CNC machining cost calculation requires understanding how time, materials, machine capabilities, and business overhead combine into a final price. This guide provides a structured, engineering-oriented overview so you can evaluate quotes, build internal cost models, and make sound manufacturing decisions.

Cost Structure of CNC Machining

CNC machining costs are generally built from several core components. At a high level, total part cost can be expressed as:

Total CNC Machining Cost = Material Cost + Setup Cost + Machining Cost + Tooling Cost + Finishing Cost + Inspection Cost + Overhead and Margin

Each of these terms is further driven by part geometry, tolerances, quantity, and process choices. A systematic estimate identifies and quantifies each contribution instead of treating the price as a single opaque figure.

Calculate Your Estimated CNC Machining Cost

CNC Machining Cost CalculatorKey Cost Drivers in CNC Machining

Cost drivers are factors that strongly influence machining time, scrap, and resource usage. Understanding them allows more accurate estimates and better design decisions.

Part Geometry and Complexity

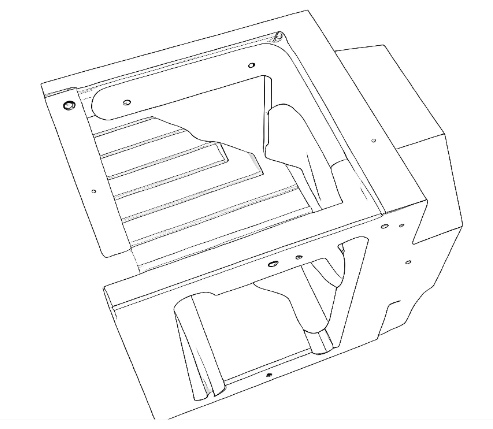

Complex geometry is usually the primary cost driver. Features that typically increase cost include:

- Deep pockets with high depth-to-diameter ratios

- Thin walls and fragile sections prone to deflection

- Undercuts, internal cavities, and difficult chip evacuation areas

- Frequent tool changes due to varying feature sizes

- Multiple setups to reach all faces, especially on 3-axis equipment

Complexity increases programming effort, setup work, machining time, and risk of defects. For the same volume of material removed, a more intricate part typically consumes more spindle hours and operator intervention.

Tolerance, Surface Finish, and Geometric Accuracy

Tighter tolerances and improved finishes generally increase cost because they demand slower cutting parameters, more accurate machines, and often additional operations. Influential aspects include:

- Dimensional tolerances (for example ±0.01 mm vs ±0.1 mm)

- Geometric tolerances (flatness, perpendicularity, position, runout)

- Surface roughness requirements (Ra values and specified processes)

Achieving strict tolerances may require extra inspection time, calibrated fixtures, and climate-controlled environments, increasing both direct and overhead costs.

Material Type and Properties

Material affects both the raw stock price and the machining effort. Key material-related drivers are:

Raw material cost per kg: Varied across metals and plastics, with high-performance alloys generally more expensive than standard steels or aluminum.

Machinability: Hardness, toughness, abrasiveness, and thermal properties determine allowable feed rates, tool life, and cooling requirements. Poor machinability results in slower cutting speeds, more passes, and shorter tool life.

Required stock oversize: Some processes need additional allowance for clamping or distortion, raising raw material usage.

Production Volume and Batch Size

Setup cost is largely fixed per batch. As quantity increases, setup cost per part decreases. Production volume affects:

- Per-part share of programming and setup time

- Feasibility of dedicated fixtures and jigs

- Potential for process refinement and repeatability

Very low quantities (for example prototypes) often see high unit costs due to one-time programming and setup efforts, even if machining time is moderate.

