TC1, TC2, TC3 and TC4 are widely used titanium alloys in aerospace, chemical processing, marine, power generation and general engineering applications. They are primarily alpha or alpha+beta titanium alloys with different balances between strength, ductility, corrosion resistance and processing characteristics. Selecting the appropriate grade requires understanding the specific service conditions, required properties and manufacturing route.

Overview of TC1, TC2, TC3 and TC4 Titanium Alloys

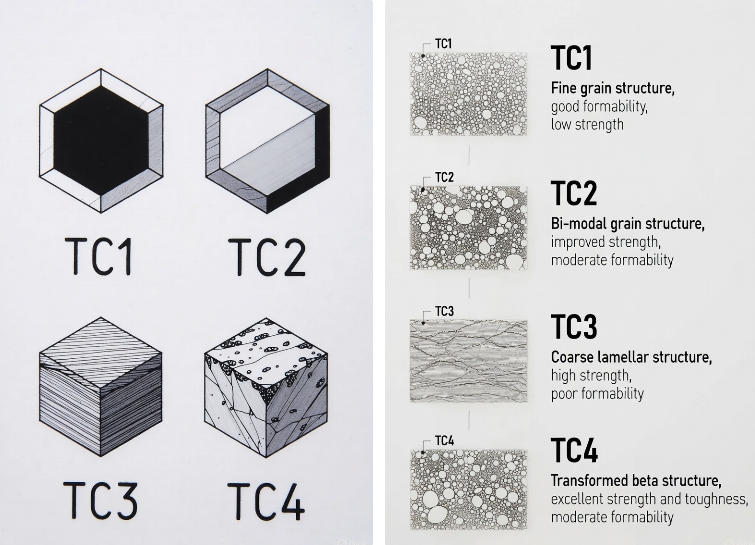

TC-series grades are commonly used wrought titanium alloys distinguished by their alloying elements, microstructure and strength levels. In many industrial systems, TC1 and TC2 are relatively low-strength commercially pure or near-commercially-pure alpha alloys, TC3 is a strengthened alpha alloy, and TC4 is a higher-strength alpha+beta alloy containing aluminum and vanadium (similar in concept to Ti-6Al-4V).

All four alloys share the core advantages of titanium materials: low density, high specific strength, good corrosion resistance in many media and non-magnetic behavior. However, differences in composition and phase constitution lead to distinct performance windows and recommended uses.

Typical Chemical Composition and Phase Characteristics

The chemical composition determines phase structure (alpha or alpha+beta), heat treatment response and many mechanical and corrosion properties. While exact composition limits can vary slightly across standards and producers, the following table summarizes typical ranges and roles of key alloying additions.

| Alloy | Main Composition (wt.%) | Typical Phase Type | Key Characteristics from Composition |

|---|---|---|---|

| TC1 | Ti ≥ 99% (impurities such as Fe, C, N, O tightly limited) | Alpha (commercially pure titanium) | Very good ductility and corrosion resistance, lower strength, excellent weldability |

| TC2 | Ti with slightly higher interstitials (O, Fe) than TC1 | Alpha (strengthened CP Ti) | Higher strength than TC1, still good ductility, minor reduction in cold formability |

| TC3 | Ti with controlled additions (often Al and small alloying elements) | Alpha or near-alpha | Higher strength than TC1/TC2, moderate corrosion resistance, maintains good weldability |

| TC4 | Ti-6Al-4V–type composition (Al ~6%, V ~4%, balance Ti) | Alpha+beta | High strength and specific strength, good fatigue performance, good but slightly reduced corrosion resistance vs CP Ti |

In this family, TC1 and TC2 rely mainly on interstitial strengthening (oxygen, nitrogen, carbon, iron at low levels) while maintaining a fully alpha matrix. TC3 slightly increases alloying to raise strength without moving fully into a strong two-phase field. TC4 clearly belongs to the alpha+beta category, offering a significant strength increment due to substantial aluminum and vanadium additions and the presence of a beta phase.

