Overview of Hastelloy C-276 and C-22

Hastelloy C-276 and Hastelloy C-22 are widely used corrosion-resistant nickel-chromium-molybdenum (Ni-Cr-Mo) alloys. Both alloys are designed for harsh chemical environments containing reducing and oxidizing media, chlorides, and other aggressive chemicals. They are commonly used in chemical process plants, flue gas desulfurization systems, pharmaceutical manufacturing, and other demanding industrial sectors.

Although they belong to the same general alloy family, C-276 and C-22 differ significantly in chromium content and some secondary alloying elements, which leads to differences in corrosion resistance profiles, weldability, and suitability for specific environments. Understanding these differences is essential for correct material selection and long-term reliability of equipment.

Chemical Composition Comparison

Both alloys are nickel-based and contain chromium and molybdenum as the principal alloying elements, with additions of tungsten, iron, cobalt, and controlled levels of carbon, silicon, and manganese. The key distinctions are higher chromium content and different iron/tungsten balance in C-22 compared with C-276.

| Element | Hastelloy C-276 (typical / spec range) | Hastelloy C-22 (typical / spec range) |

|---|---|---|

| Nickel (Ni) | Balance (approx. 57–63) | Balance (approx. 56–65) |

| Chromium (Cr) | 14.5–16.5 | 20.0–22.5 |

| Molybdenum (Mo) | 15.0–17.0 | 12.5–14.5 |

| Iron (Fe) | 4.0–7.0 | 2.0–6.0 |

| Tungsten (W) | 3.0–4.5 | 2.5–3.5 |

| Cobalt (Co) | ≤ 2.5 | ≤ 2.5 |

| Manganese (Mn) | ≤ 1.0 | ≤ 0.5 |

| Silicon (Si) | ≤ 0.08 | ≤ 0.08 |

| Carbon (C) | ≤ 0.01 | ≤ 0.015 |

| Phosphorus (P) | ≤ 0.04 | ≤ 0.02 |

| Sulfur (S) | ≤ 0.03 | ≤ 0.02 |

Key composition implications:

- C-22’s higher chromium improves resistance to oxidizing media and enhances passivity in many chloride-containing environments.

- C-276’s higher molybdenum and tungsten contents contribute to strong resistance in reducing and mixed acid environments, especially where localized corrosion is driven by reducing species.

- Both alloys maintain extremely low carbon content to reduce carbide precipitation and intergranular corrosion after welding.

Microstructure and Metallurgical Characteristics

Hastelloy C-276 and C-22 are solid-solution strengthened Ni-Cr-Mo alloys, designed to maintain a single-phase austenitic structure in the solution-annealed condition. Their microstructures are carefully controlled through composition and heat treatment to minimize detrimental secondary phases.

Important metallurgical characteristics include:

1) Single-phase austenitic matrix: The main phase is face-centered cubic (FCC) austenite, ensuring good ductility and formability over a wide range of temperatures.

2) Control of secondary phases: Excessive intermetallic phases such as mu and sigma, as well as M6C or M23C6 carbides, can embrittle the alloy and reduce corrosion resistance. The low carbon levels and balanced Mo-W-Cr contents help minimize these phases when appropriate solution annealing and rapid cooling are employed.

3) Sensitivity to thermal exposure: Prolonged exposure in the temperature range of roughly 600–1000 °C can lead to precipitation of intermetallic phases at grain boundaries. This can reduce toughness and localized corrosion resistance in both alloys, but careful thermal history management and subsequent solution treatment mitigate the issue.

4) Weld heat-affected zones (HAZ): Microstructural stability in weld HAZ is critical. C-22 generally offers somewhat better resistance to weld-related corrosion in oxidizing environments due to its higher chromium, while C-276 has a long track record and established welding procedures that maintain favorable microstructures in many industrial conditions.

