such as toughness and temper resistance.

Typical tempering practice:

Tempering temperature is usually in the range of 540 – 650 °C, often with double or triple tempering to ensure stability. Tempering time is commonly at least 2 hours per cycle, depending on section size, with air cooling between tempers.

Key considerations in tempering:

A tempering temperature range that results in secondary hardening is generally targeted, maintaining hardness commonly between 44 – 52 HRC for hot work tooling. Tempering below a certain threshold (around 500 °C) may leave residual stresses and insufficient toughness, while too high temperatures may reduce hardness below required levels.

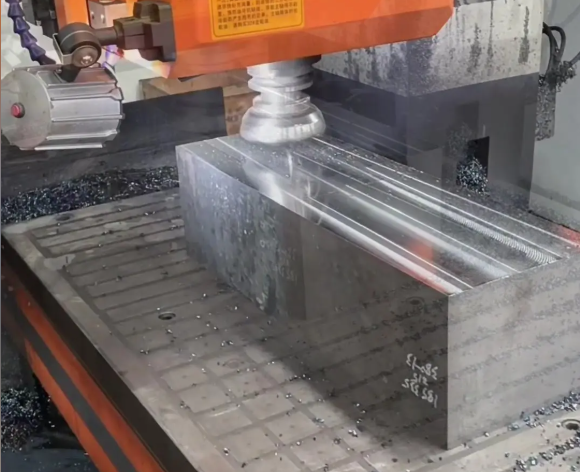

Machinability and Processing

In the annealed condition, 40CrMoV5 / H13 offers moderate to good machinability for a hot work tool steel, though it is more demanding to machine than low-alloy structural steels. Appropriate tooling, cutting speeds and coolants are necessary to achieve efficient machining and acceptable tool life.

Typical machining operations:

Turning, milling, drilling and grinding are standard processes. Carbide tools or coated high-speed steel tools are often used. Prehardened or quenched and tempered material requires more rigid setups and optimized parameters to limit tool wear and maintain dimensional precision.

Grinding considerations:

For hardened 40CrMoV5 / H13, grinding must be carefully controlled to avoid grinding burns and tensile residual stresses that can promote cracking during service. Proper cooling, wheel selection and feed rates are important. Subsurface cracks caused by improper grinding are a common source of premature tool failure.

Weldability and Repair Welding

40CrMoV5 / H13 is generally weldable using appropriate procedures, although it is not as straightforward as welding mild steel. Welding is mainly applied for tool repair, modification or buildup.

Key aspects of welding:

Preheating is usually required to reduce thermal shock and minimize the risk of cracking. Typical preheat temperatures fall around 250 – 350 °C, depending on tool size and hardness level. Interpass temperatures should be controlled. Post-weld heat treatment (stress relieving or tempering) is strongly recommended to restore toughness and reduce residual stresses.

Filler materials should be compatible with 40CrMoV5 / H13 composition, and matching or slightly over-alloyed weld metals are often used. Controlled welding procedures and qualified welders are important to maintain tool performance after repair.

Surface Treatment and Coating

Surface treatments can enhance wear resistance, reduce friction, and improve resistance to soldering and thermal fatigue.

Common surface treatments:

Nitriding: Gas or plasma nitriding of quenched and tempered 40CrMoV5 / H13 produces a hard diffusion layer (nitrided case) while retaining a tough core. Nitrided layer hardness typically ranges around 900 – 1200 HV depending on process parameters. This is widely used for die casting and forging dies.

Coatings: Physical vapor deposition (PVD) or chemical vapor deposition (CVD) coatings (e.g., TiN, TiAlN, CrN and related coatings) can be applied on properly prepared and heat-treated surfaces to improve wear resistance and reduce sticking of molten metal.

Surface preparation and prior heat treatment condition are important to ensure coating adhesion and to avoid distortion during nitriding or other thermochemical processes.

Corrosion and Oxidation Behavior

40CrMoV5 / H13 is not a stainless steel and will corrode in humid or aggressive environments without protection. However, its relatively high chromium content provides better oxidation resistance at elevated temperature than standard low-alloy steels.

Oxidation resistance in service:

In hot work applications such as die casting, the steel surface is exposed to high temperatures and molten metal. Controlled heat treatment, surface finishing and appropriate lubricants help reduce scaling and oxidation. Nitriding or coatings can further improve resistance to surface degradation.

Storage and maintenance:

Tools and semi-finished products should be stored in dry conditions and protected with rust-preventive oils or coatings during downtime to avoid surface corrosion, which can later act as crack initiation points.

