Alpha titanium alloys are a subset of titanium alloys whose microstructure is dominated by the alpha (α) phase, a close-packed hexagonal (HCP) crystal structure stable at lower temperatures. These alloys are designed for good weldability, corrosion resistance and elevated-temperature strength, and are used widely in aerospace, marine, chemical processing and high-performance engineering components.

Fundamentals of Alpha Titanium Alloys

Titanium exists in two primary allotropic forms: alpha (α) and beta (β). The α phase has a hexagonal close-packed crystal structure stable from room temperature up to the beta transus temperature. The β phase has a body-centered cubic structure stable above the beta transus. Alpha titanium alloys are based on compositions that stabilize and retain the α phase over the entire service temperature range.

Alpha alloys may be classified as commercially pure (CP) titanium or as alloyed α grades containing alpha stabilizing elements. Their structure is predominantly α with no significant retained β phase under equilibrium conditions. Metastable amounts of β can sometimes be present after certain thermomechanical treatments, but the design intent is an α-dominated microstructure.

Alpha Phase and Microstructural Characteristics

The core of alpha titanium alloy behavior lies in their microstructure. The α phase has the HCP lattice, which provides relatively high strength and good creep resistance at elevated temperatures but limits room-temperature ductility compared with β or α+β alloys.

Alpha Phase Crystal Structure

The α phase of titanium has the following characteristics:

- Crystal structure: hexagonal close-packed (HCP)

- Coordination number: 12 nearest neighbors

- Typical c/a ratio: approximately 1.587 for pure titanium

- Slip systems: primarily basal, prismatic and pyramidal

The limited number and activity of slip systems at room temperature contribute to the lower formability of α titanium compared with β-rich alloys. However, at elevated temperatures, additional slip systems become active, improving hot workability.

Alpha Alloy Microstructural Forms

Depending on composition and processing, alpha titanium alloys can exhibit different microstructural morphologies:

- Equiaxed alpha: fine, equiaxed α grains; typical of wrought CP titanium and some low-alloy α grades.

- Widmanstätten (basketweave) alpha: plate-like α colonies formed on cooling from the β field; more common in α+β alloys but may be present in some α alloys with partial β field processing.

- Globular alpha: rounded α grains resulting from extensive recrystallization during thermomechanical processing.

In strictly α-stabilized compositions processed entirely below the β transus, the microstructure is fully α, often with a relatively uniform equiaxed or slightly elongated grain morphology. Grain size control is critical for balancing strength and fracture toughness.

Alloying Elements in Alpha Titanium Alloys

Alpha titanium alloys are defined by the use of alpha stabilizing elements and the limitation or absence of beta stabilizers. Alloying design aims to retain the α phase, adjust transformation temperatures and modify mechanical and corrosion properties.

Alpha Stabilizers

Alpha stabilizing elements increase the stability range of the α phase and raise the β transus temperature. Common α stabilizers include:

- Oxygen (interstitial)

- Aluminum (substitutional)

- Nitrogen (interstitial)

- Carbon (interstitial)

- Gallium, germanium and others in specific experimental or niche alloys

Oxygen and aluminum are the most important alpha stabilizers in commercial alloys. Oxygen is present as a controlled interstitial element, while aluminum is added in substitutional solid solution.

Neutral and Beta Stabilizing Elements

Elements such as tin (Sn), zirconium (Zr) and hafnium (Hf) are often considered neutral with respect to α/β stabilization but contribute to solid solution strengthening and creep resistance. True beta stabilizers, such as molybdenum (Mo), vanadium (V), chromium (Cr), iron (Fe), manganese (Mn), niobium (Nb) and tantalum (Ta), are kept very low or absent in alpha alloys.

By limiting β stabilizers, the alloy retains its α character over a wide temperature range, avoiding large fractions of retained β at service temperatures.

Classification and Overview of Alpha Titanium Grades

Alpha titanium alloys can be broadly divided into:

- Commercially pure (CP) titanium (essentially α with interstitial alloying)

- Alloyed α titanium grades with significant aluminum and other α/neutral elements

CP titanium grades (often designated Grade 1 to Grade 4 in standards such as ASTM B348) are technically unalloyed but contain controlled amounts of oxygen, nitrogen, carbon and iron. These interstitials strongly influence strength and ductility but maintain a single-phase α microstructure.

