Reliable CNC machined parts are essential for maintaining performance, safety and long-term stability in demanding industrial applications. Selecting a supplier that combines process capability, dimensional accuracy, material expertise and responsive service is critical for global OEMs and system integrators across automotive, aerospace, medical, electronics, robotics and heavy industry.

What Makes a CNC Machined Parts Supplier Reliable

A reliable CNC machined parts supplier provides consistent quality, predictable delivery and transparent technical communication from RFQ to after-sales support. This reliability is not based only on machine tools, but on the entire system behind them.

- Stable process capability and repeatability for long-term programs

- Traceable quality control and documentation across all batches

- Clear, engineering-focused communication and DFM support

Key attributes include:

Process stability: Documented procedures, controlled cutting parameters, qualified tooling and systematic maintenance minimize variation and reduce rework risk.

Dimensional reliability: The supplier consistently meets the defined tolerance bands, not just in prototype quantities but through full-scale production with statistical process control where applicable.

Supply reliability: Capacity planning, flexible scheduling and safe inventory strategies allow the supplier to maintain punctual shipments even during demand peaks or complex product mixes.

Core CNC Machining Capabilities

Comprehensive CNC capabilities allow a supplier to support diverse industries and part geometries with stable performance. Typical core processes include CNC milling, CNC turning, mill-turn, drilling, tapping and secondary finishing operations.

CNC Milling

CNC milling is used for prismatic, plate, housing and structural components with complex surfaces and pockets. A capable supplier operates 3-axis and multi-axis machining centers with flexible fixturing and workholding.

| Parameter | Typical Capability |

|---|---|

| Axes | 3, 4 and 5-axis vertical and horizontal machining centers |

| Max workpiece size | Up to 1200 mm × 700 mm × 600 mm (larger with special fixturing) |

| Dimensional tolerance | ±0.005 mm to ±0.02 mm depending on geometry and material |

| Surface roughness (Ra) | 0.4–1.6 μm with appropriate tooling and cutting conditions |

| Spindle speed | Up to 20,000 rpm (high-speed machining centers) |

| Materials | Aluminum, steels, stainless steels, copper alloys, titanium, engineering plastics |

Multi-axis milling enables undercuts, compound angles and reduced setups, which in turn improves geometric accuracy between features and lowers cumulative error.

CNC Turning

CNC turning is suited for shafts, bushings, rings, spacers, connectors and other rotational parts. Modern turning centers often integrate live tooling and sub-spindles to complete complex parts in a single setup.

Typical CNC turning features:

- Through and between-center turning for varying lengths

- Grooving, threading, knurling and parting-off operations

- Radial and axial milling using live tools

Common performance metrics include:

Maximum turning diameter often ranges from 300 mm to 450 mm for standard machines, with length capacities up to 800–1500 mm. Dimensional tolerances around ±0.005 mm on critical diameters and runout control within a few microns are achievable with appropriate process setups and tool selection.

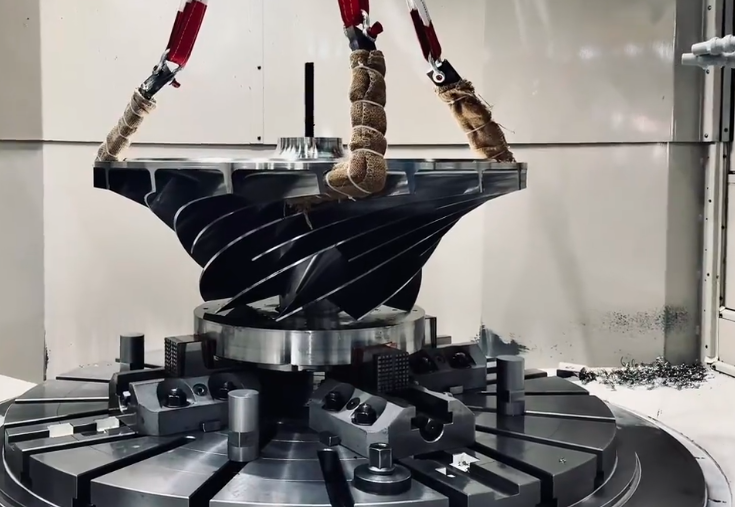

Mill-Turn and Complex Machining

Mill-turn centers combine turning and milling in a single machine. They are effective for parts with concentric and non-concentric features, angled ports, side holes and complex functional interfaces.

