CNC aluminum parts are widely used in industries such as automotive, aerospace, robotics, medical devices, consumer electronics, and industrial equipment. This guide explains key technical aspects, common decision points, and practical FAQs for engineers, purchasers, and product developers who need reliable CNC aluminum components.

Why Aluminum Is Popular for CNC Machining

Aluminum is a preferred material for CNC machining because it combines low density, good strength, and excellent machinability. It can be milled, turned, drilled, and tapped efficiently, supporting both rapid prototyping and mass production.

Key advantages include:

- Low weight with good stiffness-to-weight ratio

- Good corrosion resistance, especially with anodizing

- High thermal and electrical conductivity for specific applications

- Consistent machinability leading to stable cycle times and predictable quality

- Compatibility with a wide range of surface finishes and coatings

Aluminum is suitable for housings, brackets, fixtures, heatsinks, optical and electronic enclosures, structural frames, jigs, and many other precision components.

Common Aluminum Alloys for CNC Machining

Different aluminum grades offer specific combinations of strength, corrosion resistance, machinability, and cost. Selecting the right alloy is critical for performance and manufacturability.

| Alloy | Temper | Typical Uses | Main Characteristics |

|---|---|---|---|

| 6061 | T6 | General structural parts, brackets, fixtures, housings | Balanced strength, good machinability, good weldability, widely available |

| 6082 | T6 | Structural components, machine frames | Similar to 6061, slightly higher strength, good corrosion resistance |

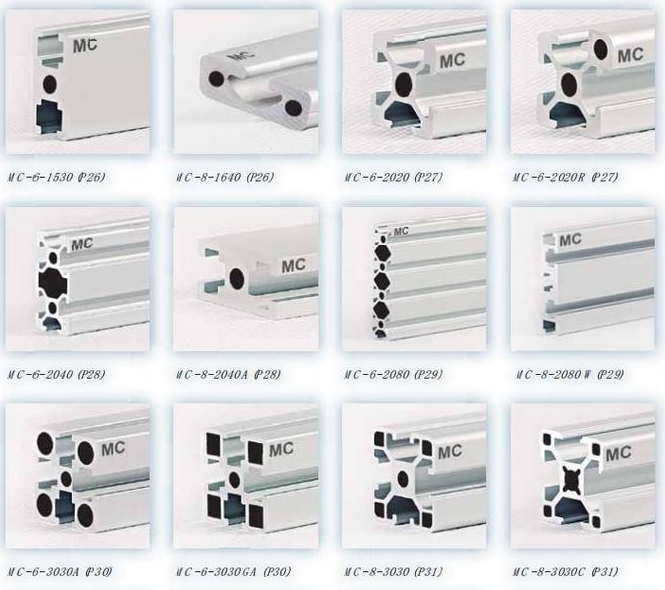

| 6063 | T5/T6 | Extrusions, frames, decorative parts | Excellent extrudability and surface finish, moderate strength |

| 7075 | T6/T651 | Aerospace fittings, high-load components | Very high strength, lower corrosion resistance, moderate machinability |

| 2024 | T3/T351 | Aerospace structural parts, high fatigue strength parts | High strength and fatigue resistance, lower corrosion resistance |

| 5052 | H32 | Sheet metal, enclosures, marine parts | High corrosion resistance, good for sheet machining and bending |

| 5083 | O/H116 | Marine, cryogenic tanks, high corrosion environments | Excellent corrosion resistance, good weldability, lower machinability than 6xxx |

| 1050/1100 | O/H14 | Electrical, thermal, decorative components | Very high conductivity and corrosion resistance, low strength |

For general CNC machined components, 6061-T6 is often the default choice due to its balance of cost, availability, and performance. For high-strength applications, 7075-T6 is preferred, though it requires more attention to corrosion protection and surface treatment.

