CNC manufacturing covers a broad set of subtractive machining processes driven by computer numerical control. Among these, milling, turning, and 5-axis machining are the core capabilities used to produce precise components for aerospace, automotive, medical devices, industrial equipment, consumer products, and many other applications.

This page explains the technical foundations, machine configurations, machinable materials, achievable tolerances, and typical applications of CNC milling, CNC turning, and 5-axis machining. It also outlines selection considerations when choosing the appropriate process for a specific part.

Fundamentals of CNC Manufacturing

CNC (Computer Numerical Control) manufacturing is a subtractive process in which cutting tools remove material from a workpiece based on a programmed toolpath. The toolpath is generated from CAD (Computer-Aided Design) data via CAM (Computer-Aided Manufacturing) software and executed automatically by CNC machine tools.

Core characteristics of CNC manufacturing include:

- Numerically controlled motion along one or more axes (linear and rotational)

- High repeatability based on closed-loop servo systems and feedback devices

- Capability to produce precise geometries with tight dimensional control

- Compatibility with a wide range of metals and engineering plastics

The three most widely used CNC process groups described here are:

CNC Milling: A rotating cutting tool removes material from a stationary or moving workpiece, primarily using linear axes (X, Y, Z).

CNC Turning: A rotating workpiece is cut by a stationary or moving tool, ideal for cylindrical and rotational parts.

5-Axis Machining: A variant of milling with simultaneous or indexed motion in five axes, enabling complex geometry and multi-face machining.

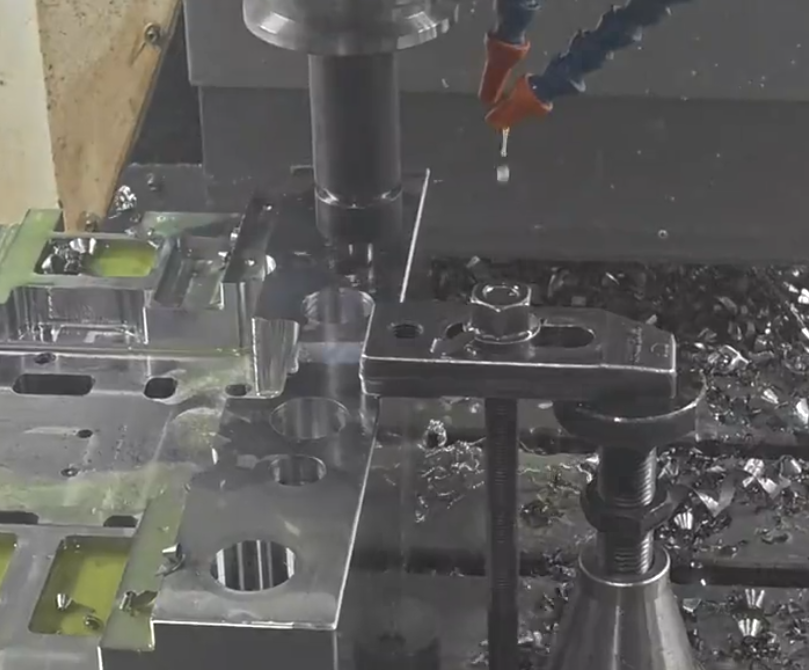

CNC Milling Capabilities

CNC milling is the most common CNC machining process and is used to produce prismatic and freeform components with flat surfaces, pockets, slots, bosses, holes, and complex contours. Milling machines may be configured as vertical machining centers (VMC), horizontal machining centers (HMC), or gantry-type machines, with 3, 4, or 5 axes of motion.

Milling Machine Configurations and Axes

CNC milling centers typically have three primary linear axes:

- X-axis: Left-right movement

- Y-axis: Front-back movement

- Z-axis: Up-down movement

Additional rotary axes may be provided by rotary tables or trunnion systems, expanding to 4 or 5 axes. Machine configurations include:

| Machine Type | Axes | Characteristics | Typical Uses |

|---|---|---|---|

| 3-Axis VMC | X, Y, Z | Vertical spindle, common configuration | Plates, brackets, housings, molds with simple features |

| 3-Axis HMC | X, Y, Z | Horizontal spindle, pallet changer | Production of prismatic parts, improved chip evacuation |

| 4-Axis Mill | X, Y, Z + A or B | Additional rotary axis for indexing or simple contouring | Parts requiring features on multiple sides, gears, splines |

| 5-Axis Mill (Trunnion/Table) | X, Y, Z + 2 rotary | Full multi-axis motion, complex geometry | Impellers, turbine blades, complex medical and aerospace parts |

Key Milling Operations

Common CNC milling operations include:

Face milling: Producing flat surfaces and controlling part thickness using a tool whose cutting edges are primarily on the face.

