C40 steel (according to EN standards) and 1040 steel (according to AISI/SAE standards) are widely used medium carbon steels. They are valued for their balance of strength, hardness, and machinability, making them common in shafts, bolts, automotive parts, and general engineering components.

Overview of C40 / 1040 Steel

C40 and AISI 1040 belong to the family of non-alloy medium carbon steels with nominal carbon content around 0.40%. They are primarily supplied as hot-rolled or normalized bar, plate, and sometimes forgings. These steels are not stainless and rely on surface protection or controlled environments to limit corrosion.

In European nomenclature, C40 is described in EN standards such as EN 10083 (engineering steel for heat treatment). In North American practice, similar material is labeled AISI/SAE 1040. Depending on the standard, slight variations in composition limits and mechanical property requirements can occur, but in practice these steels are often considered functionally equivalent for many engineering applications, subject to design verification.

C40 / 1040 Steel Standards and Designations

The material can appear under different designations depending on region, product form, and standard. Knowing the equivalences helps in cross-referencing material data and sourcing.

| System / Region | Designation | Notes |

|---|---|---|

| European (EN) | C40, C40E, C40R | EN 10083 series; variants differ in sulfur content and degree of deoxidation |

| European numeric | 1.0511 (C40), 1.1189 (C40E) | EN numeric steel numbers |

| USA (AISI/SAE) | 1040 | SAE J403 chemical composition specification |

| ISO | C40 | Non-alloy quality steel; similar ranges to EN definitions |

| Other common notations | Ck40, 40C, 40C8 (older national standards) | Legacy or national designations; verify composition before substitution |

When substituting between C40 and 1040, engineers typically check:

- Chemical composition, especially carbon, manganese, sulfur, and phosphorus limits.

- Delivery condition (hot-rolled, normalized, quenched and tempered, cold-drawn).

- Required mechanical properties for the specific product form and section size.

Chemical Composition

C40 / 1040 steel is a plain carbon steel with limited alloying additions. Small amounts of manganese, silicon, and residual elements are present to assist deoxidation, strength, and processability.

| Element | C40 (EN) typical range | 1040 (AISI/SAE) typical range |

|---|---|---|

| C (Carbon) | 0.37 – 0.44 | 0.37 – 0.44 |

| Mn (Manganese) | 0.50 – 0.80 | 0.60 – 0.90 |

| Si (Silicon) | ≤ 0.40 | 0.15 – 0.35 |

| P (Phosphorus) | ≤ 0.035 | ≤ 0.040 |

| S (Sulfur) | ≤ 0.035 (C40), ≤ 0.040 (typical) | ≤ 0.050 (standard grade); lower for resulfurized variants |

| Cr, Ni, Mo, Cu | Usually ≤ 0.25 each as residuals | Usually ≤ 0.25 each as residuals |

Some variants (such as free-cutting grades) may contain increased sulfur content to improve machinability. These are usually indicated with special suffix letters in the standard designation and should not be used where high toughness or weldability is critical.

Physical Properties

As a medium carbon, non-alloy steel, the physical properties of C40 / 1040 are similar to those of other standard carbon steels.

Typical physical properties at room temperature:

- Density: approximately 7.85 g/cm³ (7850 kg/m³)

- Melting range: about 1460 – 1500 °C

- Thermal conductivity: roughly 45 – 50 W/m·K (in normalized condition)

- Specific heat capacity: approximately 460 – 500 J/kg·K

- Coefficient of thermal expansion (20–100 °C): about 11 – 12 × 10⁻⁶ /K

- Electrical resistivity: approximately 0.15 – 0.20 μΩ·m

Physical properties can vary slightly with microstructure and exact composition but are sufficient for most engineering calculations using generic carbon steel data.

Mechanical Properties

Mechanical properties of C40 / 1040 depend strongly on product form, section size, and delivery condition. Common conditions include as-rolled, normalized, or quenched and tempered. Designers must refer to the specific material standard and inspection certificates for exact values.