Benefits include reduced handling, fewer fixtures, improved geometric relations between features and shorter overall lead time for complex components.

Materials and Material-Specific Expertise

Reliable performance requires not only machine capability but also knowledge of the behavior and machining characteristics of different materials. The supplier should be able to recommend materials based on mechanical requirements, environmental conditions and regulatory constraints.

Metals

Common metal materials for CNC machined parts include:

| Material Group | Typical Grades | Key Properties / Applications |

|---|---|---|

| Aluminum | AL6061, AL6082, AL7075, AL5052 | Lightweight, good machinability, widely used for housings, brackets, structural frames |

| Carbon Steel | Q235, 1018, 1045, 4140 | High strength, cost-effective for mechanical components, shafts, bases |

| Stainless Steel | SS304, SS316, SS316L, 17-4PH | Corrosion resistance for food, medical, marine and chemical environments |

| Copper Alloys | Brass C3604, C3771, Bronze, Pure Copper | Excellent electrical and thermal conductivity for connectors, terminals and heat sinks |

| Titanium | Ti-6Al-4V, Grade 2 | High strength-to-weight ratio, corrosion resistance for aerospace and medical parts |

Material-specific considerations include cutting speed, tool wear, thermal deformation, burr formation and surface integrity. For example, stainless steel and titanium require lower cutting speeds and robust coolant management to control heat and maintain dimensional stability.

Engineering Plastics

Engineering plastics are frequently used for lightweight, electrically insulating, wear-resistant or chemically resistant components.

Typical materials include POM (acetal), PA (nylon), PC (polycarbonate), PEEK, PTFE and ABS. Each material demands specific clamping, feed rate and tool geometry strategies to avoid deformation, residual stress, cracking or surface defects.

Tolerances, Surface Finish and Geometric Accuracy

Industries with safety and performance requirements rely on precise tolerances and defined surface finishes. A reliable supplier demonstrates clear control over dimensional and geometric accuracy.

Linear and Dimensional Tolerances

Typical achievable tolerances for CNC machined parts are:

- General dimensions: ±0.05 mm to ±0.1 mm

- Critical dimensions: ±0.005 mm to ±0.02 mm, depending on geometry and material

- Hole diameters: H7–H9 fits and tighter with reaming or honing

The supplier should review drawings, identify critical features and propose reasonable tolerances that balance functional requirements, manufacturability and cost.

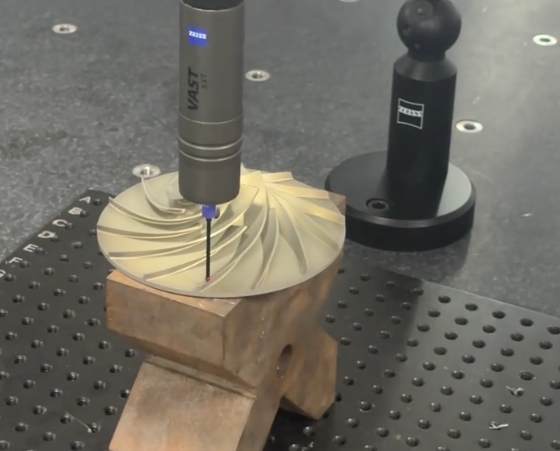

Geometric Dimensioning and Tolerancing (GD&T)

GD&T is essential for controlling form, orientation and position in complex assemblies. Common requirements include flatness, parallelism, perpendicularity, cylindricity, profile tolerance and true position.