Mechanical Properties Comparison

The mechanical properties of Hastelloy C-276 and C-22 are broadly similar and comparable to other Ni-Cr-Mo alloys. Both exhibit high strength, good toughness, and excellent ductility across a wide temperature range. The exact values depend on product form (plate, bar, pipe) and heat treatment, but typical room-temperature values illustrate the similarities.

| Property | Hastelloy C-276 | Hastelloy C-22 |

|---|---|---|

| Ultimate tensile strength (MPa) | ~ 690–760 | ~ 690–760 |

| 0.2% proof (yield) strength (MPa) | ~ 280–355 | ~ 280–345 |

| Elongation (%, 50 mm gauge) | ~ 40–50 | ~ 40–50 |

| Hardness (HRB) | ~ 90–100 | ~ 90–100 |

| Density (g/cm³) | ~ 8.89 | ~ 8.69 |

| Modulus of elasticity (GPa) | ~ 205 | ~ 205 |

| Melting range (°C) | ~ 1325–1370 | ~ 1350–1400 |

Both alloys retain useful mechanical properties at elevated temperatures and exhibit good creep and stress-rupture resistance for many process conditions. However, they are not typically selected primarily for high-temperature strength; rather, they are chosen for corrosion resistance combined with adequate mechanical properties.

Corrosion Resistance: General Comparison

Corrosion resistance is the primary reason for choosing C-276 or C-22. Both alloys provide outstanding performance in many aggressive environments, but their corrosion profiles differ in important ways. C-276 historically has been regarded as an all-purpose Ni-Cr-Mo alloy for mixed environments, whereas C-22 was developed to further improve resistance in strongly oxidizing and mixed oxidizing/chloride conditions.

Main distinctions:

- In strongly oxidizing environments, especially those with chlorides, C-22 generally outperforms C-276 due to its higher chromium content and improved ability to maintain a passive film.

- In reducing environments with high concentrations of hydrochloric acid and other non-oxidizing acids, C-276 often provides comparable or slightly superior resistance, particularly regarding uniform corrosion rates.

- In many mixed-acid and mixed-oxidizing/reducing environments, both alloys perform at a high level, and the choice often depends on detailed composition of the media and long-term test data.

Behavior in Specific Corrosive Environments

The performance of C-276 and C-22 depends strongly on the chemistry, temperature, and concentration of the corrosive medium. Below is a more detailed overview in common industrial environments.

1) Hydrochloric Acid (HCl) and Reducing Acids

Hydrochloric acid is a strongly reducing medium that is very aggressive to stainless steels and many high-alloy materials. Both C-276 and C-22 are designed to resist HCl, but C-276 has historically been more widely used for reducing acid service.

Key points:

- C-276 typically exhibits low corrosion rates in HCl at moderate temperatures and acid concentrations, outperforming many other nickel alloys.

- C-22 also performs well in HCl, though in some test conditions, C-276 shows slightly lower uniform corrosion rates in pure reducing acid environments.

- In mixed HCl with oxidizing contaminants (e.g., ferric ions, dissolved oxygen, wet chlorine), the advantage of higher chromium in C-22 becomes more pronounced, improving resistance to localized attack.

2) Sulfuric Acid (H2SO4)

Sulfuric acid behavior depends on concentration, temperature, and presence of oxidizing species. Both alloys offer improved resistance compared with standard stainless steels and many nickel alloys.

General trends:

- At low to moderate concentrations and temperatures, both C-276 and C-22 show very good uniform corrosion resistance.

- In high-concentration sulfuric acid, especially at elevated temperatures, C-276 is frequently used; however, the presence of oxidizing impurities can shift the advantage toward C-22.

- For sulfuric acid mixtures containing chlorides or other halides, C-22’s higher chromium can improve resistance to pitting and crevice corrosion.

3) Nitric Acid and Oxidizing Acids

Oxidizing acids such as nitric acid require materials with strong passivation ability. Chromium content plays a major role here.

Performance aspects:

- C-22, with higher chromium, generally offers better resistance in nitric acid and other strongly oxidizing environments, particularly when chlorides are also present.

- C-276 can be used in certain oxidizing acid conditions but may show higher corrosion rates or be more susceptible to localized attack at specific temperature/concentration combinations.

- For processes where nitric acid is dominant or where oxidizing conditions alternate with reducing conditions, C-22 often provides a more robust margin of safety.

4) Chloride-Induced Pitting and Crevice Corrosion

Chloride-bearing environments, especially under stagnant conditions or in crevices, can cause pitting and crevice corrosion in many alloys. While both C-276 and C-22 are highly resistant, C-22 is generally recognized as offering superior resistance in many chloride scenarios.

Reasons for this include:

- Higher chromium and balanced molybdenum content enhance passivation and reduce the tendency for localized film breakdown.