Typical Applications of 40CrMoV5 / H13

40CrMoV5 / H13 is widely used in tooling for high-temperature operations. Its combination of hot strength, temper resistance and toughness makes it well suited for highly loaded tools subjected to thermal cycling.

Representative applications include:

Die casting tools:

Pressure die casting inserts, cores, cavities and complete die sets for aluminum, magnesium and zinc alloys. The steel’s thermal fatigue resistance and hot strength are key for extending die life.

Hot forging tools:

Forging dies, headers, mandrels, punches and extrusion dies for hot forming of steels and nonferrous alloys. 40CrMoV5 / H13 withstands repeated impacts and high thermal loads when correctly heat treated.

Extrusion tooling:

Extrusion dies and tooling for aluminum and other materials where dimensional stability at elevated temperatures is important.

Other applications:

Shear blades for hot cutting, hot work rolls, hot piercing tools and various high-temperature wear parts. In some cases, similar compositions are used for plastic mold components requiring high toughness and moderate hot strength.

Advantages and Practical Considerations

40CrMoV5 / H13 is popular because it offers a balanced property profile that meets the requirements of many hot work environments.

Main advantages:

- Good combination of high-temperature strength, toughness and thermal fatigue resistance.

- Reasonable machinability in the annealed state.

- Reliable and well-documented heat treatment behavior, simplifying process control.

- Compatibility with nitriding and hard coatings for enhanced surface performance.

Typical practical considerations and constraints:

Tool life is strongly influenced by heat treatment quality, temperature control during service, lubrication and cooling design. Improper hardening or tempering, inadequate preheating in service, or excessive thermal shock can lead to premature cracking, heat checking and deformation. Dimensional changes during heat treatment must be considered during design and machining, particularly for large tools.

Comparison with Similar Hot Work Steels

40CrMoV5 / H13 is often compared with other hot work tool steels, especially those within the H13 / 1.2344 family and related grades. Although specific designations may differ, the general behavior is similar when composition and quality levels are comparable.

Comparison aspects:

Compared to lower-alloy hot work steels, 40CrMoV5 offers better temper resistance and hot strength. Compared with some premium microalloyed or remelted variants (e.g., electroslag remelted versions), standard 40CrMoV5 / H13 may have slightly lower cleanliness and toughness, but typically at a more economical cost. For critical applications, remelted variants with enhanced microcleanliness can be selected.

When switching between grades, it is important to review the full property set (including toughness, hot yield strength and thermal fatigue resistance) as well as supplier-specific process recommendations.

Design and Application Guidelines

Effective use of 40CrMoV5 / H13 requires coordinated design, material processing and operational practices.

Key guidelines:

Design for uniform cross-sections where possible and avoid sharp transitions in thickness to reduce heat treatment stresses. Include adequate fillet radii in highly stressed regions. Place cooling channels to promote uniform temperature distribution and moderate thermal gradients, thus limiting thermal fatigue. Allow for dimensional adjustments after heat treatment due to distortion and size changes.

Operating practices:

Ensure appropriate preheating of tools before exposure to molten metal or high-temperature workpieces. Maintain suitable lubrication and cooling to avoid extreme temperature shocks. Monitor tool surfaces for early signs of heat checking, cracking or erosion, and schedule maintenance or repair welding before severe damage occurs.

FAQ about 40CrMoV5 / H13

What is 40CrMoV5 / H13 steel?

40CrMoV5 / H13 is a chromium-molybdenum-vanadium alloy steel known for its high strength, good toughness, and excellent resistance to wear and heat. It is commonly used in tooling, molds, and high-stress mechanical components.

What are the typical applications of 40CrMoV5 / H13?

40CrMoV5 / H13 is widely used for hot work tools, die-casting molds, forging dies, extrusion tools, and structural parts that operate under high temperature and high load conditions.

Is 40CrMoV5 / H13 suitable for CNC machining?

Yes, 40CrMoV5 / H13 can be CNC machined effectively, especially in the annealed or pre-hardened condition. Proper cutting parameters and tooling are recommended due to its high strength.

What are the key mechanical properties of 40CrMoV5 / H13?

This steel offers high tensile strength, good impact toughness, excellent fatigue resistance, and good thermal stability, making it suitable for demanding industrial applications.

What surface treatments are suitable for 40CrMoV5 / H13 parts?

Common surface treatments include nitriding, polishing, coating, and shot peening, which further enhance wear resistance and surface hardness.