Hastelloy C-276 is a nickel-molybdenum-chromium superalloy widely used in chemical processing, pollution control, energy, and marine environments due to its resistance to pitting, crevice attack, and stress corrosion cracking. Its excellent mechanical and corrosion properties also make it demanding to machine. This guide provides a structured, in-depth reference on tooling selection, cutting parameters, process strategies, and best practices for machining Hastelloy C-276 in industrial environments.

Material Characteristics Relevant to Machining

Understanding the physical and metallurgical behavior of Hastelloy C-276 is essential for selecting tools and setting cutting conditions.

Chemical and Microstructural Features

Hastelloy C-276 is primarily a nickel-based alloy with significant molybdenum and chromium, plus smaller additions of iron, tungsten, and other elements. Key implications for machining include:

- High work-hardening rate of the nickel matrix

- High strength at elevated temperatures

- Good toughness and ductility at room and low temperatures

The combination of strength and work-hardening means the material resists chip formation and responds negatively to rubbing, dull tools, and low feed rates.

Mechanical and Thermal Behavior During Cutting

During machining, Hastelloy C-276 exhibits:

- High cutting forces compared with carbon and stainless steels

- High heat generation concentrated at the tool-chip interface

- Tendency to form built-up edge if parameters and coolant are not optimized

These behaviors increase tool wear, especially notch wear and crater wear, and can compromise surface integrity if not controlled. Stable machine tools, rigid workholding, sharp tooling, and adequate coolant delivery are essential.

General Machinability Considerations

Compared with low-alloy steels and common stainless steels, Hastelloy C-276 has lower machinability in conventional cutting operations. Practical implications include:

Key considerations:

- Tool life is typically shorter; tooling costs and setup frequency can be higher

- Cutting speeds must be kept relatively low while feeds are kept moderate to high to avoid rubbing

- Chip evacuation is more demanding due to tough, stringy chips in some conditions

Despite these constraints, consistent, predictable machining is achievable when tooling and parameters are selected for the alloy rather than adapted from mild steel or standard stainless settings.

Tool Material Selection for Hastelloy C-276

Tool material and grade strongly influence productivity and cost in Hastelloy C-276 machining. Selection should account for operation type, production volume, and required dimensional and surface tolerances.

Cemented Carbide Tools

Cemented carbide is the most common choice for turning, milling, and drilling Hastelloy C-276. Recommendations include:

- Submicron or fine-grain carbide substrates for strength and edge integrity

- High cobalt content (typically 8–12%) for toughness in interrupted cuts

- PVD-coated grades (TiAlN, AlTiN, AlCrN, or multilayer nanocomposites) for improved hot hardness and oxidation resistance at moderate speeds

Where thermal cracking is a concern, uncoated fine-grain carbides may be selected and run at lower speeds to maintain stable temperatures.

Cermet and Ceramic Tools

Cermets and ceramics are less widely used for Hastelloy C-276 than for some other high-temperature alloys because:

- Toughness demands are high, especially in interrupted cuts

- Thermal shock risk is significant with heavy coolant application

However, in very stable, continuous turning at elevated cutting speeds and with carefully controlled coolant delivery (or dry cutting in specific cases), whisker-reinforced or SiAlON ceramics may be applied for roughing. These setups usually require dedicated process development, conservative depths of cut, and robust fixturing.

High-Speed Steel (HSS) Tools

HSS is suitable mainly for:

- Low-speed drilling, reaming, and tapping

- Tool geometries not readily available in carbide, such as special form tools

Cobalt-enriched HSS grades (e.g., M35, M42) are preferred because of their hot hardness and red hardness. Cutting speeds must be low, with generous coolant and careful peck cycles for drilling.

PCD and CBN Tools

Polycrystalline diamond (PCD) is not suitable for Hastelloy C-276 due to chemical affinity issues and rapid tool degradation. Cubic boron nitride (CBN) is also rarely used because its advantages are less pronounced in nickel-based, work-hardening alloys than in hardened steels. Carbide and, in special cases, ceramics remain the primary choices.

