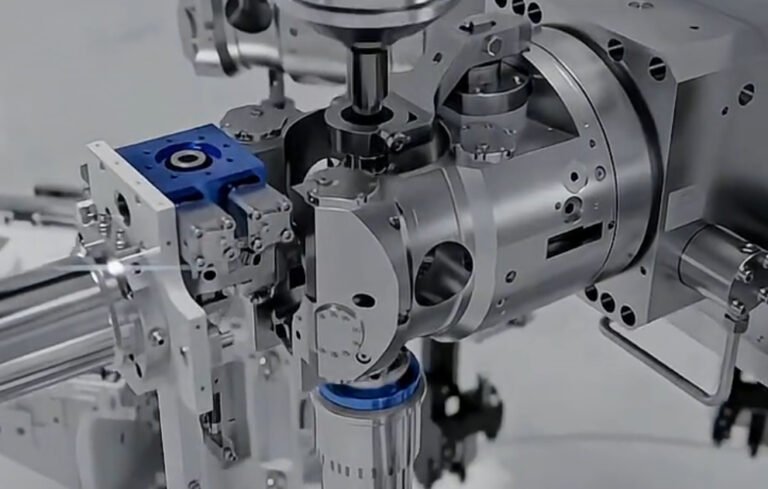

Multi-axis machining is a CNC manufacturing approach where the cutting tool and/or workpiece can move along more than three linear and rotary axes simultaneously. Typical configurations include 3+2 axis, 4-axis and 5-axis machining centers, as well as multi-axis mill-turn machines. Compared with conventional 3-axis machines, multi-axis technology provides significant advantages in accuracy, cycle time, part complexity and overall manufacturing economics.

What Is Multi-Axis Machining?

Multi-axis machining refers to computer numerically controlled (CNC) milling or turning operations where the machine tool can move the cutting tool or the workpiece along multiple linear and rotary axes under coordinated control. Common axes are:

- X, Y, Z: Linear axes

- A, B, C: Rotary axes around X, Y, Z respectively

The most widely used configurations include:

- 4-axis machining: X, Y, Z plus one rotary axis (typically A or B) for indexed or simultaneous rotation.

- 5-axis machining: X, Y, Z plus two rotary axes (A/B/C) that can be used in indexed or fully simultaneous modes.

In many applications, multi-axis machines combine milling and turning capabilities in a single platform (mill-turn or turn-mill) with multiple spindles, sub-spindles and tool turrets.

Key Advantages Over Conventional 3-Axis Machining

Compared with 3-axis CNC machines, multi-axis machining provides a different level of geometric freedom, process integration and accuracy. Major advantages include:

- Access to complex geometries and undercuts

- Reduction or elimination of multiple setups and re-fixturing

- Shorter machining cycles and lead times

- Better dimensional accuracy and repeatability

- Improved surface finish and contour quality

- Fewer dedicated fixtures and lower tooling inventory

- More robust machining of difficult materials

The following sections analyze these benefits in a systematic, application-oriented way, with emphasis on technical parameters that influence performance and cost.

Enhanced Capability for Complex Geometries

Multi-axis machining significantly extends the range of manufacturable features. By tilting and rotating the tool or the workpiece, the machine can approach surfaces from optimal directions that are impossible or inefficient with 3-axis setups.

Access to Undercuts and Deep Cavities

Multi-axis configurations enable direct machining of complex features, such as:

- Undercuts and recessed features on turbine blades, impellers and blisks

- Conformal cooling channels in molds and dies

- Complex bone plates and orthopedic implants with multi-directional curvatures

- Ports, manifolds and internal passages in engine components

In 3-axis machining, such features often require EDM, special tooling, or split-part designs. Multi-axis machines can approach these areas via tool tilting, using shorter tools with more stable cutting conditions, improving both accessibility and accuracy.