Alloyed α titanium grades introduce substitutional elements to further strengthen and stabilize the α phase, often for elevated temperature service. Examples include Ti-5Al-2.5Sn and Ti-8Al-1Mo-1V types that behave as near-alpha or alpha-rich alloys depending on classification convention.

| Designation | Nominal Composition (wt%) | Microstructural Type | Typical Applications |

|---|---|---|---|

| CP Ti Grade 1 | Ti (balance), very low O, N, C, Fe | Alpha (commercially pure) | Chemical processing, heat exchangers, biomedical |

| CP Ti Grade 2 | Ti (balance), O up to ~0.25%, small Fe, N, C | Alpha (commercially pure) | Pressure vessels, piping, marine hardware |

| CP Ti Grade 3 | Ti (balance), O up to ~0.35% | Alpha (commercially pure) | Higher strength CP components, plates and forgings |

| CP Ti Grade 4 | Ti (balance), O up to ~0.40% | Alpha (commercially pure) | Implants, airframe components, high-strength CP parts |

| Ti-5Al-2.5Sn (Ti-5-2.5) | Al ~5, Sn ~2.5, Ti balance | Alpha / near-alpha | Aerospace structures, cryogenic tanks |

| Ti-8Al-1Mo-1V (Ti-8-1-1) | Al ~8, Mo ~1, V ~1, Ti balance | Near-alpha (alpha rich) | High-temperature aerospace components |

The exact classification of some alloys as “alpha” versus “near-alpha” may vary by standard and industry practice. Technically pure α alloys contain negligible β stabilizer content, whereas near-α alloys contain modest β stabilizer additions but remain α-dominated in service.

Key Physical and Mechanical Properties

Alpha titanium alloys share certain generic properties derived from their titanium base and α microstructure. Actual property values depend on composition, processing history, product form and test conditions.

Physical Properties

Typical physical properties of alpha titanium alloys at room temperature include:

- Density: approximately 4.5 g/cm³

- Melting range (titanium base): roughly 1660–1670 °C

- Modulus of elasticity: about 100–120 GPa (depending on alloy and direction)

- Poisson’s ratio: approximately 0.3–0.34

- Thermal conductivity: around 6–8 W/m·K for CP grades

- Coefficient of thermal expansion: about 8–9 × 10⁻⁶ /K

Compared to steels and nickel-based alloys, alpha titanium alloys provide lower density and intermediate elastic modulus, making them attractive for weight-sensitive applications.

Mechanical Properties

Typical room-temperature mechanical properties for alpha titanium alloys cover a wide range depending on purity and alloy content:

| Grade / Alloy | Condition | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| CP Ti Grade 1 | Annealed | ~170–240 | ~240–340 | ~24–40 |

| CP Ti Grade 2 | Annealed | ~275–410 | ~345–550 | ~20–30 |

| CP Ti Grade 4 | Annealed | ~480–550 | ~550–680 | ~15–20 |

| Ti-5Al-2.5Sn | Annealed | ~620–760 | ~690–860 | ~10–18 |

| Ti-8Al-1Mo-1V | Solution + aging or annealed | ~830–930 | ~900–1030 | ~8–15 |

In addition to static strength, alpha titanium alloys exhibit:

- Good fatigue performance in air with appropriate surface finish and design.

- Good creep resistance for certain α and near-α alloys up to intermediate temperatures.

- Reasonable fracture toughness considering their relatively high strength and low density.

Properties at elevated temperatures depend strongly on alloy content; aluminum- and tin-containing α alloys retain useful strength to higher temperatures than CP grades.

Corrosion and Oxidation Resistance

One of the principal advantages of alpha titanium alloys is their corrosion resistance. Titanium forms a stable, adherent and self-healing oxide film (primarily TiO₂) in many environments. This passive film provides excellent resistance to a wide range of corrosive media.

General Corrosion Behavior

Alpha titanium alloys demonstrate:

- Excellent resistance to seawater and marine atmospheres.

