Aluminum chromium nitride (AlCrN) coatings are widely used physical vapor deposition (PVD) hard coatings designed for demanding machining and forming operations. They combine high hardness, excellent high-temperature oxidation resistance and low wear rates, making them a standard choice for modern cutting and forming tools.

Fundamentals of AlCrN Coatings

AlCrN is a multi-element ceramic coating in which aluminum and chromium are combined with nitrogen to form a dense, adherent layer on the tool or component surface. It is typically deposited by PVD methods such as cathodic arc evaporation or magnetron sputtering.

The coating structure is usually based on a cubic (NaCl-type) or mixed cubic/hexagonal nitride phase, depending on Al/Cr ratio and deposition conditions. The high aluminum content promotes the formation of a stable protective Al-rich oxide at elevated temperature, while chromium contributes to toughness and additional oxidation resistance.

Chemical Composition and Phase Structure

Typical AlCrN coatings are expressed as (Al,Cr)N or AlxCr1‑xN, where x defines the aluminum fraction in the metal sublattice. Common ranges are:

- Al content: approximately 50–70 at.% of the metallic elements (Al + Cr)

- Cr content: approximately 30–50 at.% of the metallic elements

- N content: close to stoichiometric ratio with (Al + Cr)

With increasing Al content, the coating tends to form metastable cubic AlCrN at moderate Al levels and a mixture of cubic and hexagonal phases at higher Al levels. Coating suppliers tune the Al/Cr ratio to balance hardness, thermal stability and residual stress.

Deposition Methods

AlCrN coatings are produced in vacuum PVD systems. The two dominant technologies are:

- Cathodic arc evaporation using composite AlCr targets or separate Al and Cr cathodes. This method yields high ionization, strong adhesion and dense coatings, often with characteristic macroparticles.

- Magnetron sputtering (including DC, pulsed DC and HiPIMS) using alloy or segmented targets. This can provide smoother coatings and precise control of composition and stress.

Typical deposition conditions involve substrate temperatures between about 350–550 °C, bias voltages to tailor ion bombardment and low-pressure nitrogen-containing atmospheres.

Key Material Properties of AlCrN Coatings

AlCrN coatings are selected based on a combination of mechanical, tribological and thermal properties. The exact values depend on deposition technology, coating architecture and substrate, but certain ranges are representative.

| Property | Typical Range / Description |

|---|---|

| Hardness (nanoindentation) | 25–35 GPa (sometimes higher for optimized systems) |

| Elastic modulus | 300–450 GPa |

| Coefficient of friction (dry vs. steel) | ≈0.4–0.7 (depends strongly on counter material and conditions) |

| Adhesion (Rockwell or scratch test) | Typically high adhesion; critical loads often > 60 N in scratch tests (method dependent) |

| Oxidation resistance | Stable oxide formation typically up to about 1000–1100 °C, depending on composition |

| Maximum recommended operating temperature | Commonly up to about 900–1000 °C in cutting applications |

| Thickness (tool coatings) | ≈1–5 µm (multi-layer or graded designs possible) |

| Color/appearance | Dark grey to black, sometimes with metallic sheen depending on process |

| Residual stress | Typically compressive; magnitude controlled by process parameters |

Hardness and Mechanical Strength

AlCrN coatings exhibit high hardness in the range of approximately 25–35 GPa, which significantly reduces abrasive and adhesive wear on cutting edges and forming surfaces. The combination of high hardness and tailored residual compressive stresses improves resistance to crack initiation and propagation under cyclic mechanical loads.

The elastic modulus of AlCrN is generally in the 300–450 GPa range, resulting in a stiff but not excessively brittle coating. The ratio of hardness to elastic modulus (H/E) and the ratio of hardness squared to modulus (H2/E) can be used as indicators of resistance to elastic strain and plastic deformation, respectively. Well-optimized AlCrN systems achieve favorable H/E and H2/E values, contributing to improved fatigue resistance of coated tools.

Thermal Stability and Oxidation Resistance

One of the main advantages of AlCrN over classical TiN or TiCN coatings is its superior performance at elevated temperatures. During high-speed cutting or dry machining, tool surfaces can reach temperatures where conventional coatings soften or oxidize rapidly.

In AlCrN, aluminum promotes the formation of a dense, adherent alumina-rich oxide layer, which acts as a diffusion barrier and slows further oxidation. Chromium contributes to the formation of additional protective oxide phases. As a result, AlCrN coatings maintain structural stability and functional hardness up to temperatures around 900–1000 °C, depending on composition and service conditions.

Tribological Behavior and Friction

The coefficient of friction of AlCrN against steel and other workpiece materials depends strongly on temperature, surface finishing, lubrication and the presence of reaction layers. Typical dry friction values are around 0.4–0.7, which can be reduced with cutting fluids or specialized lubricants.

