On-demand custom CNC machined parts manufacturing is a flexible production model that uses computer numerical control (CNC) equipment to produce precision components directly from digital designs, in quantities ranging from single prototypes to full production batches. This model emphasizes short lead times, repeatable quality, and a wide material selection to support diverse industrial applications.

Fundamentals of CNC Machining for Custom Parts

CNC machining is a subtractive manufacturing process where cutting tools remove material from a solid workpiece according to programmed toolpaths. Custom parts are produced from 3D CAD models and machining programs (G-code) that define tool movements, speeds, and cutting conditions.

CNC machining is suitable for metals, plastics, and some composites, and is widely used when dimensional accuracy, surface quality, and material performance are critical. Compared to manual machining, CNC provides higher repeatability, unattended operation capability, and better integration with digital product development workflows.

Key Processes: Milling, Turning and Secondary Operations

On-demand CNC machining services typically combine multiple processes to achieve the final part geometry and required features.

CNC Milling

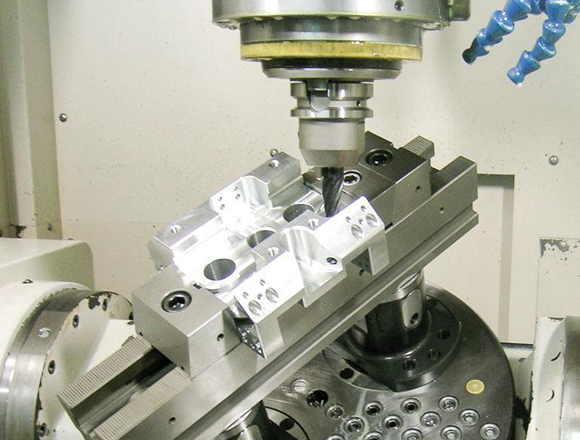

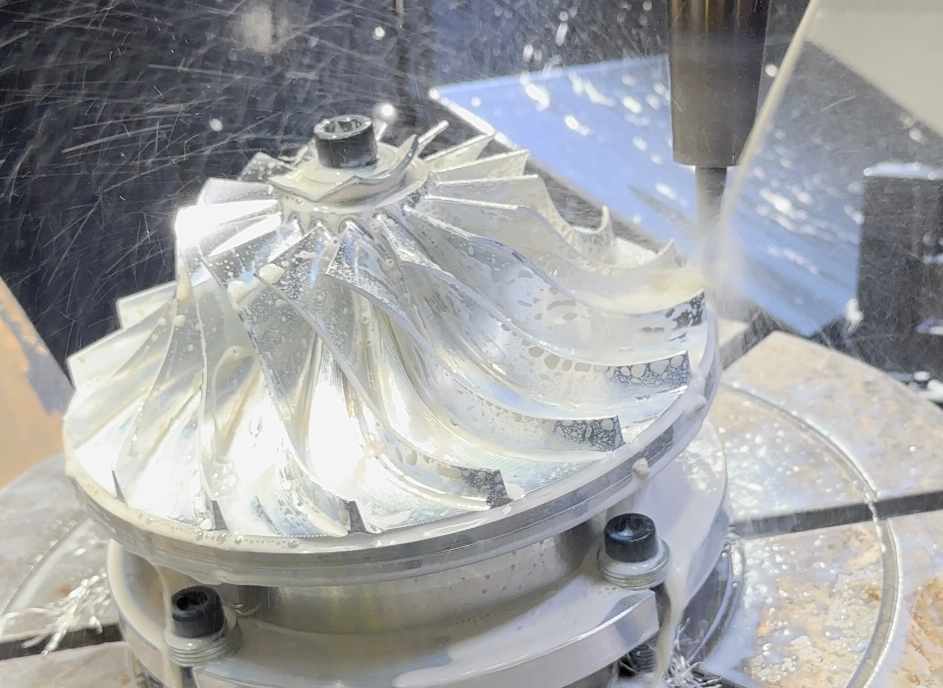

CNC milling uses rotating cutting tools to remove material from a fixed or moving workpiece. It is ideal for prismatic parts and complex 3D surfaces.

- Typical operations: facing, slotting, contouring, pocketing, drilling, tapping.

- Axes: 3-axis, 3+2-axis, and 5-axis configurations to reach different surfaces.

- Applications: housings, brackets, fixtures, manifolds, covers, molds, and dies.

CNC Turning

CNC turning uses a rotating workpiece and stationary or moving cutting tools. It is designed for parts with rotational symmetry.

- Typical operations: external turning, boring, grooving, threading, parting-off.

- Configurations: 2-axis lathes, live-tool lathes, and multi-axis turn-mill centers.

- Applications: shafts, bushings, sleeves, fasteners, fittings, pulleys, and rollers.

Secondary and Complementary Operations

To achieve complete custom parts, CNC machining is combined with additional operations, such as:

- Drilling and deep-hole drilling for through-holes and blind holes.

- Tapping and thread milling for internal threads.

- Reaming and boring for accurate hole sizes and improved finish.

- Broaching (internal keyways and splines, where available).

- Deburring and edge breaking to remove sharp edges and burrs.