Mechanical Properties Comparison

Mechanical property requirements are often the primary selection driver. Room-temperature tensile strength, yield strength, elongation and reduction of area are used as baseline indicators. Impact toughness, fracture toughness and fatigue behavior may also be decisive in safety-critical aerospace or pressure-containing components.

| Alloy | Density (g/cm³) | Yield Strength Rp0.2 (MPa) | Tensile Strength Rm (MPa) | Elongation A (%) | Typical Condition |

|---|---|---|---|---|---|

| TC1 | ~4.51 | ≥ 240–275 | ~345–450 | ~24–35 | Annealed, wrought |

| TC2 | ~4.51 | ≥ 350–400 | ~500–550 | ~18–25 | Annealed, wrought |

| TC3 | ~4.51 | ≥ 450–550 | ~600–650 | ~13–18 | Annealed, sometimes mill-annealed |

| TC4 | ~4.43–4.50 | ≥ 800–900 (depending on condition) | ~900–1000+ | ~10–15 | Solution treated and aged or mill-annealed alpha+beta |

Within typical specifications, TC1 sits at the lowest strength and highest ductility end, while TC4 delivers the highest strength with a moderate reduction in elongation. TC2 and TC3 occupy intermediate positions, giving designers options to match the required static strength and formability.

Corrosion Resistance and Environmental Performance

One of titanium’s major advantages is the stable, adherent oxide film that provides broad corrosion resistance. However, alloying additions and microstructure can influence behavior in specific environments, especially where hydrogen uptake, crevice corrosion or stress corrosion cracking may occur.

TC1 and TC2 generally provide the best overall corrosion resistance among the four, especially in:

- Chloride-containing media (sea water, brines) at moderate temperatures

- Many oxidizing acids (nitric acid in certain concentration ranges)

- Neutral and mildly reducing environments

TC3 retains good corrosion resistance but can be slightly less resistant than TC1/TC2 in the most aggressive media where alloying levels become more influential. TC4 usually provides excellent corrosion resistance in many practical environments, but the presence of aluminum and vanadium means its performance in some strong reducing acids or highly specialized chemical media may be marginally lower compared with commercially pure grades.

In practice:

- For maximum corrosion resistance with relatively low mechanical loading, TC1 or TC2 are preferred.

- For applications combining higher stress levels with marine or mildly corrosive chemical environments, TC3 and TC4 are often used, provided that appropriate design safety factors are applied.

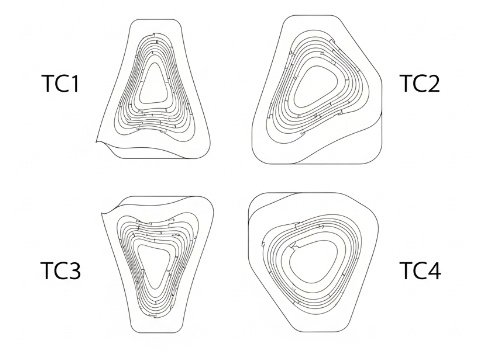

Microstructure, Heat Treatment and Phase Control

Microstructure is a key determinant of strength, toughness and fatigue properties. Alpha alloys (TC1, TC2, TC3) and alpha+beta alloys (TC4) respond differently to thermal processing.

Alpha Alloys: TC1, TC2, TC3

TC1 and TC2 are fully alpha with low alloy content. Typical microstructures are equiaxed alpha grains after conventional annealing. The main heat treatment operations are:

Annealing: used to relieve residual stresses, stabilize dimensions after cold working and optimize ductility. Annealing temperatures commonly lie below the beta transus to avoid introducing a beta phase.

Stress-relief: suitable for components subjected to machining or forming operations where dimensional stability and low residual stress are required but minimal changes in strength are acceptable.

TC3, with slightly elevated alloying, can exhibit finer alpha grains and slightly higher strength after controlled annealing. It still does not have strong martensitic or precipitation-hardening response, so its properties are less sensitive to quench and age-type heat treatments than TC4.

Alpha+Beta Alloy: TC4

TC4 can be processed through a broader range of heat treatments to tailor properties:

Solution treatment and aging (STA): the alloy is solution treated in the alpha+beta or near-beta region, quenched and then aged. This increases strength via precipitation and refinement of the alpha and beta phase distribution. It is often used in aerospace structural parts and high-stress components.

Mill anneal: a conventional annealing heat treatment at intermediate temperature, providing a balanced combination of strength, ductility and toughness with stable microstructure and good machinability.

Beta heat treatment: for specific applications, higher temperature treatments can create a transformed beta microstructure delivering very high strength but often with reduced toughness and lower machinability. This is less common for general engineering components.

Formability, Machinability and Weldability

Processability is a practical factor in alloy selection. The ability to form, machine and weld titanium effectively affects manufacturing cost, dimensional accuracy and defect risk.

Formability

TC1 has excellent cold and hot formability due to its low strength and high ductility. It is suitable for deep drawing, bending and other extensive plastic deformation processes without severe cracking, as long as proper lubrication and tooling are used.