Peripheral milling: Cutting along the side of the tool to produce slots, shoulders, and profiles.

Pocketing: Removing material from cavities of specified depth, often using roughing and finishing passes.

Drilling, reaming, and tapping: Creating and finishing holes and threads, often in a single setup using tool changers.

Contour and 3D surface milling: Generating freeform surfaces using ball nose or bull nose cutters with controlled step-over and step-down values.

Milling Materials and Cutting Parameters

CNC milling supports a wide variety of materials. Common groups include:

- Aluminum alloys (e.g., 6061, 6082, 7075)

- Carbon steels and alloy steels

- Stainless steels (e.g., 304, 316, 17-4PH)

- Copper and copper alloys (brass, bronze)

- Nickel-based alloys (e.g., Inconel series)

- Titanium alloys (e.g., Ti-6Al-4V)

- Engineering plastics (e.g., POM, PEEK, PTFE, nylon)

Typical ranges for important milling parameters (actual values depend on material, tool, machine, and setup):

Spindle speed: From a few hundred rpm for hard steels to 20,000–40,000 rpm or higher on high-speed machining centers for aluminum and plastics.

Feed rate: From fractions of a mm per revolution up to several hundred or more mm/min, depending on tool diameter and chip load.

Depth of cut (axial): May range from 0.1 mm finishing passes to several millimeters or more for roughing operations, constrained by tool stiffness, workholding, and machine power.

Milling Tolerances and Surface Finish

Standard CNC milling processes can achieve:

General tolerances: ±0.05 mm to ±0.10 mm on many features when machines are properly maintained and setups are rigid.

Precision tolerances: ±0.01 mm or better for critical dimensions with dedicated fixturing, controlled environments, and optimized programs.

Hole tolerances: Reamed holes may reach IT7–IT8; precision bores with boring tools can achieve tighter fits for bearings or mating components.

Surface roughness (Ra) values achievable by milling:

Roughing: Approximately 3.2–6.3 μm Ra.

General finishing: Approximately 1.6–3.2 μm Ra.

Fine finishing / high-speed milling: Approximately 0.8–1.6 μm Ra or better with optimized parameters and suitable tooling.

Secondary processes such as grinding, honing, lapping, bead blasting, anodizing, plating, and painting can be applied to meet specific surface and functional requirements.

Milling Workholding and Fixturing

Workholding has a direct influence on accuracy and productivity in milling. Common methods include:

Machine vises: Used for small to medium-sized prismatic parts.

Clamps and step blocks: For large or irregular workpieces.

Dedicated fixtures and jigs: Designed for specific parts to improve repeatability and reduce loading time.

Vacuum fixtures: For thin plates and non-ferrous materials where clamping distortion must be minimized.

Poor workholding can lead to part deflection, vibration, dimensional inaccuracy, and poor surface finish. Robust fixture design and suitable clamping forces are essential to maintain tolerances, especially for thin-walled or long parts.