Machine Type and Capability

Different machine categories carry different hourly rates and performance characteristics:

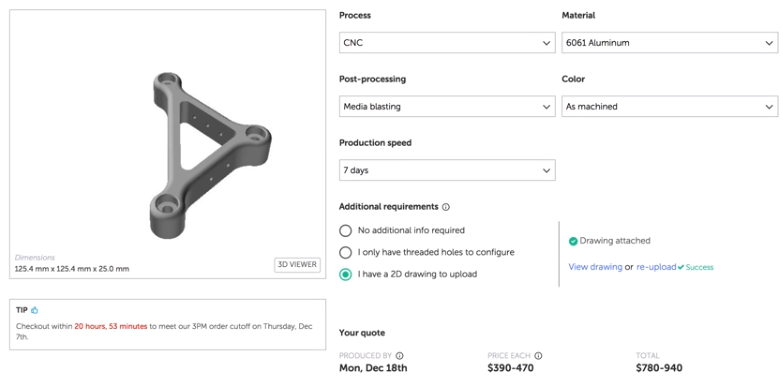

3-axis machining centers: Generally lower hourly rates, suitable for prismatic parts and simpler multi-face access using multiple setups.

4-axis and 5-axis machining centers: Higher hourly rates but can reduce setups, shorten cycle times, and improve accuracy on complex or multi-sided parts.

Turning centers and mill-turn machines: Efficient for rotational parts; mill-turn combinations may complete parts in one clamping, reducing handling and alignment tasks.

The economically optimal machine is not always the cheapest per hour; total cost depends on the trade-off between machine rate and machining hours.

Tooling, Fixturing, and Programming

Special tooling or complex fixtures add upfront cost but can reduce cycle time and scrap in higher volumes. Programming complexity depends on feature count, 3D surfaces, and required toolpaths. These factors influence:

- CAD/CAM engineering time

- Fixture design and manufacturing cost

- Tool selection, inventory, and replacement frequency

Secondary Processes and Logistics

Non-cutting steps contribute meaningfully to total cost:

- Deburring, cleaning, and surface treatments

- Heat treatment and stress relief

- Coating, plating, anodizing, or painting

- Assembly and kitting

- Packaging, labeling, and shipping

Each step adds direct process cost and may increase lead time, handling, and quality control requirements.

Typical CNC Cost Components and Ranges

The economic structure of a CNC part can be broken into line items. While values depend on region and facility, typical relative contributions and order-of-magnitude ranges are useful benchmarks.

| Cost Component | Description | Indicative Range / Notes |

|---|---|---|

| Material Cost | Raw stock, cut to size, including waste | From a few USD/kg (common aluminum, mild steel) to significantly higher for specialty alloys |

| Machine Hourly Rate | Charge per spindle hour or machine occupied hour | Approx. 30–100+ USD/h for standard CNC mills/turns; higher for 5-axis and large machines |

| Setup Cost | Programming, job preparation, fixturing, initial setup | Often 30–300+ USD per setup depending on complexity and facility rates |

| Tooling Cost | Cutting tools, holders, inserts, wear allowance | From a few dollars for standard tools to higher amounts for custom or high-performance tooling |

| Finishing Cost | Surface treatments, coatings, post-machining processes | Small share for basic deburring; higher for specialized finishes and coatings |

| Inspection and QA | Dimensional checks, documentation, certifications | Minor for basic checks; higher where CMM or full reports are mandatory |

| Overhead and Margin | Indirect costs and profit, applied to direct costs | Varies widely; commonly a significant portion of final quoted price |

These figures are indicative only and used as practical references during preliminary cost estimation rather than as fixed rules.

Step-by-Step CNC Machining Cost Calculation Method

A systematic cost calculation method follows a structured sequence. The steps can be implemented in a spreadsheet or integrated into internal costing tools.

1) Define Requirements and Constraints

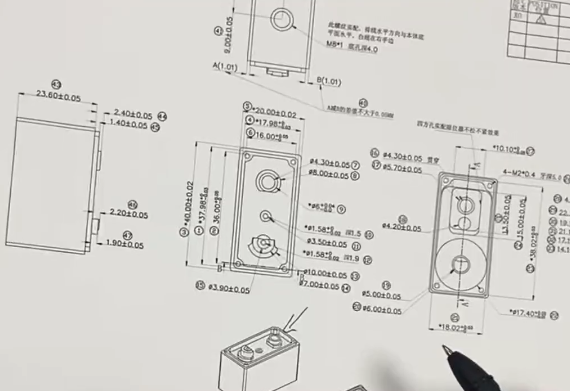

Accurate cost calculation starts with precise input data:

- 3D model (and 2D drawings when applicable)

- Material specification (grade, hardness, heat treatment)

- Tolerances, surface finishes, and geometric requirements

- Quantity, batch size, and required delivery schedule

- Special requirements such as certificates, traceability, or packaging

2) Estimate Raw Material Cost

First, determine the volume of raw material needed, including machining allowance and clamping margins.

