Automotive CNC machining is a cornerstone manufacturing method for precision metal and plastic components used in passenger vehicles, commercial trucks, motorsport, off-road, and specialty vehicles. This guide explains how it works, what materials and tolerances are typical, how costs are formed, and how to evaluate suppliers for prototyping and production.

What Is Automotive CNC Machining

Automotive CNC machining refers to the use of Computer Numerical Control (CNC) equipment to cut, drill, bore, mill, turn, and finish components used in vehicle systems. CAD models are translated into machine-readable toolpaths, allowing automated, repeatable production of parts with tight dimensional tolerances.

In the automotive sector, CNC machining is used for:

- Prototype components from early design to pre-production validation

- Low to medium volume production runs and service parts

- High-precision features on castings, forgings, and extrusions

CNC equipment typically includes 3-axis and 5-axis milling centers, lathes with live tooling, multi-tasking turn-mill centers, and grinding machines. Automotive requirements often emphasize stable dimensional accuracy, consistent surface finish, and repeatability across large part batches.

Key CNC Processes Used in Automotive Parts

Automotive CNC machining uses several core subtractive processes. These can be applied individually or combined in multi-tasking machine tools.

CNC Milling

CNC milling removes material using rotating cutting tools. It is widely used for prismatic and complex 3D shapes. In automotive applications, milling is used for:

- Engine blocks, cylinder heads, and combustion chambers

- Transmission housings and casings

- Brackets, knuckles, suspension components, and structural mounts

Common configurations:

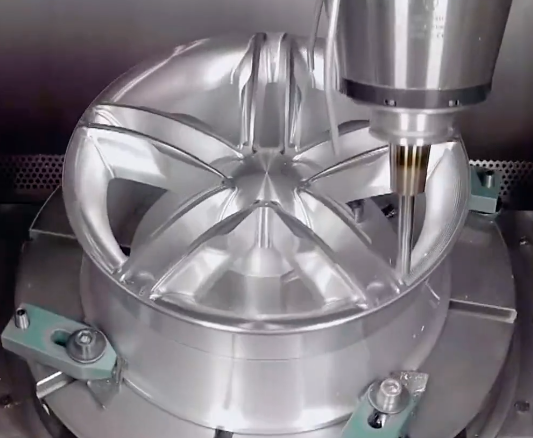

3-axis milling is used for planar faces, pockets, slots, and standard 3D contours. 4-axis and 5-axis milling allow tool access from multiple orientations, enabling machining of complex geometries in fewer setups, improving positional accuracy and reducing run time for intricate automotive parts such as impellers, housings with intersecting bores, and complex brackets.

CNC Turning

CNC turning spins the workpiece while a cutting tool shapes the outer diameter (OD), inner diameter (ID), and features such as grooves or threads. It is primarily used for rotational parts, including:

- Axles, shafts, hubs, and pins

- Steering components and tie-rod ends

- Fasteners, bushings, spacers, and sleeves

Turn-mill centers combine turning with milling operations, supporting off-center drilling, flats, keyways, and complex end features in a single setup. This is common for transmission shafts and other drivetrain components requiring multiple secondary features.

Drilling, Boring, and Reaming

Many automotive parts require precise hole geometries for fasteners, fluid passages, and alignment features:

Drilling produces holes quickly; boring enlarges and improves circularity; reaming ensures tight dimensional control and better surface finish, especially in critical interfaces such as cylinder bores, valve guides, and precision bearing seats.

Grinding and Honing

Grinding and honing are applied when very tight dimensional tolerances and specific surface textures are required. Examples:

- Crankshaft journals and camshaft bearing surfaces

- Gear teeth finishing for reduced noise and improved meshing

- Hydraulic components where leakage and friction must be minimized

These finishing processes are often used after CNC turning or milling to achieve final size and finish.

Secondary Operations and Integrated Machining

Automotive CNC machining is frequently combined with operations such as:

- Threading (tapping or thread milling)

- Broaching (for internal splines or keyways)

- Deburring (manual, machine, or thermal)

Integrating these steps into a single machining cell helps ensure consistent quality and reduces handling time.

Typical Automotive Components Produced by CNC

CNC machining is applied across multiple automotive systems:

Engine and Powertrain Components

Typical components include:

Engine blocks and cylinder heads: Machining of deck surfaces, bores, ports, and threaded features. Tolerances here are critical for compression ratio, sealing, and durability.

Crankshafts and camshafts: Rough turned, then precision ground. Keyways, oil passages, and flanges may be machined on CNC lathes and mills.

Intake manifolds and throttle bodies: Machined mounting faces, bores, and connections for sensors and actuators.

Transmission components: Shafts, housings, synchronizer hubs, and gear blanks often involve a mix of turning, milling, drilling, and grinding.

Chassis and Suspension Components

Machined parts are used in steering, suspension, braking, and body-in-white attachment points. Examples:

Steering knuckles, control arms, and brackets: Often machined from forgings or castings to final dimensions, especially for bearing seats, brake caliper mounts, and sensor interfaces.

