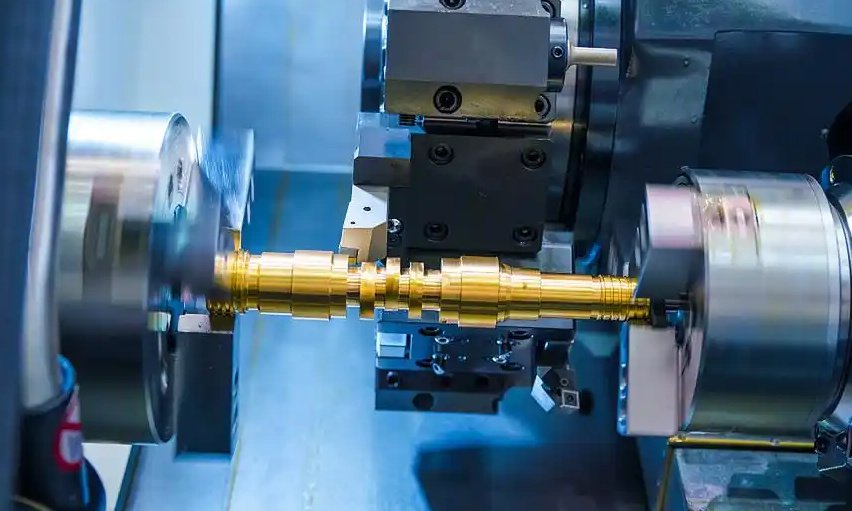

Custom CNC turned parts are critical components across industrial sectors such as machinery, automotive, energy, aerospace, instrumentation, and medical equipment. These parts are manufactured on CNC lathes and turning centers that remove material from rotating workpieces to form precise cylindrical and prismatic shapes. Understanding the technical aspects of CNC turning helps engineers, buyers, and manufacturing planners specify, evaluate, and source parts that meet demanding performance requirements.

What Are CNC Turned Parts?

CNC turned parts are components produced by computer numerical control (CNC) turning processes, where cutting tools remove material from a rotating bar, tube, or preform. The process is highly repeatable and suitable for prototypes, small batches, and large-volume production.

Typical CNC turned components include:

- Shafts, axles, spindles, and pins

- Bushings, sleeves, collars, and spacers

- Fittings, couplings, and connectors

- Valve components and manifolds

- Fasteners, nuts, screws, and threaded inserts

CNC turning is used for both external and internal features, such as outside diameters (OD), inside diameters (ID), threads, grooves, and complex profiles. The CNC system controls feed rates, spindle speeds, tool paths, and tool changes, ensuring consistent dimensions and surface quality.

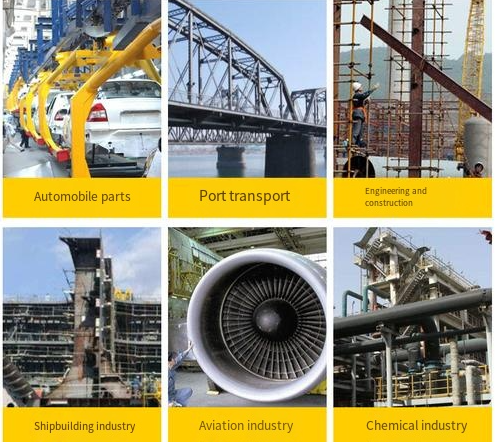

Industrial Applications of Custom CNC Turned Parts

Industrial applications for custom CNC turned parts are broad and often involve high loads, tight tolerances, and long service life. Some representative sectors and component types include:

General Machinery and Equipment

Machine tools, production lines, packaging machines, pumps, and compressors use turned parts such as:

- Rotating shafts, couplings, and hubs

- Bearing seats, sleeves, and alignment pins

- Threaded connectors and adjustment screws

Parts must withstand cyclic loading, wear, and sometimes corrosive environments, which drives material selection and surface treatment requirements.

Automotive and Commercial Vehicles

In automotive applications, turned parts are found in powertrain, steering, braking, suspension, and fluid systems, including:

- Engine and gearbox shafts, dowel pins, and studs

- Brake pistons, fasteners, and fittings

- Sensor housings and injector bodies

Requirements typically include tight dimensional tolerance, controlled surface roughness for sealing or sliding, and compatibility with heat treatments and coatings.

Aerospace and Defense

Aerospace relies on high-strength, low-weight materials and strict quality control. CNC turned items include:

- Hydraulic fittings and couplings

- Landing gear bushings and sleeves

- Fasteners, spacers, and control system shafts

These parts often require aerospace-grade alloys, traceability, and additional processes such as non-destructive testing and special surface treatments.

Energy and Power Generation

Power plants, oil and gas facilities, and renewable energy systems use turned components such as:

- Valve stems and seats

- Flange adapters and threaded connectors

- Measurement instrument housings and sensor bodies

Here, resistance to corrosion, high temperature, and pressure is critical, as well as leak-free threads and sealing surfaces.

