Ti-6Al-6V-2Sn (often abbreviated as Ti-6-6-2 or Ti-662) is a high-strength alpha-beta titanium alloy designed for elevated-temperature service and demanding fatigue-critical applications. It offers a combination of strength, toughness, and creep resistance superior to many conventional titanium alloys while maintaining relatively low density and good corrosion resistance.

Chemical Composition and Alloy Design

Ti-6Al-6V-2Sn is an alpha-beta titanium alloy in which aluminum and tin act primarily as alpha stabilizers, while vanadium is a beta stabilizer. The alloy also often contains controlled levels of iron, copper, and other trace elements to tailor strength and hardenability.

| Element | Typical Range (wt%) |

|---|---|

| Titanium (Ti) | Balance |

| Aluminum (Al) | 5.5 – 6.8 |

| Vanadium (V) | 5.0 – 6.5 |

| Tin (Sn) | 1.8 – 2.2 |

| Iron (Fe) | ≤ 0.25 – 0.40 |

| Copper (Cu) | ≤ 0.35 |

| Oxygen (O) | ≤ 0.15 – 0.20 |

| Carbon (C) | ≤ 0.05 |

| Nitrogen (N) | ≤ 0.05 |

| Hydrogen (H) | ≤ 0.015 |

Aluminum increases strength and raises the alpha-transus temperature, while tin further supports high-temperature strength and creep resistance. Vanadium stabilizes the beta phase, enabling heat treatment and improving hardenability and strength. Low but controlled oxygen and interstitial contents are important to balance strength and ductility.

Microstructure and Heat Treatment

As an alpha-beta alloy, Ti-6Al-6V-2Sn can be processed to produce a range of microstructures, from equiaxed alpha in a beta matrix to basket-weave (Widmanstätten) alpha or bimodal structures. The microstructure strongly influences tensile strength, fracture toughness, and fatigue performance.

Alpha-beta phase characteristics

The alloy contains a mixture of alpha (hcp) and beta (bcc) phases at room temperature. Volume fractions depend on composition, processing, and heat treatment. Controlling the alpha/beta balance and morphology is a key tool for tailoring properties for different applications, such as thick-section forgings vs. thin plate or bar.

Solution treatment and aging practices

Ti-6Al-6V-2Sn is typically supplied in solution-treated and aged (STA) or mill-annealed conditions. Representative processing routes include:

- Solution treatment in the alpha-beta or near-beta region, followed by controlled cooling to adjust alpha morphology.

- Aging at intermediate temperatures to precipitate fine alpha within the beta matrix, increasing strength and fatigue resistance.

- Annealing for stress relief and to stabilize microstructure after forging or machining.

Processing temperatures and times vary by specification and section thickness but are selected to balance strength, ductility, and fracture toughness, especially in thick aerospace components.

Physical Properties

Physical properties of Ti-6Al-6V-2Sn are similar to other alpha-beta titanium alloys but with specific high-temperature capabilities.

| Property | Typical Value |

|---|---|

| Density | ~4.6 – 4.7 g/cm³ |

| Melting range | ~1620 – 1660 °C |

| Beta-transus temperature | ~900 – 960 °C (alloy and batch dependent) |

| Thermal conductivity (at 25 °C) | ~6 – 8 W/m·K |

| Specific heat (at 25 °C) | ~0.50 – 0.55 kJ/kg·K |

| Electrical resistivity (at 20 °C) | ~1.6 – 1.8 µΩ·m |

| Modulus of elasticity (tension) | ~110 – 120 GPa |

| Poisson’s ratio | ~0.30 – 0.34 |

| Coefficient of thermal expansion (20–400 °C) | ~8.5 – 9.0 ×10⁻⁶ /K |

The relatively low density combined with a moderate elastic modulus provides a high specific stiffness, which is advantageous for aerospace and high-performance structures where weight reduction is critical.

Mechanical Properties

Mechanical properties of Ti-6Al-6V-2Sn depend on the product form, section thickness, and heat treatment condition. In general, the alloy offers high tensile strength, good fatigue performance, and useful strength retention at elevated temperatures compared with widely used alloys such as Ti-6Al-4V.