Tool Geometry and Edge Preparation

Tool geometry has a significant impact on cutting forces, heat generation, chip control, and surface integrity. Geometry should be tailored to the toughness and work-hardening characteristics of Hastelloy C-276.

Rake, Clearance, and Edge Hone

General guidelines for carbide tools:

- Positive rake angles (e.g., +5° to +15°) to reduce cutting forces and heat

- Adequate clearance (relief) to prevent rubbing without creating a weak cutting edge

- Small edge hone or micro-radius to strengthen the edge while retaining sharpness

For finishing operations, use a smaller hone and higher rake for lower cutting forces and better surface finish. For roughing, a slightly larger hone and moderate rake can improve edge strength and predictability.

Chipbreaker Design

Nickel alloys like Hastelloy C-276 may produce long, continuous chips if chipbreaker design, feeds, and depths of cut are not matched. Effective chipbreakers for this alloy typically feature:

- Positive cutting geometry with well-defined chip forming grooves

- Designs optimized for moderate feeds (rather than extremely light cuts)

- Capability to break chips at depths of cut that match the actual operation, not just nominal values

Poor chip control can lead to chip wrapping, tool damage, and inconsistent surface finish. When standard chipbreakers are ineffective, adjusting feed and depth of cut is often more productive than changing speed alone.

Helix and Point Geometry for Drills

For drilling Hastelloy C-276:

- Use high-quality carbide or cobalt HSS drills with a split point (often 135°) to reduce thrust

- Employ polished flutes and optimized helix angles to assist chip evacuation

- Consider parabolic flute designs or through-coolant drills for deeper holes

Proper point geometry helps minimize work-hardening at the hole entrance and improves positional accuracy.

Cutting Parameters: Overview and Key Principles

Cutting parameters must balance tool life, productivity, and part quality. For Hastelloy C-276, there are consistent principles across operations:

- Use lower cutting speeds than for carbon or stainless steels

- Maintain sufficient feed to prevent rubbing and work-hardening

- Select depths of cut that stay above previously work-hardened layers when possible

- Use generous coolant flow, especially in continuous, heavy cuts

The following sections give representative starting ranges, which should be adjusted based on tool grade, machine rigidity, coolant, and specific part features. Always verify with toolmaker data and shop trials.

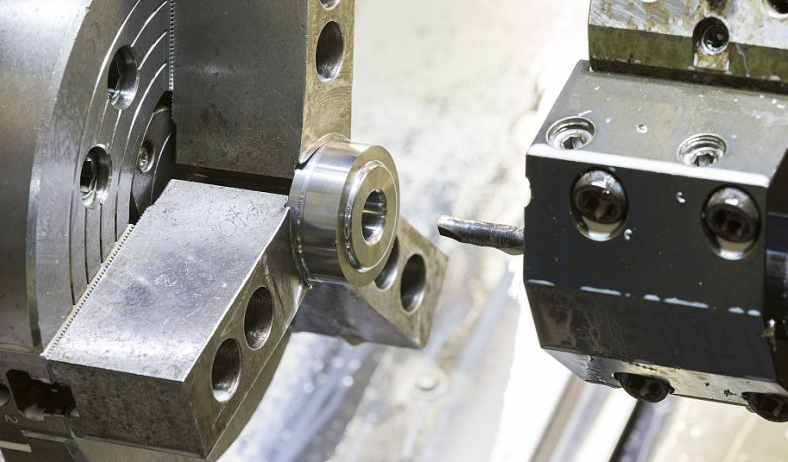

Turning Hastelloy C-276

Turning is one of the most common operations on Hastelloy C-276 bar, forgings, and rings. It covers roughing, semi-finishing, and finishing operations with carbide inserts on rigid lathes or multi-axis turning centers.