- C-22 typically exhibits higher pitting resistance equivalent numbers (PREN-like indicators), reflecting improved performance in critical pitting temperature and potential tests.

- In crevice corrosion tests, C-22 often shows lower corrosion rates and higher critical crevice temperatures than C-276 in oxidizing chloride solutions.

5) Wet Chlorine, Hypochlorites, and Chlorine Dioxide

Applications involving wet chlorine gas, sodium hypochlorite, and chlorine dioxide are highly oxidizing and can cause severe pitting and stress corrosion cracking in many materials.

In these media:

- C-22 generally demonstrates better performance than C-276, especially in high-oxidation potential environments where stable passive films are required.

- C-276 can still be used, but service limits may be tighter regarding maximum temperature and concentration to avoid localized corrosion.

- For equipment where both reducing acids and strong oxidizing chlorine-based solutions are present at different stages, careful process mapping is needed to decide which alloy offers the best overall behavior.

6) Seawater and Brine Solutions

Seawater contains chlorides, dissolved oxygen, and biological activity. Both alloys considerably outperform stainless steels in seawater environments, particularly at elevated temperatures and under crevice conditions.

Selection considerations:

- C-22 tends to offer a higher safety margin against pitting and crevice corrosion in warm, aerated seawater, especially for complex geometries with tight crevices.

- C-276 is also resistant but may be more sensitive to localized attack under extreme conditions, depending on temperature and flow regime.

- For long-term immersion in hot seawater or high-chloride brines with oxidizing conditions, C-22 is often favored.

Resistance to Localized Corrosion and Stress Corrosion Cracking

Localized corrosion and stress corrosion cracking (SCC) are critical failure mechanisms in chloride-containing and mixed environments.

Localized corrosion:

- C-22 typically exhibits higher critical pitting temperature (CPT) and critical crevice temperature (CCT) in standardized test solutions compared with C-276, reflecting better resistance to localized attack in many oxidizing chloride environments.

- C-276 still provides very strong resistance to localized corrosion in many applications, particularly in more reducing environments or where oxidizing species are limited.

Stress corrosion cracking:

- Both C-276 and C-22 show excellent resistance to chloride-induced SCC compared with stainless steels, especially at moderate temperatures.

- In highly oxidizing chloride environments at elevated temperatures, C-22’s composition can be advantageous, but practical SCC resistance is influenced by stress level, fabrication practices, and actual service conditions for both alloys.

Weldability and Fabrication

Both Hastelloy C-276 and C-22 are well-known for good weldability compared with many high-alloy materials. They can be welded using common processes such as Gas Tungsten Arc Welding (GTAW/TIG), Gas Metal Arc Welding (GMAW/MIG), and shielded metal arc welding (SMAW), with suitable filler metals.

Key points of comparison:

- Heat-affected zone corrosion: C-22 generally exhibits improved resistance in the weld heat-affected zone when exposed to oxidizing chloride environments. Its higher chromium content helps to ensure passive film stability even in microstructurally altered regions.

- Filler metal choice: Dedicated C-22 and C-276 filler metals are available. It is common practice to use matching or slightly over-alloyed filler to maintain corrosion resistance in the weld metal and HAZ.

- Hot cracking: Both alloys are relatively resistant to solidification cracking when proper welding parameters and filler selection are applied.

- Post-weld cleaning: Thorough removal of heat tint and surface oxides after welding is important for both alloys to ensure optimum corrosion resistance, especially in oxidizing environments.

- Post-weld heat treatment: Most applications do not require post-weld heat treatment, but solution annealing may be specified for critical components or when extensive cold work and welding have been performed.

Formability, Machinability, and Fabrication Considerations

Both C-276 and C-22 possess good formability and can be cold-formed using standard techniques for high-strength nickel alloys. However, their high strength and work-hardening rates require adequate power and robust tooling.

Forming:

- Cold forming operations such as bending, rolling, and deep drawing are feasible but may need intermediate annealing to restore ductility and reduce work hardening.

- Minimum bend radii are typically larger than those for austenitic stainless steels due to higher strength.

Machining:

- Both alloys are more challenging to machine than carbon steels and stainless steels because of their toughness and work-hardening behavior.

- Use sharp, rigid tooling, low cutting speeds, and adequate lubrication. Carbide or advanced tool materials are recommended.