The supplier’s engineering team must accurately interpret GD&T symbols, set up reference datums in fixtures and verify compliance using calibrated measurement equipment such as CMMs and height gauges.

Surface Finish Requirements

Surface roughness directly affects sealing, wear, fatigue and aesthetic appearance. CNC processes can deliver a wide range of Ra values depending on material and tooling. For functional surfaces, the supplier can combine rough machining, semi-finish and finish passes to meet defined Ra and Rz values while preserving geometric accuracy.

Typical Industries Served and Application Scenarios

A reliable CNC machined parts supplier supports a wide range of global industries, each with specific technical and documentation expectations.

Automotive and Commercial Vehicles

Automotive applications require high-volume repeatability and traceability for safety-related components. Parts may include brackets, housings, sensor mounts, engine components, drivetrain parts and interior structural elements.

Requirements often involve PPAP documentation, material certificates, controlled surface treatments and robust packaging to prevent shipping damage.

Aerospace and Aviation

Aerospace components demand high strength-to-weight ratios, corrosion resistance and tight tolerances. Typical parts include structural brackets, interior components, connector housings, mounting blocks and hydraulic system parts.

Aerospace-grade materials such as aluminum 7075, 6061, titanium alloys and specific stainless steels are commonly used, requiring precise process control and documentation.

Medical Devices and Laboratory Equipment

Medical and laboratory applications focus on biocompatibility, cleanliness and corrosion resistance. Typical products include surgical instrument components, pump bodies, manifolds, frames for diagnostic equipment and fixtures for laboratory use.

Stainless steels, titanium and certain engineering plastics such as PEEK and PTFE are frequently specified. Documentation may include material traceability and compliance with relevant regulatory standards at the part level.

Industrial Automation, Robotics and Machinery

Automation and robotics require complex mechanical parts with accurate interfaces and mounting points, such as gear housings, arms, end-effectors, couplings and linear motion components.

These projects often involve continuous engineering changes and incremental improvements, requiring a supplier that can implement drawing revisions quickly while keeping dimensionally stable processes.

From Prototype to Mass Production

Different project stages require different machining strategies and resource allocation. A reliable supplier can manage the full life cycle from concept validation to stable mass production.

Rapid Prototyping

During development, small quantities are needed to verify design, fit, function and assembly. The supplier must be able to:

- Quickly evaluate manufacturability from 3D models and 2D drawings

- Recommend modifications to reduce risk in later production stages

- Deliver prototypes in short lead times while maintaining specified tolerances

Flexible fixturing, modular tooling and experienced programmers are essential in this phase.

Pre-Series and Pilot Runs

Before mass production, pre-series batches validate process stability and production documentation. This stage is used to confirm machining strategies, cycle times, quality control plans and packaging methods.

Measurements from pilot runs are used to fine-tune tool paths, cutting conditions and inspection frequencies, and to confirm that dimensional capability meets customer requirements.

Mass Production and Long-Term Supply

For stable production, the supplier must implement robust process controls and continuous monitoring. Key elements include standardized work instructions, documented setups, tooling management and planned machine maintenance.

Long-term supply involves forecasting, capacity allocation, backup equipment and dual-sourcing strategies for critical materials and surface treatments when requested by the customer.

Quality Management System and Certifications

A structured quality management system (QMS) is the foundation of reliable machining supply. Documentation and control measures ensure consistent output and traceability.

Quality System Elements

Typical QMS components include:

- Incoming material inspection with certification verification

- In-process inspection at defined checkpoints

- Final inspection with dimensional reports when required

- Non-conformance control, corrective and preventive action procedures

- Calibration management for measurement instruments

Common certifications include ISO 9001 for general quality management and, depending on the industry, additional certifications for automotive, aerospace or medical applications.