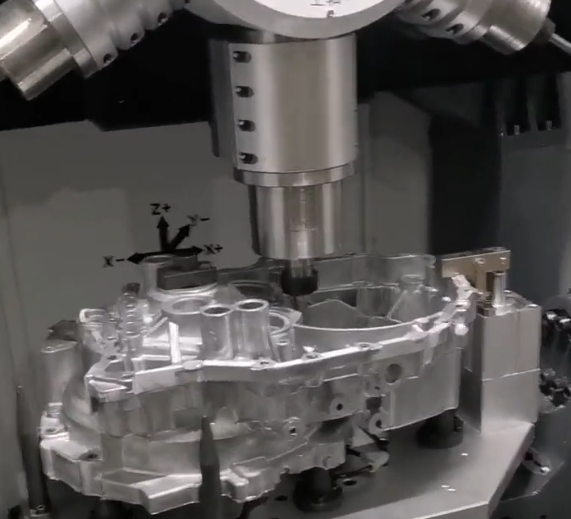

Continuous Machining Around Multiple Faces

By coordinating rotation and translation, multi-axis machining can continuously follow part contours around several faces in one setup. Typical examples include:

- Blades and vanes with complex airfoil geometry

- Impellers and pump rotors with twisted channels

- Automotive cylinder heads with multi-angle ports and combustion chambers

- Aerospace structural parts with pockets and ribs oriented in different directions

This capability is essential when geometric accuracy between multiple surfaces is critical, such as maintaining aerofoil profiles or consistent wall thickness in lightweight aerospace structures.

Reduced Setups and Re-Fixturing

One of the most impactful advantages of multi-axis machining is the reduction of setups. Fewer setups translate directly into higher accuracy, lower labor content and shorter lead times.

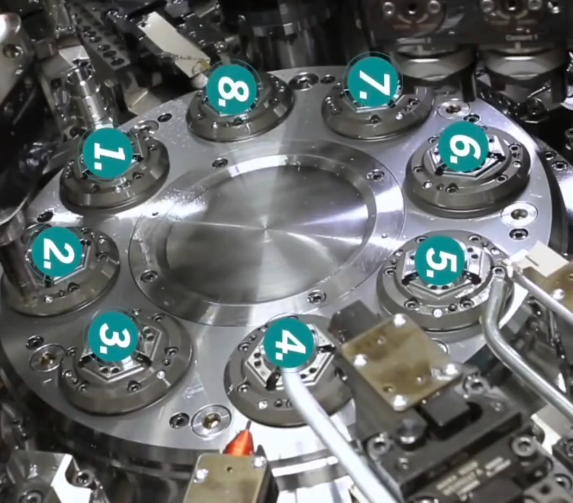

Single-Setup Machining

With 4-axis and 5-axis machines, many components can be fully machined in one or two setups rather than multiple clamping operations. Typical conversions include:

- Turning a 5–7 setup 3-axis process into a single 5-axis operation

- Combining roughing and finishing on multiple faces without removing the part

- Machining prismatic parts on all sides using a trunnion table or rotary pallet

Single-setup machining minimizes cumulative errors caused by part re-clamping. The datum structure is preserved throughout the process, and all critical dimensions can be referenced to the same coordinate system.

Lower Fixturing Complexity and Cost

Because multi-axis machines can orient the part relative to the tool, many custom fixtures and angle plates become unnecessary. Standard vises, modular fixturing plates and simple locating features are often sufficient.

Benefits include:

- Reduced fixture design and manufacturing time

- Lower inventory of dedicated fixtures

- Simplified setup for low-volume or prototype work

- Faster changeovers between jobs

For high-mix, low-volume production, this reduction in fixturing effort is often a primary economic driver for multi-axis adoption.

Shorter Cycle Times and Lead Times

Multi-axis machining reduces non-cutting time and allows more aggressive cutting conditions, resulting in shorter overall cycle times and faster delivery.

Minimized Non-Cutting Movements

In 3-axis machining, toolpaths often include long retracts and repositioning moves to avoid collisions or reach new surfaces. Multi-axis machines can instead tilt the tool and keep it in continuous engagement with the workpiece, minimizing air cuts and rapid moves.

Cycle time reductions typically arise from:

- Continuous 5-axis contouring instead of multiple 3-axis passes

- Eliminating manual repositioning of the part between operations

- Shorter tool-change sequences due to process consolidation

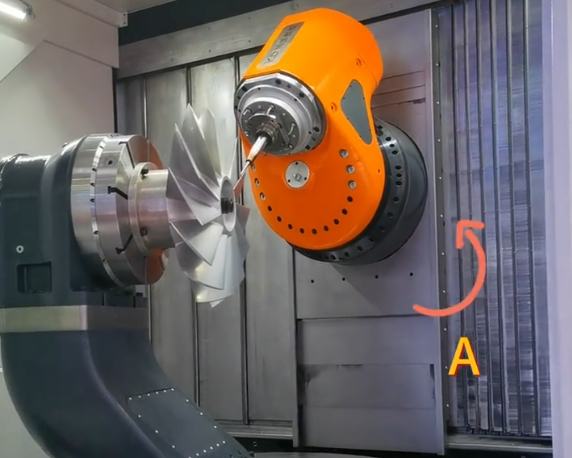

Higher Material Removal Rates

The ability to tilt the tool allows more stable cutting conditions with shorter tool overhangs and optimal engagement angles. This can permit higher spindle speeds, larger stepovers and deeper axial cuts within the limits of machine rigidity and tool capability.