Key Advantages of CNC Turning for Industrial Parts

CNC turning offers several advantages when compared to manual turning and other machining processes for industrial applications:

High Precision and Repeatability

CNC turning centers can maintain consistent dimensions across hundreds or thousands of components. Computer control ensures repeatable tool paths, controlled spindle speeds, and precise interpolation for complex contours.

Wide Range of Materials and Part Sizes

CNC turning supports many engineering materials, including steels, stainless steels, non-ferrous alloys, engineering plastics, and specialty materials. Machine configurations range from small precision lathes for miniature parts to large turning centers capable of handling long shafts and large diameters.

Efficient Production and Automation Capability

Automatic bar feeders, parts catchers, and multi-axis turning centers allow efficient, unattended operation once a program and setup are validated. This is particularly beneficial for medium to high-volume industrial production where consistent output is important.

Complex Features in a Single Setup

Multi-axis CNC lathes and turning-milling centers can perform turning, drilling, milling, and tapping in one setup, reducing cumulative error and shortening total processing time. This allows the creation of complex turned parts with flats, slots, cross holes, and other features without multiple fixturing steps.

CNC Turning Processes and Machine Types

CNC turning involves multiple operations performed on various machine configurations. Understanding these helps in planning manufacturable designs and realistic specifications.

Basic Turning Operations

Common operations on CNC lathes include:

- Facing: squaring the end of the workpiece to create a flat reference surface.

- Straight turning: reducing the outer diameter to a specified size along a length.

- Taper turning: producing conical profiles with defined angles or taper per unit length.

- Grooving: machining grooves for retaining rings, seals, or snap rings.

- Parting (cut-off): separating the finished part from the bar or stock.

- Drilling and boring: producing and enlarging internal holes and bores.

- Threading: cutting external or internal threads using threading tools or thread rolling heads.

Common Machine Configurations

Several types of CNC lathes are used in industry:

1) Two-axis CNC lathes

These machines have X and Z axes and are widely used for general turning tasks. They are suitable for many shafts, bushings, pins, and simple stepped parts.

2) Multi-axis turning centers

Machines with Y-axis, live tooling, and sometimes B-axis allow complex features such as:

- Side drilling and tapping

- Milled flats, keyways, and hex profiles

- Off-center bores and slots

This reduces the number of setups and provides higher positional accuracy between turned and milled features.

3) Swiss-type (sliding headstock) lathes

Swiss-type machines are designed for slender, high-precision parts often used in medical, electronics, and instrumentation fields. A guide bushing supports the material close to the cutting zone, improving stability for small-diameter, long components.

4) Vertical CNC lathes

Vertical lathes position the spindle vertically and are used for larger, heavier workpieces like flanges, large housings, and discs in heavy equipment and energy sectors.

Materials for Custom CNC Turned Parts

Material selection directly impacts machinability, mechanical performance, corrosion resistance, and cost. The following table summarizes commonly used materials and typical applications.

| Material Category | Examples | Key Properties | Typical Industrial Uses |

|---|---|---|---|

| Carbon steels | 1045, 1020, 1215 | Good strength, economical, suitable for heat treatment (medium carbon grades) | Shafts, pins, fasteners, couplings |

| Alloy steels | 4140, 4340, 8620 | High strength, toughness, can be case-hardened or through-hardened | Powertrain components, heavy-duty shafts, gears (pre-turned blanks) |

| Stainless steels | 303, 304, 316, 17-4PH | Corrosion resistance, some grades with high strength, good for harsh environments | Fittings, valves, food and pharma equipment, marine components |

| Aluminum alloys | 6061, 6082, 7075 | Lightweight, good machinability, good strength-to-weight ratio | Housings, mounts, pneumatic components, instrument parts |

| Copper alloys | Brass (C3604), bronze, CuNi | Excellent machinability (brass), good electrical and thermal conductivity | Electrical connectors, fluid fittings, bushings, instrumentation |

| Engineering plastics | POM (Delrin), Nylon, PTFE, PEEK | Low weight, low friction, chemical resistance, electrical insulation | Insulators, wear parts, seals, lightweight bushings |

| Specialty alloys | Inconel, Hastelloy, titanium | High temperature and corrosion resistance, high strength-to-weight | Aerospace, chemical processing, high-performance applications |

When specifying materials for custom CNC turned parts, it is important to define:

- Exact material grade and standard (e.g., ASTM, DIN, EN, JIS)

- Required mechanical properties (tensile strength, yield strength, hardness)

- Heat treatment condition (e.g., annealed, quenched and tempered, precipitation hardened)

- Corrosion or temperature requirements

Dimensional Tolerances and Geometric Accuracy

Dimensional and geometric accuracy are crucial for the functionality and interchangeability of industrial components. Specifications should be realistic and aligned with the capabilities of CNC turning processes.

