DFM (Design for Manufacturability) is a crucial engineering principle in product development. It refers to fully considering the feasibility, efficiency, and cost of manufacturing processes at the product design stage, ensuring that the product can be stably produced at lower cost, with higher quality, and at greater speed.

Simply put, it means “you should think about how to make it while you design it,” so that the product is easy to manufacture, easy to assemble, less prone to errors, and cost-effective.

DFM is not about “picking faults,” but about “turning good designs into good products.” It represents a sense of design responsibility and a way of thinking. Designers need to be accountable for whether their designs can actually be manufactured. This is the true essence of “engineering thinking.”

As the saying goes:

“You can’t inspect quality into a product, you must design it in.”

You cannot add quality into a product through inspection; you must design it in from the very beginning.

DFM is one of the key paths to realizing this concept.

Why implement DFM?

Implementing DFM is not just a “nice-to-have,” but a critical step in product development. It is directly related to product cost, quality, delivery lead time, and market competitiveness. DFM turns “firefighting after the fact” into “preventive action up front,” serving as a strategic tool to control quality and cost at the source.

1. Avoid “good-looking design that cannot be manufactured” — bridging the gap between design and manufacturing

Many engineers create perfect designs on the computer, only to find at the factory that a certain structure requires five-axis CNC machining, making the cost extremely high; plastic parts are too thin to be properly filled; or the assembly space is too small for operators to reach in with their hands.

The role of DFM is to bring in manufacturing process knowledge at the design stage, ensuring that designs are machinable, assemblable, and testable. It’s like checking the foundation and construction conditions before building a house, instead of just drawing beautiful blueprints.

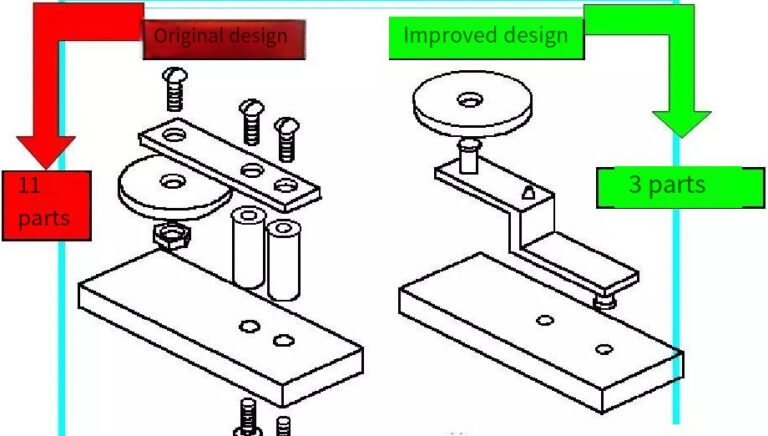

2. Significantly reduce manufacturing costs

DFM can reduce waste at the source, decrease the number of parts (one less part = one less item to purchase, machine, inspect, and assemble), select more cost-effective materials or processes, and simplify structures to reduce machining time.

For example, a home appliance company optimized its design through DFM and reduced the number of housing components from 8 to 3, cutting the per-unit manufacturing cost by 18%.

3. Improve product quality and consistency

DFM helps set tolerances reasonably, avoid stress concentrations, and increase assembly tolerance (such as through mistake-proofing designs), making the manufacturing process more stable. This reduces defect rates, rework, and customer complaints. The goal is to “enable ordinary people using ordinary equipment to make good products.”

4. Shorten product development cycles and speed up time-to-market

Without DFM, you often see repeated loops of design, trial production, problem discovery, design modification, another trial run, and more modifications, which can drag on for months.

With DFM, manufacturing risks are anticipated during the design stage so things are done right the first time, reducing the number of trial builds.

5. Increase production efficiency and yield

With DFM-optimized designs, machining steps can be reduced, assembly becomes simpler, and testing is easier. This directly shortens unit production time, makes frontline operations smoother, and lowers process defect rates.

6. Enhance manufacturability and collaboration across the supply chain

Good designs enable more suppliers to have the capability to undertake production, avoiding reliance on “exclusive processes” or “special equipment,” thereby increasing negotiation leverage and reducing supply risks.

At which stages should DFM be applied?

Implementing DFM (Design for Manufacturability) is not a one-time task, but a continuous activity throughout the entire product development cycle. The earlier it is introduced, the more it can deliver its value in “problem prevention, cost reduction, and efficiency improvement.” Conversely, the later the issues are discovered, the higher the price to pay.