- High resistance to chlorides, including brines under many conditions.

- Good resistance in oxidizing acids, such as nitric acid, under controlled conditions.

- Resistance to many organic acids and chlorinated solvents.

The corrosion behavior may be affected by alloying elements; however, typical CP and α/near-α alloys maintain good passivity. The presence of crevices, deposits, or reducing conditions can influence local corrosion behavior, so design considerations are important.

Oxidation Resistance and Temperature Limits

Alpha titanium alloys display adequate oxidation resistance at moderately elevated temperatures in air due to the formation of a protective oxide scale. The maximum continuous use temperature depends on the specific alloy, oxygen partial pressure and time of exposure. Certain near-α alloys with higher aluminum content are specifically developed for improved high-temperature oxidation resistance in aerospace engine environments.

Heat Treatment and Beta Transus Considerations

Heat treatment of alpha titanium alloys is more limited than for α+β or β alloys because the available transformation behavior is constrained by their predominantly α composition. Nevertheless, thermal treatments are important for stress relief, recrystallization and microstructure control.

Beta Transus Temperature

The β transus temperature is the temperature above which the β phase is stable as a single phase. For pure titanium, this temperature is approximately 882 °C. Alpha stabilizers, such as Al and O, raise the β transus, while beta stabilizers lower it. Alpha titanium alloys typically have β transus temperatures higher than the service temperature range and, depending on composition, higher than those of α+β alloys containing significant β stabilizers.

Knowledge of the β transus is essential for selecting hot-working and possible solution-treatment temperatures. For CP titanium, common annealing temperatures are kept well below the β transus, while some α/near-α alloys may be processed close to or slightly above the transus to modify microstructure.

Typical Heat Treatment Practices

Common heat treatments for alpha titanium alloys include:

- Stress relief annealing: to reduce residual stresses after cold working or welding; usually at moderate temperatures below full recrystallization.

- Full annealing: to restore ductility, refine microstructure and homogenize mechanical properties; temperatures are chosen to avoid excessive grain growth.

- Duplex annealing (for some near-α alloys): involving temperatures near the β transus followed by a lower temperature anneal to tailor α plate morphology and mechanical properties.

Due to the absence of substantial β phase, alpha titanium alloys do not respond dramatically to solution treatment and aging in the same way as α+β or metastable β alloys. Precipitation strengthening via β→α transformation or fine α precipitation is more limited, and the primary strengthening mechanisms are solid solution hardening, grain refinement and work hardening.

Forming and Machining Characteristics

The processing behavior of alpha titanium alloys is governed by their HCP structure, high reactivity at elevated temperatures and relatively low thermal conductivity. These factors influence forging, rolling, sheet forming, machining and welding operations.

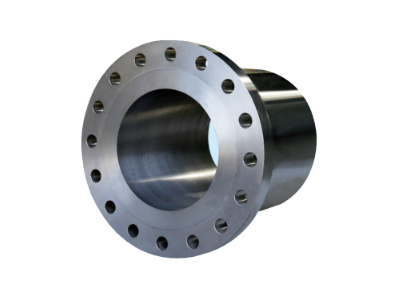

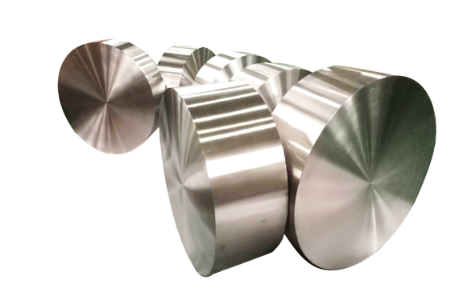

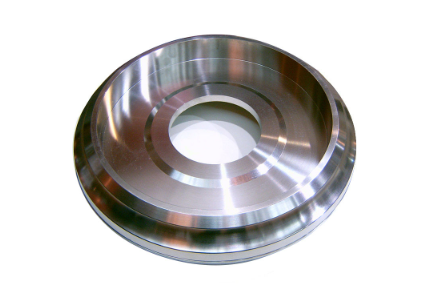

Hot Working and Forging

Alpha titanium alloys are generally forged and hot worked in the α or (α+β) temperature ranges, depending on alloy classification and the desired microstructure. Key aspects include:

- Typical hot-working temperatures: roughly 700–950 °C, adjusted by alloy and β transus.