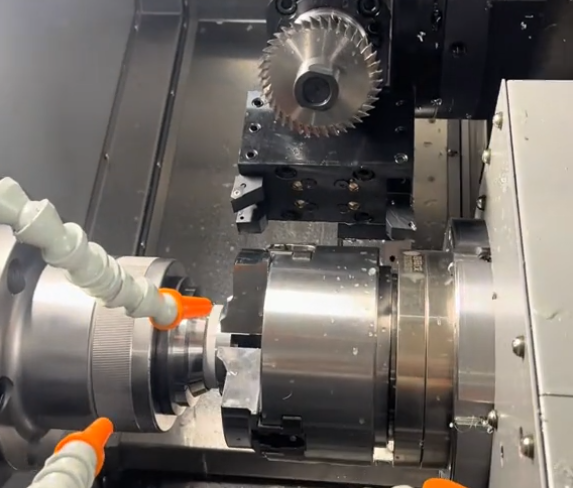

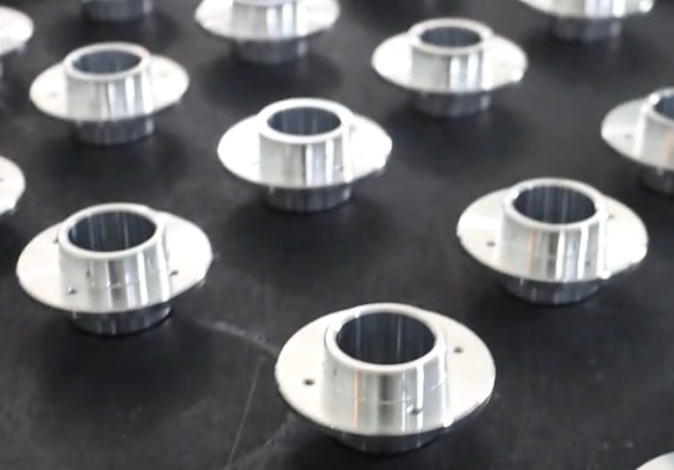

CNC Turning Capabilities

CNC turning is based on a rotating workpiece and stationary or moving cutting tools. It is especially suited for producing parts with rotational symmetry, such as shafts, bushings, fasteners, rings, and threaded components. Turning centers may include live tooling and secondary axes, enabling combined turning and milling operations.

Turning Machine Types and Axis Layouts

Typical CNC turning centers have:

Main spindle: Rotates the workpiece around the Z-axis.

Turret or tool changer: Holds multiple turning and boring tools.

Linear axes: X-axis for radial motion, Z-axis for axial motion.

More advanced machines may include:

Sub-spindle: For back-side machining and part transfer, enabling machining of both ends in one setup.

Y-axis: For off-center milling and drilling operations using live tools.

Live tooling (driven tools): For milling flats, slots, and holes on turned parts.

Main Turning Operations

CNC turning operations include:

Facing: Producing flat surfaces perpendicular to the axis of rotation.

External turning: Reducing outside diameter to specified dimensions.

Internal turning (boring): Enlarging and finishing internal diameters.

Grooving: Cutting grooves on external or internal surfaces.

Parting (cut-off): Separating finished parts from bar stock.

Threading: Cutting internal or external threads (metric, unified, or other standards).

Drilling and boring on center: Creating axial holes, often combined with reaming and tapping.

Turning Materials and Dimensional Capabilities

Like milling, turning supports a wide range of materials. Common bar stock diameters are available for steels, stainless steels, brass, aluminum, and certain plastics, allowing efficient production from bar feeders for medium to high quantities.

Typical dimensional capabilities for CNC turning:

General tolerances: ±0.05 mm on diameters and lengths for standard production.

Precision tolerances: ±0.005–0.01 mm on critical diameters with stable processes and fine finishing tools.

Roundness and concentricity: Often better than 0.01 mm with proper setup, especially when machining in a single chucking.

Surface roughness values (Ra) for turning:

Standard turning: Approximately 1.6–3.2 μm Ra.

Fine finishing and micro-turning: Approximately 0.4–1.6 μm Ra with sharp inserts, fine feeds, and appropriate nose radius.

Bar Feeding and Production Efficiency

For repeated production of turned parts, bar feeders can supply continuous stock to the main spindle. This reduces manual loading and enables extended unattended operation. Key considerations include:

Bar diameter and length capacity of the bar feeder.

Spindle bore size and chuck type.

Chip evacuation and coolant system design.

For shorter production runs or large-diameter parts, pre-cut blanks are often loaded manually or with automation systems such as gantry loaders or robotic arms.

Common Considerations in Turning

Factors that strongly affect the quality and cost of CNC turning include:

Material machinability: Free-cutting steels and brass machine faster than hardened steels and tough alloys.

Part geometry: Deep, narrow grooves, thin walls, or long slender sections may require specialized tooling and conservative parameters to avoid chatter and deflection.

Workholding: Collets provide better concentricity for smaller diameters; three-jaw or four-jaw chucks handle a wider range of shapes and sizes.

Misalignment, insufficient clamping force, or excessive stick-out from the chuck can introduce runout, vibration, and dimensional variation, especially at higher spindle speeds.

