Oil and gas CNC machining focuses on producing high-precision, high-reliability metal components used in exploration, drilling, completion, production, transmission, and refining systems. Components operate under high pressure, high temperature, corrosive media, and cyclic loading, so machinability, dimensional control, and traceability are as important as material selection and design.

Role of CNC Machining in the Oil and Gas Industry

CNC machining is widely applied where dimensional accuracy, repeatability, and robust mechanical performance are required across onshore, offshore, and subsea environments. It supports both short-run customized parts and repeat production of standard oilfield components.

Common application areas include:

- Downhole drilling tools and string components

- Surface and subsea valves, manifolds, and chokes

- Well completion and intervention tools

- Pumps, compressors, and turbine components

- Pipelines, connectors, flanges, and fittings

- Measurement, monitoring, and control instrumentation

CNC technology allows tight control over tolerances, geometric features, and surface finish, enabling reliable sealing, thread engagement, and fatigue resistance under demanding conditions.

Key Features of Oil and Gas CNC Machined Components

Oil and gas components typically require a combination of mechanical strength, corrosion resistance, pressure containment, and precise geometry. CNC machining must support these requirements at scale while maintaining consistent quality and documentation.

Critical Dimensional and Geometric Requirements

Oilfield parts are often subject to strict dimensional control to ensure interchangeability and compliance with API, ISO, or customer-specific standards. Important aspects include:

- Close tolerances for mating parts, seals, and bearing fits

- Controlled runout and concentricity for rotating tools and shafts

- Flatness and parallelism of sealing faces

- Perpendicularity and positional accuracy of ports, holes, and threads

Geometric dimensioning and tolerancing (GD&T) is frequently applied. Features such as bores, shoulders, grooves, and counterbores must be machined with stable process capability, often supported by in-process or post-process metrology.

Threading, Connections, and Sealing Surfaces

Connections are a central element in oil and gas equipment. CNC machining must produce accurate threads and sealing interfaces to withstand high pressure and repeated make-and-break cycles.

Typical threaded and sealing features include:

- Premium and API rotary-shouldered connections on drill string components

- API casing and tubing threads (e.g., LTC, STC, BTC, premium gas-tight threads)

- NPT, BSPP, BSPT, and metric threads for instrumentation and auxiliary connections

- Metal-to-metal seal profiles on valve seats, gates, and ring-type joint (RTJ) flanges

Surface finish and profile tolerances on sealing faces are usually tightly specified to avoid leakage and galling. CNC lathe and mill-turn centers with thread cutting, thread milling, and profile turning capabilities are commonly used.

High-Pressure and High-Temperature Suitability

Many applications are classified as HPHT (high pressure, high temperature). While exact conditions vary, operational environments may involve:

High pressures for:

- Downhole tools in deep wells

- Surface and subsea wellhead valves

- High-pressure manifolds and choke systems

Elevated temperatures for:

- Deep reservoir conditions

- Thermal recovery operations

- Compressor and turbine components

Under these conditions, machining must maintain tight tolerances that remain functional when parts experience thermal expansion and internal stresses. Features like shoulders, stress-relief grooves, and fillets are machined to mitigate stress concentrations.

Wear, Corrosion, and Erosion Considerations

Oil and gas media can be corrosive, erosive, or both. Produced fluids may contain CO₂, H₂S, chlorides, sand, and other solids. CNC machining supports the integration of wear-resistant and corrosion-resistant materials and features such as:

- Hard-facing overlays and wear sleeves

- Replaceable inserts and nozzles

- Machined pockets and grooves for protective coatings and liners

Precision machining of overlay surfaces and transitions is important to avoid turbulence, localized erosion, or coating delamination.