Indicative mechanical properties for C40 / 1040 in typical conditions (for reference only):

As-rolled or normalized (medium section bar):

- Tensile strength (Rm): about 600 – 750 MPa

- Yield strength (Re or Rp0.2): about 350 – 450 MPa

- Elongation (A5): roughly 16 – 22%

- Brinell hardness: typically 170 – 220 HB

Quenched and tempered (moderate section, typical target values):

- Tensile strength: roughly 700 – 900 MPa (depending on tempering)

- Yield strength: typically 450 – 650 MPa

- Brinell hardness: about 200 – 280 HB after tempering for general-purpose components

The attainable through-hardness decreases as section size increases because of limited hardenability. C40 / 1040 is suitable for surface hardening (induction or flame) when higher surface hardness is required while maintaining a tougher core.

Heat Treatment of C40 / 1040 Steel

C40 / 1040 steel is responsive to standard heat treatments used for medium carbon steels. Proper control of heating and cooling is important to achieve the required mechanical performance and dimensional stability.

1. Normalizing

Normalizing is commonly used to refine grain structure and reduce residual stresses from hot working.

- Typical normalizing temperature: 850 – 880 °C

- Holding time: usually about 30–60 minutes per 25 mm of section, depending on furnace load and geometry

- Cooling: air cooling in still air

Normalizing produces a fine pearlitic-ferritic structure and gives a good compromise of strength and toughness for many general engineering components.

2. Annealing

Full annealing is applied when improved machinability and maximum softness are required. It reduces hardness and relieves internal stresses.

- Typical annealing temperature: 800 – 840 °C

- Cooling: very slow cooling in the furnace, often 20 – 30 °C per hour down to around 600 °C, then air cooling

- Resulting hardness: generally around 150 – 180 HB

3. Quenching and Tempering

Quenching and tempering can significantly increase strength and wear resistance relative to normalized condition.

Typical process route:

- Austenitizing temperature: about 830 – 870 °C

- Holding: sufficient time to equalize temperature through section

- Quenching medium: oil is often used to reduce cracking risk; water quenching is possible but more severe

- Tempering temperature: commonly 450 – 650 °C depending on the desired combination of strength, hardness, and toughness

Higher tempering temperatures reduce hardness and strength while improving toughness and ductility. The specific tempering regime should be selected based on service loads and life requirements, and verified by mechanical testing.

4. Stress Relieving

Stress relieving is applied after machining, welding, or cold working to minimize distortion during service.

- Typical stress-relief temperature: 500 – 650 °C

- Holding time: around 1–2 hours, followed by slow cooling in air

5. Surface Hardening (Induction / Flame Hardening)

C40 / 1040 steel is suitable for surface hardening due to its carbon level. Surface hardening provides a hard, wear-resistant surface and a tough core.

- Recommended surface hardening carbon range: approx. 0.35 – 0.50% C, which is well matched by C40 / 1040.

- Surface hardness after induction or flame hardening: typically 50 – 60 HRC, depending on process parameters.

- Effective case depth: often around 1 – 4 mm, depending on application and hardening frequency.

Microstructure

The microstructure of C40 / 1040 varies with processing condition:

- As-rolled: mixture of ferrite and pearlite, sometimes with banding from rolling.

- Normalized: refined and more uniform ferrite-pearlite structure, improved toughness and machinability.

- Quenched: predominantly martensite (and possibly some retained austenite depending on quenching severity).

- Tempered: tempered martensite with varying amounts of ferrite, depending on tempering temperature.

Microstructural control is critical for achieving consistent mechanical properties and minimizing anisotropy, especially in highly stressed components such as shafts and axles.

