TC1 is a widely used titanium alloy in the titanium designation system. It is a near-alpha titanium alloy positioned between pure titanium and higher strength α+β alloys. TC1 offers a balanced combination of strength, plasticity, corrosion resistance and weldability, making it suitable for aerospace structures, chemical equipment and high-performance industrial components.

Overview of TC1 Titanium Alloy

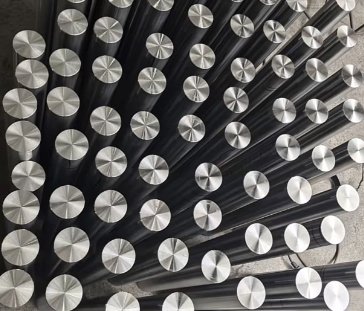

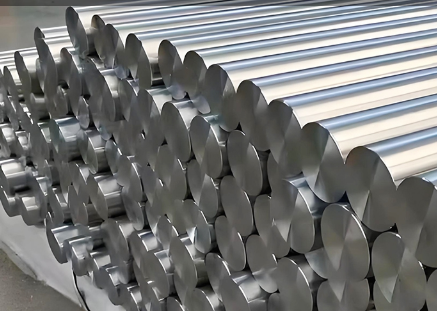

TC1 titanium alloy belongs to the near-alpha (near-α) titanium alloy group. Compared with commercially pure titanium, it has higher strength and better elevated-temperature performance, while maintaining relatively good ductility and formability. It is typically supplied in plate, sheet, bar, forging, wire and tube forms.

In the corresponding aerospace standards, TC1 is generally considered an early-generation structural titanium alloy. It is often used for moderately stressed parts where good weldability and reliability are more important than reaching the maximum possible strength level.

Chemical Composition of TC1

The exact composition range of TC1 is defined in relevant standards, but typical chemistry is characterized by controlled aluminum as the main alpha stabilizer and limited beta stabilizers such as manganese, iron or others in trace amounts. Impurity elements such as carbon, nitrogen, hydrogen and oxygen are tightly controlled.

| Element | Typical Range (wt%) | Function / Influence |

|---|---|---|

| Ti | Balance | Base metal, forms α and β phases |

| Al | ~2.0 – 3.0 | Alpha stabilizer, increases strength and creep resistance |

| Mn, Fe or other β-stabilizers | Each typically <2.0 | Improve strength and refine microstructure at moderate contents |

| O | ≤ 0.20 (typical max) | Solid solution strengthening; excessive oxygen reduces toughness |

| C | ≤ 0.10 (typical max) | Should be low to avoid embrittlement |

| N | ≤ 0.05 (typical max) | Excess nitrogen increases hardness and brittleness |

| H | ≤ 0.015 (typical max) | Hydrogen pickup can cause delayed cracking, must be minimized |

| Others (each) | ≤ 0.10 (typical max) | Residual elements controlled for stability and performance |

The exact values and tolerances depend on the particular national standard, aerospace specification or mill standard. Control of interstitial elements (O, N, H, C) is essential for maintaining ductility and fracture toughness.

Microstructure and Phase Characteristics

TC1 is a near-alpha alloy with microstructure dominated by α phase and a small amount of β phase. Its microstructure is sensitive to thermomechanical processing and heat treatment, which determine grain size, distribution of α and β phases, and therefore mechanical properties.

Alpha and Beta Phases

- Alpha (α) phase: Hexagonal close-packed structure, responsible for high specific strength, good creep resistance and good weldability.

- Beta (β) phase: Body-centered cubic structure, present in smaller fraction; improves hardenability and enhances strength after appropriate treatment.

In TC1, the β transus temperature is relatively high. Most service conditions rely on a predominantly α matrix with dispersed β regions, which leads to a good compromise between strength and plasticity.

Typical Microstructural Conditions

The following microstructural conditions are commonly encountered:

- Equiaxed α with small β at grain boundaries, obtained after hot rolling or forging followed by air cooling.

- Slightly elongated α grains along the working direction, typically seen in rolled plate or bar products.