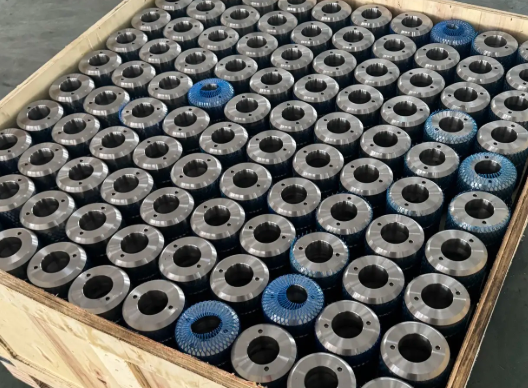

Traceability and Repeatability

Oilfield projects often require documented traceability from raw material to finished part. CNC machining operations must support:

- Traceable material certificates (e.g., mill test reports)

- Documented machining routes and process parameters

- Inspection records and dimensional reports

- Serialization and part marking

Consistent CNC programming and tool management enable stable repeatability for long-term projects where spare parts must match original geometry precisely.

Typical Oil and Gas CNC Machined Components

CNC machining is integral across the oil and gas equipment chain, from drill bit connections to refinery valves. The following categories represent typical use cases and machining features.

Downhole Drilling and Completion Components

Downhole tools operate in constrained boreholes under high load and temperature, often involving complex internal fluid paths and multi-step assemblies.

Common machined parts include:

- Drill collars, stabilizers, jars, and subs

- MWD/LWD tool housings and instrument carriers

- Rotary steerable system housings and mandrels

- Packer components, sleeves, and mandrels

- Completion subs, crossovers, and hanger components

These parts typically require deep-hole boring, long thread engagement, extended-length turning, and precise alignment of internal features. Multi-axis mill-turn centers are often used to reduce setups and maintain coaxiality.

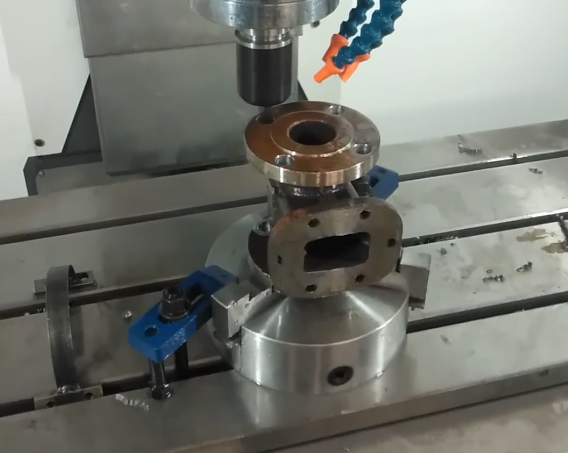

Surface and Subsea Valves and Manifolds

Valves and manifolds control flow and pressure on surface facilities and subsea production systems. CNC machining is used to produce:

- Gate valve bodies, bonnets, stems, and seats

- Ball valve bodies, balls, trunnions, and seats

- Choke bodies, beans, and cages

- Subsea manifold blocks and connector hubs

Valve components often combine thick-wall geometry, intersecting internal passages, and precision sealing surfaces. Manifold and block machining may involve deep intersecting bores with tight positional tolerances for ports and threaded connections.

Pumps, Compressors, and Turbine Components

CNC machining supports rotating equipment used in pipelines, gas processing plants, and offshore platforms. Components typically include:

- Shafts and rotor components

- Impellers, diffusers, and volute inserts

- Bearing housings and support structures

- Casing components with complex internal passages

Balance, roundness, and surface finish are critical for dynamic performance and efficiency. CNC grinding may complement turning and milling for tight runout and surface roughness on shaft and bearing surfaces.

Pipelines, Flanges, Fittings, and Connectors

CNC machining is used for pressure-containing components in pipeline systems and wellhead connections. Typical parts include:

- Flanges (e.g., weld neck, blind, slip-on, RTJ)

- Couplings, tees, crosses, reducers, and elbows with machined ends

- Clamp connectors and hubs

- Threaded and grooved pipe ends

Machining focuses on sealing surface flatness, surface roughness, and accurate bolt hole patterns. For RTJ flanges, the groove profile and finish are tightly controlled to ensure gasket performance.