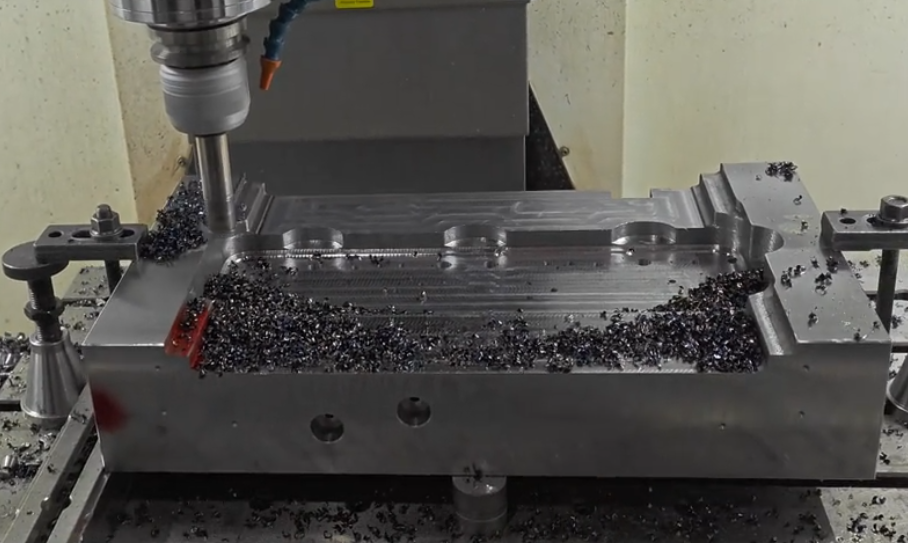

Machinability

C40 / 1040 offers moderate machinability compared with low carbon steels and free-cutting steels. The machinability index is often quoted around 55–65% relative to a standard free-machining steel (such as AISI 1212 at 100%). Machinability is strongly affected by condition and hardness:

- Annealed or normalized condition: generally preferred for rough machining and drilling.

- Quenched and tempered condition: more demanding on tools; suitable for finishing operations after roughing in softer condition.

Typical machining considerations include:

- Use of appropriate cutting speeds and feeds to avoid excessive tool wear and built-up edge.

- Application of cutting fluids for heat dissipation and surface finish improvement, especially in drilling, tapping, and reaming.

- Selection of tool materials: carbide tools are often used for higher productivity; HSS tools may be adequate for lower speeds or intermittent operations.

Variants with controlled sulfur additions can improve chip breaking and tool life but may reduce transverse toughness. Such free-cutting variants are not recommended for highly loaded, dynamically stressed components.

Weldability

Compared with low carbon steels, weldability of C40 / 1040 is limited. The carbon content around 0.40% increases the risk of cold cracking and hardness in the heat-affected zone (HAZ). Welding can be carried out, but requires careful procedure control.

Key welding considerations:

- Preheating is usually necessary, especially for thick sections (preheat often in the range 150 – 250 °C; exact value depends on plate thickness, restraint, and hydrogen level).

- Use of low-hydrogen electrodes and consumables to minimize the risk of hydrogen-induced cracking.

- Interpass temperature control to avoid excessive hardness or softening in the HAZ.

- Post-weld heat treatment (PWHT) or stress relief may be required for critical components to reduce residual stresses and restore toughness.

C40 / 1040 is generally not the first choice where extensive welding is expected. For weld-intensive structures, steels with lower carbon content and better weldability are typically preferred. When welding cannot be avoided, qualified welding procedures and trials are recommended.

Forming and Forging

C40 / 1040 can be hot formed and forged effectively, but its medium carbon content makes cold forming more restricted than in mild steels.

Hot Forming and Forging

Typical forging parameters:

- Forging temperature range: approximately 1150 – 850 °C.

- Initial forging at the higher temperature end to ensure plasticity.

- Stop forging near 800 – 850 °C to avoid cracking during deformation.

- Allow slow cooling after forging, followed by normalizing or annealing to refine grain structure and homogenize mechanical properties.

Cold Forming

Cold bending and forming operations are more limited than for low carbon steels:

- Small cold bends with generous radii are possible, especially in annealed condition.

- Heavier cold forming (deep drawing, severe drawing) is usually avoided or requires prior softening treatment.

- After significant cold work, stress relieving may be advisable to reduce residual stresses.

Corrosion Resistance and Surface Protection

C40 / 1040 is a plain carbon steel with no significant alloying elements for corrosion resistance. In most environments it will corrode if unprotected, especially in the presence of moisture, salts, or industrial pollutants.

Typical protection methods:

- Painting and coating systems (epoxy, polyurethane, or other protective paint systems).

- Electroplating (e.g., zinc plating) for small components, fasteners, and fittings.

- Phosphating combined with oiling for temporary corrosion protection and wear resistance in some applications.

- Case hardening plus oiling where wear and mild corrosion resistance are both needed; note that this does not transform the material into a stainless steel.

Corrosion allowance in design is sometimes used for heavy sections operating in mildly corrosive atmospheres, but for aggressive environments alternative materials or robust coating systems are normally preferable.