Inspection Equipment

To verify tight tolerances and GD&T requirements, the supplier typically uses:

Coordinate measuring machines (CMM) for complex geometries and positional tolerances, optical measurement systems for small features, surface roughness testers, hardness testers, height gauges, plug gauges and ring gauges. A structured calibration schedule ensures measurement reliability over time.

Surface Treatments and Secondary Operations

CNC machining often represents only one stage in the complete production chain. Many parts require additional surface treatments or mechanical operations to meet final functional requirements.

Common Surface Finishes

Typical surface treatments include anodizing for aluminum (clear or colored), hard anodizing for wear resistance, zinc plating, nickel plating, chrome plating, black oxide, passivation for stainless steel, powder coating and painting.

The supplier should manage these treatments through qualified internal processes or controlled subcontractors, with documented specifications and test reports such as thickness measurements, adhesion tests and corrosion resistance tests where applicable.

Mechanical and Assembly Operations

Secondary mechanical operations include deburring, polishing, grinding, honing, reaming, thread rolling and laser marking. Assembly services may cover the integration of bushings, bearings, threaded inserts, seals, o-rings and simple sub-assemblies.

By offering end-to-end services, the supplier reduces the need for multiple vendors, shortens lead times and simplifies quality responsibility for the customer.

Engineering Collaboration and DFM Support

Reliable suppliers contribute engineering expertise rather than only executing machining instructions. Collaboration during the design stage can reduce cost and improve manufacturability without compromising performance.

Design for Manufacturability (DFM)

DFM support typically includes recommendations on wall thickness, fillet radii, hole depths, thread types, datum structures, tolerance distribution and material selection. The goal is to ensure parts are robust to manufacturing variation while meeting functional requirements.

Suppliers can also propose standardization of features such as hole sizes, fastener types and surface finishes across part families to simplify assembly and inventory for the customer.

Drawing and Model Management

Engineering collaboration requires controlled management of 3D models and 2D drawings. The supplier should maintain revision control, document acknowledgment of engineering changes and ensure that only the latest approved versions are in production.

Global Logistics and Supply Chain Support

For international customers, logistics reliability is as important as machining accuracy. The supplier must understand export procedures, packaging requirements and transportation options.

Packaging and Protection

Appropriate packaging minimizes damage and corrosion during transportation and storage. Common methods include vacuum packing, VCI (volatile corrosion inhibitor) bags, foam inserts, custom trays, anti-static packaging for electronics-related parts and wooden crates for large or heavy components.

Part labeling and barcoding support traceability and simplify warehouse management for the customer.

Shipping and Delivery Options

Depending on order volume, weight and urgency, the supplier may arrange courier services, air freight or sea freight. Clear communication of Incoterms, lead times and customs documentation helps avoid delays and unexpected costs in cross-border shipments.

Key Considerations When Selecting a CNC Machined Parts Supplier

Selecting a CNC supplier for global industries involves technical, logistical and commercial evaluation. The following aspects are commonly assessed during supplier qualification and audits.

Technical Capability and Capacity

Assessment points include types and numbers of machines, maximum part size, achievable tolerances, supported materials, surface treatment options, inspection equipment and engineering resources. The supplier’s current machine utilization and expansion plans indicate capacity stability for long-term projects.

Quality and Traceability

Customers often review quality manuals, process flow diagrams, control plans, failure mode and effects analysis (FMEA) where applicable, inspection records, calibration logs and sample documentation packages. Traceability from raw material to finished part and shipment lot is particularly important for regulated industries.

Communication and Project Management

Effective communication channels and dedicated project coordinators support timely resolution of technical questions, engineering changes and delivery planning. The supplier should provide clear response times for RFQs, feedback on manufacturability, progress updates and structured issue handling.

Cost Structure and Total Cost of Ownership

While piece price is important, total cost of ownership also includes scrap risk, rework, line stoppages, logistics complexity and administrative effort. A reliable supplier can help reduce total cost by improving yield, simplifying processes and providing stable, predictable performance over the life of the project.