Monel 400 (Alloy 400, UNS N04400, W.Nr. 2.4360/2.4361) is a solid-solution nickel–copper alloy widely used where seawater, hydrofluoric acid and alkaline media attack common stainless steels. This guide covers its composition, mechanical and corrosion properties, commercial product forms, cost structure, machining and fabrication recommendations, and typical industrial uses.

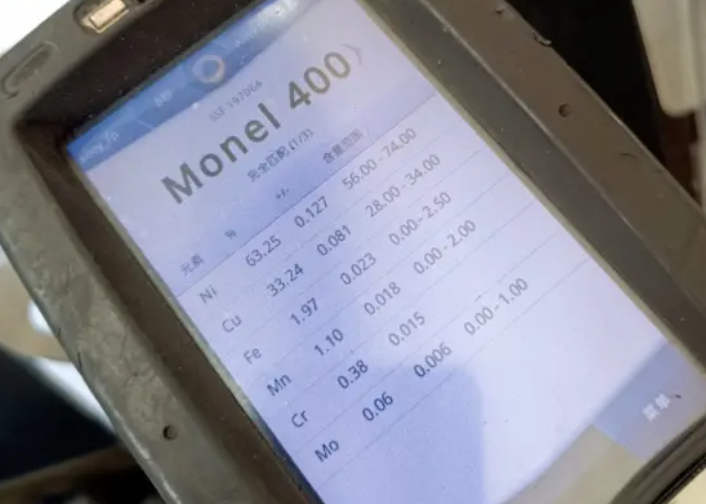

Chemical Composition and Standards

Monel 400 is a single-phase, solid-solution nickel–copper alloy with controlled additions of iron and manganese. Its composition is designed to balance corrosion resistance, strength and metallurgical stability, particularly in chloride and reducing environments.

| Element | Typical Range (%) | Notes |

|---|---|---|

| Nickel (Ni) | 63.0 min | Includes cobalt (Co); principal element |

| Copper (Cu) | 28.0–34.0 | Provides resistance in seawater and HF |

| Iron (Fe) | 2.0 max | Strengthening impurity; kept low |

| Manganese (Mn) | 2.0 max | Improves hot workability |

| Silicon (Si) | 0.5 max | Deoxidizer; excess may affect hot work |

| Carbon (C) | 0.3 max | Controls hardness and weldability |

| Sulfur (S) | 0.024 max | Kept very low for corrosion performance |

Common standards and designations for Monel 400 include:

- UNS: N04400

- Werkstoff: 2.4360 (hot-worked) / 2.4361 (cold-worked)

- ASTM/ASME (examples): B127 (plate, sheet, strip), B164 (bar, rod, wire), B163/B165 (seamless pipe and tube), B564 (forgings, flanges)

- ISO/EN (examples): EN 2.4360, EN 2.4361

Physical and Mechanical Properties

The physical and mechanical properties of Monel 400 combine moderate to high strength with excellent ductility and stable performance across a wide temperature range.

Physical Properties

Key physical characteristics relevant to design and process selection include:

- Density: ~8.80 g/cm³ (0.318 lb/in³)

- Melting range: approximately 1300–1350 °C (2370–2460 °F)

- Modulus of elasticity (tension): ~179 GPa (26 × 10³ ksi)

- Poisson’s ratio: ~0.32

- Thermal conductivity (at ~25 °C): ≈ 21 W/m·K

- Coefficient of thermal expansion (20–100 °C): ~13.9 × 10⁻⁶ /K

- Electrical resistivity (at 20 °C): ≈ 0.49 μΩ·m

- Magnetic behavior: essentially non-magnetic at room temperature

Mechanical Properties at Room Temperature

Typical mechanical properties depend on product form and degree of cold work. The values below are representative for standard plate or bar products tested at room temperature.

| Condition / Form | Yield Strength 0.2% (MPa) | Tensile Strength (MPa) | Elongation (%) | Hardness (HBW) |

|---|---|---|---|---|

| Annealed plate | 170–240 | 480–620 | ≥ 35 | ~130–180 |

| Annealed bar | 200–275 | 550–690 | ≥ 30 | ~150–190 |

| Moderately cold-drawn bar | 310–415 | 655–760 | ≥ 20 | ~200–240 |

Monel 400 retains useful strength at sub-zero temperatures without ductile-to-brittle transition and maintains mechanical stability up to about 480 °C (900 °F) in many applications, though design codes and environment-specific limits should be consulted.