Typical Turning Parameters

| Operation | Cutting Speed vc (m/min) | Feed f (mm/rev) | Depth of Cut ap (mm) | Notes |

|---|---|---|---|---|

| Rough turning | 20–40 | 0.20–0.40 | 1.5–4.0 | Use robust chipbreaker, high coolant flow |

| Semi-finishing | 30–45 | 0.15–0.30 | 0.8–2.0 | Balance tool life and surface quality |

| Finishing | 35–55 | 0.08–0.18 | 0.3–1.0 | Sharp tools, stable machine, consistent coolant |

These ranges assume stable setups, PVD-coated fine-grain carbide inserts, and flood coolant. When using ceramics in continuous cuts, speeds may be increased, but this requires careful process development.

Roughing Strategies in Turning

For rough turning Hastelloy C-276:

- Use strong insert geometries with high edge toughness and robust chipbreakers

- Maintain a consistent depth of cut that penetrates below any work-hardened surface created by previous passes

- Choose feeds high enough for chip breaking and to avoid sliding and smearing

Interrupted cuts should be minimized. When unavoidable, reduce cutting speed, select tougher grades, and avoid excessive depth of cut at entry and exit points.

Finishing Strategies in Turning

For finishing operations:

- Use sharp inserts with smaller edge hones and fine-grain carbides

- Use moderate cutting speeds and reduced feed to achieve target surface roughness

- Ensure stable clamping to minimize vibration, which is detrimental to both surface finish and tool life

Stable thermal conditions are important: sudden changes in coolant flow or cutting load can cause microcracking or accelerated wear.

Milling Hastelloy C-276

Milling operations on Hastelloy C-276 include face milling, slotting, contour milling, and high-precision finishing. Milling requires particular attention to chip load and radial engagement, as interrupted cutting intensifies thermal and mechanical cycling of the tool.

Face and Peripheral Milling Parameters

For carbide end mills and face mills cutting Hastelloy C-276, typical starting values are:

- Cutting speed vc: 20–40 m/min for solid carbide; 25–45 m/min for indexable mills

- Feed per tooth fz: 0.03–0.10 mm/tooth, depending on tool diameter, rigidity, and operation (roughing vs. finishing)

- Axial depth of cut ap: up to 1.0–2.0 × tool diameter for roughing, reduced for finishing

- Radial width of cut ae: 10–40% of tool diameter for improved tool life and chip evacuation

Conservative radial engagement with higher axial depth often yields better tool life than full-width slotting at similar material removal rates.

| Operation | vc (m/min) | fz (mm/tooth) | ae (% of D) | ap (mm) |

|---|---|---|---|---|

| Rough side milling | 20–35 | 0.04–0.08 | 20–40% | 0.5–1.0 × D |

| Finishing side milling | 30–45 | 0.03–0.06 | 5–20% | 0.2–0.5 × D |

| Face milling | 25–45 | 0.05–0.10 | 60–80% | 0.5–3.0 |

Milling Strategy and Cutter Selection

Key points for milling Hastelloy C-276:

- Prefer positive rake indexable inserts or sharp solid carbide end mills to reduce cutting forces

- Use tools with variable helix and pitch to limit vibration and chatter

- Avoid full-width slotting when possible; use trochoidal or radial step-over strategies to manage heat and forces

In climb milling (down milling), chip thickness starts high and decreases, which helps reduce rubbing and work-hardening compared with conventional milling. Climb milling is generally favored where machine backlash and rigidity allow.

Tool Wear Patterns in Milling

Common wear mechanisms include:

- Flank wear from abrasion by work-hardened material

- Notch wear at the depth-of-cut line due to localized hardening and chemical interaction

- Thermal cracking on cutting edges exposed to alternating hot cutting and cooler air/coolant

Mitigation strategies include more stable coolant delivery, controlled chip thickness, and avoidance of dwell or repeated rubbing passes over the same surface.

Drilling and Hole-Making in Hastelloy C-276

Hole-making is critical in many components made from Hastelloy C-276, including nozzles, manifolds, and pressure vessels. Drilling places a high demand on tool strength, chip removal, and coolant delivery.

Drill Selection

Recommended tools include:

- Carbide twist drills with through-coolant channels and optimized geometry for nickel-based alloys

- Cobalt HSS drills for smaller diameters or short runs, with low cutting speeds

- Parabolic flute drills for improved chip evacuation in deep holes

High-quality drills with tight manufacturing tolerances are important to maintain straightness and hole size accuracy in this tough alloy.