- Avoid rubbing or dwell, which can cause rapid work hardening and shorten tool life.

Surface finish and cleanliness are important, particularly for components used in aggressive media, to minimize initiation sites for localized corrosion.

High-Temperature and Low-Temperature Performance

Hastelloy C-276 and C-22 are primarily corrosion-resistant alloys rather than high-temperature structural alloys, but they retain useful mechanical properties over a broad temperature range.

High-temperature performance:

- Both alloys maintain good strength and oxidation resistance up to moderate high temperatures typically encountered in chemical process equipment.

- Prolonged exposure within the temperature range where intermetallic phases can precipitate (approximately 600–1000 °C) should be minimized or followed by solution annealing to restore optimum corrosion resistance.

- For very high-temperature structural applications, other alloys specifically designed for high-temperature strength may be more suitable.

Low-temperature performance:

- Both C-276 and C-22 exhibit good toughness at low temperatures, with no ductile-to-brittle transition within the usual industrial temperature ranges.

- This allows their use in cryogenic or sub-zero applications where both corrosion resistance and mechanical integrity are required, subject to applicable design codes.

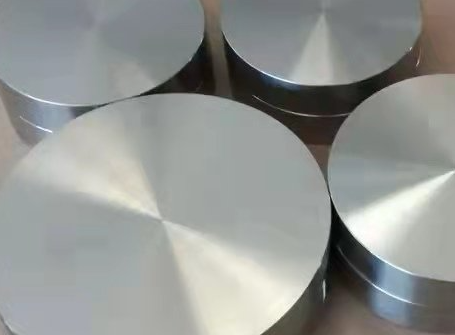

Common Product Forms and Standards

Hastelloy C-276 and C-22 are available in a wide variety of product forms to suit different fabrication requirements and industry standards.

Typical forms include:

- Plates and sheets for pressure vessels, linings, and structural components.

- Pipes and tubes (seamless and welded) for process piping, heat exchangers, and condensers.

- Bars, rods, and forgings for shafts, fittings, fasteners, and other machined parts.

- Welding consumables (wires, rods, electrodes) matching or over-alloyed for joint fabrication.

Both alloys have corresponding UNS designations and are covered by ASTM and ASME specifications for various product forms. These standards define chemical composition limits, mechanical property requirements, and testing methods to ensure consistency and quality.

Typical Industrial Applications of Hastelloy C-276

Hastelloy C-276 is widely recognized as a versatile alloy for extremely corrosive environments. It has decades of successful use in multiple industries.

Common applications include:

- Chemical processing equipment: reactors, columns, distillation units, pipelines handling mixed acids, halides, and sulfidic media.

- Flue gas desulfurization (FGD): absorber towers, reheaters, dampers, and ductwork exposed to flue gases containing chlorides, sulfates, and other contaminants.

- Pulp and paper: bleaching equipment, digesters, and parts exposed to chloride-bearing liquors and acidic condensates.

- Pollution control and waste treatment: components handling waste streams containing organic acids, chlorides, sulfides, and oxidizing species in varying concentrations.

- Oil and gas, petrochemicals: equipment exposed to sour gas, wet H2S, and chloride-bearing production fluids in challenging conditions.

C-276 is often selected where process conditions are not fully defined, or where a wide range of corrosive species and upset conditions are expected.

Typical Industrial Applications of Hastelloy C-22

Hastelloy C-22 was developed to offer improved resistance in oxidizing and mixed environments, particularly where localized corrosion protection is critical.

Typical uses include:

- Chemical processing: reactors, agitators, and piping in processes involving mixed oxidizing acids, chlorides, and halogens where high localized corrosion resistance is required.

- Pharmaceutical and biotech: equipment requiring superior corrosion resistance and cleanliness in environments containing chlorides, cleaning agents, and oxidizing sanitizers.

- Waste treatment and environmental control: treatment systems handling oxidizing waste streams, chlorinated solvents, and aggressive oxidizing agents.

- Power industry: parts in scrubbers, condensers, and cooling water systems where warm, oxygenated, chloride-bearing water poses a risk of pitting and crevice corrosion.

- Desalination and high-chloride water systems: heat exchangers and high-risk components exposed to warm, aerated seawater or concentrated brines.

C-22 is frequently chosen when the dominant concern is pitting, crevice corrosion, and weld-zone corrosion in oxidizing chloride environments.