Typical improvements include:

- Use of high-feed cutters with optimal approach angles for roughing

- Tilted ball-nose finishing, maintaining constant effective cutter radius

- Improved chip evacuation in deep pockets by tilting away from the vertical

This leads to higher material removal rates while maintaining or improving tool life.

Improved Dimensional Accuracy and Repeatability

Multi-axis machining improves geometric control by maintaining the part in a fixed clamping condition and by allowing optimal tool orientation relative to the feature being cut.

Elimination of Cumulative Setup Errors

When parts require multiple setups on 3-axis machines, each new clamping introduces potential misalignment in translation and rotation. Multi-axis machining minimizes these sources of error by machining most or all features in a single setup, referenced to a common datum.

Typical outcomes include:

- Tighter positional tolerance between features on different faces

- Improved coaxiality and true position for bores and bosses

- Better angular relationships between surfaces

Optimal Tool Orientation for Geometric Control

Tilting the tool to maintain a normal (perpendicular) or controlled angle to the surface can improve dimensional accuracy. For example:

- Drilling and boring operations executed along the exact axis of angled holes

- Machining sealing surfaces at precise compound angles

- Cutting undercuts with tools oriented to minimize deflection

These capabilities support tighter geometric tolerances with less process variation, particularly in aerospace, medical and precision instrumentation components.

Superior Surface Finish and Contour Quality

Surface quality is a critical factor in many industries, affecting performance, fatigue life, sealing, aesthetics and downstream finishing requirements. Multi-axis machining directly contributes to superior surface conditions.

Consistent Scallop Height and Step-Over

With simultaneous 5-axis machining, the tool can maintain an optimal orientation to the surface throughout the toolpath. This enables constant scallop height strategies that deliver uniform surface roughness even on steep or highly curved areas.

Typical surface finish benefits include:

- Reduced faceting and blending lines between passes

- Improved surface uniformity on freeform surfaces

- Lower Ra and Rz values for a given step-over and feed rate

Reduced Need for Hand Finishing

Better surface finish from the machine reduces or eliminates manual polishing, blending or secondary machining. This is particularly important for:

- Mold and die surfaces where manual polishing is labor-intensive

- Aerofoil surfaces where manual operations may disturb the profile

- Implant and medical device surfaces requiring tight geometric control

Reduced manual rework improves consistency and lowers labor costs, while preserving precise CAD-defined geometry.

Tool Life, Tooling Choices and Stability

Multi-axis machining improves the mechanical conditions at the cutting edge, contributing to longer tool life and more predictable wear patterns.

Shorter Tool Overhang and Reduced Deflection

On 3-axis machines, long tools are often required to reach deep features or undercuts, increasing deflection, chatter and premature tool wear. Multi-axis configurations allow the spindle or part to be tilted, making it possible to reach the same features with shorter tools.

Advantages include:

- Reduced bending moments on the tool and holder

- Lower vibration and improved surface quality

- More consistent dimensional accuracy in deep pockets

Optimized Engagement and Chip Evacuation

Tilting the tool can maintain a favorable cutting angle, distribute wear evenly along the cutting edge and improve chip flow. Examples include:

- Tilting ball-nose end mills away from the 0° point to avoid rubbing

- Orienting the tool to direct chips away from the cutting zone

- Adjusting tool angle to moderate cutting forces in hard or abrasive materials

These factors contribute to extended tool life, reduced tool-change frequency and more predictable process planning.

Manufacturing Flexibility and Part Consolidation

Multi-axis machining provides high flexibility for handling different part families without extensive retooling or fixturing changes.

High-Mix, Low-Volume Production

Because complex fixturing and multiple dedicated setups are minimized, multi-axis machines are particularly effective for high-mix, low-volume production environments. Job changes can often be managed primarily through program and tooling updates.