Drilling Parameters and Techniques

Typical starting parameters for drilling with carbide:

- Cutting speed vc: 10–25 m/min, depending on drill diameter and coolant

- Feed per revolution f: 0.05–0.20 mm/rev, adjusted for hole size and rigidity

- Peck drilling: recommended for deep holes, with controlled peck depth to break chips and reduce heat

For HSS drills, cutting speeds are lower (often 5–12 m/min) with proportionally adjusted feeds. Oversized pre-drilling followed by reaming or boring may be used when tight tolerances or high surface finishes are required.

Chip Evacuation and Hole Quality

Because Hastelloy C-276 produces tough chips, chip removal is critical:

- Ensure adequate coolant pressure and flow through the drill for deep holes

- Use peck cycles with chip evacuation, avoiding excessive dwell at the bottom of the hole

- Monitor cutting forces for signs of chip packing or tool wear

Good practice also includes avoiding excessive runout and ensuring rigid fixturing to prevent hole drift and poor surface quality.

Coolant Strategy and Lubrication

Effective coolant application is central to controlling temperature, reducing tool wear, and improving surface integrity in Hastelloy C-276 machining.

Coolant Type and Concentration

Water-based, high-performance metalworking fluids with additives for high-pressure, high-temperature cutting are commonly used. Recommendations include:

- Emulsion coolants with appropriate concentration to balance lubrication and cooling

- Semi-synthetic or synthetic coolants for cleanliness and thermal performance

- Lubricity-enhancing additives for tapping and other high-friction operations

Concentration should follow coolant supplier guidelines, with regular monitoring to maintain consistent performance.

Delivery Method and Pressure

Coolant delivery methods for Hastelloy C-276 include:

- Flood coolant for turning and milling, directed at the cutting zone to flush chips and control temperature

- High-pressure coolant for deep-hole drilling and demanding milling operations

- Through-tool coolant in drills, end mills, and some turning tools to improve cooling and chip evacuation

Steady coolant flow is important. Avoid intermittent coolant application during high-temperature cutting, which can induce thermal shock and lead to cracking in some tool materials.

Workholding, Machine Tool Requirements, and Rigidity

Because Hastelloy C-276 is strong and tough, adequate rigidity of the machine-tool-workpiece system is essential for stable cutting conditions and satisfactory tool life.

Machine Tool Requirements

Effective machining requires:

- High structural stiffness in the machine tool and spindle

- Minimal backlash and high-quality axis control for milling and multi-axis turning

- Stable, vibration-free operation at the moderate speeds typical for this alloy

Machines with high torque at low spindle speeds are beneficial for drilling and heavy turning operations where cutting speeds are limited by tool life.

Fixturing and Workholding

Workholding should be designed to:

- Minimize deflection of the workpiece under cutting loads

- Provide accessible paths for chip flow and coolant application

- Support the workpiece close to the cutting zone to avoid chatter and dimensional errors

Soft jaws and custom fixtures are often required for complex geometries or thin-walled parts. Proper pre-clamping assessment and verification can prevent distortion and misalignment.

Surface Integrity and Dimensional Control

Surface integrity in Hastelloy C-276 includes not only geometric accuracy and roughness, but also microstructural condition, residual stresses, and absence of surface damage such as micro-cracks or smearing.

Surface Finish Targets and Methods

Typical surface roughness requirements vary by application:

- Roughing: Ra in the range of 3.2–6.3 µm, using robust roughing parameters

- Semi-finishing: Ra around 1.6–3.2 µm with reduced feed and optimized tool geometry

- Finishing: Ra 0.4–1.6 µm or finer with sharp tools and stable conditions

For very tight surface finish requirements, a combination of controlled finishing cuts, appropriate coolant, and subsequent honing, lapping, or grinding may be used.

