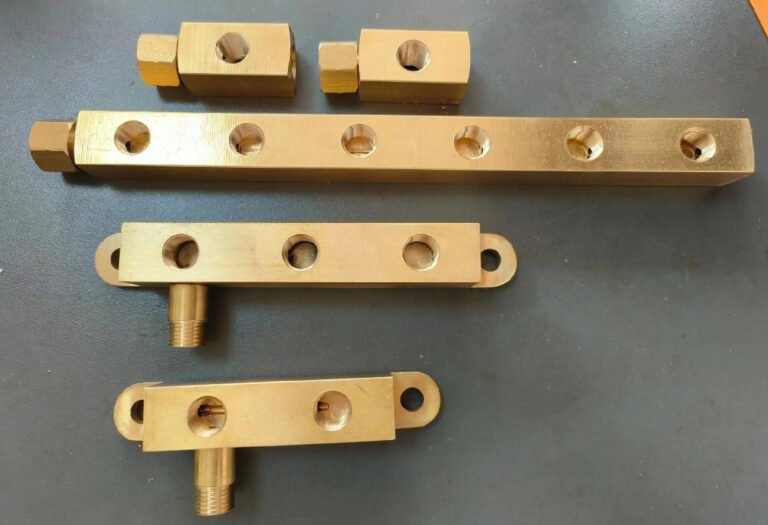

In industries such as valves, plumbing, gas systems, refrigeration, and electrical connectors,

copper alloy products are everywhere.

Many people know that copper is “easy to machine”, but anyone with real mass-production experience understands the truth:

Copper alloy machining looks simple, but the pitfalls are numerous.

Rapid tool wear, unstable dimensions, surface tearing, uncontrollable burrs, and poor batch consistency are common issues.

In most cases, the root cause is not the machine tool itself, but an insufficient understanding of copper alloy material behavior and machining characteristics.

This article explains copper alloy machining systematically from five aspects:

material → process → tooling → defects → control.

Material First: Not All “Copper” Is the Same

Many machining problems are already determined during material selection.

Common Copper Alloys and Machining Characteristics

| Type | Typical Grades | Machining Characteristics |

|---|---|---|

| Brass | HPb59, H62 | Easy to machine, stable dimensions |

| Leaded Brass | HPb57-3, HPb58-3 | Excellent machinability, environmental restrictions |

| Lead-Free Brass | C46500, CW511L | Reduced machinability, prone to built-up edge |

| Bronze | Tin bronze, aluminum bronze | High strength, rapid tool wear |

| Pure Copper | T2 | High ductility, extremely sticky during cutting |

Conclusion: Even within copper alloys, machining parameters can never be shared universally.

The Core Contradictions in Copper Alloy Machining

- Good ductility → easy tool adhesion

- High thermal conductivity → high tool tip temperature

- Soft material → surface tearing and burr formation

Once cutting parameters are slightly inappropriate, problems emerge immediately.

Key Process Control Points in Copper Alloy Machining

1) Cutting Speed: Faster Is Not Always Better

High cutting speed:

→ higher tool temperature

→ material softening and built-up edge

Low cutting speed:

→ poor chip breaking

→ surface scratching

Practical guidelines:

- Brass: medium to high speed, focus on stability

- Lead-free brass: reduced speed to prevent adhesion

- Bronze: low speed with high system rigidity

2) Feed Rate Is More Important Than You Think

Too small feed rate:

→ tool rubs instead of cuts

→ shiny surface but drifting dimensions

Proper feed rate:

→ stable cutting

→ better dimensional consistency

3) Cooling Method Determines Surface Quality

- Dry cutting: surface tearing and short tool life

- Emulsion coolant: standard choice

- High-pressure coolant: very effective for lead-free copper and complex geometries

The key is not whether coolant is used, but whether it effectively reaches the tool tip.

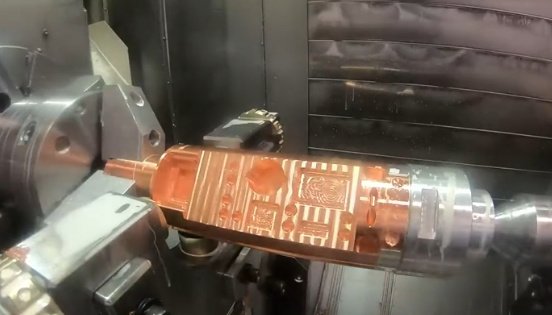

Tool Selection: The Turning Point of Copper Alloy Machining

1) Tool Material Recommendations

- Cemented carbide: mainstream choice

- Coated tools: strongly recommended for lead-free brass and bronze

Proper coatings significantly reduce built-up edge and adhesion.

