Choosing between 3-axis and 5-axis CNC machining is a critical decision that directly affects part quality, manufacturability, cost, and delivery time. Both technologies remove material with high precision, but they differ significantly in the number of controlled motion axes, the complexity of geometry they can handle, and the economic profile of a job. This guide explains the technical differences, typical use cases, and decision criteria so that engineers, product designers, and buyers can select the most suitable option for each part.

Fundamentals of CNC Machining Axes

In CNC milling, “axes” refer to independent directions of controlled motion between the tool and the workpiece. More axes provide more degrees of freedom, which can reduce setups and enable machining of more complex geometries.

Linear and Rotary Axes

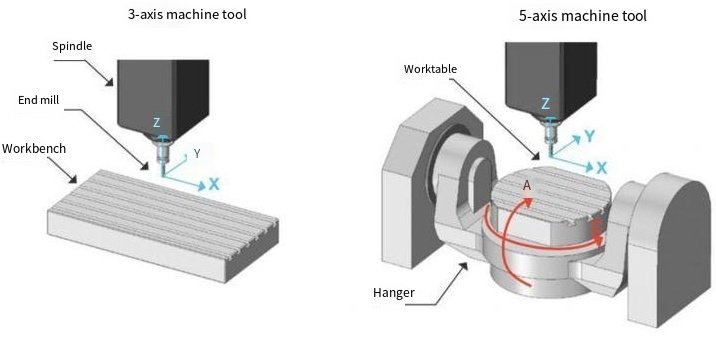

A typical milling center includes:

- Linear axes: X, Y, and Z, defining movement along three perpendicular directions.

- Rotary axes: additional A, B, or C axes that rotate either the table or the spindle around one of the linear axes.

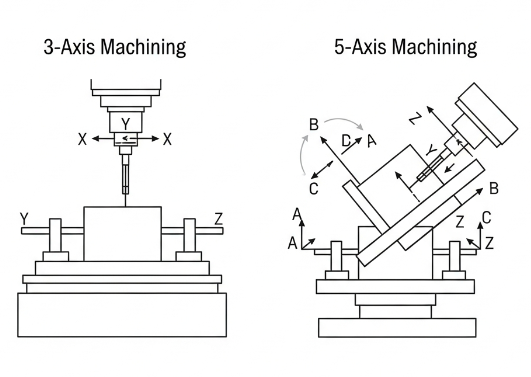

3-axis machining uses only X, Y, and Z. 5-axis machining uses X, Y, Z plus two rotary axes (commonly A and B, or B and C). These extra axes allow the tool to approach the part from multiple angles without reclamping the workpiece.

Simultaneous vs Indexed Motion

Multi-axis machines can operate in two main ways:

- Simultaneous (continuous) multi-axis: multiple axes move at the same time during cutting, enabling complex surface machining and smooth tool orientation changes.

- Indexed (3+2) multi-axis: rotary axes position the part or tool to a fixed orientation, after which cutting is performed using the 3 linear axes. The rotary axes do not move continuously during cutting.

Both approaches exist in 5-axis machining. 3-axis machining is inherently simultaneous in three linear directions but lacks the rotary degrees of freedom needed for more advanced surface strategies.

What Is 3-Axis Machining

3-axis machining is the most common and widely accessible CNC milling configuration. The cutting tool moves along X, Y, and Z axes relative to a stationary or simply translating workpiece. It is ideal for parts that can be fully machined from one or more primary directions without requiring undercuts or complex compound angles.

Typical 3-Axis Machine Configuration

A standard 3-axis vertical machining center (VMC) often has the following characteristics (typical, not universal):

- X travel: approximately 500–1,000 mm.

- Y travel: approximately 400–600 mm.

- Z travel: approximately 400–700 mm.

Spindle speeds can range from around 6,000 rpm for heavy-duty machines to 20,000 rpm or more for high-speed machining centers. Typical positioning accuracy is on the order of ±0.005–0.01 mm, with repeatability often better than ±0.003–0.005 mm when properly maintained and calibrated.

Geometries Suited to 3-Axis Machining

3-axis machining is well suited to parts with features accessible from a limited number of directions. Examples include:

- Flat or prismatic components with pockets, slots, and holes oriented along the principal axes.

- Simple 3D contours that do not require tool access from multiple compound angles.

