Ti-5Al-2.5Sn is a well-established near-alpha titanium alloy used primarily in aerospace, cryogenic and high-reliability engineering structures. It offers high specific strength, good weldability and excellent toughness at low and cryogenic temperatures. This alloy is supplied in several product forms and tempers, including standard and extra-low interstitial (ELI) grades for demanding environments.

Overview and Alloy Classification

Ti-5Al-2.5Sn belongs to the near-alpha family of titanium alloys. Its behavior is dominated by a stable alpha phase with a limited amount of beta phase at elevated temperature. The alloy is commonly designated as:

- Ti-5Al-2.5Sn (standard interstitial level)

- Ti-5Al-2.5Sn ELI (extra-low interstitial, optimized for fracture toughness and cryogenic service)

- UNS designations such as R54520 (standard) and R54521 (ELI), depending on specification system

Near-alpha alloys like Ti-5Al-2.5Sn are typically selected where combinations of high stiffness, moderate-to-high strength, weldability and resistance to low-temperature embrittlement are required. Compared with alpha-beta alloys, they are generally less hardenable through heat treatment but better for service at elevated and cryogenic temperatures, with good resistance to creep and microstructural instability.

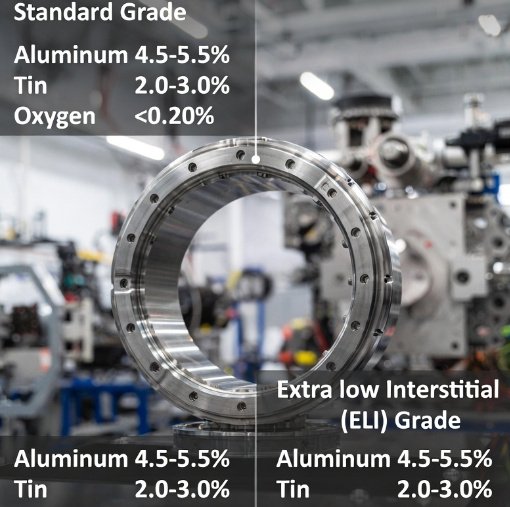

Chemical Composition

The chemical composition of Ti-5Al-2.5Sn is tightly controlled because interstitial elements such as oxygen, nitrogen and carbon strongly influence tensile strength, ductility and toughness. The ELI variant further reduces interstitials to improve fracture toughness and low-temperature performance.

| Element | Standard grade (typical limits) | ELI grade (typical limits) |

|---|---|---|

| Titanium (Ti) | Balance | Balance |

| Aluminum (Al) | 4.5 – 5.5 | 4.5 – 5.5 |

| Tin (Sn) | 2.0 – 3.0 | 2.0 – 3.0 |

| Oxygen (O) | ≤ 0.20 | ≤ 0.13 (typical ELI) |

| Iron (Fe) | ≤ 0.25 | ≤ 0.25 |

| Carbon (C) | ≤ 0.08 | ≤ 0.08 (often lower in practice) |

| Nitrogen (N) | ≤ 0.05 | ≤ 0.03 – 0.04 (spec-dependent) |

| Hydrogen (H) | ≤ 0.015 | ≤ 0.012 (typical ELI) |

| Other single | ≤ 0.10 | ≤ 0.10 |

| Other total | ≤ 0.40 | ≤ 0.40 |

Aluminum is the primary alpha stabilizer, raising strength and modulus while retaining good creep resistance. Tin also acts as a solid-solution strengthener with minimal adverse effect on weldability. The control of oxygen and other interstitials is especially critical in the ELI grade to ensure high fracture toughness and resistance to crack growth at low temperature.

Microstructure and Phase Characteristics

Ti-5Al-2.5Sn is classified as a near-alpha titanium alloy. Its microstructure consists predominantly of alpha (hcp) phase with a small fraction of beta (bcc) phase at high temperatures. The beta transus temperature is typically in the range of approximately 980–1030 °C, depending on exact chemistry and processing history.