Although some alternative coatings can provide lower friction coefficients, the combination of stable friction, high hardness and oxidation resistance allows AlCrN-coated tools to maintain sharpness and dimensional accuracy over extended tool life. In many applications, the reduced flank wear and crater wear offset any moderate friction levels.

Adhesion to Substrates

Adhesion is a critical property in tooling applications because coating delamination leads to sudden loss of protection and rapid tool failure. PVD-deposited AlCrN coatings, when combined with proper substrate pretreatment (such as cleaning, heating and ion etching), achieve strong adhesion on common tool materials:

- Carbide (WC-Co), often with interlayers or graded interfaces to control cobalt diffusion and stress

- High-speed steel (HSS), with pre-polishing and possible nitriding or interlayer design

- Cemented carbides for indexable inserts

- Some stainless steels and hot-work tool steels after suitable surface preparation

Adhesion is often evaluated by Rockwell indentation tests or scratch tests. Optimized systems show high critical loads and a cohesive failure pattern rather than adhesive spallation.

Coating Architectures and Variants

AlCrN coatings can be produced in different architectures to adjust performance to specific tasks. The following concepts are widely used in industrial practice.

Monolayer AlCrN

Monolayer coatings consist of a single, compositionally uniform AlCrN layer. They offer a straightforward, robust configuration with predictable behavior and are commonly used in general-purpose cutting and forming applications. The thickness is typically 2–4 µm for cutting tools, depending on edge geometry and machining conditions.

Multilayer and Graded AlCrN

Multilayer designs combine alternating layers of slightly different compositions or phases, such as AlCrN/CrN or AlCrN/AlTiN stacks. These multilayers exploit interface effects to increase toughness, crack deflection and residual stress control. Graded coatings gradually change composition from the substrate to the surface, improving adhesion and reducing stress concentrations.

In high-performance milling or drilling tools, multilayer and graded AlCrN structures are often used to balance surface hardness, thermal stability and edge toughness.

Doped and Composite AlCrN Systems

Some commercial variants introduce additional elements (e.g., Si, Ti, Nb, or Y) to tailor grain refinement, oxidation behavior, thermal conductivity or stress state. While specific compositions vary among manufacturers, the underlying purpose remains to adapt AlCrN-based coatings to particular workpiece materials and cutting conditions.

Key Benefits of AlCrN for Industrial Users

AlCrN coatings provide multiple benefits in production environments where tool performance directly affects machining cost, dimensional accuracy and process reliability.

Extended Tool Life

The high hardness, combined with stable performance at elevated temperatures, leads to significant improvements in tool life for many operations. By reducing flank wear, crater wear and chipping, AlCrN-coated tools require fewer changes and regrinds, lowering tooling costs and production interruptions.

Improved Performance in Dry and High-Speed Machining

Dry machining and high-speed cutting are widely used to increase productivity and reduce coolant consumption. Under such conditions, cutting edges experience high thermal loads. AlCrN coatings are particularly suitable because their oxidation-resistant surface maintains hardness and protects the substrate, even when cooling is limited.

Compared to standard TiN or TiCN layers, AlCrN often allows higher cutting speeds and feeds while preserving acceptable wear rates and surface finish quality.

Stable Dimensional Accuracy and Surface Quality

By minimizing wear and micro-chipping of the cutting edge, AlCrN coatings help maintain tolerances over longer production runs. Reduced edge rounding and damage also contribute to consistent surface roughness and improved repeatability for critical dimensions.

Protection Against Abrasive and Adhesive Wear

Abrasive wear caused by hard phases in the workpiece or chips is mitigated by the high hardness and compact structure of AlCrN. In addition, the chemical stability and oxide-forming tendency of AlCrN at temperature reduce adhesion of workpiece material onto the tool. Less built-up edge means smoother chip flow, fewer edge fractures and lower risk of sudden tool failure.

Potential Pain Points and Considerations

While AlCrN offers many advantages, users should consider several practical aspects when selecting and implementing this coating:

- AlCrN is not universally optimal for all materials; in some cases, other coatings may provide better behavior, for example, in operations dominated by adhesive wear at low temperature where very low friction is crucial.

- The performance of AlCrN depends strongly on matching coating type, substrate grade and cutting parameters. Inappropriate cutting data can still cause premature failure despite the coating.

- Cost per tool can be higher than for basic coatings, so the economic benefit needs to be evaluated based on tool life extension and productivity gains.

- Coating thickness and edge preparation must be controlled carefully for very fine or sharp cutting edges; excessive thickness may alter cutting geometry or create stress concentrations.