Pros and Cons of Hastelloy C-276

Hastelloy C-276 offers a set of advantages and certain limitations that must be considered for each project.

Pros:

- Broad corrosion resistance: Excellent performance in a wide variety of reducing and mixed chemical environments, including many acids, halides, and wet process streams.

- Good track record: Long history of field use and extensive corrosion data, which supports reliable material selection and design.

- Good weldability: Established welding procedures and consumables, with strong performance of welds in many service environments.

- Versatile product range: Available in many product forms, dimensions, and standards, easing procurement for complex projects.

Cons:

- Not optimal in some oxidizing chloride environments: In highly oxidizing, chloride-bearing solutions (such as certain bleach and chlorine dioxide systems), C-22 may provide better localized corrosion resistance.

- Material and fabrication cost: As a high-nickel, high-molybdenum alloy, C-276 is significantly more expensive than stainless steels and many other alloys, and machining requires careful control.

- Sensitivity to intermetallic precipitation: Exposure to certain intermediate temperatures can reduce corrosion resistance unless appropriate heat treatment and thermal history control are maintained.

Pros and Cons of Hastelloy C-22

Hastelloy C-22 was developed to enhance performance in specific areas, but it also has its own balance of advantages and considerations.

Pros:

- Superior resistance in oxidizing chloride environments: High chromium content gives C-22 excellent resistance to pitting, crevice corrosion, and weld-zone attack in many oxidizing media.

- Enhanced weld-zone corrosion resistance: Welded components in C-22 often show better performance in oxidizing chloride service compared with C-276, which is valuable for complex equipment with many welds.

- Wide range of aggressive service conditions: Suitable for environments containing combinations of oxidizing acids, chlorides, and halogens that are difficult for many alloys.

Cons:

- Cost and availability: C-22 is also a premium alloy with high nickel and molybdenum content, and in some regions or product forms, it may be less readily available than C-276.

- Performance in strongly reducing environments: While still very corrosion resistant, C-22 does not always outperform C-276 in purely reducing acids like hydrochloric acid; selection requires review of specific data.

- Fabrication demands: Like C-276, C-22 has high strength and work-hardening characteristics, requiring robust tooling and careful machining practice.

Key Differences Between Hastelloy C-276 and C-22

The following summarizes the most important differences that influence alloy selection:

- Composition: C-22 contains higher chromium (about 20–22.5%) and slightly lower molybdenum than C-276, which has 14.5–16.5% chromium and 15–17% molybdenum with more tungsten. This shift enhances oxidizing corrosion resistance in C-22.

- Oxidizing environments: C-22 offers better resistance in oxidizing chloride-containing media (e.g., bleach solutions, wet chlorine, hypochlorites), particularly with respect to pitting, crevice corrosion, and weld-affected zones.

- Reducing environments: C-276 has strong performance in reducing acids such as hydrochloric acid and in many mixed reducing conditions. In some cases, C-276 is preferred where reducing conditions dominate.

- Localized corrosion: C-22 tends to have higher resistance to localized corrosion (pitting and crevice) under strongly oxidizing conditions, especially at elevated temperatures.

- Application history: C-276 has a longer and broader history of service in many industries, providing extensive performance data. C-22, while also proven, is specifically favored for environments where oxidizing conditions and localized corrosion risks are more severe.

Selection Guidelines for C-276 vs C-22

Choosing between Hastelloy C-276 and C-22 requires detailed consideration of the process environment, equipment design, fabrication methods, and life-cycle expectations. The following guidelines help frame a systematic selection process.

1) Characterize the environment:

- Identify the primary corrosive species (e.g., HCl, H2SO4, HNO3, chlorides, oxidizing agents).

- Define concentrations, temperatures, and possible fluctuations or upset conditions.

- Determine whether the environment is predominantly reducing, oxidizing, or mixed, and whether oxidizing chloride conditions are present.

2) Evaluate localized corrosion risk:

- Consider the presence of crevices, stagnant zones, and complex geometries where pitting and crevice corrosion can initiate.

- Assess chloride concentration, oxidizing potential, and planned operating temperatures.

- If oxidizing chloride environments with high localized corrosion risk are dominant, C-22 often provides greater safety margin.