Tensile and yield strength

Typical room-temperature tensile values for wrought products in optimized STA conditions often include:

- Ultimate tensile strength: approximately 1100 – 1300 MPa.

- 0.2% yield strength: approximately 1000 – 1200 MPa.

- Elongation: about 8 – 15% depending on product form.

- Reduction of area: typically 15 – 35%.

Mill-annealed or less heavily strengthened conditions show lower strength but higher ductility and toughness. Specification limits are set by aerospace and industrial standards and may vary from these typical ranges.

Fracture toughness and fatigue performance

Ti-6Al-6V-2Sn is used in highly stressed components where damage tolerance and fatigue resistance are essential. Important characteristics include:

- Fracture toughness (KIC) in a range suitable for critical rotating components and landing gear, highly dependent on microstructure and defect control.

- Good high-cycle fatigue strength relative to its density, particularly under carefully controlled surface finish and residual stress conditions.

- Sensitivity of fatigue performance to surface defects, machining marks, and inclusions, requiring strict process control, inspection, and finishing.

Fine, controlled microstructures and proper heat treatment are often applied to balance high strength with adequate fracture toughness.

Creep and elevated temperature behavior

Ti-6Al-6V-2Sn was developed with improved elevated-temperature performance in mind. Compared with more general-purpose alloys:

- Strength retention is favorable up to intermediate temperatures (for example, service temperatures up to around 400 – 450 °C, depending on design limits and specifications).

- Creep resistance is enhanced by the presence of tin and by microstructures designed for high-temperature stability.

- Long-term dimensional stability and load-carrying capacity at elevated temperature must be evaluated for specific duty cycles and environmental conditions.

Corrosion and Oxidation Resistance

Ti-6Al-6V-2Sn inherits the excellent general corrosion resistance typical of titanium alloys due to the formation of a stable, adherent titanium oxide film on the surface.

General corrosion behavior

The alloy exhibits good resistance in many environments, including:

- Atmospheric and marine environments.

- Many chlorides at moderate temperatures, although careful evaluation is needed for high-chloride, high-temperature conditions.

- Neutral and mildly oxidizing environments, where passive oxide films remain protective.

Under reducing conditions or in the presence of specific species (such as certain acids or fluorides), titanium alloys may require testing and qualification for safe use. Galvanic coupling with more noble metals in conductive media should also be evaluated.

Oxidation at elevated temperature

At elevated temperatures, titanium alloys can oxidize rapidly if not adequately protected. For Ti-6Al-6V-2Sn:

- In air, oxide scale growth increases with temperature and exposure time, so design allowable service temperatures should consider both mechanical and oxidation limits.

- Protective coatings or environmental barriers may be used when the alloy is exposed to hot gas streams or combustion products.

- Surface contamination and oxygen pickup during heat treatment must be controlled to avoid formation of brittle oxygen-enriched layers known as alpha-case.

Product Forms and Standards

Ti-6Al-6V-2Sn is available in a variety of wrought and forged product forms to meet different design needs. Typical forms include:

- Forgings and near-net-shape forged components.

- Bars, billets, and rods for machining into complex parts.

- Plates and sheets for structural elements requiring high strength-to-weight ratio.

- Rings and discs for rotating components and structural frames.

Material is commonly produced to aerospace and industrial specifications that define chemical composition limits, mechanical property requirements, heat treatment conditions, microstructure control, and nondestructive inspection procedures.

Key Applications of Ti-6Al-6V-2Sn

The alloy’s combination of high strength, good elevated-temperature capabilities, and corrosion resistance makes it a preferred choice for demanding structural components in weight-sensitive systems.

Aerospace structures and landing gear

Ti-6Al-6V-2Sn is widely used in aerospace applications including:

- Landing gear components where high static strength and fatigue resistance are required.

- Fuselage and wing attachments, fittings, and structural links.

- Actuator components, brackets, and critical fasteners operating under high load.

Its strength and relatively high toughness in thick sections are valuable in safety-critical parts subject to complex loading and impact scenarios.