Instrumentation, Measurement, and Control Components

Oil and gas operations rely on accurate measurement and control. CNC machining supports housings and fittings for:

- Pressure and temperature transmitters

- Flow meters and sampling systems

- Safety shutdown and control valves

- Sensor and transducer housings

These parts often require complex small-diameter internal passages, precise thread and O-ring groove geometry, and corrosion-resistant materials to maintain measurement integrity.

Materials for Oil and Gas CNC Machining

Material selection in oil and gas applications is driven by mechanical loads, corrosion environment, temperature, and regulatory requirements. CNC machining must accommodate both standard steels and advanced corrosion-resistant alloys (CRAs).

| Material Category | Typical Grades | Key Properties and Use Cases |

|---|---|---|

| Carbon & Low-Alloy Steels | ISO 15156-compatible structural and pressure vessel grades | Used for general structural components, flanges, and fittings when corrosion is controlled by coatings or inhibitors. |

| Alloy Steels | High-strength quenched and tempered grades | Applied for drill collars, heavy-duty shafts, and high-stress components requiring high yield strength. |

| Martensitic & Ferritic Stainless Steels | Oilfield tool and valve stem grades | Used where a balance of strength and moderate corrosion resistance is needed, such as valve internals and downhole tools. |

| Austenitic Stainless Steels | Common Cr-Ni and low-carbon variants | Applied in less severe sour environments, instrumentation parts, and non-magnetic housings. |

| Duplex & Super Duplex Stainless Steels | Oil and gas grade duplex alloys | Used extensively for subsea equipment, manifolds, and tubing in chloride-rich environments, offering high strength and corrosion resistance. |

| Nickel-Based Alloys | Corrosion and temperature resistant nickel alloys | Applied in highly corrosive sour service, high-temperature components, and critical sealing parts. |

| Titanium Alloys | Aerospace-type titanium grades adapted to oil and gas | Used where weight reduction and corrosion resistance are important, including subsea structures and some completion tools. |

| Non-Ferrous Alloys | Copper-based and aluminum alloys | Applied in components where conductivity, weight savings, or specific tribological properties are required. |

Machinability Characteristics of Key Material Groups

Different alloys show distinct machining behaviors. CNC machining strategies must be adapted in terms of cutting speed, feed rate, tool geometry, coolant strategy, and tool material.

Carbon and Alloy Steels

Carbon and alloy steels are generally machinable with standard carbide tools. However, high-strength quenched and tempered steels require controlled cutting conditions to avoid excessive tool wear and surface damage. Features include:

- Stable chip formation and good dimensional control

- Potential for hard spots after heat treatment, affecting tool life

- Susceptibility to surface work hardening if feeds are too low

Stainless Steels

Martensitic, ferritic, and austenitic stainless steels tend to work harden and have lower thermal conductivity than carbon steels. CNC machining strategies typically consider:

- Use of sharp, positive-rake carbide tools for efficient cutting

- Avoidance of rubbing and low feed rates to reduce work hardening

- High-pressure coolant to control heat and chip evacuation

Duplex and super duplex steels combine high strength with corrosion resistance, but this results in higher cutting forces and more demanding machining. Lower cutting speeds and robust tooling are generally applied.

Nickel-Based Alloys

Nickel alloys offer excellent corrosion and temperature resistance but can be difficult to machine due to high strength, tendency to work harden, and poor thermal conductivity. CNC machining considerations include:

- Relatively low cutting speeds with consistent, firm feeds

- Use of high-quality carbide or advanced tool materials

- Controlled depth of cut to cut below the work-hardened layer

- Increased attention to tool wear monitoring and replacement intervals

Titanium Alloys

Titanium alloys provide high strength-to-weight ratio and corrosion resistance, but they are prone to heat build-up at the cutting edge. Effective machining requires:

- Moderate cutting speeds with high feed rates

- Generous coolant application to control temperature

- Rigid setups to avoid vibration and chatter

CNC Capabilities for Oil and Gas Applications

Oil and gas components can be large, heavy, or long, requiring specialized machine configurations and process planning. CNC equipment choice directly influences achievable tolerances, lead times, and cost.

