Our Factory

At XCM, our production strength comes from a highly modernized workshop system and a continuously expanding fleet of advanced manufacturing equipment. Designed for efficiency, accuracy, and scalability, our facilities enable us to deliver precision parts from prototype to mass production with consistent quality.

Our workshops are divided into specialized zones—including CNC milling, CNC turning, 5-axis machining, sheet metal fabrication, 3D printing, quality inspection, and surface finishing—ensuring a streamlined and professional workflow. Each area follows strict ISO9001, ISO13485, and IATF16949 standards, supported by real-time process monitoring and professional engineering teams.

Workshops and Machines

DMU80 MonoBlock Universal Machining Center By DMG Germany Maximun Working Travel: 800MM X 650 MM X 550MM Max. Speed: 20,000(RPM)

DMU75 MonoBlock Universal Machining Center By DMG Germany Maximun Working Travel 750MM X 650 MM X 560MM Max. Speed:65 X 50 X 80 (m/min)

The Mikron MILL E 500 U By GF Machining Solutions UK Maximun Working Travel: 500MM X 450 MM X 400MM Max. Speed: 20,000 (RPM)

G550 5-Axis Universal Machining Center By GROB Germany Maximun Working Travel: 800MM X 1020 MM X 970MM Max.Speed: 65/50/80(m/min)

Mazak Milling complex machining center Specifications: QTN100MSY/KS 18,000 rev / min Accuracy: 0.003mm (Linear encoder)

Matsuura 5-Axis matsuura nx- 520 18,000 rev / min Accuracy: 0.005mm (Linear encoder)

Mazak 9-Axis Mill&Turn Center Specifications:INTEGFEX 1- 200S 24,000 rev / min Accuracy: 0.003mm (Linear encoder)

5-Axis High-Speed Gantry Machining Center By APEC Tai Wan China Maximun Working Travel: 4000MM X 2500 MM X 1000MM Max. Speed: 24,000 (RPM)

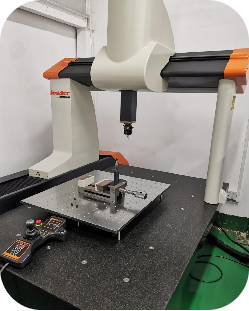

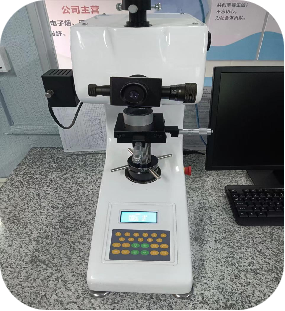

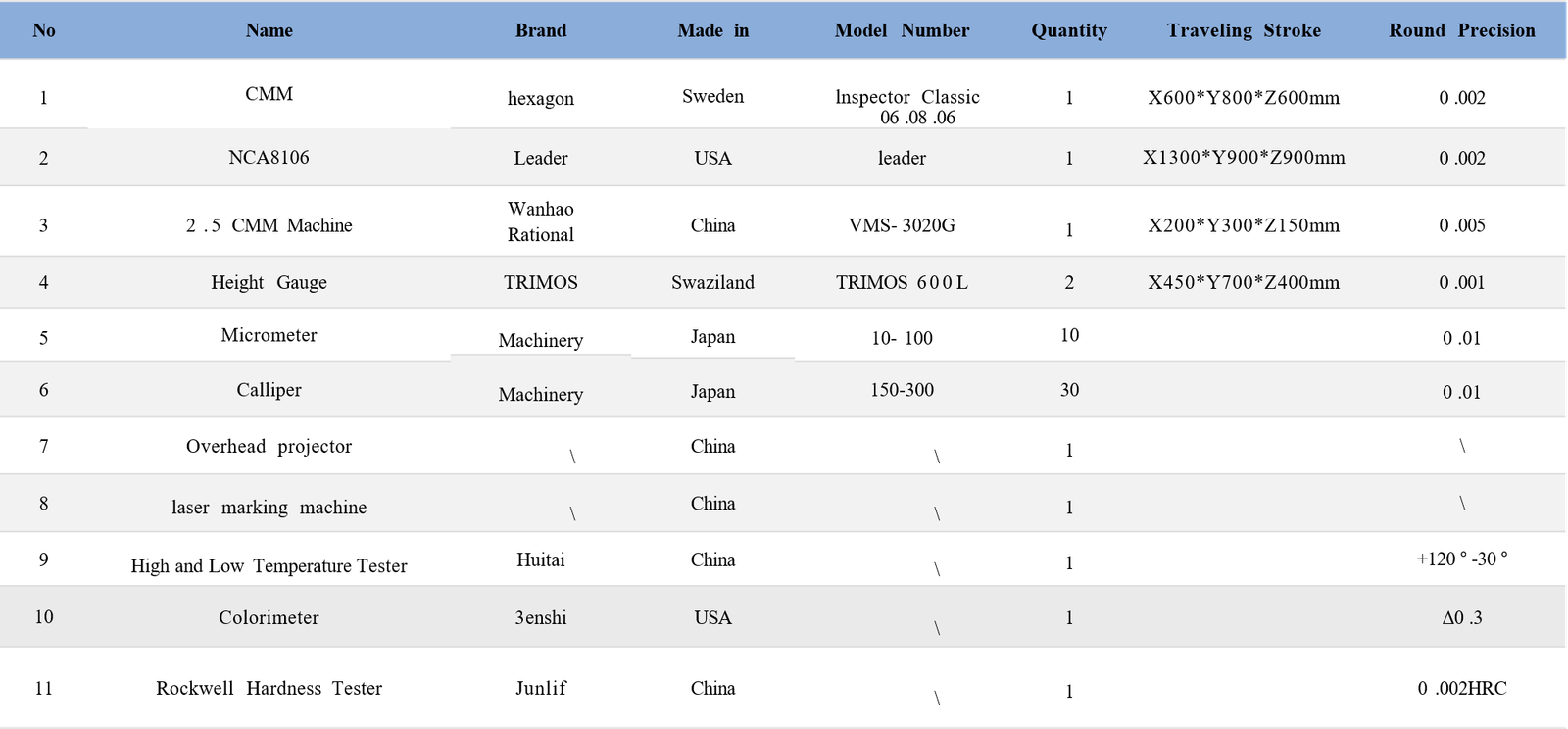

Quality Control Equipments

Adhering to ISO9001 standards, XCM established a robust quality management system. XCM prioritized customer satisfaction and continuous improvement. Our development strategy revolves around closely customers’needs.We employ strategic approaches like SPQP and PMP, along with control methods such as SPC and DFMEA. In case of any issues, we implement corrective measures using the 8D method, while ensuring precise measurement analysis through MSA to uphold quality standards. To further assure the quality of our products,we possess the top notch inspection equipment and provide comprehensive documentation including FAI Reports, Full Dimensional Reports and Material Certifications.