On-Demand Manufacturing Model and Workflow

On-demand CNC machining services are organized around flexible capacity and digital workflows to support quick turnaround and variable order sizes.

Typical Workflow Steps

- Design submission: customer uploads CAD files (e.g., STEP, IGES) and drawing (PDF) if needed.

- Automated or engineer-supported manufacturability review to detect undercuts, inaccessible features, or excessive tolerances.

- Quotation based on geometry, material, quantity, and post-processing requirements.

- CAM programming and process planning, including tool selection, setups, and fixtures.

- Machining, in-process inspections, and any required intermediate heat treatment steps.

- Surface finishing, cleaning, marking, and final inspection.

- Packing, documentation, and shipping to the customer.

Order Quantities and Lead Times

On-demand services usually support a wide range of batch sizes:

Typical ranges include single prototypes, small batches (10–100 parts), medium runs (100–1,000 parts), and certain high-volume parts when CNC is the preferred method due to geometry or material constraints. Lead times depend on part complexity, material availability, and required post-processing, with simple prototypes often available in a few days.

Materials for Custom CNC Machined Parts

Material choice is a primary design and sourcing decision. On-demand CNC machining can handle many engineering metals and plastics. The table below summarizes representative material categories and typical use cases.

| Material Category | Representative Grades | Key Properties | Typical Applications |

|---|---|---|---|

| Aluminum Alloys | 6061-T6, 6082, 7075-T6, 2024 | Low density, good machinability, corrosion resistance (some grades), good strength-to-weight ratio | Aerospace structures, enclosures, brackets, heat sinks, fixtures |

| Carbon Steels | 1018, 1045, 4140 (alloy), 4340 | High strength, toughness, suitable for heat treatment, good cost-performance | Shafts, gears, tooling, structural components |

| Stainless Steels | 303, 304, 316, 17-4PH | Corrosion resistance, good mechanical properties, some grades hardenable | Food and medical equipment, marine parts, precision mechanical components |

| Titanium Alloys | Ti-6Al-4V | High strength, low density, excellent corrosion resistance, biocompatibility | Aerospace, medical implants, high-performance components |

| Copper Alloys | Copper, brass, bronze | High electrical and thermal conductivity, good machinability (brass), wear resistance (bronze) | Electrical components, connectors, bearings, heat transfer components |

| Engineering Plastics | ABS, POM (Delrin), Nylon, PEEK, PTFE, PC | Low weight, electrical insulation, chemical resistance, low friction (some grades) | Insulators, bushings, manifolds, functional prototypes, medical and laboratory parts |

Material selection should consider mechanical loads, thermal conditions, environment (corrosion, chemicals), weight targets, regulatory requirements, and cost. Many on-demand providers support certification requirements such as material test reports upon request.

Dimensional Tolerances and Geometric Accuracy

Tolerances specify how much variation from the nominal dimensions is allowed. CNC machining is capable of tight tolerances, but actual achievable values depend on machine capability, process setup, tool wear, material, and part geometry.

General Tolerance Guidelines

Typical machining tolerances on on-demand platforms often fall into ranges such as:

- Standard tolerances: ±0.1 mm to ±0.05 mm for most features without special specification.

- Tight tolerances: down to approximately ±0.01 mm for selected features with appropriate process controls.

- Hole tolerances: fits specified using ISO tolerance classes (e.g., H7, H8) when detailed drawings are provided.

Geometric dimensioning and tolerancing (GD&T) is used to control form, orientation, and position, such as flatness, cylindricity, perpendicularity, and true position. For on-demand orders, clear communication of critical features is important to ensure that process planning and inspection focus on these features.

Surface Finish and Post-Processing Options

CNC machining inherently produces a range of surface roughness values depending on tooling, cutting parameters, and toolpath strategies. Additional finishing processes can be applied to achieve functional or aesthetic requirements.

| Finish / Process | Description | Common Use |

|---|---|---|

| As-machined | Tool marks visible, Ra typically around 1.6–3.2 μm depending on parameters | Functional prototypes, internal surfaces, non-decorative parts |

| Bead blasting | Uniform matte surface using glass beads or similar media | Enclosures, visible aluminum parts, components requiring non-glare surfaces |

| Anodizing (Type II) | Electrochemical coating on aluminum, can be dyed in various colors | Corrosion protection, improved appearance, moderate wear resistance |

| Anodizing (Hardcoat, Type III) | Thicker anodic layer for higher wear and corrosion resistance | Mechanical components, sliding parts, harsh environment assemblies |

| Powder coating | Polymer coating powder-cured to form a continuous layer | Industrial equipment, consumer products, protective and decorative purposes |

| Electroplating | Metallic coating (e.g., nickel, chrome) applied by electrochemical deposition | Wear resistance, corrosion resistance, decorative finishes, electrical contact surfaces |

| Passivation | Chemical treatment for stainless steels to enhance corrosion resistance | Medical, food processing, and marine stainless parts |

| Black oxide | Conversion coating for carbon steel and some stainless steels | Light corrosion resistance, reduced glare, aesthetic black finish |

Surface roughness specifications (e.g., Ra values) should be defined only where functionally required, as finer finishes often increase machining time and cost.