- Parts that can be machined in a few setups using conventional fixtures.

Typical features include drilled and tapped holes, milled pockets and cavities, planar faces, and basic 3D surfaces where the tool can remain largely perpendicular to a single reference plane.

Common Applications of 3-Axis Machining

3-axis machines are used in a wide range of industries for both prototypes and production runs, including:

- Mechanical brackets, housings, and enclosures.

- Base plates, fixtures, and jigs.

- Simple molds and dies with straightforward parting lines.

- Structural components where all critical features are aligned with main axes.

What Is 5-Axis Machining

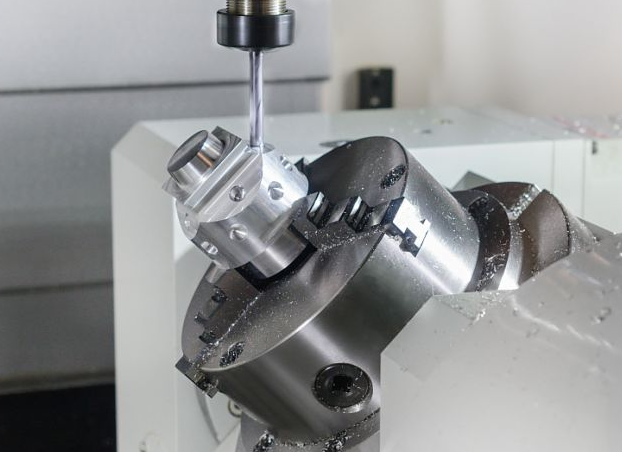

5-axis machining adds two rotary axes to the three linear axes, providing five controlled degrees of freedom. This can be achieved by rotating the table (trunnion type), the spindle head (swivel head type), or a combination of both. 5-axis machining can be either simultaneous (all axes moving during cutting) or indexed (3+2 positioning).

Types of 5-Axis Machines

The two most common architectures are:

- Trunnion-style 5-axis machines: the table tilts (around the X or Y axis) and rotates (around the Z axis). This is well suited to parts that can be mounted on a fixture or a rotary table and require access from multiple sides.

- Swivel-head 5-axis machines: the spindle head tilts and rotates, while the table generally remains stationary or has limited rotation. This configuration is often chosen for larger parts where rotating the entire workpiece is impractical.

Typical capabilities for a mid-range 5-axis machine might include:

- Linear travel lengths comparable to 3-axis machines (for example X up to about 800–1,000 mm).

- Rotary axes with rotation ranges from at least ±110° to full 360° for one or both axes.

- Positioning accuracy down to around ±0.005 mm or better with high-quality machines and appropriate calibration.

Simultaneous 5-Axis vs 3+2 Machining

5-axis machining is often categorized into:

- 3+2 (indexed) machining: The rotary axes orient the part to a fixed angle, then X, Y, and Z cuts are made. This allows access to multiple faces in a single setup but does not continuously change tool orientation along a surface.

- Simultaneous 5-axis machining: All five axes can move during cutting. This enables highly efficient toolpaths on complex curved surfaces, better surface finish on freeform geometry, and optimized tool engagement for long-reach cutting.

3+2 machining is commonly used to reduce the number of setups and reach multiple faces. Simultaneous 5-axis machining adds the ability to create complex geometries like turbine blades and impellers with continuous smooth toolpaths and controlled tool orientation.

Geometries Suited to 5-Axis Machining

5-axis machining is particularly beneficial for:

- Parts with deep cavities or steep walls where standard tools would collide or require excessive length.

- Undercuts and features obstructed from a single direction, requiring tool access at compound angles.

- Freeform surfaces and sculpted shapes requiring continuous, smooth tool orientation changes.

- Parts that must maintain tight tolerances across multiple faces relative to each other.