TC2 is slightly less formable than TC1, but still offers good cold deformation capabilities for thin sheet and tubing. The increased strength requires slightly higher forming loads.

TC3, with higher strength, may need warm or hot forming for more complex geometries. Cold forming is possible for moderate deformation, but springback and required forming forces are higher than for TC1/TC2.

TC4, particularly in higher strength conditions, typically calls for hot or warm forming (often 700–900°C) to achieve significant shape changes. Cold forming is restricted to small adjustments and requires careful control to prevent cracking.

Machinability

All four alloys share typical titanium machining characteristics: low thermal conductivity, chemical reactivity with tool materials at elevated temperature and a tendency for work hardening near the surface. These properties demand optimized cutting parameters, rigid machines and appropriate tooling.

TC1 and TC2 are easier to machine than TC3 and especially TC4, due to their lower strength and hardness. TC4 in high-strength conditions often leads to high tool wear, requires reduced cutting speed, generous cutting fluid supply and the use of carbide or advanced coated tools.

Weldability

All four grades can be welded using common processes like gas tungsten arc welding (GTAW/TIG), electron beam welding (EBW) and laser welding, provided that inert gas shielding is strictly controlled to prevent contamination by oxygen, nitrogen or hydrogen.

TC1 and TC2 exhibit excellent weldability, with welded joints often achieving properties close to or slightly below base metal levels. TC3 retains good weldability but requires somewhat stricter control of heat input to avoid excessive grain growth.

TC4 weldability is generally good but the higher alloy content may make the heat-affected zone more sensitive to microstructural changes. Post-weld heat treatment can be considered when joint toughness or fatigue strength is critical.

Fatigue Performance and Fracture Behavior

In cyclic loading or high reliability applications, fatigue performance becomes crucial. Surface condition, residual stress, microstructure and environmental factors all influence fatigue behavior.

TC1 and TC2, with their lower strength, show moderate fatigue limits in absolute terms, but their fatigue performance is often satisfactory given their typical loading levels. The absence of significant beta phase and the fine, equiaxed alpha grains contribute to stable fatigue behavior, provided surfaces are smooth and stress concentrators are minimized.

TC3, with its slightly elevated strength, tends to provide improved fatigue strength compared with TC1/TC2. It is often selected when both moderate corrosion resistance and better fatigue performance are needed, for example in certain airframe parts and rotating components operating at medium stress levels.

TC4 is commonly chosen for structural components requiring high fatigue strength at relatively high stress levels, such as critical aircraft structural elements and high-speed rotating parts. Its alpha+beta microstructure can be optimized via thermomechanical processing and heat treatment to improve fatigue and fracture toughness balance.

Temperature Capability

The performance of titanium alloys is temperature dependent. At elevated temperatures, strength decreases and creep resistance becomes relevant, while at low temperatures, toughness behavior can change.

TC1 and TC2 are suitable for service up to moderate temperatures where their strength is sufficient. For long-term service, temperatures are usually kept below approximately 300–350°C to avoid significant loss of properties and microstructural instability.

TC3 can be used at slightly higher temperatures than TC1/TC2 due to its strengthened alpha matrix, but still falls in the moderate temperature range compared to specialized high-temperature titanium alloys.

TC4, especially in optimized alpha+beta microstructures, can maintain reasonable strength and fatigue performance up to around 350–400°C in many designs. However, for highly demanding high temperature environments, more specialized near-alpha or fully alpha high-temperature alloys may be required.

Selection by Application Scenario

Practical selection often starts from the application type. Below are typical scenarios where each alloy tends to be favored, assuming that specific standards and certification requirements are met.

General Engineering and Structural Components

For non-extreme structural applications where corrosion resistance and low weight are important but peak strength requirements are moderate, TC2 is often favored. It provides a better balance of strength and ductility than TC1 while remaining easier to form and machine than stronger grades.

TC1 may be selected when exceptional ductility, ease of forming or welding are critical and stress levels are relatively low, such as in some architectural, biomedical (where permitted by standards) or low-pressure equipment parts.

Chemical Processing and Corrosive Environments

In chemical plants, pipelines, heat exchangers and storage vessels exposed to aggressive media, TC1 and TC2 are common choices. TC1 is often used where maximum corrosion resistance is needed and mechanical loads are minimal. TC2 is preferred when components must withstand moderate pressure or mechanical loads while maintaining corrosion resistance.

TC3 or TC4 may be considered in corrosive environments if mechanical demands (higher pressure, cyclic stress) exceed the capabilities of TC1/TC2, and an engineering evaluation confirms their corrosion performance in the given medium.