Shock absorber components and spring seats: Turned and milled features for tight fits and alignment.

Brake system components: Caliper housings, master cylinder bodies, pistons, and brackets, requiring precise dimensions and smooth sealing surfaces.

Drivetrain and Axle Components

In rear-wheel and all-wheel-drive vehicles, many drivetrain elements rely on CNC machining:

Drive shafts, stub axles, hubs, and flanges: CNC turning, drilling, and spline machining.

Differential housings and carriers: Complex milling and boring operations to ensure correct gear alignment and bearing preload.

Interior, Exterior, and Accessory Parts

Although many visual components are molded, CNC machining is used for:

Metal trim, pedals, and custom interior components: Small-batch or high-precision parts, often in aluminum or stainless steel.

Mounting brackets and fixtures for seats, dashboards, and electronic modules.

Lighting housings, heat sinks, and structural supports for LED modules.

Materials for Automotive CNC Machining

Material selection in automotive CNC machining balances strength, weight, thermal properties, corrosion resistance, machinability, and cost. Metals dominate structural applications, while plastics are used for housings, covers, and non-load-bearing components.

| Material | Typical Grades | Key Properties | Typical Automotive Uses |

|---|---|---|---|

| Aluminum alloys | 6061, 6082, 7075, A356, 4032 | Lightweight, good strength-to-weight, good corrosion resistance, high machinability | Engine covers, housings, brackets, intake components, motorsport parts |

| Carbon steels | C45, 1045, 1018, 1020 | Good strength and toughness, low cost, can be heat-treated | Shafts, axles, fasteners, structural brackets |

| Alloy steels | 4140, 4340, 8620, 42CrMo4 | High strength, fatigue resistance, suitable for quenching and tempering | Crankshafts, gears, high-load drivetrain parts, suspension components |

| Stainless steels | 303, 304, 316, 17-4PH | Corrosion resistant, may be hardened (17-4PH), lower machinability than aluminum | Exhaust components, fasteners, sensors, fluid system parts |

| Copper alloys | Brass (C360), bronze | Excellent machinability, good conductivity, good corrosion resistance | Electrical connectors, bushings, valve components |

| Magnesium alloys | AZ31, AZ91 | Very lightweight, good machinability, requires careful handling and corrosion protection | Motorsport and lightweight housings, brackets |

| Engineering plastics | PA6/PA66, POM, PEEK, PTFE | Low weight, electrical insulation, chemical resistance, lower stiffness vs. metals | Housings, spacers, bushings, clips, low-load brackets |

Aluminum in Automotive CNC Machining

Aluminum is widely used for CNC machined automotive parts because of its combination of low density, adequate strength, and high machinability.

Common considerations:

Grade 6061 is often selected for brackets, mounts, and housings where weldability and corrosion resistance are valued. Grade 7075 is used where higher strength is needed, for example in motorsport suspension and aerospace-derived components. Cast aluminum alloys such as A356 are machined after casting to achieve critical surfaces and tolerances.

Steel and Alloy Steel

Carbon and alloy steels remain essential for high-strength components. CNC machining of steels requires control of cutting parameters and tool selection to manage tool wear. Heat treatment processes, such as induction hardening or quench and temper, are often integrated before or after machining depending on the part design and function.

Stainless Steel and High-Temperature Alloys

Stainless steels are used where corrosion resistance is essential. For exhaust systems, high-temperature materials may be utilized for flanges, mounting components, and sensor housings. CNC machining parameters need to be adjusted for lower thermal conductivity and higher work hardening behavior compared with carbon steels.

Plastics and Composites

For non-structural components or where electrical insulation is required, plastics are frequently machined. CNC machining of plastics demands attention to:

Heat buildup and potential material deformation; tool geometry to avoid edge chipping; and clamping methods that avoid part distortion. Plastics can offer precise, lightweight solutions for clips, covers, and internal housings.

Design for Automotive CNC Machining

Designing parts for CNC machining can significantly influence cost, manufacturability, and performance. Automotive components must often meet strict package constraints while allowing efficient machining.

Feature Geometry and Tool Access

Considerations include:

Avoid extremely deep pockets with small corner radii where possible, as they require specialized long tools and slow machining. Maintain constant wall thickness where practical to reduce distortion in thin-walled parts, especially in aluminum and magnesium. For 5-axis machining, ensure that tool access angles and collision clearances are considered early in design.

Tolerances and GD&T

Automotive parts often require geometric dimensioning and tolerancing (GD&T) to define datums, coaxiality, flatness, and profile controls. When setting tolerances:

Match tolerances to functional requirements rather than applying tight tolerances everywhere. Overly restrictive tolerances raise machining time, inspection requirements, and scrap risk. Group critical features within the same setup when possible to minimize stack-up errors.

Threads, Chamfers, and Fillets

Thread selection should consider assembly conditions, load, and material. Standardizing thread sizes across a component family reduces tooling and inspection complexity.

