CNC Milling

Professional CNC milling services for high-precision metal and plastic parts. We offer 3-axis, 4-axis, and 5-axis CNC milling for rapid prototyping and production, supporting aluminum, stainless steel, titanium, brass, and engineering plastics. Fast turnaround, tight tolerances, full surface finishing, and reliable custom machined parts for aerospace, automotive, robotics, marine, medical, and industrial applications.

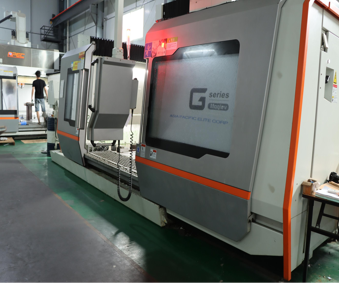

G550 5-Axis Universal Machining Center By GROB Germany Maximun Working Travel: 800MM X 1020 MM X 970MM Max.Speed: 65/50/80(m/min)

The Mikron MILL E 500 U By GF Machining Solutions UK Maximun Working Travel: 500MM X 450 MM X 400MM Max. Speed: 20,000 (RPM)

5-Axis High-Speed Gantry Machining Center By APEC Tai Wan China Maximun Working Travel: 4000MM X 2500 MM X 1000MM Max. Speed: 24,000 (RPM)

At XCM, advanced CNC milling allows us to machine complex components with fewer setups, delivering exceptional efficiency and stable, repeatable quality. Our engineering team optimizes CAM programming in advance, simulating and refining every milling toolpath to ensure smooth operations and precise results. This “right-first-time” approach reduces production costs, shortens lead times, and guarantees the high-accuracy milled parts our customers rely on.

From simple components to highly complex specifications, XCM select the best machining equipment to produce your CNC Milled parts based on suitability and price, never compromising on quality.

Material

| 6061 | 6063 | 6082 | 5083 | 5754 |

| 2011 | 2014 | 2024 | 5052 | 6101 |

| 6060 | 7075 | A356 | A380 | ZLD107 |

| AiSI6Cu4 | LM21 |

Properties: Aluminum is a lightweight, corrosion-resistant, and high-strength metal that is easy to machine and has good electrical and thermal conductivity.

Applications: Aerospace, automotive manufacturing, construction, electronics packaging.

General Surface Treatments: Anodizing, Electroplating, Passivation, Blackening, Electrophoresis, Spray Painting, Screen Printing, Laser Engraving.

| HPb59-1 | CuZn39pb1 | C3600 | CZ122 | CuSn6 |

| CA104 | C10100 | C12000 | QSn7-0.2 | CuZn40 |

| CZ109 | CZ122 | TP1 | TP2 | CU-OF |

| C17200 | Cucr1 | CuBe2 | H62H65 | QSn7-0.2 |

| QAI9-4 | QA110-4-4 | C62300 | C63020 | C65500 |

| 17-4PH | 0Cr17Ni4Cu4Nb | S17400 | SUS630 | SUS316 |

| SUS304 | SUS303 | SUS316Ti | SUS321 | SUS420 |

| SUS430 | SUS431 | 4Cr13 | 1Cr13 | 0Cr18Ni9 |

| 1Cr18Ni9MoZn | 0Cr17Ni13Mo | 1Cr18Ni9Ti | 1.4301 | 1.4305 |

| 1.4401 | 1.4435 | 1.4104 | 1.4034 |

| Polyformaldehyde | POM | Polyetheretherketone | PEEK | Teflon |

| PTFE | Nylon | PA6 | PA66 | Polyphenylsulfide |

| PPS | Polycarbonate | PC | Polysulfone | PSU |

| Monel 400 | Monel 500 | Inconel 718 | Inconel 625 | Inconel 600 |

| Inconel X-750 | C-276 | GH4169 | 2.4360 | UNS NO4400 |

| TC4 | TC6 | TC9 | Ti-6A-4V | Grade5 |

| Grade25 | TA11 | TA15 | IMI3173Al | TC17 |

| TC11 | TA1 | TA2 | TC20 | TC1 |

| Ti-5Al-2.5Sn | Ti-6Al-6V-2Sn | Ti-13V-11Cr |

Application

Maritime and Oil & Gas

XCMCNC passed ISO9001, Marine oil field machining components rely on five-axis linkage ultra-precision machining technology, combined with Inconel/Ti-6Al-4V and other special alloy materials, the precision of key components up to ±0.005mm, nano-coating and deep nitriding treatment, corrosion resistance increased by 60%, Can withstand 1000℃ high temperature and 180MPa high pressure environment. XCM extends component life up to 120,000 hours through four-stage gas seal testing and stress/temperature/wear/vibration suppression technology.

Aerospace

Micron machining 5-axis CNC technology (accuracy ±0.003mm) supports complex surface processing of titanium alloy and nickel-based superalloy; The intelligent cutting parameter optimization system controls the tool load in real time and reduces the machining loss by 22%.Complex Geometry Fabrication Achieves intricate shapes (e.g., turbine disks, airfoils) via CNC programming, meeting aerodynamic and lightweight requirementsAutomated Production Minimizes human errors and enhances efficiency through CNC automation, ensuring consistency in large-scale manufacturing

Medical

Through ISO 9001 and ISO 13485 certification, relying on five-axis ultra-precision machining technology, combined with medical grade titanium alloy (Ti-6Al-4V ELI), cobalt-chromium alloy and biocompatible materials such as PEEK, the processing accuracy of key implants is up to ±0.005mm, and through nano-level electrolytic polishing and passivation treatment, surface roughness can reach to Ra≤0.1μm. Through stress optimization and microdefect control technology make the component life of more than 15 years, the defect rate < 0.005%.

Energy

The advantages of XCM in the field of energy component processing are reflected in three aspects: technology, efficiency and sustainability. The five-axis linkage CNC system and ultra-precision machining technology can complete high-precision machining of high-end components such as complex surfaces and thin-walled structures (accuracy up to ±0.003mm), meeting the requirements of harsh working conditions such as wind turbine blades and nuclear power seals. Through computer software programming and process optimization, the processing efficiency can be increased by more than 30%, material loss can be reduced by 15%, and the unit cost can be reduced by 20%.

Robotics & Automation

XCMcnc has become an ideal partner for robot component manufacturing with its high-precision processing technology and industry experience. We use imported five-axis CNC equipment (accuracy ±0.01mm) and strict quality inspection processes to ensure the durability and dynamic performance of key components such as robot arm joints and reducers. The mature one-stop service covers design optimization, material selection to mass production, supports the processing of special materials such as titanium alloy and carbon fiber, and meets the lightweight requirements of collaborative robots and high load requirements of industrial robots.

Automotive

As a professional partner in the field of precision parts processing in the automotive industry, XCMcnc provides customers with high-precision and high-reliability component solutions with advanced CNC machining technology, intelligent production systems and rich industry experience. We use advanced machine tools such as five-axis linkage machining centers and turning and milling equipment, combined with a strict IATF 16949 quality management system to ensure that the dimensional accuracy of various metal parts reaches the micron level, fully meeting the stringent requirements of key parts such as engines and transmission systems.