Key Technical Differences Between 3-Axis and 5-Axis

The choice between 3-axis and 5-axis machining impacts multiple aspects of part production. The following table summarizes core differences.

| Aspect | 3-Axis Machining | 5-Axis Machining |

|---|---|---|

| Controlled axes | X, Y, Z | X, Y, Z + 2 rotary axes (e.g., A, B or B, C) |

| Tool approach directions | Primarily along a single main axis per setup | Multiple orientations in one setup; tool can tilt/rotate to reach complex features |

| Number of setups | Often multiple; part reclamped for different faces | Fewer; many faces accessible in a single clamping |

| Typical achievable geometry | Prismatic parts, simple 3D contours | Freeform surfaces, deep cavities, undercuts, complex multi-face parts |

| Cycle time per part | Longer for complex parts due to multiple setups and manual handling | Shorter for complex parts because of consolidated setups and efficient toolpaths |

| Dimensional consistency over multiple faces | More dependent on setup alignment; stack-up of setup errors | Better relative accuracy between faces due to single setup capability |

| Programming complexity | Lower; standard CAM strategies | Higher; advanced 5-axis CAM and post-processing required |

| Machine investment | Lower capital cost, widely available | Higher capital cost, requires more specialized equipment |

| Operator and programmer skill level | Moderate | Higher, especially for simultaneous 5-axis |

Accuracy, Tolerances, and Surface Finish

Both 3-axis and 5-axis machining can achieve high accuracy and fine surface finishes when properly configured, but multi-axis capability can improve consistency and overall dimensional control on complex parts.

Dimensional Accuracy

Typical positioning accuracies for modern machining centers can be within ±0.005–0.01 mm, depending on machine quality, maintenance, and environmental conditions. In practice, achievable tolerances on parts are influenced by tooling, fixturing, material properties, and process parameters. For many applications:

- 3-axis machining can reliably hold tolerances on the order of ±0.02–0.05 mm on critical features, with tighter tolerances possible under controlled conditions.

- 5-axis machining can provide similar absolute tolerance capability but with improved relative accuracy between features on different faces because fewer setups are required.

When a part requires multiple faces to maintain tight positional relationships, 5-axis machining often reduces geometric deviations that could otherwise accumulate across separate setups in 3-axis machining.

Surface Finish

Surface finish quality depends on toolpath strategy, tool geometry, feed rates, spindle speed, and machine rigidity. 5-axis machining offers additional control over tool orientation, which can be used to:

- Maintain a constant angle of engagement to reduce tool marks.

- Use shorter, more rigid tools with less deflection, improving surface uniformity.

- Align the tool to the local surface normal on freeform surfaces, allowing finer stepovers and more consistent finish.

3-axis machining can achieve excellent surface finish on planar and simple contoured surfaces, but may require more passes or specialized strategies on complex geometry to reach equivalent results.

Setup, Fixturing, and Workholding Considerations

Workholding and setups are major contributors to machining time, cost, and accuracy. The number of setups affects not only labor but also cumulative positioning error.

Setups in 3-Axis Machining

In 3-axis machining, parts are commonly repositioned to access multiple faces. For a part with complex geometry or features on several sides, this can require:

- Multiple clampings (for example, top, bottom, and side faces).

- Custom fixtures or soft jaws for each orientation.

- Alignment operations to ensure consistent datum references across setups.

Each additional setup introduces potential misalignment and increases total cycle time due to manual handling and fixturing changes.

Setups in 5-Axis Machining

With 5-axis machining, the rotary axes allow access to many part surfaces in a single setup. This yields:

- Reduced need for re-clamping, lowering the chance of positional errors between features.

- Simplified fixturing, often relying on one robust fixture or vise instead of multiple dedicated fixtures.

- Shorter non-cutting time because fewer loading and alignment operations are required.

However, 5-axis workholding must still ensure adequate rigidity and clearance for the rotating movements. The fixture design must consider potential collisions with the spindle, tool holder, and machine structure during rotation.

Tooling and Toolpath Strategies

Tooling capabilities influence achievable geometries, cutting efficiency, and overall process stability. Toolpath strategies differ significantly between 3-axis and 5-axis machining, especially for complex parts.

Tool Length and Deflection

In 3-axis machining, reaching deep features often requires long tools. This increases deflection under cutting forces, potentially leading to:

- Dimensional inaccuracy at the bottom of deep cavities.

- Chatter and poor surface finish.

- Reduced permissible feed rates to maintain stability.

5-axis machining can tilt the tool or part to shorten the effective reach. This allows the use of shorter, stiffer tools for the same feature depth, reducing deflection and improving accuracy and surface quality.

Toolpath Generation

Typical 3-axis toolpaths include:

- 2.5D operations for pockets, profiles, and drilling.

- 3D contouring with constant Z-level or parallel finishing strategies.