3) Consider weld density and weld-zone exposure:

- For equipment with extensive welds directly exposed to aggressive oxidizing chloride media, C-22’s weld-zone resistance is a significant advantage.

- For systems with fewer critical welds or where reducing conditions dominate, C-276 remains an excellent choice.

4) Review available corrosion data and experience:

- Use laboratory test data, field experience, and published corrosion tables relevant to the exact chemical mixture and temperatures.

- Consult with material suppliers and experienced engineering teams to interpret data for complex mixtures and non-standard conditions.

5) Factor in cost, availability, and fabrication considerations:

- Compare availability of product forms in required dimensions and standards for both alloys.

- Consider machining, forming, and welding capabilities of fabricators familiar with high-alloy nickel materials.

- Evaluate the total life-cycle cost, including inspection, maintenance, and potential consequences of failure.

Typical Pain Points and How Alloy Choice Helps

In many industrial plants, corrosion-related issues lead to unplanned downtime, leakage, contamination, and costly repairs. Understanding common pain points can clarify where C-276 or C-22 offers the best mitigation.

Typical issues:

- Premature pitting and crevice corrosion in stainless steel or lower-alloy materials, especially near welds and crevices, in chloride-bearing and oxidizing media.

- Rapid uniform corrosion or stress corrosion cracking in standard alloys exposed to mixed acids and chlorides.

- Frequent replacement of components in bleach plants, chlorination systems, or chemical reactors due to localized attack at elevated temperatures.

How C-276 helps:

- Provides robust resistance to a broad range of reducing and mixed environments, greatly reducing uniform corrosion rates and extending component life.

- Good resistance to many sulfidic and acidic waste streams, reducing leakage and unplanned shutdowns in pollution control and waste treatment units.

How C-22 helps:

- Offers improved localized corrosion resistance in oxidizing, chloride-rich media, particularly at welds and crevices, reducing the risk of sudden pitting failures.

- Supports stable operation in systems using strong oxidizing agents, such as chlorine-based chemicals, where many other materials experience rapid attack.

Summary: When to Choose C-276 vs C-22

Hastelloy C-276 and C-22 are both high-performance Ni-Cr-Mo alloys for severe corrosion service, but they are not interchangeable in all cases. Understanding their comparative strengths leads to more reliable and cost-effective material selection.

- Choose Hastelloy C-276 when:

- The environment is predominantly reducing or contains strong reducing acids such as HCl.

- You need a proven, versatile alloy with a long track record across diverse process conditions.

- Localized corrosion risk in highly oxidizing chloride environments is moderate or can be managed by design and operating limits.

- Choose Hastelloy C-22 when:

- The environment is strongly oxidizing, especially with significant chloride content (e.g., bleach, hypochlorite, wet chlorine).

- High resistance to pitting, crevice corrosion, and weld-zone corrosion in oxidizing chloride media is critical.

- Components include many welds and complex geometries where crevices and stagnation are unavoidable.

In many complex chemical processes, a detailed corrosion study, testing, or consultation with specialists is recommended. In some cases, a combination of alloys in different parts of a system may provide the optimal balance of performance and cost. By carefully matching the alloy to the exact environment, Hastelloy C-276 and C-22 can deliver long service life and high safety margins in some of the most aggressive industrial conditions.

FAQ: Hastelloy C-276 vs C-22

Which is better for seawater: Hastelloy C-276 or C-22?

Both alloys offer significantly better seawater corrosion resistance than stainless steels, particularly regarding pitting and crevice corrosion. However, Hastelloy C-22 generally provides a higher margin of safety in warm, aerated seawater and chloride-rich brines, especially for components with tight crevices and many welds. Its higher chromium content improves resistance to localized corrosion in oxidizing chloride environments. C-276 can still be used successfully in many seawater applications, but for the most demanding conditions, C-22 is often preferred.

Is Hastelloy C-22 always superior to C-276?

No. Hastelloy C-22 is not universally superior to C-276; the better alloy depends on the specific environment. C-22 generally excels in strongly oxidizing, chloride-containing media where pitting, crevice corrosion, and weld-zone attack are critical concerns. Hastelloy C-276, on the other hand, remains an excellent choice in predominantly reducing acid environments, such as certain hydrochloric acid services, and offers a long track record across mixed process conditions. Proper selection requires analyzing the actual chemical composition, temperature, concentration, and operating conditions of the service environment.