For rectangular stock, calculate:

Stock Volume = Length × Width × Height

Then convert volume to mass:

Mass = Volume × Material Density

Finally, compute material cost:

Material Cost = Mass × Price per kg + Cutting and Handling Surcharges (if any)

If only bar or plate stock dimensions are available, allow for necessary excess due to standard size increments and kerf losses.

3) Calculate Setup Cost

Setup cost covers CAM programming, NC verification, and machine setup:

Setup Cost = (Programming Time × Engineering Hourly Rate) + (Setup Time × Setup Hourly Rate)

Programming time depends on:

- Number of operations (milling, turning, drilling, etc.)

- Presence of 3D surfaces and complex toolpaths

- Reuse of existing programs or templates

Setup time depends on fixture complexity, number of tools, and machine type. For repeated orders, programming may be partially or fully amortized over multiple batches.

4) Estimate Machining Time

Machining time often dominates direct costs. It is estimated from toolpaths, feeds, and speeds or by using historical benchmarks for similar features.

Core formula for a linear toolpath:

Machining Time (per pass) = Path Length / Feed Rate

For milling a pocket, total machining time includes:

- Roughing: Volume removed / Material Removal Rate

- Semi-finishing and finishing passes as required by surface finish and tolerance

Material Removal Rate (MRR) for milling can be approximated as:

MRR = Width of Cut × Depth of Cut × Feed Rate

For turning operations, time is approximated using:

Turning Time = (Cut Length × Number of Passes) / Feed Rate

Computer-aided manufacturing systems can output detailed cycle times, but manual estimation uses simplified geometrical approximations combined with typical cutting parameters for the material and machine.

5) Compute Machining Cost

Once total machining time per part is known, the direct machine cost is:

Machining Cost = Machine Hourly Rate × Machining Time per Part

If the part requires multiple setups or machines, sum the machining cost for each operation. For example, a part may require roughing on a 3-axis mill, finishing on a 5-axis machine, and drilling on a dedicated drill-tap center; each segment is costed separately.

6) Account for Tooling Usage and Wear

Tooling cost is typically small per part but becomes relevant in abrasive materials, long production runs, or where specialized cutting tools are necessary.

A practical approach is:

Tooling Cost per Part = (Tool Purchase Cost / Expected Tool Life in Parts) + Tool Change Labor Share

Tool life can be specified in cutting length, cutting time, or number of parts. Tool changes also involve non-productive machine time, which adds to indirect cost.

7) Include Finishing, Inspection, and Handling

Non-cutting operations are calculated similarly by time and rate or with per-piece pricing from suppliers:

Finishing Cost per Part = Σ (Operation Time × Operation Hourly Rate) + External Service Fees

Inspection time depends on the number of dimensions checked, measuring methods (manual gauges vs CMM), and documentation requirements. Handling includes cleaning, deburring, and packaging.

8) Combine Overhead, Risk, and Margin

Manufacturers apply overhead and margin to cover indirect costs and achieve target profitability. Two common methods are:

- Applying a multiplier to direct labor and machine costs

- Adding a percentage markup on total direct cost

Overall cost calculation can be summarized as:

Total Part Cost = Direct Costs × Overhead Factor + Profit Margin

Direct Costs include material, setup, machining, tooling, finishing, and inspection. Overhead factors reflect rent, utilities, maintenance, administration, and other indirect items.

Illustrative Calculation Example

The following simplified example shows how the fundamental relationships come together. Values are representative and not universal.