- Fine recrystallized α structure in annealed sheets, beneficial for forming and for uniform mechanical properties.

Mechanical Properties of TC1

TC1 is designed to provide moderate strength levels compared with high-strength titanium alloys such as TC4 (Ti-6Al-4V), but with better formability and weldability than many higher alloyed grades. Mechanical properties depend strongly on product form, heat treatment and test temperature.

| Property | Typical Value Range | Notes |

|---|---|---|

| Density | ~4.5 g/cm³ | Approximately 60% of steel density |

| 0.2% Yield Strength (σ0.2) | ~400 – 650 MPa | Varies with condition (annealed, hot worked, etc.) |

| Ultimate Tensile Strength (σb) | ~500 – 750 MPa | Sheet often at lower end; bar/forging at higher end |

| Elongation (A) | ~15 – 30% | Depends on product form and thickness |

| Reduction of Area (Z) | ~25 – 45% | Indicative of plasticity and toughness |

| Hardness | Approx. 160 – 260 HB | Higher after deformation or strengthening treatments |

| Fatigue Strength (rotating bending) | Typical mid-range for near-α alloys | Exact values depend on surface condition and environment |

At elevated temperatures, TC1 maintains useful strength and creep resistance in a temperature range generally up to around 300–400 °C depending on specific application constraints and design margins.

Physical and Chemical Properties

As a titanium alloy, TC1 retains the key physical and chemical characteristics of titanium, modified slightly by alloying elements.

Physical Properties

Typical physical properties include:

- Density: approximately 4.5 g/cm³, leading to high specific strength compared with steels and nickel alloys.

- Melting range: similar to other titanium alloys, roughly 1600–1700 °C.

- Thermal conductivity: relatively low versus steels and aluminum alloys, which affects heat dissipation during machining and welding.

- Coefficient of thermal expansion: intermediate compared with steels and aluminum, important for fit, assembly and thermal cycling design.

- Modulus of elasticity: lower than steels (around 100–120 GPa for titanium alloys), influencing stiffness and vibration characteristics.

Corrosion Resistance

TC1 exhibits good corrosion resistance due to the stable and dense oxide film formed on the surface in many environments. Key features include:

General corrosion resistance: In oxidizing media and atmospheric conditions, TC1 forms a protective TiO₂ film that self-heals when damaged.

Resistance to many chlorides and seawater: It resists pitting and crevice corrosion better than many steels in low to moderate temperature seawater and chloride-containing media, though attention must be paid to crevice conditions and stagnant zones.

Compatibility with many chemical media: It can be used in certain acidic and alkaline solutions where stainless steels may suffer from stress corrosion cracking or rapid general corrosion. Selection must be based on detailed medium composition, temperature and concentration data.

Heat Treatment of TC1 Titanium Alloy

Heat treatment is used to adjust microstructure and properties of TC1 for different applications. The heat treatment procedures are simpler than for some α+β alloys because TC1 is near-α and usually not treated for very high strength levels.

Typical Heat Treatment Processes

Common heat treatments include:

Annealing: The most widely used treatment. TC1 is heated to a suitable temperature below the β transus, held long enough to promote recrystallization and homogenization, then cooled in air or furnace as specified. Annealing reduces residual stresses, improves ductility and stabilizes microstructure.

Stress relieving: After cold forming, welding or extensive machining, a lower temperature stress relief treatment may be applied to reduce residual stresses without significantly changing mechanical properties.

Solution and aging: Some specifications allow solution treatment below or near the β transus followed by aging to refine microstructure and enhance strength. However, due to the near-α nature of TC1, the strengthening effect is more limited than in α+β alloys, and such treatments are less common for general industrial use.

Influence of Heat Treatment on Properties

By adjusting the annealing temperature and cooling method, it is possible to shift the balance between strength and ductility. Higher annealing temperatures generally coarsen grains and may reduce strength but improve high-temperature stability. Lower annealing temperatures help maintain finer grains, resulting in higher strength but sometimes lower ductility.