Comparison of AlCrN with Other PVD Coatings

To make informed decisions, it is useful to compare AlCrN with other common tool coatings such as TiN, TiCN and AlTiN. While exact performance depends on the specific system, certain tendencies are frequently observed.

| Coating | Relative Hardness | High-Temperature Performance | Typical Use Highlights |

|---|---|---|---|

| TiN | Baseline; lower than AlCrN | Moderate; limited at higher speeds | General-purpose, low to medium speed machining, decorative and tribological uses |

| TiCN | Higher than TiN; still commonly lower than AlCrN | Better than TiN but less than Al-based coatings | Wear-resistant for interrupted cuts, some forming operations, moderate temperatures |

| AlTiN / TiAlN | High hardness; similar or slightly different range compared to AlCrN depending on system | Good oxidation resistance; widely used for high-speed machining | High-speed, dry or semi-dry machining; many steels and cast irons |

| AlCrN | High hardness; comparable to advanced AlTiN-type coatings | Excellent oxidation resistance and thermal stability | Demanding high-speed and dry machining, abrasive and hard materials, forming of high-strength alloys |

In many practical applications, AlCrN is chosen when superior high-temperature stability and abrasive wear resistance are needed, especially in operations where thermal softening of the coating would otherwise limit performance.

Industrial Applications of AlCrN Coatings

AlCrN coatings are used across multiple industries, particularly where metal cutting and forming are core processes. The coating is commonly specified for end mills, drills, taps, inserts and forming tools operating under demanding conditions.

Cutting Tools for Steels and Stainless Steels

AlCrN is widely used on solid carbide and HSS tools for machining medium to high alloy steels, carbon steels and stainless steels. Typical examples include:

- End mills for roughing and finishing operations, especially at high cutting speeds

- Drills for high penetration rates in alloy steels and stainless steels, often in limited coolant environments

- Taps and thread-forming tools designed for high-strength steels

- Turning inserts for continuous and light interrupted cuts

The coating supports stable performance in the presence of work-hardened layers and allows better resistance to notch wear at the depth-of-cut line.

Machining of Hardened Steels and Tool Steels

AlCrN coatings are used for machining hardened steels and various tool steels in mold and die manufacturing, automotive and general engineering sectors. For example:

In high-speed milling of hardened mold steels, AlCrN-coated end mills can sustain the high tool–chip interface temperatures and maintain edge sharpness. This contributes to improved surface finish and reduced polishing time. The oxidation-resistant nature of the coating is particularly beneficial for dry or minimum quantity lubrication (MQL) strategies.

Machining of Cast Iron and High-Strength Alloys

In machining gray and ductile cast irons, the abrasive graphite and carbide inclusions can cause severe wear on uncoated tools. AlCrN coatings provide a hard barrier that delays flank wear and micro-chipping. In some high-strength alloys used in automotive and mechanical engineering, AlCrN can help manage the combination of abrasive and adhesive wear under elevated temperatures.

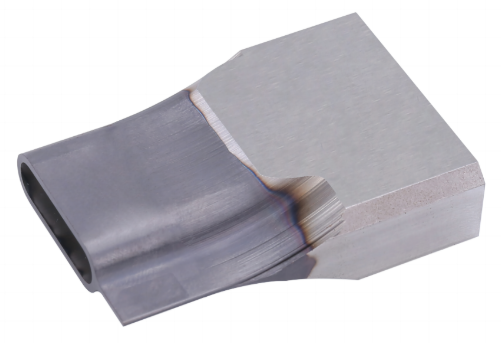

Forming and Stamping Tools

AlCrN coatings are also used in forming, stamping and fine-blanking operations. Applications include:

- Cold forming punches and dies for high-strength steels

- Progressive dies for sheet metal forming where galling and adhesive wear are issues

- Tools for stainless steel forming, where high contact pressures and friction generate local heating

By reducing wear and adhesion, AlCrN-coated forming tools maintain their geometry for longer, improve component dimensional consistency and reduce downtime for tool maintenance.

Hot-Work and High-Temperature Tooling

In certain hot-working operations and tools exposed to cyclic thermal loads, such as some extrusion dies, AlCrN coatings can enhance resistance to erosion and oxidation of tool surfaces. The protective oxide layer formed at elevated temperature reduces scaling and chemical attack, helping to preserve surface quality.

Precision and Micro-Tools

Small-diameter drills, micro end mills and other precision tools benefit from AlCrN coatings when machining abrasive or hard materials. The coating preserves edge sharpness, which is critical when tool diameters are small and any wear quickly alters the effective geometry. Careful control of coating thickness and edge preparation is required to avoid excessive rounding on very fine tools.

Substrate Compatibility and Pretreatment

The performance of AlCrN coatings depends not only on their intrinsic properties but also on substrate material selection, heat treatment and surface preparation.

Common Substrates

AlCrN is typically applied to:

- Tungsten carbide (WC-Co) grades with various binder contents

- High-speed steels (HSS), including powder metallurgy grades

- Some hot-work and cold-work tool steels

- Selected stainless steels and other alloys, depending on application

For each substrate, the thermal expansion coefficient, hardness and toughness must be considered to ensure that the coating–substrate system can withstand mechanical and thermal stresses.