Key microstructural features include:

- Equiaxed primary alpha grains after conventional mill annealing

- Alpha plates or colonies within transformed beta regions when processed near or above the beta transus

- Fine-scale alpha within the prior beta matrix after certain thermomechanical and cooling routes

The alloy is usually supplied in an annealed or solution-treated and aged condition with a relatively stable microstructure that changes slowly in service up to moderately elevated temperatures. Because it is near-alpha, precipitation hardening effects are weaker than in some alpha-beta alloys. Strength is mainly controlled by:

– Solid solution strengthening from Al and Sn

– Grain size and alpha morphology

– Interstitial content, particularly oxygen

Physical Properties

Ti-5Al-2.5Sn maintains the characteristic low density and relatively high stiffness of titanium alloys. Typical physical properties at room temperature are as follows (representative values, may vary slightly by product form and condition):

| Property | Typical value | Notes |

|---|---|---|

| Density | ≈ 4.45 – 4.55 g/cm³ | High specific strength compared with steels |

| Melting range | ≈ 1600 – 1700 °C | Solidus and liquidus depend on chemistry |

| Modulus of elasticity (Young’s) | ≈ 105 – 115 GPa | Lower than steels (≈ 200 GPa) |

| Poisson’s ratio | ≈ 0.32 – 0.34 | Typical for titanium alloys |

| Thermal conductivity | ≈ 6 – 8 W/m·K | Relatively low, influences machining and heat management |

| Specific heat capacity | ≈ 0.50 – 0.60 kJ/kg·K | Increases with temperature |

| Coefficient of thermal expansion | ≈ 8.0 – 8.8 × 10⁻⁶ /K | Generally lower than steels and Ni alloys |

| Electrical resistivity | ≈ 1.6 – 1.8 μΩ·m | Low electrical conductivity |

The combination of low thermal conductivity and moderate specific heat has direct implications for machining: heat tends to concentrate at the cutting interface, which can accelerate tool wear unless speeds, feeds and cooling are controlled appropriately.

Mechanical Properties

The mechanical properties of Ti-5Al-2.5Sn depend on product form (plate, sheet, bar, forgings, tube), heat treatment condition and whether the material is standard or ELI grade. The alloy is known for a good balance of strength, ductility and excellent toughness at cryogenic temperatures.

Tensile properties at room temperature

Typical room temperature tensile properties for annealed material are:

– Yield strength (0.2% offset): ≈ 690 – 830 MPa (standard), ≈ 620 – 760 MPa (ELI, depending on spec)

– Ultimate tensile strength: ≈ 760 – 900 MPa

– Elongation: ≈ 10 – 18 %

– Reduction of area: ≈ 25 – 45 %

The ELI variant usually sacrifices a small amount of strength for improved ductility and toughness, especially at low and cryogenic temperatures. Strength can be increased by cold working or certain thermomechanical treatments, at the expense of ductility and toughness.

Low-temperature and cryogenic performance

One of the distinguishing characteristics of Ti-5Al-2.5Sn, particularly in the ELI grade, is its excellent mechanical behavior down to cryogenic temperatures (e.g., liquid hydrogen and liquid helium temperature ranges). Typical aspects include:

– Increase in yield and tensile strength with decreasing temperature

– Retention or moderate improvement of elongation compared with room temperature

– High fracture toughness and resistance to brittle fracture

This behavior makes Ti-5Al-2.5Sn ELI a standard choice for cryogenic pressure vessels, tanks and structural components in aerospace and space launch systems.

Fatigue and fracture toughness

Fatigue performance is influenced by surface condition, microstructure, stress ratio, environment and mean stress. With proper surface finish and design, Ti-5Al-2.5Sn exhibits good high-cycle fatigue resistance and crack growth behavior typical of near-alpha titanium alloys. The ELI grade improves fracture toughness by limiting interstitials, which reduces crack initiation and propagation sensitivity.

Typical qualitative trends:

– Fatigue strength (R = –1) at 10⁷ cycles is often in the range of 350 – 500 MPa, depending on processing and surface condition

– Fracture toughness (K_IC) values for ELI material are higher than for standard grade, supporting critical cryogenic structures

Creep and elevated temperature performance

Although often used at ambient or low temperatures, Ti-5Al-2.5Sn retains reasonable strength and microstructural stability up to moderately elevated temperatures. It is not a dedicated high-temperature titanium alloy, but it offers:

– Moderate creep resistance in the approximate range of 250 – 400 °C

– Good resistance to microstructural coarsening within this temperature band over typical aerospace service times

For long-term high-temperature applications, specialized titanium alloys or nickel-based superalloys are usually preferred, but Ti-5Al-2.5Sn can support short-duration or moderate-temperature duty where its density advantages are beneficial.

Standards, Specifications and Product Forms

Ti-5Al-2.5Sn is covered by multiple aerospace and industrial standards, depending on region and application. While specific document numbers differ between organizations, typical categories include:

– Plate, sheet and strip specifications

– Bar and billet specifications

– Seamless and welded tubing specifications

– Forging and forging stock specifications

– Welding wire and filler metal specifications

Common product forms supplied include:

– Plate, sheet and strip for skins, panels and formed parts

– Bars and billets for machined components and fasteners

– Forgings for highly stressed structural parts

– Seamless tube for pressure vessels, hydraulic lines and cryogenic conduits

– Welded tube where acceptable and supported by design requirements

Corrosion and Environmental Resistance

Like most titanium alloys, Ti-5Al-2.5Sn relies on a stable, adherent oxide layer for corrosion protection. In many environments, its corrosion resistance is comparable to commercially pure titanium and other near-alpha alloys.