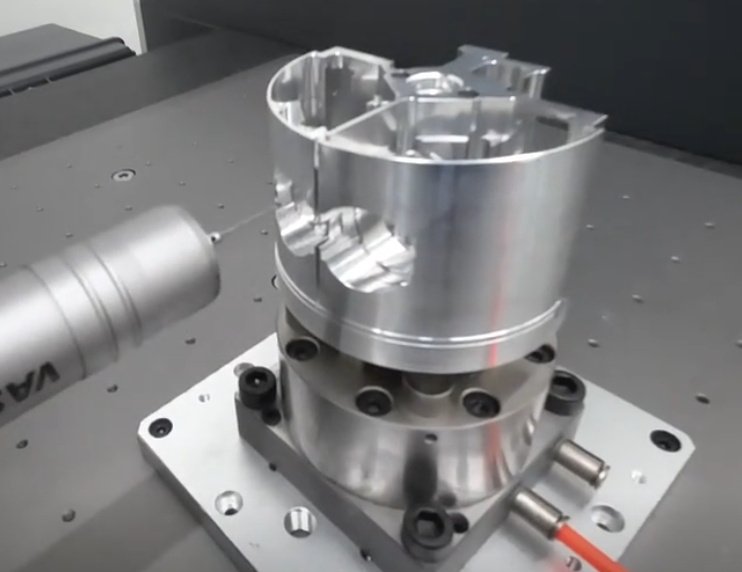

5-Axis CNC Machining Capabilities

5-axis machining is an advanced form of CNC milling that adds two rotary axes to the three linear axes. This allows the cutting tool or the workpiece to tilt and rotate, enabling access to multiple faces and generating complex geometries in fewer setups.

Types of 5-Axis Configurations

Common 5-axis machine configurations include:

Table-table: Both rotary axes are integrated into the table, rotating and tilting the workpiece.

Head-table: One rotary axis in the head (tilting spindle) and one in the table.

Head-head: Both rotary axes in the spindle head, allowing the tool to approach the part from many directions.

5-axis motion may be:

Simultaneous (full 5-axis): All five axes move at the same time along a toolpath, used for true multi-axis contouring and freeform surfaces.

Indexed (3+2): The rotary axes position the part, then remain fixed while 3-axis milling occurs; multiple index positions allow machining of several faces in one setup.

Advantages in Geometry and Setup Reduction

5-axis machining enables:

Machining undercuts and deep cavities by tilting the tool.

Shorter tools and improved rigidity by orienting the tool more favorably to the workpiece surface.

Reduced setup count by accessing multiple part faces without manual re-clamping.

Consistent datum references, improving accuracy between features on different faces.

This is particularly beneficial for:

Aerospace components such as brackets, structural nodes, and blisks.

Medical implants with organic surfaces (e.g., orthopedic implants).

Molds, dies, and tooling inserts with complex 3D contours.

5-Axis Tolerances and Surface Quality

In terms of basic dimensional accuracy, high-quality 5-axis machines can match or exceed the capabilities of advanced 3-axis machines. Typical ranges are:

General tolerances: ±0.02–0.05 mm on most dimensions.

Precision zones: ±0.005–0.01 mm with careful calibration, probing, and optimized cutting parameters.

Surface finish is influenced by toolpath strategy, step-over, and machine dynamics. For sculpted surfaces in molds or aerodynamic components, 5-axis motion can maintain consistent tool contact and orientation, improving surface uniformity and reducing the need for manual polishing.

Programming and Process Planning Considerations

5-axis machining requires more complex CAM programming compared to 3-axis processes. Important considerations include:

Collision avoidance between tool, holder, and workpiece.

Tool axis orientation strategies to balance surface quality, tool life, and machine motion limits.

Use of tool length, holder, and machine kinematics libraries within CAM software.

In-machine probing to set and verify work offsets and critical dimensions.

Despite the greater programming effort, 5-axis machining can lower total production time for complex parts by reducing manual handling, intermediate fixtures, and secondary operations.

Comparison of Milling, Turning, and 5-Axis Machining

Choosing between milling, turning, and 5-axis machining depends on part geometry, quantity, tolerances, and surface requirements. The following table summarizes key distinctions.

| Aspect | CNC Milling | CNC Turning | 5-Axis Machining |

|---|---|---|---|

| Best-suited geometries | Prismatic parts, pockets, slots, planar faces | Rotational parts, shafts, bushings, threaded features | Complex 3D surfaces, multi-face parts, undercuts |

| Workpiece motion | Primarily stationary, linear tool motion | Rotating workpiece, linear tool motion | Workpiece and/or tool rotation plus linear motion |

| Typical tolerances | ±0.01–0.05 mm | ±0.005–0.05 mm | ±0.005–0.05 mm |

| Setup complexity | Low to medium, depends on fixturing | Low for simple parts, medium for multi-op parts | Medium to high, complex programming and fixturing |

| Production suitability | Low to high volume | Highly efficient for medium to high volume via bar feeding | Most effective for complex parts or consolidation of operations |

| Common stock forms | Plates, blocks, near-net shapes | Bars, tubes, pre-machined blanks | Blocks, castings, forgings, complex blanks |

Material and Surface Finish Options

Milling, turning, and 5-axis machining can be applied to a similar set of machinable materials, with specific process parameters tailored to each material’s characteristics. Selection of material and surface finish strongly impacts performance, cost, and lead time.