Types of CNC Machining Processes for Aluminum Parts

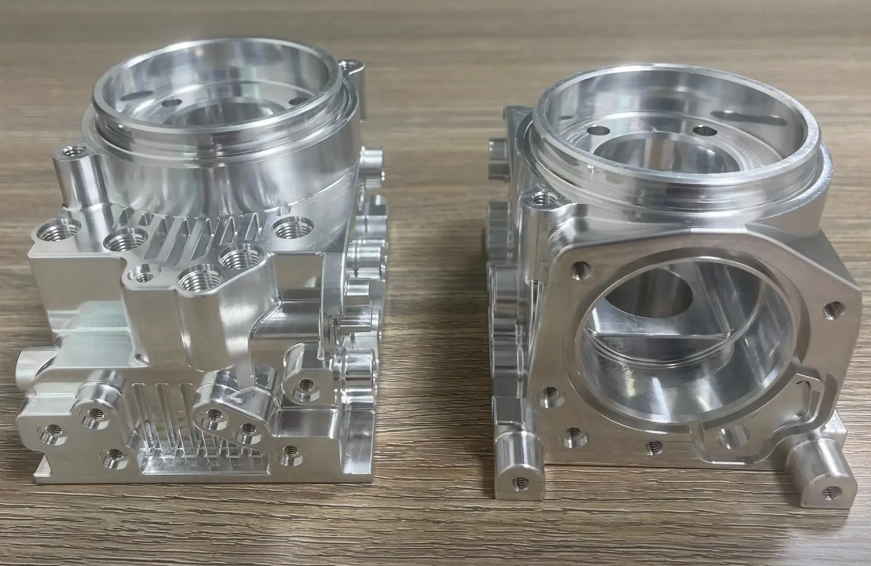

CNC aluminum parts can be produced using various subtractive processes, often combined in a single process chain.

CNC Milling

CNC milling uses rotating cutting tools and multi-axis motion to remove material and create complex geometries.

Typical operations include:

- Face milling and contour milling

- Pocketing and slotting

- Drilling, tapping, and reaming

- 3-axis and 4/5-axis profiling for complex surfaces

CNC milling is suitable for prismatic parts, housings, covers, brackets, plates, and components requiring precise flatness and surface finish.

CNC Turning

CNC turning rotates the workpiece while stationary tools perform cutting, ideal for rotationally symmetric parts.

Typical turned aluminum components include:

shafts, bushings, spacers, threaded connectors, valves, and cylindrical housings.

For complex turned parts, live tooling and C/Y-axis lathes allow milling features like flats, keyways, and cross holes in a single setup.

Multi-Axis Machining

4-axis and 5-axis CNC machines allow tool orientation to change during machining, enabling undercuts, complex contours, and machining on multiple faces without multiple setups.

Applications include:

impellers, robotics components, optical and aerospace parts, and complex fixtures. Multi-axis machining improves accuracy between features and reduces cumulative setup error.

Secondary Machining and Operations

Depending on requirements, additional operations may be needed:

boring, honing, grinding, EDM (for features that are difficult to mill), and thread forming. Secondary machining is often used to achieve tight tolerances on critical surfaces and holes.

Design Guidelines for CNC Aluminum Parts

Good design for manufacturability (DFM) reduces machining time, improves quality, and lowers cost. When possible, consider manufacturability early in the design phase.

Wall Thickness and Stiffness

For milled aluminum parts, walls that are too thin may deflect during cutting, causing chatter, poor surface finish, and dimensional inaccuracies.

General recommendations:

- Minimum wall thickness for structural parts: typically ≥ 1.0–1.5 mm for small features, ≥ 2–3 mm for larger walls

- For deep pockets, use ribs or partial walls rather than a single large thin wall

- Try to keep the height-to-thickness ratio of walls moderate to limit vibration

Hole Sizes and Depths

Standard drill sizes are more economical. Extreme aspect ratios for holes are more difficult and may require special tools.

Guidelines:

through holes are easier than deep blind holes; for deep threads, consider partial-depth threading where acceptable; if very tight positional tolerances are required for holes, ensure sufficient material around the feature for stability during machining.

Internal Radii and Corners

Internal corners in pockets and slots must have a radius due to tool geometry. Sharp internal corners require EDM or additional processes.

Recommendations:

choose corner radii that match standard end mill sizes (for example 2, 3, 4, 5 mm); avoid very small radii in deep pockets to reduce tool deflection and tool breakage; match the radius to the functional requirement and tolerance, not smaller.

