CNC coolant, also called metalworking fluid or cutting fluid, is a liquid or semi-liquid medium used during machining to cool, lubricate, and protect both cutting tools and workpieces. Proper coolant selection, mixing, and maintenance are critical to dimensional accuracy, tool life, surface finish, and shop reliability.

Core Functions of CNC Coolant

CNC coolant performs multiple roles simultaneously. Understanding these functions helps you choose and manage fluids that match your machining operations, materials, and equipment.

Cooling and Heat Removal

Machining generates significant heat at the cutting zone due to plastic deformation and friction. Excessive temperature can soften cutting tools, cause thermal expansion in the workpiece, and degrade dimensional accuracy.

- Coolant absorbs heat from the tool and chip.

- Flowing coolant transports heat away from the cutting zone.

- Stable temperature reduces thermal distortion and helps maintain tolerances.

High-speed and high-feed operations especially depend on aggressive cooling to prevent tool edge break-down and workpiece burning.

Lubrication and Friction Reduction

Lubrication reduces direct metal-to-metal contact between tool and workpiece. This lowers cutting forces and improves surface integrity.

- Boundary lubrication forms a thin protective film on tool and workpiece.

- Reduced friction decreases wear mechanisms such as abrasion and adhesion.

- Improved chip sliding lowers cutting power and spindle load.

Operations like tapping, reaming, broaching, and deep-hole drilling particularly rely on strong lubricity to avoid galling and tool breakage.

Chip Evacuation and Flushing

Chips retained in the cutting zone cause recutting, notching, and surface damage. Coolant helps transport chips away from the cutting interface.

Key effects:

- High-volume flood or through-tool coolant flushes chips from deep pockets and holes.

- Improved visibility in the cutting area for manual interventions.

- Reduced risk of chip welding or packing in flutes and grooves.

Surface Finish and Dimensional Stability

Effective coolant application improves surface finish by controlling temperature and friction and by preventing chip re-cutting.

Benefits include:

- Reduced tool chatter and built-up edge formation.

- Fewer burrs and micro-cracks.

- More consistent size and roundness, especially in tight-tolerance bores and shafts.

Tool Life and Cost Impact

Coolant directly influences tool life, which in turn affects cost per part and machine uptime.

Proper coolant selection and maintenance can:

- Reduce flank wear and crater wear rates.

- Limit thermal shock in carbide and ceramic tools.

- Decrease unexpected tool breakage.

Over time, consistent coolant management can significantly reduce tooling costs and scrap rates.

Major Types of CNC Coolant

Metalworking fluids for CNC machining are normally grouped into several main categories, each with distinct properties, advantages, and drawbacks. Selection depends on materials, processes, machine configuration, and environmental conditions.

| Coolant Type | Base Composition | Typical Use Cases | Key Characteristics |

|---|---|---|---|

| Straight Oils | Undiluted mineral or synthetic oils, often with EP additives | Heavy-duty cutting, tapping, broaching, difficult alloys | Excellent lubricity, poor cooling, high mist and smoke potential |

| Soluble Oils (Emulsions) | Oil-in-water emulsion, typically 60–90% oil in concentrate | General-purpose machining of steels, cast iron | Good lubrication, moderate cooling, milky appearance |

| Semi-Synthetic Fluids | Lower oil content (5–30%) plus synthetic components | Mixed-material shops, CNC milling and turning | Balanced cooling and lubricity, better cleanliness |

| Fully Synthetic Fluids | Water-based, no mineral oil, synthetic additives | High-speed machining, grinding, aluminum, cast iron | Excellent cooling, low residue, low foaming when matched correctly |

| Specialty Fluids | Ester-based, vegetable-based, fire-resistant, etc. | Environmental requirements, specific aerospace or medical uses | Tailored properties; must follow manufacturer’s guidance |

Straight Oil Coolants

Straight oils are undiluted petroleum or synthetic oils, sometimes blended with fatty oils, sulfur, chlorine, or phosphorus extreme-pressure additives. They provide maximum lubricity and are common in:

- Threading and tapping of alloy steels.

- Gear hobbing, shaping, and broaching.

- Deep-hole drilling and gun drilling.

Limitations include lower heat capacity, higher mist and smoke, and potential fire risk if not managed correctly.

Soluble Oil (Emulsion) Coolants

Soluble oils are concentrates that form a milky oil-in-water emulsion when mixed with water. They are widely used due to their versatility and relatively low cost.

Typical features:

- Good lubricity for turning, milling, and drilling.

- Adequate cooling for moderate cutting speeds.

- Suited to ferrous materials; some formulations adapted for aluminum.

They can be more prone to bacterial growth and tramp oil contamination, so monitoring and maintenance are important.

Semi-Synthetic Coolants

Semi-synthetics combine reduced oil content with synthetic components for an intermediate behavior between soluble oils and synthetics.