Turning and Mill-Turn Machining

Many cylindrical components such as housings, collars, subs, shafts, and valve stems are produced on CNC lathes and mill-turn centers. Common capabilities include:

- Large spindle bores for long tubular parts

- Steady rests and follow rests for long slender components

- C-axis and Y-axis milling for ports, flats, and slots in a single setup

- Thread cutting and thread milling for API and premium connections

Mill-turn machines reduce the number of setups and help maintain alignment between internal and external features. This is important for multistep tools where concentricity and runout directly influence performance.

Milling, Boring, and Machining Centers

Valves, manifolds, and structural components often require multi-face machining. CNC vertical and horizontal machining centers provide:

- Multi-axis capability for complex internal cavities and intersecting ports

- High-precision boring and reaming of critical bores

- Rotary tables or indexing to access multiple faces in one setup

Horizontal machining centers are frequently used for block-type parts and manifolds with deep intersecting passages where chip evacuation and coolant flow are important.

Deep-Hole Drilling and Gun Drilling

Downhole tools and valve internals often require deep, straight holes of controlled diameter. Dedicated deep-hole drilling and gun drilling machines may be used when hole length-to-diameter ratios exceed typical machining center capabilities. Critical aspects include:

- Coolant-through tooling and high-pressure coolant

- Control of hole straightness and diameter over long distances

- Surface finish compatible with flow and sealing requirements

Grinding, Honing, and Finishing Processes

To reach final dimensional and surface requirements, grinding and honing are applied to selected features:

- OD grinding of shafts, mandrels, and seal diameters

- ID grinding or honing of precision bores

- Lapping of sealing faces for low leakage applications

These finishing processes support tight tolerances for clearance fits, bearing surfaces, and sealing interfaces.

Tolerances, Surface Finish, and Quality Requirements

Oil and gas CNC parts commonly have defined tolerance classes for critical dimensions and surface finish requirements to ensure leak-tight sealing, reliable assembly, and controlled wear.

Typical Dimensional Tolerances

While exact tolerances vary by part and standard, typical ranges include:

- Linear dimensions for non-critical features: general machining tolerances

- Critical diameters for shafts, bores, and seal fits: tighter limits depending on function

- Thread tolerances: per API, ISO, or OEM specifications

- Geometric tolerances (runout, concentricity, flatness, etc.): typically on the order of hundredths of a millimeter for critical features

Consistent machine calibration, tool offset management, and in-process verification help maintain these tolerances over production batches.

Surface Finish Requirements

Surface roughness is defined according to function. Examples include:

- Sealing surfaces of valves and connectors requiring low Ra for metal-to-metal contact

- Flow passages and internal bores where finish affects pressure drop and erosion

- Threads where surface finish influences make-up torque and galling resistance

Finishing operations such as fine turning, grinding, lapping, or polishing are applied where necessary. Surface profiling may be performed using contact or non-contact measurement equipment.

Inspection and Quality Control Practices

Oilfield machining often employs comprehensive inspection protocols. Typical practices include:

- Dimensional inspection using CMMs, gauges, and fixtures

- Thread gauging with API or equivalent thread gauges

- Surface roughness measurement using profilometers

- Nondestructive testing (e.g., ultrasonic testing, magnetic particle testing, dye penetrant) for critical regions

Quality systems may reference ISO 9001 or equivalent frameworks, while suppliers to certain product lines also consider API Q1 or similar standards. Full documentation packages can include inspection reports, NDT results, and material traceability records.