- Strain rate sensitivity: moderate; careful control reduces the risk of flow localization.

- Need for protective atmosphere or coatings at higher temperatures to minimize surface contamination and oxidation.

Excessive forging temperatures or prolonged exposure can cause grain coarsening and oxygen pickup, leading to surface hardening (alpha case) that requires removal. Process control and frequent reheating (with minimal time at high temperature) are commonly applied.

Cold Working and Formability

Cold formability of alpha titanium alloys is moderate. CP titanium grades, especially Grade 1 and Grade 2, offer better cold formability than higher-strength α or near-α alloys due to their lower interstitial content and lower strength. Cold rolling, bending and drawing are feasible with appropriate intermediate anneals to restore ductility and relieve work hardening.

At room temperature, the limited slip systems of the HCP structure reduce ductility compared with β-rich titanium alloys. Forming operations must account for springback, which can be significant due to the relatively low modulus.

Machining Behavior

Machining alpha titanium alloys requires attention to their low thermal conductivity, tendency to gall and high chemical reactivity at elevated cutting temperatures. Important machining characteristics are:

- Heat concentration at the tool–chip interface, leading to higher tool wear.

- Tendency for work hardening in the near-surface region when using dull tools or inappropriate parameters.

- Need for sharp, wear-resistant cutting tools, often carbide or advanced tool materials.

- Use of abundant coolant or cutting fluid to control temperature and chip evacuation.

Cutting speeds are typically kept moderate compared to steels to maintain tool life and surface quality. Proper machining practice is essential to avoid surface damage that can affect fatigue performance.

Weldability and Joining Methods

Alpha titanium alloys are generally considered to have good weldability when appropriate procedures, shielding and cleanliness are used. The strong affinity of titanium for oxygen, nitrogen and hydrogen at elevated temperatures requires stringent control during welding to prevent contamination and embrittlement.

Fusion Welding Processes

The most common welding processes for α titanium alloys include:

- Gas Tungsten Arc Welding (GTAW/TIG)

- Gas Metal Arc Welding (GMAW/MIG) under controlled conditions

- Plasma Arc Welding (PAW)

- Electron Beam Welding (EBW) in vacuum

- Laser Beam Welding (LBW)

Key requirements during welding are:

- High-purity inert gas shielding (typically argon or helium) on the weld pool and both the front and back surfaces.

- Protection of the hot heat-affected zone (HAZ) until the temperature falls below approximately 400 °C to prevent embrittling surface reactions.

- Meticulous joint preparation and cleaning to remove oils, moisture, and surface contaminants.

Welded joints in CP α titanium can achieve mechanical properties close to those of the base metal. For stronger α and near-α alloys, joint design and welding parameters must be optimized to control microstructure and residual stresses.

Solid-State Joining and Other Methods

Solid-state joining methods, such as diffusion bonding and friction welding, are also applicable to alpha titanium alloys and can produce high-quality joints with minimal microstructural alteration. Brazing using appropriate filler alloys is possible under vacuum or inert atmospheres, although joint design must account for differences in thermal expansion and reaction with braze materials.

Applications of Alpha Titanium Alloys

Alpha titanium alloys are used in applications that require a combination of low density, good corrosion resistance, acceptable mechanical strength and, for some alloys, moderate elevated-temperature capability. Their application fields span several industries.

Aerospace Structures and Components

In aerospace, alpha and near-α titanium alloys are used for:

- Airframe components: frames, bulkheads, skins and fasteners, especially where corrosion resistance and weight savings are important.

- Engine components: compressor cases, blades, vanes and other elements exposed to intermediate temperatures where oxidation resistance is required.

- Cryogenic tanks: certain α alloys such as Ti-5Al-2.5Sn have favorable properties at cryogenic temperatures, suitable for liquid hydrogen or liquid oxygen tanks.