Undercuts and Complex Features

Standard tools cannot reach certain back-side or undercut features without special toolpaths or fixtures. Design features to be accessible from as few setups as possible.

Where undercuts are required, consider:

whether feature can be redesigned to use through-holes or stepped geometry; use of 5-axis machining instead of side milling in multiple setups; potential use of T-slot cutters or lollipop cutters for special undercuts, with implications for cost and timing.

Tolerances for CNC Aluminum Parts

Tolerances define the allowable variation of part dimensions. Aluminum parts can achieve tight tolerances, especially on CNC machines with rigid setups and controlled temperatures.

Typical capability ranges:

general CNC machining: ±0.05 mm to ±0.1 mm; precision features and critical fits: ±0.01 mm to ±0.02 mm with appropriate process control; ultra-precision features may require grinding, honing, or lapping after CNC machining.

Practical considerations:

specify tight tolerances only where functionally necessary to avoid unnecessary cost; geometric tolerances (flatness, parallelism, true position) should reflect assembly and functional requirements; consider tolerance stack-up in assemblies using aluminum parts, including effects of thermal expansion.

Surface Finish and Roughness

Surface finish affects performance, sealing, aesthetics, and wear. CNC machined aluminum can achieve a wide range of surface roughness values depending on tooling, cutting parameters, and subsequent finishing.

Typical ranges (Ra):

roughing operations: ~3.2 μm to 6.3 μm; standard finishing: ~1.6 μm to 3.2 μm; fine finishing / semi-polished: ~0.8 μm to 1.6 μm; polishing and special processes can reach even lower values when needed.

To specify finish effectively:

define Ra only where critical (sealing surfaces, sliding interfaces); indicate whether the requirement applies to the entire part or localized areas; coordinate with surface treatment requirements, as some coatings can change effective roughness.

Surface Treatments and Coatings for Aluminum CNC Parts

Aluminum responds well to many surface treatments that improve corrosion resistance, hardness, appearance, and wear characteristics.

| Treatment | Main Purpose | Typical Thickness | Notes |

|---|---|---|---|

| Clear Anodizing (Type II) | Corrosion resistance, moderate wear resistance, appearance | 5–25 μm | Non-conductive layer; retains metallic look; can slightly change dimensions |

| Colored Anodizing | Corrosion resistance and color identification/branding | 5–25 μm | Properties similar to clear anodizing; wide color range possible |

| Hard Anodizing (Type III) | High wear resistance and improved surface hardness | 25–50 μm or higher | Darker appearance; dimensional allowance required; often for moving/abrasive interfaces |

| Electroless Nickel Plating | Wear resistance, uniform coating, some corrosion protection | 5–25 μm | Improves hardness; can enhance dimensional stability on critical surfaces |

| Conversion Coating (Alodine) | Corrosion resistance and paint/adhesive base | Very thin | Conductive; often used before painting or as a minimal protective coating |

| Powder Coating | Decorative and protective topcoat | Approx. 50–120 μm | Thicker layer; requires masking for critical tolerances and threads |

| Bead Blasting | Uniform matte texture and cosmetic improvement | N/A (mechanical) | Usually done before anodizing; can reduce tool marks and glare |

When specifying surface treatments, consider: functional needs (corrosion, wear, electrical conductivity), dimensional impact of layer thickness, cosmetic requirements, and whether localized masking is required for threads, fits, or sealing surfaces.

Mechanical Properties and Performance Considerations

Mechanical properties of CNC aluminum parts depend on alloy and temper. Understanding these properties helps ensure the part meets structural and functional requirements.

Key properties to consider:

yield strength and ultimate tensile strength (for load-bearing and fatigue resistance); hardness (often measured in Brinell or Rockwell); elongation at break; fatigue resistance for cyclic loading; modulus of elasticity (stiffness).

Examples (typical ranges, not guaranteed values):

6061-T6: ultimate tensile strength ~290 MPa, yield strength ~240 MPa, elongation ~8–12%; 7075-T6: ultimate tensile strength ~510–570 MPa, yield strength ~430–480 MPa, lower elongation; 5052-H32: moderate strength with excellent corrosion resistance.