Typical Dimensional Tolerances

Typical achievable linear and diameter tolerances on modern CNC lathes under stable conditions are:

- Standard tolerance: ±0.05 mm to ±0.10 mm

- Precision tolerance: ±0.01 mm to ±0.03 mm

- High-precision tolerance (special setups): up to ±0.005 mm on critical diameters for suitable materials and part sizes

Factors influencing achievable tolerances include part length-to-diameter ratio, material, machine condition, fixturing method, and thermal stability. Long, slender parts usually require looser tolerances or special support arrangements.

Geometric Dimensioning and Tolerancing (GD&T)

For industrial applications, GD&T is often used to define form, orientation, and positional requirements. Common GD&T controls for turned parts include:

- Cylindricity and circularity of shafts and bores

- Perpendicularity and parallelism between faces and axes

- Concentricity or position of diameters relative to datum axes

- Total runout for rotating interfaces and bearing seats

Clear datums and properly selected GD&T callouts help ensure that parts function correctly in assemblies, especially where bearings, seals, or precise alignments are involved.

Surface Finish and Surface Integrity

Surface finish can affect friction, wear, sealing performance, fatigue resistance, and appearance. For turned parts, surface roughness is typically expressed using Ra values (arithmetical mean roughness) in micrometers (µm) or microinch.

| Surface Roughness (Ra) | Typical Surface Quality | Common Use |

|---|---|---|

| Ra 3.2–6.3 µm | Standard turned finish | General-purpose industrial components and non-critical surfaces |

| Ra 1.6–3.2 µm | Improved finish | Bearings seats (medium requirements), shafts, general sealing surfaces |

| Ra 0.8–1.6 µm | Fine turned or combined with light polishing | Hydraulic components, high-speed rotating interfaces |

| Ra 0.4–0.8 µm | Very fine finish | Precision sealing surfaces, high-precision spindles, critical fits |

For many industrial parts, specifying excessively fine surface finishes where they are not functionally required can increase manufacturing time and cost. It is advisable to specify roughness only for surfaces with functional importance, such as sealing faces, sliding interfaces, and bearing seats.

Threads and Grooves in CNC Turned Parts

Threads and grooves are common features in custom CNC turned parts and must be clearly defined to ensure interchangeability and performance.

Thread Standards and Specifications

Threads must be specified according to recognized standards. Common standards include:

- Metric threads: ISO metric (e.g., M10 × 1.5), coarse or fine series

- Unified threads: UNC, UNF, UNEF (e.g., 1/4-20 UNC)

- Pipe threads: NPT, NPTF, G (BSPP), R/Rc (BSPT)

- Special threads: trapezoidal (Tr), Acme, buttress

Important thread parameters to specify include:

- Thread type and designation

- Tolerance class (e.g., 6g, 6H, 2A, 2B)

- Thread length and start position

- Chamfers, runouts, and undercuts if required

Grooves, Undercuts, and Retaining Features

Grooves and undercuts are used for:

- Retaining rings (circlips)

- O-rings and other seals

- Stress relief at shoulders (undercuts)

These features require careful dimensioning. For O-ring grooves, for example, standards such as ISO 3601 can be used to determine groove width, depth, and corner radius to achieve correct compression and sealing performance.

Design Guidelines for Custom CNC Turned Parts

Good design practices can improve manufacturability, ensure reliable function, and control cost. Key design considerations include:

Geometry and Feature Design

- Avoid unnecessary complexity in profiles and transitions.

- Use standard diameters and thread sizes where possible to simplify tools and gauges.

- Provide clear shoulders and reference surfaces for measurement and assembly.

- Minimize very deep, narrow grooves which are harder to machine and inspect.

Fillets, Chamfers, and Radii

Sharp internal corners concentrate stress and are more difficult to machine. Rounded fillets are preferred where functional constraints permit. Consider the following:

- Use fillet radii consistent with typical tool nose radii (e.g., 0.2–0.8 mm).

- Include chamfers on thread starts to aid assembly and protect threads.

- Provide lead-in chamfers on shafts and bores to guide assembly and avoid damage to sealing elements.

Length-to-Diameter (L/D) Ratio

Long, slender parts can deflect during machining, affecting accuracy and surface quality. Typical guidance:

- For unsupported turning, L/D ratios above approximately 3:1 may require steady rests, tailstocks, or special tooling.

- For Swiss-type lathes, higher L/D ratios are possible due to the guide bushing support.

When designing long components, consider splitting them into multiple pieces or adjusting geometry if feasible.

Typical Machining Parameters and Capabilities

While actual machining parameters depend on machine tool, tooling, coolant, and part geometry, understanding typical ranges helps when planning production and cycle times.