These alloys contribute to reduced structural weight and enhanced durability in aggressive service environments, including moisture, salt-laden air and fuel exposure.

Marine and Offshore Equipment

Alpha titanium alloys, especially CP titanium, are widely used in marine environments owing to their outstanding resistance to seawater corrosion and biofouling. Typical applications include:

- Heat exchanger tubes in seawater-cooled systems.

- Shipboard piping, valves and pump components.

- Offshore platform components and riser systems where low weight and corrosion resistance are decisive.

The durability in seawater reduces maintenance and replacement frequency, making titanium attractive despite its higher initial material cost compared with common engineering metals.

Chemical Processing and Power Generation

In chemical processing plants, CP and α titanium alloys are chosen for:

- Reactors, columns and vessels handling chloride-containing or oxidizing media.

- Heat exchangers exposed to aggressive cooling waters and process streams.

- Piping systems in desalination plants and chlorine-based processes.

In power generation, titanium components are utilized in condenser tubing and other heat transfer equipment where resistance to erosion–corrosion and fouling is important. The combination of corrosion resistance and low density reduces system weight and can improve efficiency.

Biomedical and Other Specialized Uses

CP α titanium (especially Grade 4) is used for dental implants, some orthopedic implants and medical devices due to its biocompatibility, corrosion resistance in bodily fluids and favorable strength-to-weight ratio. Surface treatments and coatings may be applied to tailor biological responses or wear resistance.

Additional specialized applications include sporting goods, high-performance automotive parts, architectural components and instrumentation where corrosion resistance, non-magnetic behavior and low weight are desired.

Pain Points and Practical Considerations

While alpha titanium alloys offer a strong combination of properties, several practical considerations influence their selection, design and processing.

Material and Processing Cost

The extraction and refinement of titanium are more energy-intensive than for many common metals. Combined with specialized processing requirements (inert atmospheres, careful heat treatment, controlled machining), the overall cost of alpha titanium components can be significant. This cost factor limits use primarily to applications where performance requirements justify the expense.

Surface Contamination and Alpha Case

During high-temperature exposure in air or insufficiently protective atmospheres, titanium can absorb oxygen, nitrogen and hydrogen, forming a hardened, brittle surface layer known as alpha case. This layer deteriorates fatigue properties and must be removed by machining, grinding or chemical milling. Avoiding or controlling alpha case formation is an important consideration in forging, heat treating and welding operations.

Design for Fatigue and Fracture

Although alpha titanium alloys have favorable fatigue performance, they are sensitive to surface condition, notches and residual stresses. Design and fabrication must ensure smooth surfaces, appropriate radii, and minimal surface damage. Post-processing operations, such as polishing or shot peening, can be used to improve fatigue resistance by reducing stress concentrations and introducing beneficial compressive residual stresses.

Limitations in High-Temperature Strength Range

While some α and near-α alloys provide useful strength and creep resistance at intermediate temperatures, they are not designed for the extreme temperature ranges where nickel-based superalloys dominate. When selecting alpha titanium alloys for elevated temperature service, engineers must carefully match the alloy’s temperature capability with the intended operating conditions to avoid excessive creep deformation or microstructural instability.

FAQ About Alpha Titanium Alloys

What are alpha titanium alloys?

Alpha titanium alloys are titanium materials that consist primarily of the alpha phase (hexagonal close-packed structure), giving them excellent high-temperature stability and corrosion resistance.

What are common examples of alpha titanium alloys?

Examples include commercially pure titanium grades (Grade 1–4), Ti-5Al-2.5Sn, and other alloys with aluminum, oxygen, or tin as alpha stabilizers.

What are the main advantages of alpha titanium alloys?

They offer superior weldability, good creep resistance, excellent corrosion resistance, and stable mechanical properties at elevated temperatures.

Are alpha titanium alloys easy to machine?

Alpha titanium alloys are generally more difficult to machine than many steels and aluminum alloys due to low thermal conductivity and work-hardening behavior, requiring optimized tooling and cooling.

What applications typically use alpha titanium alloys?

They are used in aerospace engine components, chemical processing equipment, marine hardware, heat exchangers, and medical devices where corrosion resistance is critical.