Typical environmental behaviors:

– Excellent resistance to atmospheric corrosion and marine environments

– Good performance in many oxidizing acids at moderate temperature

– Very good resistance to chloride-induced stress corrosion cracking in most aqueous conditions, especially compared with steels and aluminum alloys

Some specific considerations include:

– Hot, strongly reducing environments may attack the passive film

– Halogen-containing high-temperature gases or molten salts can be aggressive

– In hydrogen-containing environments, hydrogen pickup must be controlled to avoid embrittlement over time

Key Applications of Ti-5Al-2.5Sn

The combination of specific strength, weldability and cryogenic toughness has led to widespread use of Ti-5Al-2.5Sn in aerospace and high-performance engineering sectors. ELI grades in particular are prominent where structural integrity at very low temperature is critical.

Aerospace and space structures

In aerospace and launch vehicle sectors, Ti-5Al-2.5Sn is used for:

– Cryogenic fuel and oxidizer tanks, especially for liquid hydrogen or liquid oxygen services (ELI preferred)

– Pressure vessels for propellant management and gas storage

– Structural rings, frames and supports operating at low temperature

– Ducts and tubes for cryogenic and high-purity gas transfer

The alloy’s low density and ability to maintain toughness at cryogenic temperatures make it a strong candidate where aluminum alloys lack sufficient low-temperature toughness and steels are too heavy.

Aircraft components

In aircraft, Ti-5Al-2.5Sn is used for selected airframe and engine-related parts when its property balance is advantageous:

– Fuselage and wing structural details requiring good weldability

– Engine casings and static structures with moderate temperature exposure

– Hydraulic lines, tubes and fittings needing corrosion resistance and weight savings

Its near-alpha microstructure provides stability and strength retention in some elevated-temperature zones that are not sufficiently served by commercially pure titanium.

Cryogenic engineering and instrumentation

Beyond aerospace, the alloy is used in cryogenic engineering systems such as:

– Cryogenic storage vessels and piping for industrial gases

– Structural supports in superconducting magnet systems and test facilities

– Components of cryostats and ultra-low temperature mechanical structures

The minimal loss of toughness at extremely low temperatures, combined with relatively low thermal conductivity, offers design advantages in minimizing thermal leak paths while ensuring structural safety.

High-performance industrial applications

Ti-5Al-2.5Sn also appears in high-end industrial and scientific equipment where a combination of cleanliness, low outgassing, corrosion resistance and strength is needed. These include niche components in:

– Chemical processing equipment exposed to oxidizing environments

– High-vacuum or ultra-high vacuum installations

– Precision mechanical assemblies subjected to large temperature gradients

Forming and Fabrication

Formability of Ti-5Al-2.5Sn is influenced by its near-alpha composition. It can be formed both at room temperature and at elevated temperatures, with optimal results often achieved using warm or hot forming to reduce flow stress and springback.

Hot forging and hot working

Hot working is typically performed in the alpha-beta or near-beta temperature range below the beta transus, with typical forging temperatures on the order of 800 – 950 °C, depending on desired microstructure and grain control. Key considerations:

– Uniform preheating of both workpiece and dies to reduce thermal gradients

– Adequate lubrication to prevent sticking and surface damage

– Controlled reduction and deformation per pass to manage grain size and prevent cracking

– Air cooling or controlled cooling after forging, depending on target mechanical properties

Cold and warm forming

Ti-5Al-2.5Sn can be cold formed, but its higher strength compared with commercially pure titanium requires more force and careful control of strain distribution.

Typical practices include:

– Use of intermediate stress-relief anneals to restore ductility and remove residual stresses in heavily formed parts

– Warm forming at approximate temperatures of 150 – 400 °C to significantly reduce forming loads and improve formability

– Attention to springback, which can be pronounced; tooling compensation and forming trials are often needed for tight tolerances

Heat treatment during fabrication

Heat treatments applied during forming and fabrication are generally aimed at stress relief and microstructure refinement rather than strong precipitation hardening effects. Common treatments include:

– Stress-relief annealing at moderate temperatures (e.g., 540 – 650 °C) to reduce residual stresses from forming or machining

– Mill annealing or recrystallization annealing to refine grain structure and restore ductility after heavy working

– Controlled cooling rates to tailor alpha morphology, balancing strength and ductility

Welding and Joining

Ti-5Al-2.5Sn is considered weldable and is widely used in welded structures, especially in pressure vessels and tubing. Proper control of contamination is critical to maintain ductility and toughness in the weld and heat-affected zones.