Advantages:

- Cleaner machines and parts due to lower oil content.

- Improved cooling compared with soluble oils.

- Smaller, more stable microemulsions that resist separation.

They are popular in CNC job shops handling a wide mix of metals and operations.

Fully Synthetic Coolants

Fully synthetic fluids contain no mineral oil. They are usually clear or slightly colored and rely on chemical additives for lubrication and corrosion protection.

Typical applications:

- High-speed milling and turning.

- Grinding operations where heat removal is critical.

- Machining of aluminum and cast iron where cleanliness is important.

They generally offer excellent cooling, low foam when correctly selected, and good sump life with proper maintenance.

Key Properties and Performance Parameters

CNC coolants are defined not only by type but also by measurable properties that influence machining behavior and maintenance requirements.

Concentration and Mixing Ratios

Water-miscible coolants must be diluted with water to a specific concentration. Concentration is usually expressed as a percentage of concentrate in water.

| Operation Type | Typical Concentration Range (% by volume) | Remarks |

|---|---|---|

| Light machining / grinding | 3–5% | Focus on cooling; lower lubricity requirements |

| General turning and milling | 5–8% | Balanced cooling and lubrication |

| Heavy-duty cutting / tapping | 8–12% | Higher lubricity and EP performance |

| Broaching / deep-hole drilling | 10–15% (or as specified by supplier) | Very high load and friction conditions |

Actual values must follow manufacturer recommendations based on coolant type and material. Concentration is commonly checked with a refractometer and corrected by adjusting for the coolant’s refractometer factor.

Viscosity

Viscosity affects how coolant flows, penetrates the cutting zone, and forms a lubricating film.

- Lower viscosity: better heat transfer and flow, favored for high-speed machining and grinding.

- Higher viscosity: improved boundary lubrication, often used in heavy-duty cutting oils.

Coolant suppliers specify kinematic viscosity (commonly at 40°C) to help match fluids to application needs.

pH and Corrosion Control

Water-miscible coolants are formulated with a controlled pH, typically in the mildly alkaline range. Typical working pH values are approximately 8.0–9.5, depending on chemistry.

Functions of correct pH:

- Minimizes corrosion of machine tool components and workpieces.

- Helps resist bacterial growth.

- Maintains additive stability and lubricity.

Low pH can promote rust and skin irritation; excessively high pH may attack aluminum or paint and increase operator discomfort.

Foaming Characteristics

Foam can cause pump cavitation, inconsistent coolant delivery, and overflow. Foaming behavior depends on coolant chemistry, water hardness, and system design.

Typical considerations:

- High-pressure, high-flow systems require low-foam formulations.

- Very soft water can increase foam; moderate hardness is often preferred.

- Aeration from falling coolant streams and leaks on suction lines can aggravate foam.

Biostability and Odor

Coolant sumps can be contaminated with bacteria and fungi, especially at low concentrations or when idle for long periods. Biodegradation leads to unpleasant odors, pH drop, and loss of performance.

Biostable coolants are formulated to resist microbial attack and maintain stable performance over longer intervals. Good housekeeping and regular monitoring remain necessary.

Common CNC Coolant Delivery Methods

The way coolant is delivered to the cutting zone is as important as the coolant type. Different methods provide different levels of penetration, chip evacuation, and visibility.

Flood Coolant

Flood coolant systems deliver a continuous, high-volume flow of coolant over the cutting area.

Features:

- Common in vertical machining centers and CNC lathes.

- Effective for chip flushing and overall cooling.

- Simple plumbing and control compared with more complex systems.

Flood coolant is suitable for most general milling, turning, and drilling operations.

Mist and Minimum Quantity Lubrication (MQL)

Mist systems atomize a small amount of coolant into fine droplets carried by compressed air. MQL systems use extremely low fluid volumes, focusing on lubrication rather than bulk cooling.

Typical uses:

- Light to medium cutting of aluminum and nonferrous materials.

- Applications where minimal cleanup is required.

- High-speed operations with emphasis on lubrication at the cutting edge.

Proper enclosure and extraction are important to protect operators from airborne mist.

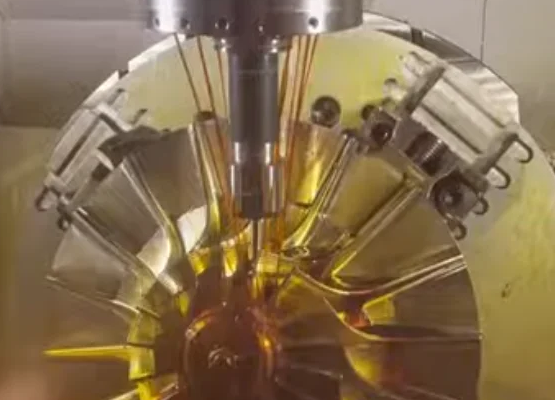

Through-Spindle and Through-Tool Coolant

Through-spindle (or through-tool) coolant delivers fluid internally through the spindle and cutting tool, exiting near the cutting edges.