Key parameters include:

- Spindle speed (rpm): determined by cutting speed and part diameter.

- Feed rate (mm/rev): selected based on material, tool, and surface finish requirements.

- Depth of cut (mm): adjusted to balance removal rate and tool life.

For example, aluminum alloys often allow higher cutting speeds and feed rates compared with stainless steels or nickel-based superalloys. Harder materials may require lower cutting speeds and more robust tooling, which affects achievable cycle times and cost.

Surface Treatments and Heat Treatments

Many CNC turned parts undergo additional treatments to enhance wear resistance, corrosion protection, and mechanical properties.

Heat Treatment

For steels and some stainless steels, common heat treatments include:

- Quenching and tempering to achieve specified hardness and toughness.

- Case hardening (carburizing, carbonitriding) for wear-resistant surfaces with tough cores.

- Precipitation hardening (e.g., 17-4PH) to obtain high strength and corrosion resistance.

Heat treatment can cause dimensional changes, so designs for high-precision parts may need allowance for post-heat-treatment grinding or finishing.

Surface Treatments and Coatings

Common surface treatments for turned industrial parts include:

- Plating: zinc, nickel, chrome for corrosion resistance and appearance.

- Anodizing: for aluminum parts, providing corrosion resistance and surface hardness.

- Nitriding and nitrocarburizing: improving surface hardness and fatigue resistance.

- Phosphate coating or black oxide: anti-corrosion and anti-galling properties for steel parts.

Coating thickness and dimensional impact must be considered in tolerance stack-ups, particularly for tight fits and threaded connections.

Quality Control and Inspection of CNC Turned Parts

Industrial-grade CNC turned parts require reliable inspection and documentation to ensure compliance with specifications.

Dimensional Inspection

Common tools and methods include:

- Calipers and micrometers for basic dimensions.

- Bore gauges and plug gauges for internal diameters.

- Thread gauges (go/no-go) for thread verification.

- CMM (coordinate measuring machine) for complex GD&T and critical geometries.

Inspection plans often define sampling rates, critical dimensions (CTQs), and acceptance criteria based on statistical methods or customer requirements.

Material and Process Verification

In many industrial sectors, additional verifications are required:

- Material certificates (e.g., EN 10204 3.1) confirming chemical composition and mechanical properties.

- Hardness testing after heat treatment.

- Non-destructive testing where required (e.g., magnetic particle, ultrasonic, dye penetrant).

- Surface roughness measurements using profilometers.

Detailed documentation and traceability help ensure compliance with regulatory, safety, and internal quality standards.

Common Pain Points When Sourcing CNC Turned Parts

Industrial buyers and engineers frequently encounter specific issues when sourcing custom CNC turned parts. Addressing these early in the project can reduce delays and rework.

Typical pain points include:

- Unclear or incomplete drawings: missing tolerances, material specifications, or surface finish requirements can lead to incorrect parts or multiple design revisions.

- Over-specified tolerances: extremely tight tolerances on non-critical features increase cost and lead time without improving function.

- Undefined heat treatment and coating requirements: late changes to surface treatment can require requalification or rework.

- Insufficient communication of inspection requirements: lack of agreed inspection plans and documentation needs (e.g., certificates, reports) may cause shipment delays.

Thorough technical documentation and early collaboration with the machining supplier help minimize these issues.

Key Considerations When Working With a CNC Turning Supplier

Selecting and working with a CNC turning supplier for industrial applications involves several technical considerations.

Important aspects include:

- Technical capability: machine types, maximum/minimum diameter and length, number of axes, and supported materials.

- Quality system: existence of quality management standards, inspection equipment, and documentation capabilities.

- Consistency: ability to maintain stable quality across repeated orders and long-term projects.

- Process control: use of process capability analysis, tool life management, and preventive maintenance.

Providing complete drawings, 3D models where applicable, and clear specifications is essential to obtaining accurate quotations and consistent results.

FAQ About Custom CNC Turned Parts

What information is needed to quote custom CNC turned parts?

To obtain an accurate quote for custom CNC turned parts, you should provide a detailed drawing (2D) and, if available, a 3D model; complete material specification (including grade and standard); required quantities and expected order frequency; dimensional tolerances and critical features; surface finish requirements; any heat treatment or coating; and special inspection or certification needs. The more complete the information, the more precise the pricing and lead time estimation will be.

How do I choose the right material for a CNC turned industrial part?

Choosing the right material depends on the part’s functional requirements: mechanical load, wear conditions, working temperature, environment (corrosion, chemicals), weight constraints, and cost targets. For example, carbon steel or alloy steel is common for high-strength shafts; stainless steel is chosen for corrosion resistance; aluminum is useful for lightweight components; and engineering plastics are used for low-friction or electrically insulating parts. It is recommended to define the operating conditions and consult relevant material standards or a knowledgeable machining supplier to select a suitable grade.