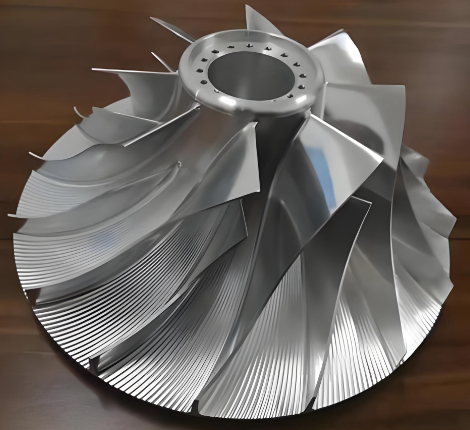

Gas turbine engine components

The alloy is used in certain zones of aircraft engines and industrial gas turbines:

- Discs, rings, and structural parts located in intermediate temperature regions.

- Cases, shafts, and support structures requiring elevated-temperature strength and good corrosion resistance.

- Components where weight reduction compared with steels is beneficial without sacrificing mechanical performance.

Material selection depends on specific temperature ranges, rotational speeds, and life requirements; Ti-6Al-6V-2Sn is often chosen for its balance between high-temperature strength and processability.

Industrial and high-performance applications

Beyond aerospace and gas turbines, the alloy is used in high-performance engineering fields such as:

- High-strength fasteners and bolts for critical structures.

- Performance automotive and motorsport components requiring lower mass and high fatigue strength.

- Specialized industrial equipment operating at elevated temperatures or in corrosive environments where stainless steels or nickel alloys are less weight-efficient.

Forming, Forging and Heat Treatment Practices

Appropriate thermomechanical processing significantly influences the final properties of Ti-6Al-6V-2Sn. Control of temperature, deformation rate, and cooling rates is essential.

Hot working and forging

Hot working is generally carried out within the alpha-beta or near-beta temperature range:

- Forging temperatures are typically selected below the beta-transus to preserve an alpha-beta structure that can be refined and controlled.

- Strain rate and reduction per pass are important to avoid defects such as fold-over, cracking, or microstructural inhomogeneity.

- Post-forge cooling may be air cooling or other controlled cooling practice depending on the desired microstructure and subsequent heat treatment plan.

Heat treatment considerations

Heat treatment sequences can include:

- Solution treatment to dissolve undesirable constituents and achieve a uniform alpha-beta distribution.

- Quenching or controlled cooling to retain metastable beta and facilitate subsequent aging response.

- Aging heat treatment to precipitate fine alpha and optimize strength and fatigue performance.

- Stress-relief anneals after major machining or welding operations to reduce residual stresses.

Heat treatment must be performed with careful temperature control and protection from contamination. Furnaces should provide inert or vacuum atmospheres where necessary, and time at temperature should be adequate to achieve transformation without excessive grain growth.

Machinability Overview

Machining Ti-6Al-6V-2Sn requires specific techniques due to its combination of low thermal conductivity, chemical reactivity with tool materials, and relatively high strength. Compared with steels, cutting forces can be similar or higher, but heat is concentrated in the tool and cutting zone.

Typical machining behavior

- Heat concentration near the cutting edge increases tool wear and can promote built-up edge or adhesion if not controlled.

- Spring-back and elastic recovery can affect dimensional accuracy, particularly in thin-walled components.

- Work hardening is limited compared to some alloys, but localized hardening can still occur in areas subjected to rubbing rather than cutting.

- Chip control can be challenging; short, segmented chips are common, and chip breaking features on tools are often beneficial.

Achieving predictable tool life and consistent surface integrity requires careful selection of cutting parameters, tooling materials, and coolant strategies.

Cutting Tool Materials and Coatings

Tooling selection has a significant effect on productivity and quality when machining Ti-6Al-6V-2Sn.

Carbide tools

Cemented carbide tools are widely used for turning, milling, and drilling operations:

- Fine-grain or ultra-fine-grain carbides with high hot hardness and toughness are typically preferred.

- Coated carbides with TiAlN, AlTiN, or similar high-temperature coatings can improve wear resistance and reduce chemical interaction with titanium.

- Sharp cutting edges and positive rake geometries help reduce cutting forces and heat generation at the tool-workpiece interface.

Ceramic and cermet tools

Ceramics and cermets can be used in some high-speed finishing operations but are more sensitive to interrupted cuts and thermal shock. They are generally more applicable to continuous turning operations with stable conditions and effective cooling or, in some cases, controlled high-speed dry cutting.