Processing and Forming of TC1

TC1 can be processed by conventional titanium alloy working methods. Compared with many high-strength titanium alloys, it has better hot and cold workability, though its formability is still lower than typical aluminum alloys or low-carbon steels.

Hot Working

Typical hot working operations include forging, rolling and upsetting. Characteristics:

Hot working temperature range: usually within the α+β single-phase and α+β two-phase ranges, below the β transus to maintain desired phase balance. Material temperature is carefully controlled to avoid excessive grain growth or damage to microstructure.

Deformation rate: Moderate deformation rates are recommended. Excessive deformation per pass at low temperatures can lead to cracking, while extremely slow deformation at high temperatures can cause grain coarsening.

Reheating: Large forgings may require multiple reheats to maintain material within the ideal hot working temperature window.

Cold Working

TC1 can undergo certain cold working operations such as bending, shallow drawing, and minor shape corrections. Due to the relatively high strength and low modulus of titanium, forming loads are higher than for many steels, and springback is more pronounced.

After heavy cold deformation, intermediate or final annealing is often required to restore ductility and reduce residual stresses. Lubrication, tool design and forming speed must be optimized to prevent surface galling or cracking.

Weldability

TC1 offers good weldability, especially in inert gas shielded processes. Main points:

- TIG or MIG welding with argon or helium shielding is commonly used.

- Strict protection from air contamination in weld zone and back side is necessary to avoid embrittlement by oxygen and nitrogen.

- Preheating is usually not required, but post-weld stress relief may be recommended for highly constrained structures.

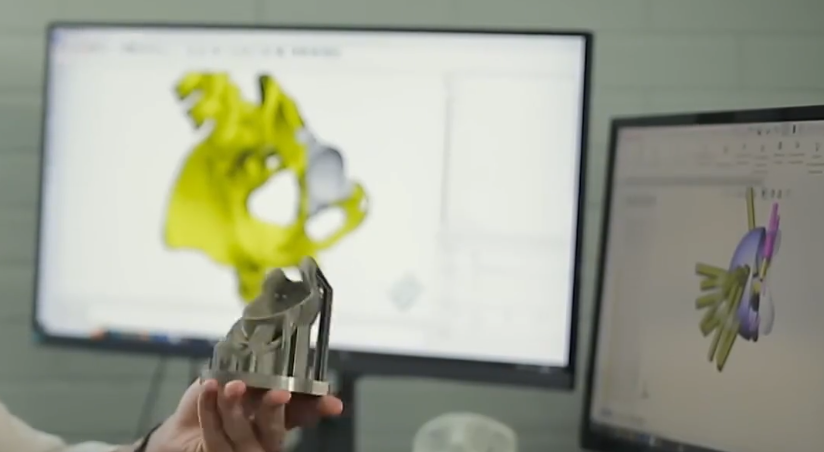

Applications of TC1 Titanium Alloy

Because TC1 combines moderate strength, low density, good corrosion resistance and weldability, it is used in diverse fields where weight saving and reliability are important.

Aerospace Applications

Aerospace is one of the primary fields where TC1 is used. Typical components include:

Airframe structures: Such as frames, ribs, brackets and secondary load-bearing parts where weight reduction is essential but ultra-high strength is not mandatory. TC1 allows improvement of payload and fuel efficiency compared with steel structures.

Engine-related auxiliary components: Certain housings, casings and support elements operating at moderate temperatures, where the material must withstand cyclic loading and corrosive environments.