Common Material Categories

Typical materials used in CNC machining include:

Aluminum: High machinability, favorable strength-to-weight ratio, good corrosion resistance (improved with anodizing), suitable for housings, brackets, and structural parts.

Carbon and alloy steels: Wide range of grades and heat treatments for structural and high-strength components, often requiring protective coatings.

Stainless steels: Corrosion-resistant materials for food, medical, chemical, and marine applications, with moderate to high machining difficulty depending on grade.

Copper alloys: Excellent electrical and thermal conductivity, good machinability for electrical and fluid components.

Titanium and nickel alloys: High strength and heat resistance for aerospace and medical parts; require careful parameter control to manage tool wear.

Engineering plastics: Low weight, good wear and chemical resistance, and electrical insulation; used in mechanical components, insulators, and fluidic features.

Surface Treatments and Their Purposes

After machining, parts can receive additional surface treatments. Typical options include:

Anodizing: Used on aluminum to increase corrosion resistance, surface hardness, and offer color coding.

Electroplating (e.g., nickel, chrome, zinc): Provides corrosion resistance, improved wear, or decorative finish.

Heat treatment: Applied to steels and certain alloys to achieve desired hardness and mechanical properties.

Passivation: Chemical treatment for stainless steels to improve corrosion resistance by enhancing the protective oxide layer.

Painting and powder coating: For aesthetics and environmental protection.

Bead blasting or shot peening: For uniform matte finishes or surface strengthening.

Machining allowances and sequencing must be planned with these processes in mind, especially when tight tolerances are required after treatment.

Accuracy, Tolerances, and Quality Control

Reliable production of CNC parts depends not only on machine capabilities but also on metrology, process control, and environmental factors.

Dimensional Control Practices

Key practices to maintain dimensional accuracy include:

Machine calibration and maintenance: Regular verification of axis positioning and backlash.

Thermal management: Stabilizing machine and ambient temperature to reduce thermal drift.

Tool management: Monitoring tool wear, using tool life strategies, and replacing tools before they cause dimensional deviation.

Workpiece probing: In-process measurement of key features or datums to compensate for minor shifts.

Inspection Methods

Inspection tools commonly used for CNC parts include:

Calipers and micrometers: For general dimensions.

Height gauges and surface plates: For heights, flatness, and squareness checks.

Pin gauges and bore gauges: For hole diameters and internal features.

CMM (Coordinate Measuring Machines): For complex geometries, profile tolerances, and multi-axis parts.

Inspection results feed back into process tuning, allowing refinement of offsets, tool paths, and cutting parameters to keep production within specification.

Typical Use Cases and Application Scenarios

CNC milling, turning, and 5-axis machining are applied across a wide variety of industries. Some representative applications include:

Aerospace: Structural brackets, engine components, turbine blades, housings, and landing gear parts, often requiring complex geometry, high-strength alloys, and tight tolerances.

Automotive: Engine and transmission components, steering and suspension parts, drive shafts, and prototype parts for performance testing.

Medical: Implantable devices, orthopedic components, surgical instruments, and diagnostic equipment parts, often with stringent surface and biocompatibility requirements.

Industrial machinery: Gearbox housings, spindles, valve bodies, pump components, and automation equipment parts.

Electronics and instrumentation: Housings, heatsinks, enclosures, and precision mechanical components for sensors and measurement systems.

For many of these applications, combinations of turning and milling or integration of 5-axis machining allow more operations to be completed in a single setup, improving consistency and reducing total cycle time.

Selecting the Right CNC Capability

When deciding which CNC process is appropriate for a part, consider these main factors:

Part Geometry

Rotational symmetry usually indicates turning as a primary process, possibly combined with milling for flats or keyways. Prismatic or plate-like geometries are typically best suited for milling. For complex freeform surfaces or parts requiring features on many faces without repositioning, 5-axis machining is often the most efficient.

Tolerances and Surface Requirements

All three processes can achieve tight tolerances with proper setup. If a part requires precise relationships between features on multiple faces, 5-axis machining or multi-operation setups with probing and fixturing might be necessary. For extremely tight tolerances or very smooth surface finishes, follow-up processes such as grinding or superfinishing may be required.

Quantity and Cost Considerations

For low quantities and prototypes, flexibility and setup simplicity are important. Milling and turning centers with quick-change tooling and modular fixturing support rapid changes between parts. For higher quantities, bar-fed turning and palletized milling systems can reduce handling time and increase throughput.

In some cases, consolidating several separate operations into a single 5-axis machining cycle can reduce total cost despite a higher hourly machine rate, due to setup reduction, fewer fixtures, and shorter lead times.