This flexibility enables manufacturers to handle:

- Prototype and pre-production series

- Small batch spares and replacement parts

- Customized components with geometry variants

Part Consolidation and Functional Integration

When complex surfaces and multiple faces can be machined efficiently, part designs can consolidate functions that previously required assemblies of simpler parts. This can reduce:

- Number of components in an assembly

- Fasteners and joints

- Assembly time and error sources

Designers gain greater freedom to optimize components for performance rather than manufacturing constraints, knowing that multi-axis machining can produce the required geometry in a single piece.

Material Capability and Difficult-to-Machine Alloys

Multi-axis machining is widely used in sectors where high-performance materials are common, such as aerospace, energy and medical industries. Many such alloys are challenging to machine and require stable, controlled cutting conditions.

Stable Cutting in High-Strength Materials

Materials such as titanium alloys, nickel-based superalloys and hardened steels benefit from the stability advantages of multi-axis machining, including:

- Optimized tool orientation to reduce cutting forces

- Short tools to minimize vibration

- Improved chip evacuation by tilting away from the chip flow direction

These factors help maintain surface integrity, dimensional accuracy and tool life when machining difficult materials.

Improved Thermal Management at the Cutting Zone

Tilting the tool and adjusting approach angles can improve coolant access and heat dissipation in the cutting region. Stable thermal conditions reduce the risk of:

- Micro-cracking or thermal damage at the surface

- Dimensional drift from thermal expansion

- Unexpected tool failure due to heat concentration

Multi-axis machines also allow more effective use of through-tool coolant in complex tool orientations, further improving thermal control.

Comparison of Multi-Axis Configurations

The choice between 3-axis, 4-axis and 5-axis machining depends on part geometry, tolerances, material and production volume. The following table summarizes typical differences in capability and benefits.

| Aspect | 3-Axis | 4-Axis | 5-Axis (Simultaneous) |

|---|---|---|---|

| Axis configuration | X, Y, Z | X, Y, Z + 1 rotary (A/B) | X, Y, Z + 2 rotary (A/B/C) |

| Access to multiple faces | Limited, requires re-clamping | Good for around-the-part indexing | Excellent, full orientation control |

| Undercut capabilities | Very limited | Moderate, depending on geometry | Extensive, suitable for complex undercuts |

| Typical setups per complex part | 3–7 or more | 2–4 | 1–2 |

| Dimensional accuracy between faces | Moderate, affected by re-fixturing | Improved, fewer re-clamps | High, single datum structure |

| Surface finish on freeform shapes | Limited by fixed tool orientation | Improved on accessible faces | Excellent via optimal tool tilt |

| Fixture complexity | High for multi-face parts | Moderate | Lower, often modular fixturing |

| Cycle time for complex parts | Longest | Reduced | Shortest |

Economic and Operational Benefits

The technical advantages of multi-axis machining translate into tangible economic and operational improvements. These benefits influence investment decisions, shop-floor organization and long-term competitiveness.

Lower Cost per Part for Complex Components

For parts with multi-face machining, tight tolerances or complex profiles, multi-axis machining often reduces the total cost per part by:

- Reducing setup and changeover time

- Decreasing manual finishing and deburring

- Lowering scrap and rework rates

- Consolidating operations on fewer machines

Even though multi-axis machines typically have higher capital cost than 3-axis machines, the overall cost per finished component can be significantly lower when all process steps are considered.

Better Machine Utilization and Workflow

When multi-axis methods replace multiple sequential operations on different machines, shop-floor workflow becomes simpler and more predictable. Benefits include:

- Shorter and more direct routing through the factory

- Lower in-process inventory and shorter lead times

- Simplified scheduling and fewer bottlenecks

Integrating probing, inspection routines and in-process measurement on multi-axis machines also supports closed-loop control and stable quality levels.

Typical Issues Addressed by Multi-Axis Machining

Manufacturers often encounter specific difficulties when using conventional 3-axis setups for advanced components. Multi-axis machining directly addresses several of these pain points.

Issue: Maintaining Accuracy Across Multiple Faces

In multi-face parts, ensuring accurate positional relationships between features often requires careful re-fixturing, multiple datums and manual alignment. This increases risk of errors and scrap.