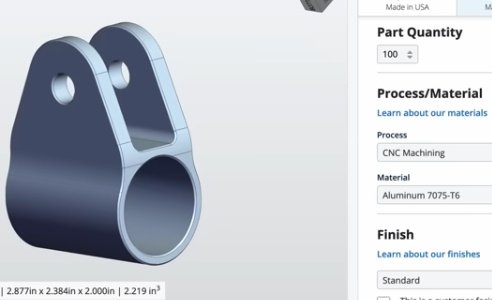

Consider a small aluminum part from a rectangular block with moderate complexity, machined in a batch of 100 pieces.

Material Estimation

Assume required stock size is 80 mm × 60 mm × 20 mm.

Stock Volume = 80 × 60 × 20 = 96,000 mm³ = 96 cm³

With a density of approximately 2.7 g/cm³ for aluminum:

Mass ≈ 96 × 2.7 = 259.2 g ≈ 0.259 kg

If material price is 6 USD/kg, then:

Material Cost per Part ≈ 0.259 × 6 ≈ 1.55 USD

Setup and Machining

Assume programming time is 3 hours at 50 USD/h and setup time is 1.5 hours at 40 USD/h.

Setup Cost = 3 × 50 + 1.5 × 40 = 150 + 60 = 210 USD per batch

Spread over 100 parts:

Setup Cost per Part = 210 / 100 = 2.10 USD

Assume actual machining time per part (including tool changes and probing) is 12 minutes (0.2 h) on a 3-axis mill at 45 USD/h.

Machining Cost per Part = 0.2 × 45 = 9.00 USD

Additional Operations

Assume basic deburring and cleaning take 2 minutes per part (0.033 h) at 30 USD/h:

Finishing Cost per Part ≈ 0.033 × 30 ≈ 1.00 USD (rounded)

Assume simple inspection averaging 1 minute per part (0.017 h) at 35 USD/h:

Inspection Cost per Part ≈ 0.017 × 35 ≈ 0.60 USD (rounded)

Assume tooling cost allocation of 0.40 USD per part.

Total Direct Cost and Final Price

Direct Cost per Part ≈ Material (1.55) + Setup (2.10) + Machining (9.00) + Finishing (1.00) + Inspection (0.60) + Tooling (0.40) = 14.65 USD

If a shop applies 30% combined overhead and profit on direct cost:

Final Selling Price per Part ≈ 14.65 × 1.30 ≈ 19.05 USD

This simplified example demonstrates how quantity, machining time, and overhead strongly influence unit price.

Practical Issues in CNC Cost Estimation

Organizations frequently encounter specific difficulties when estimating or interpreting CNC machining costs. Recognizing these areas helps target improvement efforts.

Incomplete or Ambiguous Technical Data

Missing tolerances, unspecified materials, or incomplete drawings cause divergent assumptions between buyer and manufacturer. This often yields a wide range of quotes, complicating supplier comparison and increasing the risk of re-quoting when details are clarified.

Underestimating Non-Machining Effort

Focus on cutting time alone may overlook programming, fixtures, inspections, and logistics, leading to underestimated budgets. When these omitted costs emerge later, projects can exceed initial cost expectations or require design changes.

Scaling from Prototype to Production

Per-part prices at prototype quantities do not directly predict production pricing. Failing to distinguish one-time costs from recurring costs results in inaccurate total cost of ownership assessments.

Design and Specification Considerations Affecting Cost

Engineering choices directly influence CNC cost. Reviewing designs with manufacturability in mind allows quantitative cost reductions without compromising functional requirements.

Material Selection Policies

Choosing readily machinable and widely available grades can significantly reduce cutting time and tooling wear. When engineering performance permits, substituting extremely hard or specialty alloys with standard alloys yields lower hourly machining cost and higher throughput.

Geometry Simplification

Design decisions that can reduce CNC costs include:

- Reducing the number of deep pockets or making them shallower when possible

- Avoiding excessively thin walls that require reduced feed rates

- Revising small-radius internal corners that demand micro-endmills and slower parameters

- Combining features to reduce setup count and reorientation steps

Even small changes to fillet radii, accessible faces, and feature placement can meaningfully affect cycle time and scrap rates.