It is recommended to establish “DFM mandatory review checkpoints” at each stage of product development to ensure every project undergoes manufacturability assessment.

| Stage | Key DFM Activities |

|---|---|

| Concept Design | Process selection, material matching |

| Detailed Design | Structural optimization, tolerance design |

| Design Review | Cross-functional review, DFM report |

| Prototype Build | Issue exposure, minor design adjustments |

| Pilot Run | Mass production feasibility confirmation |

| Mass Production & Changes | Continuous optimization, change review |

1. Concept design stage (Concept Design)

Once product requirements are defined and initial concepts are being explored, DFM can be introduced to avoid manufacturing issues from the very beginning.

DFM focus areas:

- Select appropriate manufacturing processes (such as injection molding, stamping, machining, 3D printing);

- Conduct preliminary feasibility assessment of materials;

- Determine whether modular and standardized design can be adopted;

- Avoid overly complex or non-standard structures.

For example, when designing a housing, first consider whether injection molding can be used instead of defaulting to CNC machining.

2. Detailed design stage (Detailed Design)

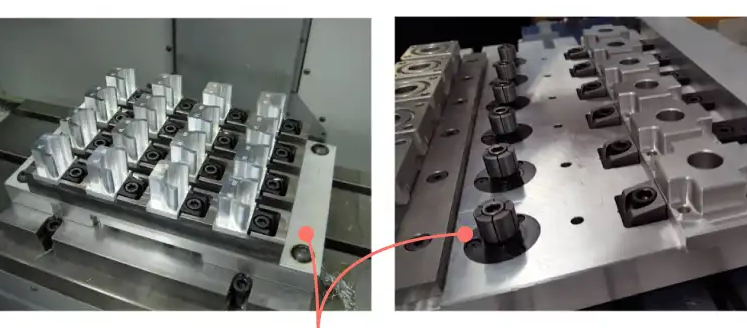

When 3D modeling and engineering drawings are being produced, DFM can be involved to optimize details and ensure manufacturability.

DFM focus areas:

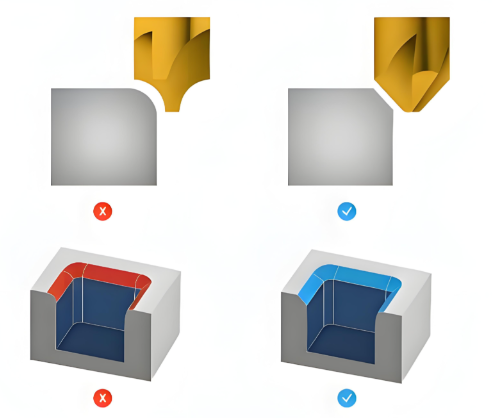

- Check whether wall thickness, draft angle, ribs, and fillets meet process requirements (e.g., for injection-molded parts, avoid abrupt thickness changes);

- Ensure tolerances are reasonable (tight control for critical dimensions, relaxed tolerances for non-critical ones);

- Confirm that mold opening and demolding are feasible;

- Ensure allowance for assembly space, test points, and fixture locating holes.

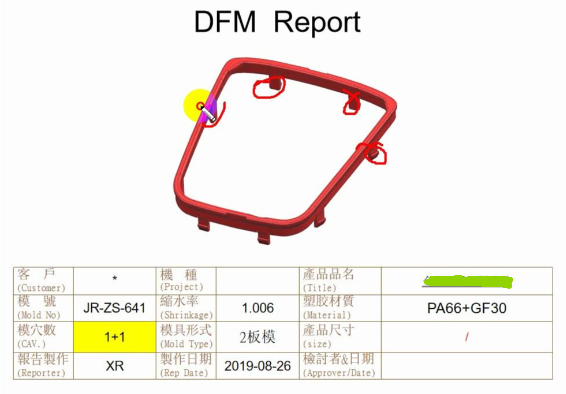

At this stage, use DFM checklists, Moldflow (injection molding simulation), and process review meetings.

3. Design review stage (Design Review)

The right time to intervene is before design freeze, making DFM review approval a prerequisite for entering the next stage.

DFM focus areas:

- Organize participation from Manufacturing (PE), Process (ME), Quality (QE), Purchasing/Supplier Quality (SQE), etc.;

- Issue a formal DFM report with improvement recommendations;

- Confirm that all manufacturing risks have been identified and closed.

4. Prototype / trial build stage (Prototype / EVT)

When mock-ups or the first batch of samples are made, DFM can be applied to verify how the design performs under real manufacturing conditions. The purpose of trial builds is not just to look good, but to uncover problems.