Multi-axis machining addresses this by:

- Maintaining a single, consistent datum structure in one setup

- Using rotary axes to orient the part instead of re-clamping

- Allowing in-machine probing to verify feature location without removing the part

Issue: High Labor Content for Finishing and Deburring

Manual finishing, blending and deburring are time-consuming, variable and difficult to scale. Complex edges and intersections are often hard to reach with manual tools, increasing the risk of quality issues.

Multi-axis machining reduces this burden by:

- Allowing access to edges and intersections from optimal directions

- Using 5-axis toolpaths to finish all visible surfaces directly

- Reducing burr formation due to controlled engagement and chip evacuation

The result is more consistent surface quality and lower reliance on manual operations.

Application Domains Benefiting from Multi-Axis Machining

While multi-axis machining is beneficial in many sectors, certain industries rely on it as a core manufacturing technology due to their geometric and tolerance requirements.

Aerospace and Defense

Typical aerospace applications include:

- Blisks, blades and vanes for compressors and turbines

- Structural components with weight-reduction pockets and complex ribs

- Actuator housings and hydraulic manifolds with multi-axis ports

Multi-axis machining supports the required combinations of complex geometry, tight tolerances and high-performance materials commonly used in this sector.

Medical Devices and Implants

In the medical sector, multi-axis machining is used for:

- Orthopedic implants such as hip stems, knee components and bone plates

- Dental abutments and custom prosthetic structures

- Surgical instruments with ergonomic, contoured surfaces

The ability to machine organic shapes and maintain surface integrity and dimension is critical for implant performance and regulatory compliance.

Energy, Automotive and Industrial Equipment

In energy generation, multi-axis machining is used for impellers, rotors, pump components and casings. In automotive and industrial equipment, it supports complex engine, transmission and fluid power components.

Across these applications, the key benefits include fewer setups, improved surface finish in flow-related areas and efficient machining of high-strength materials.

Summary of Core Benefits

Multi-axis machining delivers a combination of geometric, process and economic advantages that are particularly significant for complex, high-precision components. The table below summarizes major benefits and their primary effects.

| Benefit | Primary Effect | Typical Impact |

|---|---|---|

| Complex geometry capability | Direct machining of freeform shapes and undercuts | Enables integrated designs and reduces assemblies |

| Fewer setups | Single-setup machining for multi-face parts | Higher accuracy, lower labor content |

| Shorter cycle times | Continuous tool engagement and reduced non-cutting moves | Higher throughput and faster lead times |

| Improved accuracy | Elimination of cumulative re-fixturing errors | Tighter tolerances across all faces |

| Better surface finish | Optimal tool orientation and constant scallop strategies | Less polishing, better functional surfaces |

| Extended tool life | Shorter overhang, controlled engagement and chip flow | Lower tooling costs and more stable processes |

| Higher flexibility | Reduced fixturing and rapid changeovers | Effective for high-mix, low-volume production |

| Robust machining of difficult materials | Stable cutting conditions and thermal control | Improved reliability in high-performance alloys |

FAQ: Multi-Axis Machining Benefits

What is multi-axis machining?

Multi-axis machining is a CNC process where machines operate along three or more axes simultaneously. This allows for complex part geometries, precise angles, and intricate surface finishes that are difficult to achieve with standard 3-axis machines.

What are the main benefits of multi-axis machining?

Higher Precision: Achieve tighter tolerances and smoother surfaces.

Complex Part Production: Manufacture intricate shapes in a single setup.

Reduced Setup Time: Fewer repositionings reduce errors and production time.

Improved Tool Life: More efficient cutting reduces wear and heat on tools.

Cost Efficiency: Combining multiple operations in one setup reduces labor and machine time.

Does multi-axis machining always reduce part cost?

Multi-axis machining typically reduces part cost for components with complex geometry, tight tolerances or many machined faces, because it minimizes setups, fixturing and manual finishing. For very simple prismatic parts, 3-axis machining can remain more economical, but as geometric complexity and accuracy requirements increase, the cost advantages of multi-axis machining become more pronounced.

What Are the Types of Multi-Axis Machining?

The main types of multi-axis CNC machining are 3-axis, 4-axis, 5-axis, and higher-axis configurations such as 7-axis, 9-axis, and up to 12-axis for increasingly complex parts.

How do I choose the right type of multi-axis machining?

Consider part complexity, required precision, production volume, and cost. For simple cylindrical parts, 4-axis may be enough; for highly complex 3D surfaces, 5- or 6-axis continuous machining is preferred.