Design for CNC Machining and Typical Constraints

Design practices directly influence manufacturability, lead time, and pricing. For on-demand CNC machining, many parts originate from general-purpose 3D models that may not be optimized for machining. Adjusting certain features improves both process reliability and cost-effectiveness.

Feature Geometry Considerations

Key geometric aspects include:

- Minimum wall thickness: excessive thin walls can cause vibration, deflection, and dimensional deviation during machining. Typical minimums for metals are often around 0.8–1.0 mm for small areas; thicker walls are more robust.

- Hole sizes and depths: very small diameter or deep holes require special tools and reduced feeds, impacting cycle time. Proportions such as depth up to 10 times diameter are more straightforward than deep micro-holes.

- Internal radii: sharp internal corners are limited by tool diameter. Adding fillets compatible with standard end mill sizes improves tool life and reduces cutting forces.

- Undercuts and hidden features: features that cannot be directly reached by standard tools may require special cutters, multiple setups, or may not be feasible, depending on machine axes and fixturing options.

Tolerance and Inspection Considerations

Specifying unnecessarily tight tolerances across all features can significantly increase machining and inspection efforts. A common approach is to:

Apply tight tolerances only to critical interfaces; use standard tolerances for non-functional surfaces; provide clear datums and GD&T schemes for assemblies where positional accuracy is essential. This allows on-demand providers to plan efficient measurement strategies and select appropriate inspection tools such as calipers, micrometers, height gauges, bore gauges, and coordinate measuring machines (CMMs).

Equipment, Capabilities and Part Size Ranges

On-demand CNC machining networks and individual shops operate a variety of machine tools. Capabilities differ, but common equipment categories include:

- 3-axis vertical machining centers (VMCs) for general prismatic work.

- 5-axis machining centers for complex geometries, multi-face machining, and reduced setups.

- 2-axis and multi-axis CNC lathes, with or without live tooling.

- Turn-mill centers that combine milling and turning in a single setup for improved concentricity and throughput.

Part size ranges vary with machine travel and chuck capacity. Many on-demand services can handle small precision components a few millimeters in size up to large parts several hundred millimeters across. Very large components may require specialized equipment with extended travels or horizontal machining centers.

Quality Control and Documentation

Quality control in on-demand CNC machining is achieved by combining process controls, inspection procedures, and documentation. The scope depends on order requirements and industry standards.

Inspection Methods

Common inspection methods include first article inspection (FAI) for the initial part, in-process checks at defined intervals, and final inspection before shipping. Measurement tools range from standard gauges to advanced CMMs and optical systems for complex geometries or tight tolerances. When multiple setups are required, intermediate checks are used to verify critical dimensions before proceeding.

Traceability and Reports

For regulated industries or mission-critical parts, documentation can include material certificates, heat treatment records, plating certifications, and dimensional inspection reports. On-demand providers may offer different inspection levels, such as basic measurement reports for key dimensions or comprehensive ballooned drawing reports.

Advantages of On-Demand CNC Machined Parts

On-demand CNC machining aligns well with development cycles and production needs where flexibility and precision are required.

- Flexible quantities: from one-off prototypes to mid-volume production without tooling investment.

- Material and process diversity: broad selection of metals and plastics with multiple finishing options in one sourcing channel.

- Dimensional precision: capability to meet engineering tolerances and functional requirements for mechanical assemblies.

- Digital integration: direct use of CAD data, rapid quotation, and traceable revisions.

Typical Use Cases and Application Areas

On-demand custom CNC machined parts are used across many sectors where geometry, tolerances, or material properties require machining instead of or in addition to other manufacturing processes.

Prototyping and Functional Testing

CNC machining is frequently chosen for functional prototypes when material properties and dimensional accuracy are important, such as prototypes for load-bearing structures, thermal management components, or precision mechanisms. Using production-equivalent materials allows realistic testing and validation.

Bridge Manufacturing and Low-Volume Production

When tooling for casting, forging, or molding is not yet available or not economically justified, CNC machining serves as a bridge manufacturing method. It supports pilot runs, pre-series batches, and ongoing low-volume production for specialized equipment or replacement parts.

Custom Tooling and Fixtures

Manufacturing operations often require custom fixtures, jigs, and tooling. On-demand CNC services provide these items with the necessary precision and stiffness to support assembly lines, test rigs, and automated equipment.

Cost Factors and Practical Considerations

Cost structure in on-demand CNC machining is influenced by several technical and logistical factors. Understanding them helps in designing parts and preparing RFQs.

Main Cost Drivers

- Setup time: the effort to prepare fixtures, tools, and programs. Consolidating similar parts and minimizing setups reduces cost per part, especially for small batches.

- Cycle time: determined by material removal volume, toolpath complexity, and chosen cutting conditions.

- Material costs: strongly influenced by alloy selection, stock size, and buy-to-fly ratio (volume of raw material versus final part).

- Secondary operations: finishing, heat treatment, and inspection level have associated additional costs.

Efficient part design, aligned tolerances, and early communication of requirements help match the part to the most suitable machines and processes within an on-demand network.