Fusion welding processes

Common fusion welding methods include:

– Gas tungsten arc welding (GTAW/TIG)

– Gas metal arc welding (GMAW/MIG) for some configurations

– Electron beam welding (EBW) for high integrity, low-distortion joints

Important welding considerations:

– Strict shielding from air (oxygen, nitrogen, hydrogen) using inert gas (usually argon or helium) on both torch side and backside where accessible

– Use of suitable filler wire, often matching Ti-5Al-2.5Sn chemistry, especially for ELI applications

– Cleanliness of joint surfaces and filler metals to avoid contamination and porosity

– Control of heat input to limit grain coarsening in the fusion zone and heat-affected zone

Solid-state joining and brazing

Where applicable, solid-state processes such as friction stir welding, diffusion bonding or inertia/friction welding can be used, particularly for tube-to-tube and tube-to-fitting joints or near-net shape assemblies. These methods can produce joints with minimal microstructural degradation and lower risk of contamination compared to conventional fusion welding.

Brazing is less common for structural joints but may be considered in specialized assemblies under controlled atmospheres.

Post-weld heat treatment

Depending on service requirements, post-weld heat treatments may be applied to:

– Relieve residual stresses from welding operations

– Refine coarse microstructures in the heat-affected zone where necessary

– Restore balance between strength and ductility after heavy welding cycles

Machining Characteristics

Ti-5Al-2.5Sn can be machined using conventional machine tools, but like most titanium alloys, it presents specific machining issues that must be addressed through appropriate tooling, cutting parameters and coolant application.

Machining behavior and key issues

Typical machining behavior includes:

– Relatively low cutting speeds compared to carbon steels and aluminum alloys

– High cutting forces due to strength and work hardening, especially in cold-worked or hardened conditions

– Concentration of heat at the cutting edge because of low thermal conductivity

– Tendency for built-up edge formation and notch wear if cutting conditions are not optimized

Practical machining difficulties can include rapid tool wear, dimensional inaccuracies due to thermal effects and surface integrity problems (such as microcracks or residual tensile stresses) if coolant, speeds and feeds are not properly managed.

Tool materials and coatings

Suitable tool materials for machining Ti-5Al-2.5Sn include:

– Cemented carbide tools (submicron grain, high hot hardness) for most operations

– Polycrystalline diamond (PCD) tools for some finishing operations on non-interrupted cuts

– Coated carbide tools with wear-resistant, low-friction coatings tailored for titanium cutting

Tool geometry is also important. Sharp cutting edges with positive rake and adequate clearance angles reduce cutting forces and heat generation. Robust edge preparation can help avoid chipping in interrupted cuts.

Recommended machining practices

Although specific numerical cutting data depend on machine rigidity, tool grade and component geometry, general best practices include:

– Use moderate to low cutting speeds with relatively high feeds to minimize rubbing and work hardening

– Maintain a steady chip load; avoid light, rubbing cuts that increase friction and heat

– Apply abundant coolant, preferably high-pressure, water-based emulsions or specialized cutting fluids designed for titanium

– Use rigid setups and short tool overhangs to minimize chatter and vibration

– Opt for climb milling where possible in milling operations to improve surface finish and tool life

Drilling, tapping and hole making

For drilling and tapping, issues such as chip evacuation, hole straightness and tool life must be addressed. Guidelines include:

– Use of high-performance carbide drills with coolant-through capability for deeper holes

– Careful selection of feed and speed to avoid excessive heat and premature wear

– Frequent tool inspection and replacement before severe wear leads to dimensional drift

– Use of form taps or roll taps where applicable, as they may improve thread quality and fatigue performance in some cases

Surface integrity and finishing

Surface quality is critical in fatigue-sensitive and pressure-boundary applications. Important aspects include:

– Avoidance of excessive tensile residual stresses in the surface layer, which can reduce fatigue life

– Use of finishing operations such as grinding, honing or superfinishing with appropriate wheel selection to minimize thermal damage

– Deburring and careful handling to avoid surface scratches that can act as fatigue crack initiators

Heat Treatment and Thermal Processing

Heat treatment options for Ti-5Al-2.5Sn are more limited than for some alpha-beta titanium alloys, but appropriate thermal processing is still important for achieving target properties and microstructure consistency.