5-axis toolpaths expand the range of possibilities to include:

- Swarf cutting, where the tool’s side is used along a surface at an angle.

- Multi-axis contouring that maintains a constant tool angle relative to the surface.

- Advanced roughing strategies that maintain stable tool engagement across complex geometry.

These strategies can improve material removal rates and surface consistency on complex parts. However, generating such toolpaths requires capable CAM software and careful collision avoidance planning.

Materials and Part Types

Both 3-axis and 5-axis machining can process a wide variety of materials, including aluminum alloys, steels, stainless steels, titanium, nickel-based superalloys, engineering plastics, and composites.

Material Considerations

Material characteristics such as hardness, toughness, and thermal conductivity influence cutting forces, heat generation, and tool wear. In many cases:

- For easily machinable materials (for example, common aluminum alloys), both 3-axis and 5-axis can achieve efficient machining, and the choice depends primarily on part geometry and quantity.

- For difficult-to-machine materials (for example, titanium or hard steels), the advantages of 5-axis—shorter tools, optimized tool orientation, and more efficient toolpaths—can help manage cutting forces and tool wear more effectively.

Part Categories Typically Matched to Each Process

The following table summarizes typical part categories aligned to 3-axis and 5-axis machining. These are general guidelines; actual selection depends on detailed design requirements.

| Part Category | More Commonly 3-Axis | More Commonly 5-Axis |

|---|---|---|

| Flat/prismatic components | Yes, especially with features on 1–2 sides | Used when many sides or tight multi-face relationships exist |

| Freeform surfaces | Limited; simple contours only | Preferred for complex 3D shapes and sculpted surfaces |

| Deep cavities with small radii | Possible but may require long tools, multiple setups | Well suited due to tool tilting and shorter effective tool length |

| Impellers, blisks, turbine blades | Generally unsuitable | Typical application for simultaneous 5-axis |

| Multi-face precision components | Requires multiple setups and careful fixturing | Often preferable due to single-setup capability |

| Simple brackets and plates | Common and efficient choice | Typically used only if other 5-axis work is present or features require it |

Cost Factors and Economic Considerations

Cost is influenced by machine time, labor, tooling, fixturing, and overhead. The relative cost of 3-axis and 5-axis machining depends on job complexity, batch size, and the specific capabilities of the supplier.

Machine and Hourly Rate

5-axis machines are generally more expensive to purchase and maintain, which can translate into higher hourly rates. However, they can offset this by:

- Reducing machining time for complex parts.

- Minimizing manual handling and setup time.

- Combining multiple operations into a single setup.

3-axis machines tend to have lower hourly rates and are widely available, making them cost-effective for simpler parts or for shops without 5-axis equipment.

Setup and Programming Time

3-axis machining typically involves straightforward programming and fixturing. This can be advantageous for:

- Short runs of simple parts where programming time must be minimized.

- Repetitive work where existing programs and fixtures are already available.

5-axis machining usually requires more advanced programming and simulation to avoid collisions and to optimize toolpaths. Initial setup and programming times may be higher, particularly for parts with complex surfaces or tight clearance conditions. Once established, these programs can lead to efficient production for recurring or high-value parts.

Lead Time and Throughput

Lead time includes design review, programming, fixturing, machining, and inspection. Throughput reflects how many parts can be produced within a given timeframe.

Lead Time for Prototypes

For simple prototypes:

- 3-axis machining can offer quick turnaround, especially when the part geometry is straightforward and does not require specialized fixtures.

- 5-axis machining may add programming effort but can reduce physical setup time when multiple faces or complex geometry are involved.

For complex prototypes:

- 5-axis machining often compresses lead time by reducing the number of setups and enabling direct machining of complex surfaces without intermediate processes.

Production Throughput

In production scenarios, 5-axis machining can improve throughput for complex parts by:

- Reducing cycle time through efficient tool orientation and fewer tool changes.

- Minimizing part handling between operations.

- Allowing combined operations that might otherwise require multiple machines.

For parts with simple geometry, 3-axis machining can provide high throughput, particularly when multiple machines are available or when setups are already optimized.

Design Considerations for 3-Axis vs 5-Axis Machining

Designing with the target machining process in mind helps ensure manufacturability, control cost, and maintain functional requirements.

Designing for 3-Axis Machining

When designing parts primarily for 3-axis machining, consider:

- Aligning critical features with the main machine axes where possible.