High-speed steel (HSS) tools

HSS tools may be used for low-speed drilling, tapping, or special tooling where carbide is not practical. Cobalt-containing HSS grades improve hot hardness. Tool life will typically be shorter than carbide, so they are mainly considered for specific operations or low-volume work.

Recommended Cutting Parameters

Optimized cutting parameters depend on machine capability, tool grade, tool geometry, and whether the operation is roughing or finishing. General ranges for carbide tooling when machining Ti-6Al-6V-2Sn can include:

Turning

- Cutting speed: commonly in the approximate range of 40 – 80 m/min for roughing and up to around 90 – 120 m/min for light finishing with appropriate tooling and coolant.

- Feed rate: typically 0.10 – 0.40 mm/rev for roughing and 0.05 – 0.20 mm/rev for finishing.

- Depth of cut: roughing depths may be 1 – 4 mm or more depending on rigidity; finishing passes are often 0.2 – 1.0 mm.

Lower speeds and moderate feeds help manage heat and extend tool life. The exact values should be adjusted based on machine rigidity, clamping, and required surface finish.

Milling

- Cutting speed: often in the range of 40 – 90 m/min, with preference for lower speeds in heavy or interrupted cuts.

- Feed per tooth: approximately 0.03 – 0.20 mm/tooth depending on tool diameter, number of flutes, and operation type.

- Radial and axial depth of cut: moderate radial engagement with higher axial depth can reduce heat concentration and tool deflection.

Using high-helix, sharp-edged cutters and climb milling strategies can improve tool life and surface finish. Avoiding rubbing and ensuring consistent chip load across the cutter is critical.

Drilling and tapping

For drilling, solid carbide or high-performance HSS drills with specialized geometries for titanium are commonly used. Typical practices include:

- Use of short, rigid drills with good chip evacuation capabilities.

- Cutting speeds generally lower than for turning, often 20 – 60 m/min, depending on drill type.

- Sufficient feed per revolution to maintain a continuous cutting action.

Tapping operations benefit from form taps or high-performance coated taps designed for titanium alloys. Lubrication is critical to avoid galling and thread damage.

Coolants, Lubrication and Thermal Management

Efficient heat removal and friction reduction are crucial when machining Ti-6Al-6V-2Sn due to its low thermal conductivity and tendency to concentrate heat at the cutting edge.

Coolant selection

- High-pressure, high-flow water-soluble cutting fluids are widely used, with additives that enhance lubricity and film strength.

- Oil-based fluids or minimum-quantity lubrication (MQL) can be used in certain operations but must ensure adequate cooling and chip evacuation.

- Coolant delivery should be directed precisely at the tool-workpiece interface and chip formation area.

In deep-hole drilling and other high-aspect-ratio operations, through-tool coolant delivery is highly beneficial for chip removal and temperature control.

Thermal management strategies

- Maintain steady, continuous cutting whenever possible to avoid thermal cycling of the tool.

- Avoid dwelling or rubbing; non-cutting contact between tool and workpiece increases heat and promotes workpiece surface damage.

- Use appropriate cutting parameters and tooling to minimize cutting forces and heat generation.

Thermal management measures help maintain dimensional stability, control residual stresses, and protect surface integrity, all of which are important in fatigue-critical components.

Surface Integrity and Finishing

Surface integrity is a key concern in Ti-6Al-6V-2Sn components used in high-stress, fatigue-sensitive applications. Machining must produce surfaces with suitable roughness, residual stress state, and microstructural condition.

Surface roughness and defects

- Proper tooling and cutting conditions can achieve low roughness values suitable for fatigue-critical surfaces.

- Tool wear and built-up edge must be monitored; worn tools can cause tearing, smearing, or surface microcracking.

- Inspection of machined surfaces for laps, chatter marks, and other anomalies is important to ensure consistent part quality.

Where required, finishing operations such as grinding, honing, or polishing can further reduce surface roughness, but must be controlled to avoid excessive heat input or surface damage.

Residual stresses and subsurface effects

- Cutting conditions influence residual stress profiles; appropriate selection can help induce favorable compressive stresses at the surface.