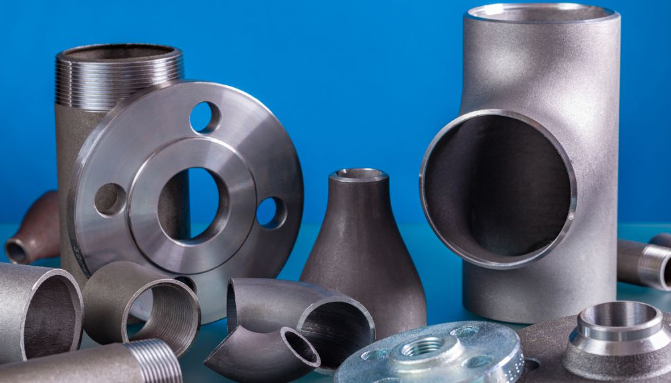

Chemical and Process Industry

TC1’s corrosion resistance makes it suitable for selected chemical processing environments:

Heat exchangers and coolers: Tubes and tube sheets for handling corrosive fluids at moderate temperatures where stainless steels suffer from localized corrosion.

Reactors, vessels and piping: Components in systems containing chloride-bearing or other aggressive media, where long service life and reliability are required.

Marine and Offshore Components

In marine engineering, TC1 can be applied to parts that must resist seawater corrosion and provide high reliability:

Seawater handling equipment: Pumps, valves and fittings in direct contact with seawater or brackish water.

Structural parts and fasteners: Where corrosion resistance and weight reduction are both important design targets.

General Industrial and High-Performance Uses

Other representative applications include:

High-performance springs and elastic elements: Taking advantage of titanium’s high specific strength and good fatigue behavior.

Precision components: In instruments or devices requiring light weight, robustness and corrosion resistance, for example in certain medical, energy or instrumentation systems subject to the applicable material regulations.

Advantages of TC1 Titanium Alloy

The selection of TC1 is usually based on several key characteristics that differentiate it from other metallic materials.

High Specific Strength

When strength is evaluated per unit density, TC1 significantly outperforms many structural steels. This translates directly into lighter components for the same load capacity, which is valuable in aerospace, marine and mobile equipment.

Good Corrosion Resistance

Compared with carbon steels and many stainless steels in certain environments, TC1 resists general and localized corrosion more effectively. This enables longer service life, reduced maintenance and improved reliability in harsh environments.

Reliable Weldability and Structural Integrity

TC1’s near-alpha composition supports stable welding behavior under proper protection conditions. Welded joints can provide mechanical properties close to the base metal if suitable process controls are applied, an important consideration for complex welded assemblies.

Balanced Mechanical Properties

TC1 does not aim for maximum possible strength; instead, it balances yield strength, ultimate strength, elongation and toughness. This makes it suitable for parts that experience variable loads and must maintain a safety margin without excessive weight.

Considerations and Limitations in Use

Despite its many advantages, TC1, like all titanium alloys, presents certain considerations that must be addressed in design and manufacturing.

Material Cost

The cost per kilogram of TC1 is higher than that of usual structural steels and many stainless steels due to extraction, processing and melting complexity. For cost-effective use, designers typically target applications where weight savings, corrosion resistance or service life clearly offset the material and processing cost.

Wear and Galling

TC1 can exhibit relatively poor wear resistance and a tendency toward galling when sliding against other metals without proper lubrication or surface treatment. Surface engineering, coatings, or use of compatible mating materials may be necessary in high friction or sliding applications.

Thermal and Elastic Behavior

Its low thermal conductivity affects heat dissipation during machining and welding, increasing the risk of thermal damage if process parameters are not optimized. The lower elastic modulus compared with steel causes increased elastic deflection and springback, which must be accounted for in both forming and structural analysis.

Machining Characteristics of TC1 Titanium Alloy

Machining TC1 requires careful control of parameters due to its combination of strength, low thermal conductivity and reactivity at high temperatures. Although TC1 is somewhat easier to machine than some high-strength α+β titanium alloys, it is still more demanding than carbon steels or aluminum alloys.

General Machinability Features

Key aspects of TC1 machinability include:

High cutting forces relative to some conventional structural metals, due to strength and work hardening.

Poor heat dissipation from cutting zone because of low thermal conductivity, resulting in higher tool temperatures and potential tool wear when parameters are not optimized.

Tendency to form built-up edge and adhere to cutting tools if inadequate cutting fluids or inappropriate tool materials are used.