Process Flow for Oil and Gas CNC Machined Parts

The manufacturing route for an oil and gas CNC machined component is structured to control material integrity, geometry, and documentation at each stage.

Design, Engineering, and Programming

The process begins with customer drawings, 3D models, or specification documents. Engineering activities include:

- Reviewing material requirements and standards (e.g., sour service, temperature rating)

- Defining machining strategy, fixtures, and sequence of operations

- Generating CNC programs (CAM) with tool paths optimized for chosen materials

- Planning inspection and NDT operations

Material Sourcing and Preparation

Material is procured according to required standards and tested as needed. Steps include:

- Verification of mill certificates and material identification

- Cutting raw stock to near-net blanks

- Pre-machining or forging where applicable

Heat treatment may be applied before final machining in some cases to achieve specified mechanical properties.

Rough and Semi-Finish Machining

Roughing operations remove the bulk of material, establishing baseline geometries and datum surfaces. Semi-finishing refines shapes while leaving stock for final cuts. Objectives:

- Control distortion and residual stress by balanced machining

- Maintain adequate stock allowance for critical surfaces

- Use robust tooling to manage chip removal efficiently

Finish Machining and Critical Features

Finish machining targets final dimensions, tolerances, and surface finishes. At this stage, CNC operations focus on:

- Critical bores, shafts, and sealing faces

- Threads, connection profiles, and mating surfaces

- Features that directly influence functional performance

In some cases, finish machining follows intermediate heat treatments or surface treatments to account for dimensional changes.

Inspection, Testing, and Documentation

After machining, parts are inspected against defined criteria. Typical steps:

- Dimensional inspection of critical and non-critical features

- NDT where required by design or standard

- Hydrostatic or pressure testing for pressure-containing parts where applicable

- Compilation of inspection reports and traceability documents

Documentation is often delivered together with the parts as part of the quality package.

Surface Treatment, Coating, and Assembly

Based on service conditions, parts may receive additional treatments:

- Phosphating, plating, or painting for corrosion protection

- Hard-facing overlays on wear surfaces

- Assembly of subcomponents into tools or valve assemblies

CNC machining sometimes includes pre-machining for coating thickness, followed by post-coating machining of critical surfaces.

Cost Drivers in Oil and Gas CNC Machining

Understanding the main cost elements helps optimize design and manufacturing strategies. Costs arise from material, machining time, tooling, inspection, and overhead associated with quality and documentation requirements.

| Cost Driver | Description | Design or Procurement Considerations |

|---|---|---|

| Material Type and Size | High-value alloys and large diameter stock increase raw material cost and waste. | Align material grade with actual corrosion and load requirements; consider near-net shapes if feasible. |

| Part Complexity | Complex geometries, deep internal features, and multiple setups add machining time. | Simplify features where possible without compromising function; group features for fewer setups. |

| Tolerances and Surface Finish | Tighter tolerances and finer finishes require slower machining and additional finishing operations. | Specify critical tolerances only where function demands; use standard tolerance ranges elsewhere. |

| Material Machinability | Difficult-to-machine alloys increase tool wear and cycle time. | Select alloys with sufficient, not excessive, corrosion resistance; plan realistic cycle times. |

| Batch Size and Repeat Orders | Setup and programming costs are spread over batch size. | Consolidate orders and standardize designs to leverage repeat production. |

| Inspection and Testing | CMM inspection, NDT, and pressure testing add labor and equipment time. | Define inspection scope aligned with risk and standards; avoid overspecification. |

| Documentation and Traceability | Quality documentation and traceability records require administrative effort. | Standardize documentation packages for similar product families. |

Impact of Material Selection on Cost

Advanced CRAs and nickel-based alloys have higher purchase prices and machining costs. Important aspects include:

- Material yield: large stock removed to reach final geometry increases waste

- Tool wear: more frequent tool changes and higher tooling cost

- Machine utilization: longer cycle times per part

Correct alignment between material class and anticipated service environment can significantly influence total installed cost while maintaining required safety margins.