- Excessive mechanical or thermal loading during machining can lead to tensile residual stresses, microstructural transformation, or localized hardening.

- Processes such as shot peening or controlled burnishing may be employed after machining to optimize surface residual stress state.

Subsurface integrity is often verified by non-destructive evaluation and, for development programs, by metallographic examination of sectioned parts.

Welding, Joining and Repair Considerations

Welding of Ti-6Al-6V-2Sn is technically feasible but requires rigorous control of atmosphere and contamination to maintain mechanical properties. Conventional arc welding processes are used, such as gas tungsten arc welding (GTAW/TIG), with appropriate filler materials matching or compatible with the base alloy.

Welding practices

- Use of inert gas shielding (argon or helium) on both torch side and root side, often with trailing shields, is necessary.

- Strict cleanliness and removal of surface contaminants are required before welding.

- Heat input should be controlled to limit grain growth and preserve microstructural characteristics.

Post-weld heat treatment may be necessary to relieve residual stresses and adjust properties in the weld and heat-affected zones. Welded components used in highly stressed aerospace structures are typically subject to strict qualification and inspection requirements.

Mechanical fastening and hybrid joining

Mechanical fasteners made from titanium or compatible alloys are commonly used for joining Ti-6Al-6V-2Sn components in aerospace structures. Attention must be given to:

- Galvanic compatibility between titanium and other metals or coatings in the joint.

- Contact pressure, preload, and fatigue behavior of fastened joints.

- Use of surface treatments, sealants, or insulating materials to mitigate galvanic corrosion where dissimilar metals are unavoidable.

In some assemblies, adhesive bonding in combination with mechanical fastening is used to improve load distribution and stiffness.

Inspection and Quality Control

Given the critical service roles of Ti-6Al-6V-2Sn, thorough quality control is applied from raw material through finished parts.

Material certification

Material is typically accompanied by certificates that confirm conformity to applicable standards, including chemical composition, mechanical properties, and heat treatment condition. Traceability of melts, heats, and processing batches is often required in aerospace and energy sectors.

Nondestructive testing

Nondestructive testing methods used on Ti-6Al-6V-2Sn components may include:

- Ultrasonic inspection for internal defects such as porosity, inclusions, and forging-related indications.

- Radiographic testing in thick sections or complex geometries where ultrasonic coverage is limited.

- Fluorescent penetrant inspection of finished surfaces to detect cracks or surface-breaking flaws.

Inspection requirements are specified by design standards and customer specifications and are tailored to the criticality of each component.

FAQ about Ti-6Al-6V-2Sn

What is Ti-6Al-6V-2Sn?

Ti-6Al-6V-2Sn is a high-strength alpha-beta titanium alloy containing aluminum, vanadium, and tin. It is designed for applications requiring excellent strength, toughness, and performance at elevated temperatures.

What are the main advantages of Ti-6Al-6V-2Sn?

This alloy offers higher strength and better creep resistance at elevated temperatures than Ti-6Al-4V. It also provides good fatigue strength, fracture toughness, and corrosion resistance.

How does Ti-6Al-6V-2Sn compare to Ti-6Al-4V?

Compared to Ti-6Al-4V, Ti-6Al-6V-2Sn delivers higher strength and improved high-temperature performance, but it is generally more difficult to machine and less commonly used for general-purpose applications.

Is Ti-6Al-6V-2Sn weldable?

Ti-6Al-6V-2Sn has limited weldability compared to some other titanium alloys. Welding requires strict control of atmosphere and procedures, and is typically avoided for critical load-bearing components unless absolutely necessary.

What are the main machining difficulties with Ti-6Al-6V-2Sn?

Machining Ti-6Al-6V-2Sn is challenging primarily because of its low thermal conductivity, relatively high strength, and chemical reactivity with tool materials. Heat tends to concentrate at the cutting edge, increasing tool wear and the risk of built-up edge. Chip control can also be difficult, and dimensional accuracy is affected by elastic recovery, especially in thin sections. To address these issues, cutting speeds are kept moderate, sharp and wear-resistant tools are used, and high-pressure coolant is applied directly at the cutting zone.