Tool Material Selection

Common tool materials for machining TC1 are:

- Cemented carbides (carbide): Widely used for turning, milling and drilling. Grades with high hot hardness and good wear resistance are preferred.

- Cermets and ceramics: May be used for certain high-speed finishing operations under stable conditions, but require carefully controlled parameters.

- Polycrystalline diamond (PCD) or cubic boron nitride (CBN): Used mainly for finishing or high surface quality requirements; PCD is especially useful for non-interrupted cuts and abrasive environments.

Cutting Parameters and Cooling

Due to heat concentration and the need to prolong tool life, cutting speeds for TC1 are typically lower than for steels of similar strength. Suggested parameter strategies include:

Moderate cutting speed: Lower than that used for many steels, particularly in roughing operations.

Relatively low to moderate feed and depth of cut: Balanced to maintain productivity while avoiding excessive cutting force and chatter.

Abundant cutting fluid: High-pressure, high-flow coolant is recommended to remove heat from the cutting zone, reduce friction and help chip evacuation. Emulsion or synthetic water-based coolants are commonly used.

Turning of TC1

In turning operations, stable fixturing, sharp tools and optimized geometry are essential. Negative rake tools are often used for increased edge strength, but for some finishing operations, positive rake tools with honed edges can reduce cutting forces and improve surface quality. Tool nose radius must be selected to balance surface finish and tool load.

Milling of TC1

For milling TC1, the following considerations apply:

Use of rigid machine tools and fixtures to minimize vibration.

Prefer climb milling to reduce rubbing and heat generation.

Lower number of teeth engaged simultaneously with proper chip load to limit heat buildup, often using high-helix cutters designed for titanium.

Drilling and Hole Making

When drilling TC1, proper drill design and lubrication are critical:

Use of specially designed drills for titanium, with reinforced edges, optimized point angle and polished flutes for efficient chip evacuation.

Application of abundant coolant through internal coolant channels if available.

Avoiding dwell and excessive retraction that can cause work hardening at the hole surface.

Grinding and Finishing

Grinding TC1 is technically feasible, but care must be taken to avoid surface overheating, which could lead to microstructural changes or surface damage. Fine finishing may also be carried out by honing, lapping or superfinishing for critical components. Clean, defect-free surfaces are important for fatigue performance, particularly in aerospace applications.

Surface Treatment and Protection

Although TC1 has good corrosion resistance, surface treatments may be applied to meet special functional requirements or extend service life.

Mechanical and Chemical Treatments

Mechanical polishing and blasting: Used to achieve desired surface roughness and cleanliness. Proper procedures avoid embedding foreign particles or causing subsurface damage.

Chemical milling and pickling: Employed to remove surface defects, oxides and contamination. Chemical pickling solutions must be carefully controlled for concentration and temperature to prevent over-etching or hydrogen pickup.

Coatings

Protective coatings may be applied to enhance wear resistance or reduce friction, such as:

Physical vapor deposition (PVD) coatings for improved wear resistance of moving surfaces.

Specialized coatings or platings on contact surfaces to reduce galling or to improve compatibility with mating materials.

Quality Control and Inspection

To ensure reliable performance of TC1 components, systematic quality control and inspection are implemented throughout production.

Material Certification and Traceability

Suppliers usually provide mill certificates and test results including chemical composition, mechanical properties and heat treatment history. Traceability is critical in aerospace and high-reliability applications, allowing each component to be linked to its original melt and processing records.

Non-Destructive Testing

Depending on the component criticality and applicable standards, various non-destructive testing methods are applied:

- Ultrasonic testing for internal flaws in forgings, bars and plates.

- Radiographic testing for welded joints and complex cast or forged shapes.

- Liquid penetrant inspection for detection of surface cracks or defects in machined parts and welds.

Dimensional and Surface Quality Control

Dimensional inspection is performed using conventional metrology and, for complex shapes, coordinate measuring machines. Surface roughness, waviness and defects are evaluated to ensure compliance with design drawings and functional requirements, especially where fatigue or sealing performance is important.