Other considerations:

for high-load parts, evaluate stress concentrations, fillets, and notch effects; for thermally loaded parts, consider aluminum’s high thermal expansion and conductivity; for moving contacts, combine proper surface treatment with suitable mating materials and lubrication.

Dimensional Stability and Thermal Expansion

Aluminum has a relatively high coefficient of thermal expansion compared to steel, which affects dimensional stability under temperature variations.

Approximate linear thermal expansion coefficient of aluminum alloys: around 23–24 × 10⁻⁶ /K.

Implications:

tight fits may vary with temperature; designs for precision assemblies should consider operating temperature range; long or thin parts may require special fixturing and machining strategies to minimize distortion during machining and cooling.

Threading in CNC Aluminum Parts

Internal and external threads are common in aluminum parts. Specific threading strategies are used to ensure strength and repeatability.

Common practices:

cutting threads by tapping or single-point threading (on lathes or mills); using thread milling for better control, especially in blind holes or larger diameters; using inserts (such as helicoils) to reinforce threads in soft aluminum where repeated assembly is expected.

Design considerations:

ensure sufficient thread engagement; for soft alloys, longer engagement improves durability; avoid placing critical threads too close to edges to maintain strength; specify thread class (fit) where necessary, especially for precision assemblies; consider coating impact on threaded areas and specify masking if required.

Typical Applications of CNC Aluminum Parts

CNC machined aluminum components appear in many industries due to their versatility.

Examples include:

automotive: brackets, housings, manifolds, pedal components, fixtures; aerospace: structural fittings, frames, housings, actuator parts; electronics: heat sinks, enclosures, connector bodies; robotics: structural arms, sensor mounts, gear housings; medical devices: instrument housings, mounts, positioning components; industrial equipment: jigs, fixtures, plates, clamps, machine frames.

Each field may have specific requirements such as regulatory standards, documentation, material traceability, and cleanliness levels that must be considered when sourcing CNC aluminum parts.

Cost Factors for CNC Aluminum Parts

The cost of CNC aluminum parts depends on multiple technical and commercial factors. Understanding them helps in designing cost-efficient parts and sourcing effectively.

Main cost drivers:

material: alloy selection, stock form (block, plate, extrusion), and material yield; machining time: complexity, volume of material removal, required tolerances, number of setups, and tool changes; tooling: special tools, tool wear rates, and fixture design; surface treatments: anodizing, plating, blasting, or coating steps; quality control: inspection, measurement reports, and certification requirements; quantity: setup cost distribution, economies of scale for larger runs.

Design choices that reduce cost:

using standard stock sizes and thicknesses where possible; avoiding unnecessary deep cavities and thin walls; consolidating features to minimize setups; using standard threads and hole sizes; specifying only necessary tolerances and finishes.

Lead Time and Production Workflow

Lead time for CNC aluminum parts is influenced by part complexity, capacity, finishing requirements, and documentation needs. Typical phases include:

DFM review: design check, feedback on manufacturability, and risk identification; programming: CAM setup, toolpath generation, and simulation; fixturing: design and manufacturing of custom fixtures if required; machining: roughing and finishing, plus any secondary operations; surface finishing: anodizing, plating, or coating; inspection: dimensional checks and functional tests; packaging and shipment preparation.

To shorten lead time:

provide clear 3D and 2D drawings with complete tolerances and finish notes; confirm alloy and temper from the outset; limit last-minute design changes; align inspection and documentation requirements with actual needs.

Quality Control and Inspection for CNC Aluminum Parts

Quality control ensures that CNC aluminum parts meet specification and functional requirements. The level of inspection depends on project criticality and standards.