Influence of Part Geometry and Size

Large and heavy parts require robust machines, lifting equipment, and secure fixturing, impacting both capital and operating cost. Features such as deep internal channels, intersecting ports, and blended sealing profiles can require specialized tooling and careful process planning. Considering manufacturability during design can reduce both cycle time and scrap risk.

Tolerances, Finishes, and Inspection Scope

Each incremental tightening of tolerance or surface finish may increase machining time and inspection effort. Carefully differentiating between critical and non-critical features allows focusing resources where they matter most, such as sealing interfaces, threads, and high-stress regions.

Typical Pain Points and Practical Considerations

While oil and gas CNC machining is well-established, recurring practical difficulties often affect timelines and costs.

Long Lead Times for Special Materials

Corrosion-resistant alloys, large-diameter forgings, or specific heat treatment conditions can require extended lead times. This affects project scheduling and may limit the ability to adjust designs late in the process. Early material planning and clear specifications help reduce delays.

Balancing Strength and Machinability

High-strength materials improve load capacity but often reduce machinability. Excessive strength beyond requirement can result in unnecessary machining challenges, higher tool consumption, and increased risk of defects such as surface tearing or residual stress.

Complex Thread and Connection Requirements

Premium connections, special clearance fits, and proprietary thread forms require accurate tooling, gauges, and programming. Misalignment or small dimensional deviations can lead to connection failure, leaks, or premature wear, so precision in thread machining and inspection is essential.

Geometric Stability During and After Machining

Long slender components, thick sections, and heavily machined areas may distort when internal stresses are released. Strategies such as intermediate stress-relief heat treatments, balanced material removal, and staged roughing/finishing are used to maintain dimensional stability.

Guidelines for Designing CNC Machined Oil and Gas Parts

Design choices strongly influence manufacturability, cost, and lead time. Coordinated design-for-manufacturing (DFM) practices are beneficial.

Standardization of Features and Interfaces

Where regulations and system design allow, standardized connection types, thread forms, and component families reduce programming, tooling, and inspection complexity. This supports faster production and easier spare parts management.

Clarity and Completeness of Specifications

Complete drawings and models, clear tolerances, and unambiguous material requirements reduce rework and clarifications. Including GD&T, surface finish symbols, and inspection criteria provides a precise definition of requirements.

Consideration of Machining Access and Setup

Designing components with machining access in mind helps minimize special fixtures and multi-step setups. Examples include:

- Ensuring tool access to internal features

- Allowing sufficient wall thickness near deep pockets

- Providing reference surfaces for clamping and datum alignment

Allowance for Coatings and Overlays

Where hard-facing or protective coatings are required, designs should define allowances for coating thickness and potential post-coat machining. This prevents undersized features or interference fits after coating.

How to Evaluate an Oil and Gas CNC Machining Supplier

Selecting a machining partner involves evaluating more than machine capacity. Oil and gas components require disciplined process control, documentation, and understanding of applicable standards.

Technical Capabilities and Equipment

Relevant evaluation points include:

- Availability of large-capacity lathes, mill-turn centers, and machining centers

- Ability to handle specified materials, including duplex and nickel alloys

- Access to deep-hole drilling, grinding, and finishing processes

- In-house or partnered heat treatment and coating services

Quality System and Traceability

A suitable supplier should maintain a documented quality system and be able to provide:

- Material certificates and heat traceability

- Inspection reports and test results

- Calibration records for critical measuring instruments

Experience with oil and gas standards and customer audits is often important for critical projects.

Experience with Oil and Gas Applications

Practical familiarity with downhole tools, subsea parts, and pressure-containing components helps avoid errors and supports efficient problem-solving. Knowledge of relevant specifications and typical operating conditions contributes to better DFM advice and smoother project execution.