Surface Preparation and Interlayers

Before deposition, substrates undergo cleaning, degreasing and often mechanical polishing to remove defects that could initiate cracks. In many cases, ion etching with argon or reactive gases is used to improve surface activation and adhesion.

Interlayers such as Cr, CrN or other metallic/ceramic layers may be added between the substrate and AlCrN to enhance adhesion, moderate residual stress and reduce diffusion of elements like cobalt from carbide substrates. These interlayers can also help tailor the hardness gradient, improving overall toughness of the coated system.

Operational Considerations for Using AlCrN-Coated Tools

To fully exploit AlCrN coatings, users should adapt cutting parameters, tool paths and cooling strategies to the coating’s characteristics.

Cutting Parameters

AlCrN-coated tools often enable higher cutting speeds and feed rates compared with uncoated or conventionally coated tools. However, parameters must be selected within safe limits for the specific workpiece and tool design. Excessive speed, feed or depth of cut may still cause thermal cracking or mechanical overload of the substrate.

Coolant and Lubrication

AlCrN is well-suited for dry and minimum quantity lubrication (MQL) operations, particularly in steels and cast irons. Where coolants are used, consistent delivery and appropriate concentration are necessary to avoid thermal shock and uneven cooling on the cutting edge.

Tool Regrinding and Recoating

Solid carbide and HSS tools with AlCrN coatings can often be reground and recoated. To maintain performance, regrinding must preserve geometry and avoid damage to the substrate. Proper stripping of old coatings and substrate preparation before recoating is essential to achieving adhesion and repeatable tool life.

Selection Guidelines for AlCrN Coatings

When deciding whether to use AlCrN for a specific application, several factors should be considered:

Workpiece Material and Hardness

AlCrN is particularly suitable for:

- Alloy steels, tool steels and hardened steels

- Stainless steels and high-strength structural steels

- Cast irons with abrasive microstructures

For non-ferrous materials, soft alloys or highly adhesive metals, other coatings or uncoated tools might be preferred, depending on the process.

Machining Mode and Thermal Load

High-speed, dry or MQL machining favor coatings with strong oxidation resistance and thermal stability. AlCrN is often advantageous in:

- High-speed milling and drilling at elevated temperatures

- Operations where coolant access is limited

- Situations where rapid tool temperature fluctuations occur

Tool Geometry and Edge Requirements

Coating thickness and edge preparation must be matched to tool geometry:

- For robust tools with larger edge radii, thicker AlCrN layers can be used for maximum wear resistance.

- For micro-tools and fine-geometry tools, thinner coatings and optimized polishing are needed to maintain sharpness.

FAQ About AlCrN Coatings

What is the main advantage of AlCrN over TiN or TiCN coatings?

The main advantage of AlCrN compared with TiN or TiCN is its significantly better performance at elevated temperatures. AlCrN forms a stable, protective oxide layer, allowing it to maintain hardness and wear resistance in high-speed and dry machining conditions where TiN or TiCN would soften or oxidize more rapidly. This often results in longer tool life, especially in machining steels, stainless steels and cast irons at high cutting speeds.

Which applications benefit the most from AlCrN coatings?

Applications that benefit most from AlCrN coatings are high-speed and dry or minimum-lubrication machining of steels, hardened steels, tool steels and cast irons, as well as forming and stamping of high-strength materials. Examples include high-speed milling and drilling of hardened mold steels, machining of stainless steel where coolant is limited and forming tools exposed to high contact pressures and local heating. The coating’s combination of high hardness and oxidation resistance is particularly valuable in these conditions.

Can AlCrN coatings be used on high-speed steel (HSS) tools?

Yes. AlCrN coatings are commonly applied to high-speed steel tools such as drills, taps and end mills. Proper surface preparation, heat treatment and interlayer design ensure good adhesion and performance. When correctly specified, AlCrN-coated HSS tools can offer improved wear resistance and extended life, particularly in machining alloy steels and stainless steels at elevated speeds and temperatures.

Are AlCrN-coated tools suitable for dry machining?

AlCrN-coated tools are well-suited for dry and minimum quantity lubrication machining, especially in steels and cast irons. The coating’s high-temperature stability and ability to form protective oxide layers reduce wear and maintain edge strength when coolant is limited or absent. However, cutting parameters and tool paths must still be optimized to prevent thermal overload and mechanical damage.

Can AlCrN-coated tools be reground and recoated?

In many cases, AlCrN-coated solid carbide and HSS tools can be reground and recoated. Successful reuse depends on maintaining the correct cutting geometry during regrinding and properly stripping and preparing the substrate before recoating. When carried out according to appropriate procedures, regrinding and recoating can be a cost-effective way to extend tool service life while preserving high performance.