Advantages:

- Direct cooling and chip evacuation in deep holes and pockets.

- High-pressure delivery helps break chips and prevent packing.

- Essential in many deep-hole drilling and high-speed drilling applications.

Pressures for through-spindle coolant systems can exceed 30 bar, and in some deep-hole or high-performance systems may be substantially higher, depending on equipment design.

Air Blast and Air-Oil Systems

Air blast uses compressed air to clear chips and cool the cutting zone by convection. Air-oil systems combine small quantities of oil with air to provide some lubrication with minimal fluid volume.

These methods are often used where coolant cannot be tolerated on the part (for example, some electronics components) or where dry machining strategies are valid for specific tools and materials.

Material-Specific Coolant Considerations

Different workpiece materials respond differently to coolant formulations and delivery methods. Matching coolant to material improves performance and reduces issues such as staining or corrosion.

Steel and Alloy Steel

Steels generally tolerate a broad range of coolants. For low-alloy and carbon steels, soluble oils and semi-synthetics at moderate concentration are common choices.

Points to consider:

- Heavy-duty cutting and threading may require higher concentration and EP-additive-rich fluids.

- High-strength alloys and stainless steels benefit from strong lubricity to resist work hardening and built-up edge.

Cast Iron

Cast iron chips and fines can form sludge, increasing maintenance and reducing coolant life.

Typical practices:

- Fully synthetic or low-oil semi-synthetic coolants improve cleanliness and reduce sticky deposits.

- Good filtration and chip separation are important to prevent abrasive wear in pumps and ways.

Aluminum and Nonferrous Alloys

Aluminum is sensitive to staining and corrosion from improper coolant chemistry or concentration.

Recommendations:

- Use formulations specifically labeled for aluminum compatibility.

- Maintain recommended concentration to avoid staining or etching.

- Avoid highly reactive extreme-pressure additives that can attack aluminum surfaces.

Titanium and Nickel-Based Alloys

These materials have poor thermal conductivity and generate high cutting temperatures.

Coolant guidelines:

- High-performance semi-synthetic or synthetic coolants with strong lubricity.

- High-pressure, directed coolant delivery (often through-tool) to minimize heat concentration.

- Adequate concentration to maintain lubricity under high loads.

Plastics and Composites

Many plastics and composites can be machined dry, but coolant or air blast may be used to control heat and remove chips or dust.

Considerations:

- Compatibility with the polymer to avoid swelling or chemical attack.

- Coolants free from components that may interfere with later bonding or finishing steps.

Coolant System Components in CNC Machines

A typical CNC coolant system includes more than just a pump and tank. Understanding major components helps in diagnosing issues and planning maintenance.

Sump or Coolant Tank

The sump holds the coolant mixture and provides residence time for chips and fines to settle. Design considerations include:

- Sufficient volume to stabilize temperature and concentration.

- Access for cleaning and sludge removal.

- Separation zones for chips and tramp oil.

Pumps and Filtration

Pumps determine flow rate and pressure available at the cutting zone. Filtration prevents abrasive particles from recirculating.

Common features:

- Centrifugal or positive-displacement pumps sized to machine requirements.

- Screens, bag filters, or magnetic separators for chip and fines removal.

- Optional cyclone or paper-bed filters for finer filtration in grinding.

Chip Conveyors and Separators

Chip conveyors remove large volumes of chips to keep coolant pathways clear. Additional separators may be used to capture small particles or floating debris.

Tramp Oil Removal

Tramp oil (hydraulic, slideway, and spindle oils) accumulates in coolant sumps and can promote bacterial growth and reduce coolant effectiveness.

Common removal devices include:

- Belt skimmers.

- Coalescing separators.

- Decanting tanks.

Coolant Maintenance and Monitoring

Even the best coolant will fail prematurely if not maintained. Systematic monitoring and basic housekeeping are essential to achieve stable performance and long coolant life.

Concentration Control

Coolant concentration changes over time due to evaporation of water, drag-out on chips and parts, and top-ups. Regular checks are necessary.

Typical practices:

- Measure concentration with a refractometer at defined intervals (for example, daily or several times per week in high-use systems).

- Apply the coolant’s refractometer factor to convert Brix readings to actual concentration.

- Adjust by adding either pre-mixed coolant or water according to measured values.

pH and Odor Monitoring

pH is an early indicator of coolant health. A falling pH often signals bacterial growth or oxidation.

Guidelines:

- Periodically measure pH with strips or a meter.

- Compare against coolant supplier’s recommended range.

- Address low pH with correct concentration, removal of contamination, or coolant change if necessary.