DFM focus areas:

Observe whether the following issues occur during trial builds:

- Machining difficulties, deformation, burrs;

- Assembly jamming or misalignment;

- Surface defects (sink marks, flash, weld lines);

- Collect feedback from production lines and make minor design adjustments.

5. Pilot run stage (Pilot Run / DVT/PVT)

The right time to intervene is during small-batch pilot runs (100–1000 units) to verify mass production feasibility. The final DFM closure report then serves as the basis for mass production release.

DFM focus areas:

- Evaluate whether production takt time meets the target;

- Track First Pass Yield (FPY);

- Check whether jigs, fixtures, and test equipment fit the design;

- Optimize the design based on pilot run issues (e.g., add guide pins, modify locating methods).

6. Mass production (MP) and post-change stages

DFM should continue during mass production and design changes for ongoing optimization and adaptation.

DFM focus areas:

- Collect long-term manufacturing issues from production lines and iterate the design;

- Ensure any Engineering Change Notice (ECN) goes through a renewed DFM assessment;

- Promote “continuous improvement in manufacturability” (Continuous DFM Improvement).

How to implement DFM?

DFM is not a single action, but a systematic, cross-functional engineering process. By combining methods, tools, and practical key points, it helps you move from “knowing” to “doing.”

The key to successful DFM implementation is top management support, integrating DFM into mandatory project milestones, establishing enterprise-level DFM standards and checklists, and leveraging digital tools to embed DFM processes into PLM/MES systems, and so on.

Step 1: Build a cross-functional team

Manufacturing and quality personnel should be involved from the early design stages, not only after the drawings are completed. Breaking down the barrier between design and manufacturing ensures multiple perspectives are included.

Typical team members:

- Product design engineers (lead)

- Manufacturing/Process engineers (PE/ME)

- Quality engineers (QE)

- Production line supervisors

- Purchasing/Supplier quality (SQE)

- Mold/Equipment engineers (if applicable)

Step 2: Define manufacturing processes and constraints

This ensures designs are grounded in reality and aligned with actual production capabilities.

Information that needs to be confirmed:

| Process Type | Key Constraints |

|---|---|

| Injection Molding | Minimum wall thickness, draft angle, rib ratio, weld line position |

| Stamping/Sheet Metal | Minimum flange length, hole-to-edge distance, blank size, tool life |

| Machining (CNC) | Tool accessibility, clamping method, machining time, tolerance capability |

| PCB Assembly (SMT) | Component layout, pad design, test point reservation |

| Assembly Line | Assembly sequence, ergonomics, mistake-proofing design |

Tool support:

- Use Moldflow (injection molding simulation);

- Use Sheet Metal Design Guides;

- Refer to internal “Process Capability Manuals.”

Step 3: Use a DFM checklist for step-by-step review

This systematically identifies potential manufacturing issues. Enterprises should develop and continuously update dedicated DFM checklists according to their product types (such as electronics, automotive, home appliances).

Example: Injection-molded part DFM checklist (partial)

| Check Item | Meets Requirement? | Notes |

|---|---|---|

| Is the wall thickness uniform? | ☐ Yes ☐ No | Avoid abrupt thickness changes that cause sink marks |

| Is there sufficient draft angle (≥1°)? | ☐ Yes ☐ No | 1–3° is recommended for external surfaces |

| Is rib thickness 0.6–0.8 times main wall thickness? | ☐ Yes ☐ No | Prevents sink marks and stress concentration |

| Are sharp corners avoided? Are fillets applied? | ☐ Yes ☐ No | Fillets increase strength and improve flow |

| Has the mold parting line location been considered? | ☐ Yes ☐ No | Avoid parting lines on critical cosmetic surfaces |

| Is ejection easy? | ☐ Yes ☐ No | Avoid whitening or deformation during ejection |

Step 4: Conduct DFM review meetings

Bring everyone together to discuss, reach consensus, and close the loop.

Typical meeting flow:

- Design engineer presents the design;

- Manufacturing/process engineers raise issues and suggestions;

- Quality engineers evaluate potential risks (e.g., linked with FMEA);

- Record all issues, assign responsible owners and due dates;

- Issue a “DFM Review Report” that includes identified problems, improvement suggestions, risk levels (high/medium/low), closure status, and signatures.

Step 5: Verification and closure (Prototype → Pilot Run)

Use real-world results to validate DFM effectiveness.

Verification methods:

- Prototype stage: check machining difficulty and assembly smoothness;

- Pilot run stage (PVT): track First Pass Yield (FPY), cycle time, and defect types;

- Feedback and closure: feed manufacturing issues back into design and iterate for optimization.