Tolerance and Finish Rationalization

Specifying tight tolerances and fine finishes only where functionally necessary helps control cost. Running a thorough tolerance review allows separation of critical surfaces from non-critical ones, enabling more aggressive machining parameters for the majority of the part.

Comparing CNC Quotes and Analyzing Variations

Different suppliers may use distinct machines, workflows, and overhead structures. Analyzing quote variations benefits from a structured comparison approach.

Decomposing Quotes into Cost Buckets

Requesting line-item breakdowns by material, setup, machining, finishing, and inspection helps align estimates and understand why prices differ. For example, one supplier may have higher hourly rates but faster cycle times on advanced equipment, while another uses lower rates but longer machining times.

Assessing Hourly Rates vs. Productivity

Higher hourly rates do not automatically mean higher total cost. If a 5-axis machine completes a part in one setup using shorter cycle times than multiple operations on 3-axis machines, the overall total may be lower despite a higher hourly rate.

Evaluating Lead Time and Capacity Constraints

Lead time expectations affect capacity allocation and pricing. Shorter required schedules may bring overtime, changeover, or priority charges that influence quoted cost. When comparing offers, it is important to verify that all quotes reflect identical lead times and delivery conditions.

Building Internal CNC Cost Models

Organizations that frequently source or produce machined parts benefit from internal cost models that support planning, design decisions, and supplier discussions.

Data Foundations

Effective models rely on current and accurate data for:

- Machine hourly rates and utilization assumptions

- Material prices, density values, and typical wastage factors

- Standard setup and programming times by part family

- Historical machining times and tool life by material and feature type

Collecting and updating this information improves model precision and allows more reliable cost forecasts.

Model Granularity

Model granularity depends on usage:

- Concept-stage estimates may use simple heuristics such as cost per kg of removed material for given material and complexity.

- Detailed pre-production estimates might consider individual features, operations, and setups with specific cycle-time formulas.

Consistency between models and actual shop-floor performance should be reviewed periodically to maintain alignment.

Summary: Applying CNC Cost Calculation in Practice

CNC machining cost calculation consolidates geometric, material, and process information into a structured financial estimate. By decomposing total cost into material, setup, machining, tooling, finishing, inspection, and overhead, engineers and buyers gain transparency and control over pricing.

Reliable calculations require clear technical documentation, realistic machining-time estimates, and methodical inclusion of all process steps. Integrating these principles into design reviews and sourcing processes leads to more predictable project costs, better supplier communication, and improved manufacturability of machined components.

FAQ

What factors affect CNC machining costs?

CNC machining costs are influenced by material type, part complexity, machining time, machine type, labor, tooling, tolerances, surface finish, and order quantity.

What is the biggest driver of CNC machining cost?

In most quotes, the biggest driver is total time: setup time (especially for low quantities) and cycle time (especially for higher quantities). Tolerances, surface finish, and number of operations primarily matter because they increase machining and inspection time and raise scrap risk.

Why do tight tolerances increase CNC cost so much?

Tight tolerances usually require additional finishing passes, slower feeds, more stable workholding, thermal control considerations, and significantly more inspection time (often including CMM). They also increase scrap and rework probability, which many shops cover with a risk allowance.

How should I estimate CNC costs for prototypes vs. production?

For prototypes, model programming, setup, and any fixture/tool purchases as non-recurring costs that dominate unit price. For production, amortize those fixed costs across quantity, then focus on validated cycle time, tooling wear per part, inspection frequency per batch, and any outside process minimum charges.

Why do CNC machining quotes differ significantly between suppliers?

Quotes differ due to variations in machine types, cutting strategies, overhead structures, labor rates, and workload. One supplier may use advanced multi-axis machines that reduce setups and cycle time, while another relies on multiple conventional setups. Some shops allocate programming and setup as separate line items, while others spread these costs across the unit price. Differing assumptions about tolerances, finishes, and inspection depth also influence final pricing, so aligning technical assumptions and requesting cost breakdowns is essential when comparing offers.