Annealing treatments

Typical annealing operations include:

– Mill anneal: applied after primary working to refine microstructure and relieve stresses

– Duplex or recrystallization anneal: used to produce a uniform equiaxed alpha structure with improved ductility

– Stress-relief anneal: performed at relatively low temperatures to reduce residual stresses after machining or welding without significant microstructural changes

Annealing parameters (temperature and time) are selected based on section thickness, desired grain size and specification requirements.

Solution treatment and aging

Being a near-alpha alloy, Ti-5Al-2.5Sn has limited response to classical solution treatment and aging compared with strongly alpha-beta or beta alloys. Solution treatment near the beta transus followed by controlled cooling can be used to adjust alpha morphology and strength, but the overall strengthening effect is moderate.

In most practical applications, the alloy is used in an annealed or thermomechanically processed condition, with heat treatments focused on stress relief and microstructure control rather than strong age hardening.

Surface Treatment and Coatings

Surface treatment of Ti-5Al-2.5Sn is used to enhance wear resistance, improve tribological behavior, adjust surface roughness and, in some cases, further improve corrosion resistance or surface cleanliness.

Mechanical and chemical surface treatments

Common treatments include:

– Grit blasting with suitable media to prepare surfaces for bonding or coating, while controlling roughness and avoiding excessive surface damage

– Pickling and chemical milling using carefully controlled acid mixtures to remove surface contaminants, oxide scales or damaged layers from forming and welding

– Polishing and electropolishing for high-purity, low-outgassing surfaces in vacuum or cryogenic environments

Coatings and surface modification

Where additional wear or erosion resistance is required, coatings may be applied, such as:

– Hard coatings (e.g., TiN, TiCN, TiAlN) through PVD or CVD processes

– Oxygen diffusion treatments or other surface hardening methods for improved galling resistance under sliding contact

Coating process parameters must be controlled to avoid excessive thermal exposure or hydrogen pickup, which can affect the underlying alloy properties.

Design and Application Considerations

When selecting Ti-5Al-2.5Sn for an application, engineers should account for its specific combination of properties and fabrication behaviors.

Material selection factors

Key reasons for choosing Ti-5Al-2.5Sn include:

– Requirement for high specific strength together with weldability in a titanium alloy

– Need for structural integrity and toughness down to very low or cryogenic temperatures

– Corrosion resistance in marine, cryogenic or oxidizing environments where aluminum or steels are inadequate

In many applications, the ELI grade is chosen when crack growth resistance and fracture toughness are critical, particularly in pressure vessels and cryogenic hardware.

Geometric and structural design

Designers should consider:

– Lower modulus of titanium compared with steels may require thicker sections or optimized stiffening to control deflections

– Coefficients of thermal expansion and thermal conductivity when designing joints and supports across large temperature gradients

– Fatigue-sensitive locations, where surface quality, residual stress control and notch avoidance are important

Fabrication and cost-related considerations

Although cost aspects are outside strict material property definitions, Ti-5Al-2.5Sn is typically more expensive than structural steels and aluminum alloys. Efficient design seeks to exploit its high specific strength and temperature capability so that weight savings, performance and service life justify material and processing costs.

Attention to machining strategy, weldability and forming methods can significantly influence overall manufacturing efficiency and component consistency.

FAQ about Ti-5Al-2.5Sn Titanium Alloy

What is Ti-5Al-2.5Sn titanium alloy?

Ti-5Al-2.5Sn is a near-alpha titanium alloy containing aluminum and tin as primary alloying elements. It is known for excellent strength, good creep resistance, and stable mechanical properties at elevated temperatures.

What are the key advantages of Ti-5Al-2.5Sn?

This alloy offers a strong balance of high strength, good fracture toughness, and superior resistance to oxidation and creep at moderately high temperatures. It also maintains good weldability compared to many other titanium alloys.

How does Ti-5Al-2.5Sn compare to Ti-6Al-4V?

Compared to Ti-6Al-4V, Ti-5Al-2.5Sn offers better creep resistance and performance at elevated temperatures, while Ti-6Al-4V generally provides higher room-temperature strength and broader general-purpose use.

Can Ti-5Al-2.5Sn be welded?

Yes. Ti-5Al-2.5Sn has good weldability when proper shielding and welding procedures are used to prevent contamination from oxygen, nitrogen, or hydrogen during welding.

Is Ti-5Al-2.5Sn difficult to machine?

Yes. Like many titanium alloys, Ti-5Al-2.5Sn is challenging to machine due to its low thermal conductivity and tendency to generate high cutting temperatures. Proper tooling, lower cutting speeds, and effective cooling are essential.