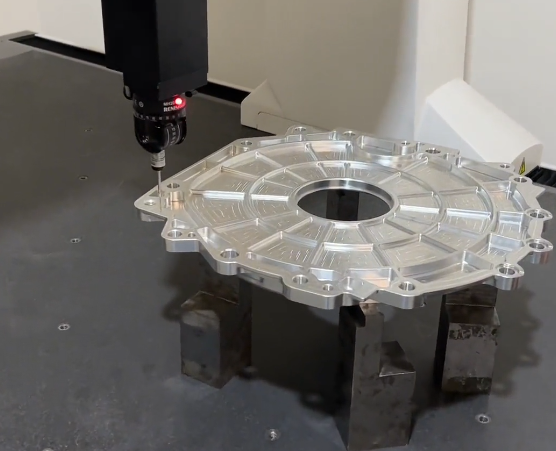

Typical inspection methods:

basic dimensional checks with calipers, micrometers, and gauges; CMM (coordinate measuring machine) inspection for complex geometries and GD&T; surface roughness measurement where specified; coating thickness measurement for anodizing or plating; hardness testing where required.

Documentation:

inspection reports listing measured dimensions versus tolerances; material certificates (mill test reports) for alloy composition; surface treatment certificates from finishing suppliers.

For critical applications (e.g., aerospace or medical), additional requirements may include traceability of material batches, process records, and controlled calibration of measuring instruments.

Practical Considerations of CNC aluminum parts

When sourcing or designing CNC aluminum parts, certain issues commonly arise.

Typical difficulties include:

distortion in thin or long parts due to residual stresses and clamping forces; mismatched expectations about tolerances, especially when only 3D models without 2D drawings are provided; unwanted dimensional changes after anodizing if coating allowances are not considered; thread damage when finishing processes are not masked or protected; cosmetic variations between different batches of anodized parts, especially when mixing alloys or different surface preparation methods.

Mitigation strategies:

discuss critical features and surfaces clearly with the machining supplier; specify acceptable ranges for cosmetic variations and functional surfaces; involve the manufacturer early for DFM review on challenging parts; request sample parts or first article inspection (FAI) before large-scale production.

How to Specify CNC Aluminum Parts to a Supplier

Clear and complete specifications help ensure that the received parts match functional needs and reduce iteration cycles.

Essential information to provide:

3D CAD model in standard format (STEP, IGES, or similar) and, where possible, 2D drawings with dimensions and tolerances; material alloy and temper (for example 6061-T6); quantity and intended use (prototype, pre-series, or production); critical dimensions, tolerances, and surface finish requirements; surface treatment details including color, thickness, and masking; any special inspection or documentation requirements (e.g., CMM report, material certificate); assembly context or mating parts when tight interfaces are involved.

Clear communication of priorities (cost, lead time, precision, cosmetic quality) helps the supplier choose appropriate processes and controls.

FAQ – CNC Aluminum Parts

What are the advantages of using aluminum for CNC machined parts?

Aluminum is lightweight, has an excellent strength-to-weight ratio, is highly corrosion-resistant, offers good thermal and electrical conductivity, is easy to machine, and is fully recyclable. It’s one of the most popular materials for CNC prototyping and production parts.

Which aluminum alloys are most commonly used in CNC machining?

The most frequently used alloys are:6061-T6 (general-purpose, good strength and corrosion resistance)

7075-T6 (aerospace-grade, very high strength)

6082 (European equivalent to 6061)

5083 (excellent for marine applications)

2024 (high strength, often used in aerospace)

MIC-6 (cast tool & jig plate, very stable for precision fixtures)

What tolerances can I expect for CNC aluminum parts?

Standard machined tolerances are typically ±0.005″ (±0.127 mm), but many shops can achieve ±0.001″ (±0.025 mm) or tighter on critical features with proper design and tooling.

How much do CNC aluminum parts typically cost?

Cost depends on part complexity, size, quantity, tolerances, and finish. A simple 100×100×20 mm bracket in 6061 might cost $15–50 each at low volume (1–10 pcs) and drop to $3–10 at higher volumes (100+ pcs). Complex aerospace parts can cost hundreds of dollars each even in moderate quantities.

What surface finishes are available for CNC aluminum parts?

Common options include:As-machined (standard machined marks visible, Ra 3.2 μm)

Bead/sand blasting

Anodizing Type II (decorative) or Type III (hardcoat)

Clear or colored anodizing

Chromate conversion coating (Alodine/Iridite)

Powder coating

Brushing or polishing