Marine and Offshore Uses

In seawater, TC1 and TC2 exhibit excellent corrosion resistance with minimal tendency to suffer from pitting or crevice corrosion under properly designed conditions. They are used in seawater piping, heat exchanger tubes and marine fasteners where strength levels are modest.

TC3 and TC4 are used when higher strength is needed, for example in load-bearing fasteners, shafts or structural members on ships and offshore platforms, provided that cathodic protection, galvanic coupling and stress levels are carefully considered.

Aerospace and High-Specific-Strength Applications

TC4 is widely used in aerospace applications where high specific strength, fatigue performance and acceptable corrosion resistance are required, such as in airframe structures, landing gear components (within limitations), engine casings and rotors. Its strength-to-weight ratio makes it the default choice for many high-performance designs.

TC3 can be used in secondary aerospace structures where intermediate strength is adequate and forming/welding simplicity is desired. TC1 and TC2 are sometimes used for non-load-bearing or low-load components, ducts and tanks where corrosion resistance and weldability are paramount.

Design Considerations and Common Constraints

When selecting among TC1–TC4, several practical constraints must be taken into account in addition to nominal properties.

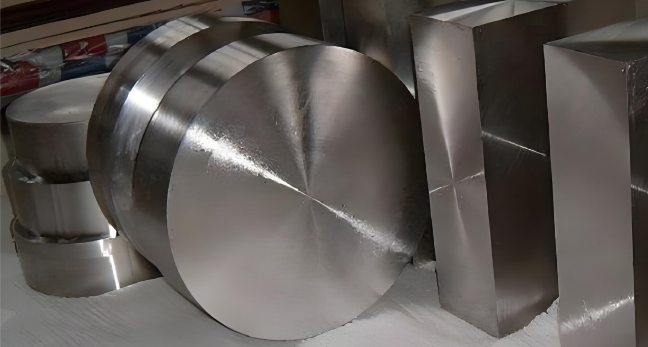

Availability and Product Forms

Availability in the required product form (plate, sheet, bar, forging, tube, casting) can influence alloy choice. TC4 is typically available in a wide range of wrought products due to its popularity in aerospace and high-performance industries. TC1 and TC2 are common in plate, sheet, tube and bar for chemical and marine applications. TC3 may be less common in some markets, so lead times and minimum order quantities should be checked.

Joining with Dissimilar Metals

In many assemblies, titanium must be joined to steels, nickel alloys or aluminum alloys. Direct welding to dissimilar metals is rarely used; instead, mechanical fastening or the use of transition inserts is common. The choice between TC1–TC4 influences galvanic behavior, mechanical compatibility and allowable service temperature, especially when coupled with other metals in conductive environments such as seawater.

Inspection and Quality Requirements

Critical parts, especially in aerospace and pressure equipment, must satisfy stringent inspection requirements such as ultrasonic testing, radiographic testing and surface inspection for defects. Higher strength alloys like TC4 may have tighter defect acceptance criteria due to higher stress levels in service. Designers and manufacturers should align alloy selection with applicable codes, standards and certification schemes.

Decision Framework: How to Choose the Right Grade

A systematic selection process helps match alloy properties to service requirements. The following approach can be used.

Step 1: Define Service Conditions

Key factors include:

- Type and level of mechanical loading (static, cyclic, impact)

- Operating temperature range and thermal cycling

- Corrosive media, concentration, flow conditions and presence of crevices

- Required design life and safety factors

Where corrosion is the dominant concern and loads are low, TC1 or TC2 will often be adequate. Where high strength and fatigue resistance are needed at moderate temperatures, TC4 is usually the first candidate.

Step 2: Assess Manufacturing Route

Evaluate forming, machining and welding operations. If the component requires extensive cold forming, TC1 or TC2 may significantly reduce forming loads and tooling wear. For forge-intensive parts with localized thick sections and high load paths, TC4 can be selected and processed via hot forging and subsequent heat treatment.

Step 3: Balance Strength vs Ductility and Toughness

When high strength alone is not the only target, the combination of yield strength, elongation and fracture toughness must be balanced. TC3 is advantageous when an intermediate strength level and good ductility are required without the full hardness and machining difficulty of TC4.

Step 4: Check Standards, Codes and Qualification

Industry standards (aerospace, pressure vessels, marine classifications) may explicitly specify suitable titanium alloys. Where a standard lists TC1, TC2, TC3 or TC4 for a given application type, using listed grades simplifies qualification, documentation and third-party approval.