Typical Applications of C40 / 1040 Steel

C40 / 1040 is widely used for components requiring higher strength and wear resistance than mild steel, but where very high hardenability or alloy content is not necessary.

Representative applications include:

- Machine shafts, axles, and spindles where moderate strength and good machinability are needed.

- Crankshafts, connecting rods (in non-highly stressed designs), and similar rotating components.

- Gears, sprockets, and pinions, often with surface hardening for improved wear resistance.

- Bolts, studs, and screws for medium-strength requirements.

- Keys, pins, couplings, and general transmission components.

- Forged parts such as levers, brackets, and flanges.

Material selection for any of these applications should consider service conditions, stress levels, presence of impact loading, ambient or operating temperatures, and any specific requirements for toughness or fatigue resistance.

Design Considerations and Limitations

When selecting or using C40 / 1040, engineers should consider both its capabilities and its limitations.

Important design considerations include:

- Medium weldability: welding requires controlled procedures, preheat, and sometimes PWHT.

- Moderate hardenability: through-hardening is effective only in relatively small cross-sections; large sections may have softer cores.

- Non-stainless behavior: corrosion protection is necessary for most outdoor or humid environments.

- Fatigue performance: adequate for many applications but can be affected by surface condition, residual stresses, and microstructural uniformity.

- Dimensional stability: heat treatment and machining sequences should be planned to minimize distortion, especially in long slender shafts and asymmetrical components.

Where higher toughness (especially at low temperatures), better weldability, or significantly improved hardenability is needed, low alloy steels or microalloyed steels may be more appropriate. However, for many medium-strength components, C40 / 1040 offers a practical balance of cost, availability, and performance.

Comparison with Related Medium Carbon Steels

C40 / 1040 is part of a broader family of medium carbon steels used in similar engineering contexts. Understanding basic comparisons helps with material substitution decisions.

- Compared with C30 / 1030: C40 / 1040 has higher carbon content, leading to higher achievable strength and hardness but reduced weldability and slightly lower toughness.

- Compared with C45 / 1045: C45 / 1045 has slightly higher carbon (~0.45%), enabling somewhat higher surface hardness after heat treatment, but with further reductions in weldability and potentially increased brittleness if not properly tempered.

- Compared with low alloy steels (e.g., 42CrMo4): these alloy steels provide higher hardenability and better performance in thick sections but at higher cost and often more complex heat treatment requirements.

Substitution between these steels should always be validated against the original design criteria and applicable codes or standards.

Quality Control and Inspection

For components made from C40 / 1040, quality control measures help ensure the material meets specified requirements and behaves reliably in service.

Common inspection aspects include:

- Chemical analysis verification, often via spectrometric methods, to confirm compliance with standards.

- Mechanical testing (tensile test, hardness test, impact testing if required) on test pieces from the same heat or batch.

- Microstructural examination, particularly for critical components where control of grain size and phase distribution is important.

- Non-destructive testing (NDT) such as ultrasonic testing or magnetic particle inspection to detect internal defects or surface cracks in forged or heat-treated parts.

- Dimensional inspection and runout checking, especially for shafts and rotating parts where balance and alignment are crucial.

Manufacturers often supply material certificates with details of chemical composition, mechanical properties, heat treatment condition, and compliance with specified standards (e.g., EN 10204 type 3.1 certificates).

FAQ

What is C40 / AISI 1040 steel?

C40 (EN 10083) / AISI 1040 is a medium carbon steel containing approximately 0.40% carbon. It offers a good balance of strength, toughness, and machinability, making it widely used for mechanical and structural components.

Is C40 steel the same as AISI 1040 steel?

They are not exactly the same standard, but they are widely considered equivalent in composition and mechanical performance. C40 is the European designation, while AISI 1040 is the American designation.

What is the difference between C40 / 1040 and 1045 steel?

1045 steel has a higher carbon content than 1040, resulting in higher strength and hardness after heat treatment, but slightly lower machinability and toughness. 1040 is often chosen when better machinability and reduced cracking risk are required.

Is C40 / AISI 1040 steel weldable?

Weldability is limited due to its medium carbon content. Preheating and post-weld heat treatment are recommended to reduce the risk of cracking.