Controlling Work-Hardening and Subsurface Condition

Work-hardening is a key concern. To minimize adverse effects:

- Avoid rubbing by maintaining adequate feed and sharp cutting edges

- Avoid repeated light passes at the same depth that only cut work-hardened material

- Use consistent parameter settings to reduce local heat accumulation

Inspection of surface and subsurface condition, particularly on critical parts, may include microhardness testing and metallographic examination to ensure integrity.

Tool Wear Monitoring and Maintenance

Due to the demanding nature of Hastelloy C-276 machining, proactive tool wear monitoring and maintenance are important for predictable performance and cost control.

Common Indicators of Tool Wear

Signs that tools require indexing or replacement include:

- Gradual increase in cutting force or spindle load at constant parameters

- Deterioration of surface finish, including tearing or smearing

- Changes in chip shape, color, or edge (such as ragged chips)

- Visible flank wear, crater wear, or notch formation

In many production environments, wear is managed by fixed tool-life limits tied to part counts or cutting length, balanced against tool cost.

Tool Management Practices

Effective practices include:

- Standardized tool identification and storage to ensure correct grade and geometry are used

- Documented cutting parameter sets for each tool and operation on Hastelloy C-276

- Regular inspection of used tools to understand wear modes and adjust parameters or grades accordingly

Iterative optimization using shop-floor data contributes to improved performance over time.

Common Issues and Practical Considerations

Several recurring issues arise when machining Hastelloy C-276; addressing them systematically improves consistency and tool life.

Chip Control and Disposal

Chips can be long, tough, and difficult to break, especially in turning and drilling. To improve chip behavior:

- Use chipbreakers designed for high-toughness alloys

- Adjust feed and depth of cut to fall within the chipbreaker’s effective window

- Maintain consistent coolant flow to reduce chip adhesion to the tool

Proper chip handling systems in the machine are also important to prevent blockages and downtime.

Thermal Management

High cutting temperatures can accelerate tool wear and affect dimensional stability. Thermal management relies on:

- Controlled cutting parameters that avoid excessive heat generation

- Effective coolant delivery to the cutting zone

- Avoidance of prolonged dwell and interrupted contact without coolant

Stable thermal conditions improve repeatability of dimensions and surface finish.

Dimensional Stability and Distortion

Because parts made from Hastelloy C-276 are often used in critical applications, tight tolerances and geometric accuracy are common requirements. Considerations include:

- Rough machining with allowance for stress relief (where applicable) before finishing cuts

- Balanced material removal to reduce distortion in thin-walled parts

- Control of clamping forces to avoid elastic deformation during machining that relaxes after unclamping

Measurement in a controlled environment helps ensure that part dimensions are stable and consistent with design requirements.

Need reliable machining for Hastelloy C-276?

XCM specializes in high-nickel alloys, delivering stable tool life, tight tolerances, and consistent surface finish on C-276 parts.

Talk to XCM today to review your drawings and get a tailored machining solution for Hastelloy C-276.

FAQ: Machining Hastelloy C-276

What tool materials work best for machining Hastelloy C-276?

For most turning, milling, and drilling operations, fine-grain cemented carbide with PVD coatings such as TiAlN, AlTiN, or AlCrN is widely used and performs well. Carbide offers a good balance of hardness, toughness, and heat resistance for this alloy. Cobalt HSS is suitable for low-speed drilling, reaming, and tapping, especially in small diameters or short-run work. Ceramics may be used in select continuous turning operations on rigid machines, but they require careful process control. PCD is not appropriate, and CBN is rarely advantageous for Hastelloy C-276.

How should cutting speed and feed be set when turning Hastelloy C-276?

Compared with carbon steels, cutting speeds must be kept relatively low and feeds moderately high to avoid rubbing and work-hardening. For carbide inserts in rough turning, a common starting range is 20–40 m/min for cutting speed with feeds of 0.20–0.40 mm/rev and depth of cut between 1.5–4.0 mm, provided the setup is rigid. For finishing, speeds of about 35–55 m/min with feeds of 0.08–0.18 mm/rev and depths of cut around 0.3–1.0 mm are typical. These values should be refined based on tool grade, coolant, machine stability, and the required surface finish and tolerances.