Persistent odour or visible slime generally indicates advanced biological contamination that may require partial or complete sump cleaning.

Filtration, Cleaning, and Sump Life

Chip load, fines, and contamination affect coolant performance and component wear.

Maintenance actions may include:

- Skimming floating oil and debris.

- Cleaning strainers, screens, and filters on a defined schedule.

- Periodic sump clean-out, including mechanical cleaning and use of system cleaner before refilling.

Coolant life depends on system size, workload, contamination level, and maintenance discipline. Some systems operate for many months or longer with controlled top-ups and periodic partial refresh.

Safety, Health, and Environmental Considerations

While properly managed CNC coolant systems are safe for routine use, attention to handling, personal protection, and disposal is required.

Personal Protection and Handling

Operators should follow the coolant manufacturer’s safety data sheet (SDS) and company procedures, including:

- Use of appropriate gloves, eye protection, and clothing when handling concentrates.

- Avoiding prolonged skin contact with contaminated coolant.

- Ensuring adequate ventilation, especially with mists or high-speed operations.

Storage and Mixing Practices

Coolant concentrates should be stored in closed containers, protected from extreme temperatures and contamination.

Typical guidelines:

- Add concentrate to water (not water to concentrate) to ensure proper emulsion formation, unless the manufacturer specifies otherwise.

- Use mixing devices or proportioners for consistent dilution.

- Label all mixed coolant containers with type and concentration.

Disposal and Regulatory Compliance

Used coolant may contain metals, tramp oils, and other contaminants. Disposal must follow local regulations.

Typical practices:

- Segregate coolant streams by type where required.

- Use oil-water separators or treatment systems before disposal or recycling.

- Keep records of disposal volumes and methods in line with environmental management requirements.

Typical Problems and Practical Considerations

CNC coolant systems can encounter recurring difficulties that reduce efficiency or drive up costs. Recognizing these issues early allows targeted corrective actions.

Foaming and Aeration

Excess foam reduces pump efficiency and can lead to coolant overflow.

Contributing factors may include:

- Incorrect coolant type for high-pressure systems.

- Very soft water or high concentration.

- Air leaks on the pump suction side.

Adjusting concentration, correcting plumbing issues, or switching to a low-foam coolant formulation can mitigate the problem.

Short Coolant Life and Frequent Changes

Rapid coolant degradation increases downtime and disposal costs.

Underlying causes often involve:

- Chronic low concentration due to topping up with water only.

- High tramp oil contamination from leaks and lack of skimming.

- Insufficient housekeeping, including rare sump cleaning.

Implementing routine testing, skimming, and controlled additions of pre-mixed coolant typically extends service life.

Corrosion and Staining of Parts

Rust on ferrous parts or staining on aluminum surfaces can result from inappropriate coolant chemistry or poor control.

Key factors:

- Concentration below recommended minimum.

- pH outside specified operating range.

- Incorrect coolant choice for the material.

Correcting concentration, monitoring pH, and selecting a properly formulated coolant for specific alloys are effective countermeasures.

Residue and Cleanliness Issues

Sticky residues on machines and parts complicate handling and finishing. These may arise from heavy soluble oils, incompatible way lubricants, or dried coolant.

Possible responses include:

- Using lower-residue semi-synthetic or synthetic fluids.

- Improving rinse or wash steps for critical parts.

- Coordinating coolant and slideway oil selections for better compatibility.

FAQ About CNC Coolant

What is CNC coolant and why is it important?

CNC coolant is a liquid used during machining to reduce heat, lubricate the cutting area, and remove chips. It helps extend tool life, improve surface finish, and prevent workpiece deformation caused by excessive heat.

What are the main types of CNC coolant?

Common types include:

Water-soluble coolant (emulsions)

Semi-synthetic coolant

Fully synthetic coolant

Straight oils (neat cutting oils)

Each type has different lubrication, cooling, and chip-removal characteristics.

How often should CNC coolant be changed?

Coolant should be replaced when:

Concentration falls out of recommended range

It becomes contaminated with chips, oils, or bacteria

It develops an odor or changes color

Typically, systems are cleaned and coolant is replaced every few weeks to a few months depending on usage.

How do I know my coolant needs maintenance?

Common signs include:

Strong odor

Excessive foaming

Rust on machine surfaces

Poor chip evacuation

Skin irritation when handled

These indicate that the coolant concentration, pH, or cleanliness may be out of spec.

What is the difference between cutting fluid and CNC coolant?

In machining, “cutting fluid” and “CNC coolant” are often used interchangeably. Both refer to liquids used to cool and lubricate the cutting process. In many shops, the term “coolant” emphasizes heat removal in CNC machines, while “cutting fluid” can also cover straight oils used on manual or specialized machines. Technically, both terms describe metalworking fluids with cooling, lubricating, and corrosion-protection functions.