- Avoiding features that require long tools or extreme depth-to-diameter ratios if not essential.

- Minimizing undercuts and internal features that cannot be reached from straightforward tool directions.

- Grouping features by orientation so that they can be machined in the same setup.

These practices reduce the number of setups and special tools needed, improving accuracy and reducing cost.

Designing for 5-Axis Machining

When designing for 5-axis machining:

- Take advantage of the ability to access multiple sides; complex curves, angled features, and compound holes can often be realized efficiently.

- Ensure that the model includes clear datums and reference features to support single-setup strategies.

- Consider tool clearance: even with rotary axes, the tool, holder, and spindle must avoid collisions with the part and fixture.

- Use consistent radii and transitions where possible to simplify toolpath generation and enable efficient tool selection.

Collaborating with the machining provider during the design phase can identify minor geometry adjustments that significantly improve manufacturability on a 5-axis machine.

Inspection and Quality Control Implications

The ability to machine multiple faces in a single setup has implications for inspection and quality control procedures.

Datum Management

In 3-axis machining with multiple setups, each setup must be aligned to the same datum structure. Small variations in fixture mounting or zero-point settings can introduce relative position errors between features. Additional inspection steps may be required to verify that multi-face relationships remain within tolerance.

With 5-axis machining, more critical features can be produced in a single datum setup, simplifying datum management and often reducing the number of intermediate inspection points. This can increase confidence that dimensional relationships between faces are maintained.

In-Process Measurement

Both 3-axis and 5-axis machines can be equipped with probes for in-process measurement. This allows:

- Automatic setting and verification of work offsets.

- In-cycle inspection of critical features for process control.

On 5-axis machines, probing can be especially useful for complex parts, ensuring that the single-setup strategy remains accurate throughout the operation and that any adjustments are made before finishing passes.

When 3-Axis Machining Is the Better Choice

3-axis machining remains the most practical choice for many parts. It is often the best option when:

- The part has simple geometry with features accessible from a limited number of orientations.

- Tolerances are moderate and do not require tight multi-face relationships.

- Production volumes are low to moderate and do not justify more complex 5-axis programming.

- Cost minimization is critical and multiple suppliers with 3-axis capability are available.

Examples include brackets, plates, simple housings, covers, and many fixture components. For these parts, 3-axis machining can deliver the required quality and precision at a competitive cost with straightforward programming and fixturing.

When 5-Axis Machining Is the Better Choice

5-axis machining is typically the preferred solution when part geometry or performance requirements exceed the practical limits of 3-axis machining.

Complex Geometry and Freeform Surfaces

Parts with complex 3D shapes, variable curvature, or multiple interacting surfaces benefit greatly from simultaneous 5-axis machining. Continuous control of tool orientation enables efficient machining of features that would otherwise require multiple 3-axis setups or compromise design intent.

Multi-Face Precision Requirements

When a part requires tight tolerances across several faces—such as in many aerospace, medical, or high-performance industrial components—it is advantageous to produce all critical features in a single setup. 5-axis machining enables this by rotating the part so that each feature can be machined relative to a common datum framework.

Deep Cavities and Difficult-to-Reach Features

5-axis machines can tilt the tool to reduce the effective reach into deep cavities, reducing the risk of tool deflection and collision. This allows tighter control over dimensions and surface finish in areas that would otherwise be challenging for 3-axis machining.

How to Decide: A Practical Selection Framework

Choosing between 3-axis and 5-axis machining for a specific part can be approached systematically by evaluating several key factors.

1) Evaluate Part Geometry

Consider:

- Number of faces requiring machining and their spatial relationships.

- Presence of undercuts, deep pockets, and complex contours.

- Tool access from straight directions vs the need for compound angles.

If all critical features are accessible from a few straightforward directions, 3-axis may be sufficient. If accessing all features requires multiple complex orientations or long-reach tools, 5-axis is often more appropriate.

2) Assess Tolerance and Surface Requirements

Review:

- Required dimensional tolerances between features on different faces.

- Surface finish requirements, especially on curved or critical surfaces.

When tight tolerances must be maintained across multiple faces or complex surfaces, 5-axis machining, especially in a single-setup strategy, can provide higher consistency and reduce tolerance stack-up.