Corrosion and Environmental Performance

Corrosion resistance is the main reason for selecting Monel 400. Its nickel–copper matrix offers outstanding performance in many chloride and reducing environments where standard stainless steels may suffer localized attack.

Seawater and Chloride Media

Monel 400 is widely used in marine environments:

- Excellent resistance to general corrosion in static and flowing seawater, especially at low to moderate temperatures

- High resistance to stress corrosion cracking in most chloride-containing environments

- Good resistance to pitting and crevice corrosion in seawater compared with many stainless steels

- Some increased corrosion rate in highly aerated, high-velocity seawater or at elevated temperatures; design must control velocity, turbulence and deposits

Acids and Alkalis

Performance varies by medium and temperature:

Hydrofluoric and fluorine-bearing media – One of the key strengths of Monel 400 is its resistance to hydrofluoric acid (HF) and fluoride salts over a wide concentration and temperature range, particularly in reducing conditions.

Hydrochloric and sulfuric acid – Monel 400 shows reasonable resistance in low-concentration and low-temperature hydrochloric and sulfuric acids, but corrosion rates increase at higher concentrations and temperatures, and careful evaluation is required.

Alkaline solutions – The alloy provides excellent resistance in caustic alkalis, including sodium hydroxide and potassium hydroxide solutions, particularly under reducing conditions and over a broad temperature range.

Oxidizing Conditions

In strongly oxidizing environments Monel 400 is less resistant than some higher-alloyed nickel-based materials:

- Limited resistance in strongly oxidizing acids such as hot, concentrated nitric acid

- Oxidizing salts and oxidizing acid mixtures may cause relatively rapid attack

In such cases, alternative alloys may be more suitable, and corrosion testing under representative conditions is recommended.

Other Media

Monel 400 is often preferred in:

- Brine and salt solutions: good resistance in many neutral and alkaline salt solutions

- Halogenated hydrocarbons: suitable in many hydrocarbon processing and chemical environments

- Hydrogen and reducing gases: stable mechanical and corrosion behavior in many reducing atmospheres