Step 5: Evaluate Cost and Lifecycle Performance

Although detailed cost analysis is project-specific, a general trend is that higher alloy content and more complex heat treatments lead to higher material and processing costs. TC4-based solutions may reduce weight, but they can increase machining cost and scrap risk. TC1 or TC2 solutions may reduce production complexity but require thicker sections or larger components to achieve the same load capacity. A lifecycle assessment should consider purchase cost, fabrication, inspection, maintenance and potential replacement intervals.

Typical Pitfalls and Considerations in Alloy Selection

While TC1–TC4 are versatile, inappropriate selection or misuse can lead to performance issues.

Inadequate Margin for Strength or Fatigue

Choosing TC1 or TC2 for components that later experience higher-than-expected loads or severe cyclic loading may lead to premature deformation or fatigue damage. Early in design, engineers should carefully evaluate worst-case load scenarios. If there is any uncertainty or potential future increase in loading, TC3 or TC4 may provide a safer margin.

Over-Specifying Alloy Strength

Selecting TC4 purely on the basis of its reputation as a “high-performance” alloy, while the application does not need such high strength, can lead to unnecessarily complex processing, higher machining costs and more difficult welding. In some cases, TC2 or TC3 can meet all performance requirements with lower overall project cost and simpler fabrication routes.

Insufficient Attention to Corrosion Environment

Although TC4 has good corrosion resistance, in certain highly reducing or specialized media, commercially pure titanium such as TC1 may be more suitable. When chemical composition of the medium or process conditions change over time, conservative selection (favoring TC1 or TC2) may reduce the risk of localized corrosion or unexpected degradation.

Ignoring Surface Finish and Cleanliness

For fatigue-critical parts, surface quality and freedom from defects are as important as base alloy strength. Even when TC4 is used, rough surfaces, machining marks or weld undercuts can drastically reduce fatigue life. Adequate finishing, polishing and non-destructive testing are essential.

Summary of Selection Guidelines

The selection among TC1, TC2, TC3 and TC4 can be summarized in terms of primary advantages and typical use cases:

TC1: lowest strength, best ductility and corrosion resistance, excellent weldability and formability. Suited for low-load structures in highly corrosive environments and components requiring extensive forming.

TC2: stronger than TC1 with still good ductility and corrosion resistance. Widely used in general engineering, chemical, marine applications where both strength and corrosion resistance are important but extreme performance is not required.

TC3: intermediate strength alpha alloy, good overall balance of strength, ductility and corrosion resistance, relatively straightforward processing. Selected when TC2 is not strong enough yet TC4 is unnecessarily strong or difficult to process.

TC4: high-strength alpha+beta alloy with very good fatigue performance and acceptable corrosion resistance. Preferred in aerospace and other high-performance applications requiring high specific strength and robust fatigue behavior, subject to appropriate processing controls.

FAQ on TC1, TC2, TC3 and TC4 Titanium Alloys

Which titanium alloy is best for seawater applications?

For continuous seawater exposure with relatively low mechanical loading, TC1 and TC2 are typically preferred because they offer excellent resistance to general and localized corrosion. TC2 is often chosen when additional strength is required, for example in piping systems or structural supports. TC4 can also be used in seawater for highly loaded components, but design should account for galvanic effects, potential crevices and higher material and processing costs.

When should TC4 be chosen instead of TC2 or TC3?

TC4 should be considered when high specific strength, high fatigue strength and good performance at moderate elevated temperatures are required. Typical cases include aerospace structural parts, high-speed rotating components and heavily loaded mechanical elements where weight reduction is a key objective. If the application does not require such a high strength level and manufacturing complexity needs to be minimized, TC2 or TC3 may be more appropriate choices.

Is TC1 always better than TC4 for corrosion resistance?

TC1 usually provides slightly superior corrosion resistance compared with TC4 in highly aggressive or specialized chemical environments because it is essentially commercially pure titanium. However, in many practical environments, including seawater and numerous industrial solutions, TC4’s corrosion resistance is still excellent. The choice should be based on detailed knowledge of the medium (composition, temperature, flow conditions) and required mechanical performance rather than a general assumption that one alloy is always better.

Can TC1, TC2, TC3 and TC4 be welded to each other?

Yes, these alloys can generally be welded to each other because they are all titanium-based, but welding procedures must be carefully controlled. Inert gas shielding on both the front and back sides of the weld is essential to avoid contamination. When welding alloys of significantly different strength (for example, TC1 to TC4), joint design and post-weld performance requirements should consider potential strength mismatch and the properties of the heat-affected zones.