3) Consider Quantity and Lifecycle

For very low volumes or one-off prototypes of simple parts, the lower programming and setup effort of 3-axis machining can be advantageous. For higher volumes, long-term programs, or parts that will be manufactured repeatedly, investing in 5-axis programming may be justified by lower cycle times and improved quality, particularly for complex parts.

4) Analyze Cost vs Value

Balance:

- Per-part machining cost, including programming, setup, and machine time.

- The functional value of precision, surface quality, and geometric complexity to the end product.

For parts where performance, assembly fit, or reliability depend heavily on precise, complex geometry, 5-axis machining can provide substantial value even if the direct machining cost is higher.

5) Engage with the Machining Supplier Early

Sharing the 3D model, 2D drawings, and functional requirements with potential suppliers at an early stage allows them to recommend whether 3-axis or 5-axis machining is more appropriate. They can identify:

- Features that might require 5-axis machining.

- Opportunities to simplify geometry for 3-axis machining without compromising function.

- Potential fixturing strategies and their impact on cost and lead time.

Summary: 3-Axis vs 5-Axis Machining

3-axis machining offers a robust, widely accessible, and cost-effective solution for many parts, especially those with simpler geometry and moderate tolerance requirements. Its strengths include lower equipment cost, straightforward programming, and high efficiency for prismatic parts with features that are readily accessible from a few orientations.

5-axis machining significantly expands the range of manufacturable geometries and improves control over multi-face features and complex surfaces. It can reduce setups, improve relative accuracy, enable shorter and more rigid tools, and provide more efficient machining of deep or intricately shaped features. These advantages become particularly important for parts with demanding dimensional, geometric, or functional requirements.

The best choice depends on a careful evaluation of the part’s geometry, tolerance and surface requirements, quantity, and cost targets. By understanding the capabilities and trade-offs of both 3-axis and 5-axis machining, designers and engineers can select the most appropriate process and achieve the desired balance of performance, quality, and cost for each project.

FAQ: Common Questions About 3-Axis and 5-Axis Machining

Is 5-axis machining always more precise than 3-axis machining?

5-axis machining is not automatically more precise than 3-axis machining in terms of absolute tolerance capability. Both types of machines can achieve high precision, and the actual accuracy depends on machine quality, calibration, tooling, fixturing, and process control. However, 5-axis machining can improve relative accuracy between features on different faces because many of them can be produced in a single setup. This reduces the cumulative errors caused by multiple setups in 3-axis machining, leading to better consistency for complex multi-face parts.

When is 3-axis machining sufficient for my part?

3-axis machining is usually sufficient when your part has relatively simple geometry, with features that can be accessed from one or a few directions using standard tools. If critical features are aligned with the main axes and do not require complex compound angles, deep cavities, or undercuts, a 3-axis machine can produce the part efficiently and accurately. For brackets, plates, basic housings, and many fixture components, 3-axis machining often provides the best balance of cost, lead time, and quality.

Does 5-axis machining always reduce part cost?

5-axis machining does not always reduce part cost. While it can significantly lower machining time and setups for complex parts, 5-axis machines typically have higher hourly rates and require more advanced programming. For simple parts that can be easily produced on 3-axis equipment, 5-axis machining may not offer a cost advantage. It becomes economically beneficial when the part’s complexity, multi-face precision requirements, or repeated production volumes allow the savings in machining and handling time to outweigh the higher machine and programming costs.

Can any 3-axis part be made on a 5-axis machine?

In general, yes—most parts that can be produced on a 3-axis machine can also be machined on a 5-axis machine, provided the work envelope and fixturing allow it. In many cases, the 5-axis machine will run the part using 3-axis strategies or simple 3+2 positioning. This can be useful in shops where 5-axis machines are available and scheduling flexibility is needed. However, using 5-axis for very simple parts may not be cost-efficient if a 3-axis machine is readily accessible at a lower hourly rate.

Do I need special CAD/CAM software for 5-axis machining?

Yes, practical 5-axis machining requires CAM software that supports 5-axis or 3+2 toolpaths and provides collision avoidance, tool orientation control, and suitable post-processors for the machine. While basic 3-axis CAM can generate toolpaths for simple parts, it cannot fully exploit the capabilities of a 5-axis machine. For production work with complex geometry, investing in appropriate 5-axis CAM software and post-processing is essential to ensure safe, efficient, and accurate machining.