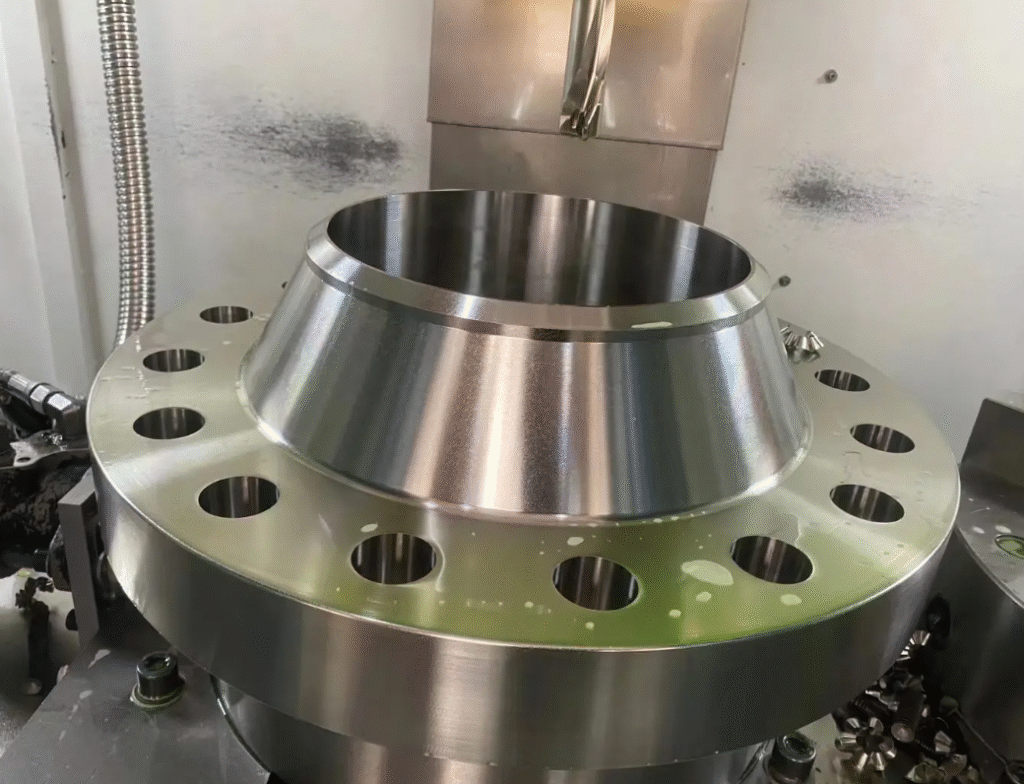

Product Forms and Supply Conditions

Monel 400 is commercially available in a wide range of semi-finished and finished product forms, enabling application from thin-walled heat exchanger tubes to heavy forgings and complex fabricated components.

Common Product Forms

Typical forms include:

- Plate, sheet and strip (hot rolled and cold rolled)

- Round bar, flat bar, hex bar and wire

- Seamless and welded pipe and tube

- Fittings: elbows, tees, reducers, caps, couplings

- Flanges and forged components

- Welding consumables: covered electrodes, filler wires and rods

Supply Conditions and Tempers

Standard conditions include:

- Annealed (solution-annealed) plate, sheet, bar and tube for general fabrication and welding

- Cold-drawn or cold-worked bar, tube and wire for higher strength requirements

- Hot-finished pipe and bar for heavy-duty components

Material certificates typically comply with ASTM, ASME, EN or ISO standards, including chemical analysis, mechanical test results and, where specified, nondestructive examination and corrosion testing.

Cost, Pricing Factors and Purchasing Considerations

Monel 400 is positioned as a higher-cost alloy compared to carbon steel and standard stainless steels because of its nickel content and specialized manufacturing route. Understanding the cost structure helps engineers and buyers evaluate its use relative to performance requirements.

Key Cost Drivers

Several factors influence the price of Monel 400 products:

- Nickel content: Nickel is the major cost contributor; Monel 400 contains a high proportion of nickel, directly affecting raw material cost.

- Product form: Seamless tubes, precision bars and heavy plates generally carry higher production costs than simple shapes like hot-rolled plate or basic bar.

- Manufacturing route: Cold drawing, precision machining, tight dimensional tolerances and special testing increase price.

- Certification and testing: Additional mechanical, corrosion or non-destructive testing, and compliance to demanding codes, add to cost.

- Order quantity and logistics: Small batch orders, custom dimensions and urgent delivery can increase unit price.

Relative Cost Positioning

Relative to other common engineering materials, Monel 400 typically falls in the following order in terms of cost per kilogram or per unit of finished part:

- Carbon steels < basic stainless steels (e.g., 304, 316) < Monel 400 < higher nickel-based corrosion resistant alloys and superalloys

However, the total cost of ownership can be favorable where Monel 400 prevents frequent replacement or unplanned downtime in corrosive service.

Purchasing Considerations

When specifying and purchasing Monel 400, it is important to define:

- Applicable standard (ASTM/ASME/EN) and product form

- Dimensions, tolerances and surface finish

- Mechanical property requirements (strength level, hardness, temper)

- Corrosion or NDT testing requirements, if any

- Certification level (e.g., 3.1 or 3.2 test certificates where applicable)

For critical components, procuring from mills and distributors with proven experience in nickel-based alloys helps ensure consistent quality and traceability.

Machinability and Cutting Parameters

Monel 400 is considered more difficult to machine than carbon steel and standard stainless steels. Its toughness, work-hardening tendency and low thermal conductivity require appropriate tooling and cutting strategies. With correct practices, consistent and reliable machining is achievable.