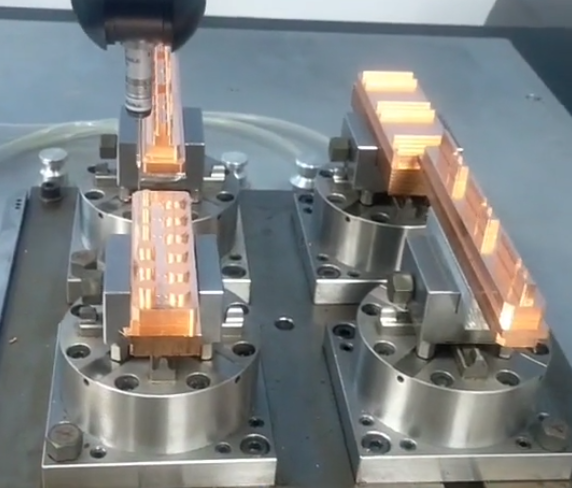

2) Tool Geometry Is Critical

- Large positive rake angle to reduce cutting force

- Sharp cutting edge to prevent surface tearing

- Proper chip breaker to avoid chip entanglement

Many dimensional instability issues originate from incorrect tool geometry, not machine accuracy.

Common Copper Alloy Machining Defects and Root Causes

Surface Scratching / Tearing

Causes: dull tools, built-up edge, insufficient cooling

Solutions: replace or coat tools, optimize coolant delivery

Excessive Burrs

Causes: tool wear, improper parameters, excessive ductility

Solutions: control tool life, optimize tool exit path, add chamfering

Dimensional Drift

Causes: rapid tool wear, thermal deformation, insufficient fixture rigidity

Solutions: fixed tool change intervals, controlled production rhythm, rigid fixturing

Quality Perspective: Copper Alloy Machining Is Not Just About Dimensions

Quality focus points include:

- Surface damage affecting sealing performance

- Micro-cracks causing later service failure

- Burrs at holes creating assembly risks

Recommendations:

- Enhanced inspection during first article approval

- Process capability (CPK) monitoring on critical dimensions

Three Practical Production Management Suggestions

1) Do Not Pursue Extreme Cycle Time

In copper alloy machining, stability outweighs single-part efficiency.

2) Standardize Tool Management

- Fixed tool life

- Fixed parameters

- Fixed suppliers

Do not rely on operator intuition for tool changes.

3) Process Documents Must Be Clear and Practical

- Clear parameter ranges

- Explicit forbidden conditions

- Defined abnormal handling procedures

Conclusion

Copper alloy machining is far from “simple metal cutting”.

It tests:

- Understanding of material behavior

- Control of machining details

- Respect for stable mass production

Only when material, tooling, parameters, and quality are connected as one system

can copper alloy machining move from experience-based to repeatable and controllable.

FAQ: Copper Alloy Machining

What are the most common types of copper alloys used in machining?

The most common copper alloys include brass (HPb59, H62), leaded brass (HPb57-3, HPb58-3), lead-free brass (C46500, CW511L), bronze (tin bronze, aluminum bronze), and pure copper (T2). Each type has different machinability and requires specific cutting parameters.

Why is copper alloy machining considered challenging?

Copper alloys have a combination of high ductility, high thermal conductivity, and softness, which can cause issues like tool adhesion, surface tearing, burrs, and dimensional drift if machining parameters are not optimized.

How should cutting speed be selected for different copper alloys?

Cutting speed depends on the alloy type:

Brass: medium to high speed with focus on stability

Lead-free brass: reduced speed to prevent built-up edge

Bronze: low speed with high rigidity

What types of tools are recommended for copper alloy machining?

Cemented carbide tools are widely used, and coated tools are recommended for lead-free brass and bronze to reduce tool adhesion and wear. Tool geometry, including positive rake angle and sharp cutting edges, is crucial.