Rapid prototyping enables designers and engineers to turn ideas into functional parts within days instead of weeks. By combining advanced digital manufacturing technologies with streamlined workflows, XCM helps teams validate designs faster, reduce development risks, and accelerate time-to-market. Whether you are creating a first concept model or a highly detailed functional prototype, our rapid prototyping service provides the precision, flexibility, and speed needed for modern product development.

Using CNC machining, 3D printing, sheet metal fabrication, and soft tooling options, XCM produces prototypes that match end-use performance requirements. These processes support a wide range of materials, including metals, engineering plastics, and high-performance composites. This allows customers to test mechanical strength, fit, assembly, surface quality, and real-world durability before moving into production.

Rapid prototyping, as offered by XCM, involves the creation of physical samples to represent new product design ideas.

This process serves as a preliminary step towards eventual production, crucial for verifying that the final product aligns with intended specifications. rapid prototyping services are sought after by new product developers for various purposes, including functional testing, design approvals, iterations, crowdfunding campaigns, trade show models, and as a bridge to low-volume manufacturing. Prototypes provided by XCM often catalyze redesigns, improvements, and modifications, enhancing the overall design before committing to larger production volumes.

Correcting design errors early in the development phase through rapid prototyping can significantly outweigh the cost of the prototype itself, making it a prudent investment for businesses.

XCM offers a range of rapid prototyping options tailored to meet diverse needs. From simple models crafted with materials like paper, plastic, modeling clay, styrofoam, or balsa wood, to high-fidelity prototypes utilizing modern machine tools and advanced materials such as various 3D printing technologies, vacuum casting, rapid tooling for injection molding, and CNC machining.

While low-fidelity prototypes provide a visual representation of the design, high-fidelity prototypes offered by XCM closely resemble the intended finished part, facilitating thorough testing and evaluation.

Selecting the appropriate rapid prototyping method is essential, and XCM offers guidance to make informed decisions. Factors such as budget, part complexity, intended functionality, development timeline, surface texture, finish, material properties, strength, durability, and resemblance to the final production version all influence the choice of prototyping technique. By considering these variables, XCM ensures that clients receive prototypes that meet their specific requirements effectively.

Rapid prototyping is a product development method that allows the production and iteration of product parts for evaluation and testing. By manufacturing your rapid prototypes with XCM guarantees, you make the best decision regarding your design. We let you test out a full range of materials and finishes, so you can make an informed decision on how to take your project forward. We have an array of rapid prototyping processes for you to choose from.

CNC machining is the epitome of high-precision rapid prototyping, combining speed and quality seamlessly. With swift turnarounds as a priority, it ensures exceptional accuracy, making it a preferred choice across industries.

Even in low volumes, CNC prototyping delivers rapid results without sacrificing quality. The produced parts, though prototypes, match the precision of mass production. While the cost might exceed that of 3D printing, the superior surface finish and sturdy part strength validate the investment.

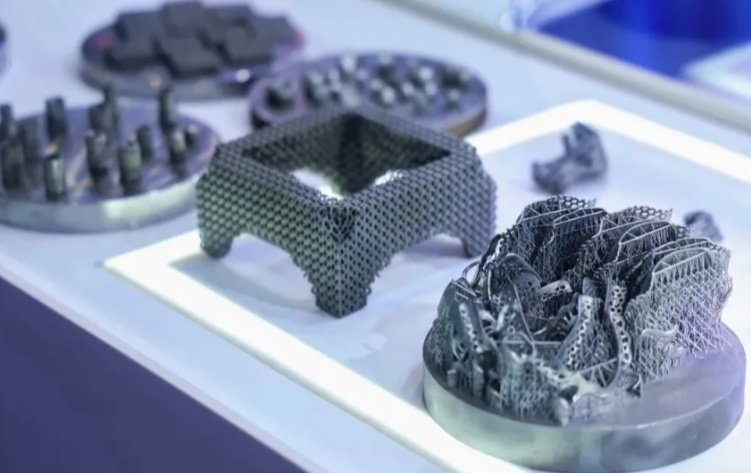

At XCM, our 3D printing rapid prototyping services excel in producing high-quality plastics and metals, offering a wide range of materials and finishing options. These cutting-edge additive manufacturing technologies can even transition seamlessly into production.

By eliminating the need for tooling, 3D printing ensures quick prototyping without compromising quality. Enjoy the benefits of geometric flexibility and cost-effectiveness, particularly for low-volume projects.

XCM's rapid sheet metal prototyping services, tailored for creating sheet metal parts through versatile forming, cutting, and assembly processes.

Ideal for flat parts like brackets and enclosures, our services accommodate various sizes, including large metal parts. While setup times may be longer, sheet metal proves highly cost-effective for large and straightforward parts.

One notable advantage is the ability to later CNC machine the solid sheet metal feedstock for additional features, ensuring versatility and precision.

We use cookies to improve your experience on our site. By using our site, you consent to cookies.

Manage your cookie preferences below:

Essential cookies enable basic functions and are necessary for the proper function of the website.

Statistics cookies collect information anonymously. This information helps us understand how visitors use our website.

Marketing cookies are used to follow visitors to websites. The intention is to show ads that are relevant and engaging to the individual user.