General Machining Characteristics

Key features affecting machining include:

- Work-hardening: The alloy work-hardens rapidly under cold deformation or if the cutting tool rubs instead of cutting cleanly, leading to harder surface layers.

- Toughness and ductility: Chip formation tends to be continuous and stringy; effective chip control is necessary.

- Low thermal conductivity: Heat concentrates at the cutting edge, increasing tool wear and risk of built-up edge if cooling is inadequate.

- Moderate hardness: In annealed condition, hardness is typically around 130–190 HBW, but localized work-hardened zones can be significantly harder.

Tooling and Cutting Recommendations

For turning, milling, drilling and other operations on Monel 400:

- Tool material: Use high-performance carbide tools or, for some operations, cermet or ceramic inserts. High-speed steel can be used at lower cutting speeds for less demanding tasks.

- Tool geometry: Positive rake, sharp edges and robust chip breakers are recommended to minimize work hardening and manage chip flow.

- Cutting speed: Generally lower than for carbon steel and standard stainless steels. Specific values depend on tool grade, machine rigidity and coolant availability, but speeds are typically in a conservative range.

- Feed and depth of cut: Use relatively high feed and sufficient depth of cut to cut below the work-hardened layer from the previous pass.

- Coolant: Generous application of cutting fluids is important for heat removal and tool life. Water-based coolants with appropriate additives are commonly used.

Operational Practices

To stabilize machining performance:

- Maintain rigid setups to minimize vibration and prevent tool chatter.

- Avoid dwelling or rubbing at the cut; continuous, steady cutting reduces work hardening.

- Use peck drilling with care in deep holes to remove chips effectively.

- Regularly inspect tools for wear and replace before excessive edge breakdown occurs.

- For threading, consider using specialized inserts and adequate lubrication to prevent tearing or galling of threads.

Correct parameter selection is often specific to the machine tool and setup. Many manufacturers of cutting tools provide dedicated recommendations for nickel–copper alloys, which can serve as a practical starting point.

Forming, Hot Working and Cold Working

Monel 400 can be successfully hot-formed and cold-formed, but its work-hardening behavior requires controlled processing and frequent intermediate anneals in severe forming operations.

Hot Working

Hot forming operations, such as forging, hot extrusion and hot rolling, are typically conducted in a specific temperature range:

- Typical hot-working range: approximately 870–1200 °C (1600–2190 °F)

- Hot forging is usually started at the upper end of this range and finished at the lower end to ensure adequate plasticity while preventing surface cracking.

- Post-hot-working annealing is often applied to restore uniform microstructure and mechanical properties, followed by appropriate cooling.

Cold Working

Cold forming operations include bending, drawing, deep drawing, cold heading and rolling:

- Monel 400 exhibits significant work hardening; formability is good but requires higher forces than many stainless steels.

- Multiple forming steps may require intermediate anneals to restore ductility and reduce forming loads.

- Springback should be considered in bending operations due to the alloy’s elasticity.

- Cold working can substantially increase strength and hardness, which may be intentionally used to achieve target properties.

Heat Treatment and Stress Relief

Heat treatment of Monel 400 is primarily aimed at stress relief and homogenization. The alloy does not harden by precipitation; higher strength is obtained by cold working.

Annealing

Full annealing is used to restore ductility after cold work or to homogenize the microstructure after hot working:

- Typical annealing temperature range: about 760–980 °C (1400–1800 °F), depending on product and required properties.

- Holding time must be sufficient to equalize temperature through section thickness.

- Cooling: often air cool; more rapid cooling (e.g., water quench) can be used to minimize surface oxidation, depending on part geometry and process setup.

Stress Relieving

Stress relief treatments can reduce residual stresses from machining, forming or welding:

- Typical stress-relief temperatures: lower than full annealing, often in a range where dimensional stability is improved with minimal impact on mechanical properties.

- Cooling conditions should limit distortion and maintain part geometry.

Welding and Joining

Monel 400 is readily weldable by most conventional processes when proper procedures are followed. Its weldability is an important advantage for complex equipment and piping systems.

Suitable Welding Processes

Common welding methods include:

- Gas tungsten arc welding (GTAW/TIG)

- Gas metal arc welding (GMAW/MIG)

- Shielded metal arc welding (SMAW)

- Submerged arc welding (SAW) for some large components

Matching or slightly overmatching filler metals based on Monel 400 or closely related alloys are typically used to maintain corrosion resistance and mechanical compatibility with the base material.

Welding Practices

Key considerations for welding Monel 400 include:

- Cleanliness: Remove oil, grease, oxides and contamination from weld preparation areas.

- Heat input: Controlled heat input is recommended to minimize distortion and maintain microstructural stability.

- Preheat and post-weld heat treatment: Usually not required for Monel 400, but procedures may vary by joint design and thickness.

- Interpass temperature control: Avoid excessive interpass temperatures to maintain consistent properties.

Applications and Industry Use Cases

Monel 400 is used where a combination of corrosion resistance, strength and fabrication flexibility is required. Applications typically involve seawater, brine, alkaline media, hydrofluoric acid and other challenging environments.

Marine and Offshore

Typical uses include:

- Pump and valve components in seawater systems

- Propeller shafts and fasteners

- Seawater intake and discharge components

- Heat exchanger tubes and tube sheets in marine environments

- Fasteners and hardware in splash zones and submerged conditions

Chemical and Petrochemical Processing

In the chemical and hydrocarbon processing sectors, Monel 400 is typically used for:

- Equipment and piping in hydrofluoric acid service

- Alkylation units and related refinery components

- Pumps, valves and fittings in caustic and salt solutions

- Heat exchangers handling corrosive brines and process streams

Power Generation and Desalination

Monel 400 is used in:

- Condenser tubes and cooling water systems in power plants

- Desalination plant components exposed to seawater

- Auxiliary systems where corrosion from brackish water is significant

Other Specialized Uses

Additional applications include:

- Oil and gas production components in sour or seawater-containing environments

- Instrumentation and control components in corrosive atmospheres

- Fasteners and springs where non-magnetic behavior and corrosion resistance are required

Selection Guidelines and Practical Considerations

Choosing Monel 400 should be based on a structured comparison between material performance and service requirements. The alloy is most effective when its specific strengths match critical design needs.

When Monel 400 Is a Suitable Choice

- Service in seawater, brackish water or chloride-bearing media where stainless steels risk localized corrosion.

- Exposure to hydrofluoric acid, fluorides or caustic alkalis where few materials offer comparable resistance.

- Requirements for material toughness and ductility at low temperatures.

- Need for a nickel–copper alloy with good weldability and formability.

Limitations and Considerations

- In strongly oxidizing acids and oxidizing salt environments, performance may be inadequate compared to higher-alloyed nickel materials.

- Machinability is more demanding than steels, requiring correct tooling and process control.

- Material cost is higher than carbon and standard stainless steels; justification often relies on lifecycle cost and reliability.

Monel 400 FAQ

What is Monel 400?

Monel 400 is a nickel-copper alloy (UNS N04400) known for its excellent corrosion resistance, high strength, and good performance in marine and chemical environments. It is widely used in aerospace, marine, oil & gas, and chemical processing industries.

What are the key properties of Monel 400?

Monel 400 offers:

Excellent resistance to seawater and salt environments

Good strength over a wide temperature range

High resistance to corrosion and stress corrosion cracking

Good thermal and electrical conductivity

Is Monel 400 easy to machine?

Monel 400 has moderate machinability. It is tougher than carbon steel and aluminum, and it tends to work-harden during machining. Sharp tools, rigid setups, and proper cutting parameters are recommended for optimal results.

How does Monel 400 compare to stainless steel?

Compared to stainless steel, Monel 400 offers superior corrosion resistance in marine and acidic environments, but it is generally more expensive and more difficult to machine. Stainless steel may be preferred for cost-sensitive or less corrosive applications.

What standards and equivalent grades does Monel 400 have?

Monel 400 is commonly identified as:

UNS N04400

ASTM B164 / B165 / B564

DIN 2.4360 / 2.4361