Chamfers and fillets improve stress distribution and aid assembly. Corner radii should align with available cutter sizes. Internal sharp corners should be avoided in favor of fillets that match or exceed minimum tool radii.

Fixturing and Orientation

During design, consider how the part will be fixtured and oriented in CNC machines. Well-planned datum surfaces and clamping points reduce setup complexity and improve repeatability. Minimizing the number of setups helps maintain alignment between critical features and reduces cumulative error.

Dimensional Tolerances and Surface Finish

Automotive CNC machining must satisfy specified tolerances and surface finishes to ensure proper function, sealing, and wear performance.

Typical Machining Tolerances

Tolerances vary by process, material, and part size. The following ranges are common for CNC machined automotive parts, assuming stable conditions and appropriate tooling:

| Feature Type | Typical Dimensional Tolerance | Typical Surface Finish (Ra) | Notes |

|---|---|---|---|

| General milled features | ±0.05 mm to ±0.10 mm | 1.6–3.2 μm | Suitable for non-critical brackets and housings |

| Precision bores and shafts | ±0.01 mm to ±0.025 mm | 0.4–1.6 μm | Common for bearing seats and alignment bores |

| High-precision interfaces | ±0.005 mm to ±0.01 mm | 0.1–0.4 μm (ground/honed) | Used for critical sealing and sliding surfaces |

| Threaded features | Per standard (e.g., 6H/6g) | 3.2–6.3 μm | Depending on thread forming method |

These values are indicative; specific requirements depend on design intent, quality standards, and the supplier’s capability.

Surface Finish Requirements

Surface finish affects sealing, friction, appearance, and fatigue behavior. Common finishing levels in automotive parts include:

Functional sealing surfaces: typically 0.2–0.8 μm Ra, achieved via fine milling, grinding, or lapping. Sliding surfaces (e.g., hydraulic components): 0.1–0.4 μm Ra to balance lubrication and sealing. Non-critical surfaces: 3.2 μm Ra or above, depending on aesthetic and corrosion requirements.

Measurement and Inspection

Dimensional verification in automotive CNC often uses coordinate measuring machines (CMMs), profilometers for surface roughness, and dedicated gauges. For higher volume production, custom fixtures and in-process measurement (e.g., probing in the machine) help keep processes under control.

Surface Treatments and Post-Processing

Many automotive CNC parts require additional treatments to improve wear resistance, corrosion protection, or appearance.

Heat Treatment

Heat treatment is applied to steels and some aluminum alloys to achieve target mechanical properties. Common automotive applications:

Through hardening of gears, shafts, and highly loaded pins. Induction hardening of localized areas, such as bearing seats or wear zones. Solution heat treatment and aging of aluminum alloys (e.g., 6061-T6) for improved strength.

Coatings and Plating

Coatings in automotive CNC applications include:

Zinc plating for steel parts to enhance corrosion resistance. Anodizing for aluminum to improve hardness and corrosion resistance while enabling color coding. Nickel or chrome plating for aesthetic or high-wear surfaces, depending on the component.

Mechanical Finishing

Additional processes may include shot peening to improve fatigue life, bead blasting for uniform matte appearance, and vibratory finishing to remove sharp edges and improve handling safety.

Cost Structure of Automotive CNC Machining

CNC machining cost in automotive projects is driven by a combination of machine time, material, labor, tooling, and overhead. Understanding each element helps in controlling budget and optimizing designs.

Factors That Influence CNC Machining Cost

Major cost contributors include:

Material type and stock size: High-performance alloys and oversized stock increase material cost and waste. Machining time: Driven by part geometry, required tolerances, and surface finish. Complex 3D surfaces, tight tolerances, and fine finishes increase cycle time.

Setup and programming: New parts require CAM programming, fixturing design, and initial setup. For low volume runs, these costs are distributed over fewer parts. Tooling and consumables: Special tools or high wear in hard materials can raise cost per part. Inspection and quality documentation: Higher inspection coverage and traceability requirements increase labor and equipment usage.

Prototype vs. Production Costs

Prototype runs typically have:

Higher per-part cost due to programming and setup spread over a small quantity. More engineering interaction and potential design iterations. Flexible processes and fixturing adapted quickly to design changes.

Production runs benefit from:

Optimized machining strategies and fixtures. Potential automation of loading, unloading, and inspection steps. Lower per-part cost due to economies of scale.

Typical Cost Ranges

Actual pricing depends heavily on region, supplier capabilities, and specific part requirements. However, some general patterns are:

Simple aluminum brackets: Low complexity, moderate tolerances, and basic finish can be relatively inexpensive per unit, especially at higher volumes. Complex 5-axis components: Higher programming and machine time requirements, often with cost concentrated in the initial setup and long cycle times. Hardened steel components with grinding or honing: Additional process steps and specialized equipment increase cost per part.

Cost Optimization Considerations

Designers and buyers can influence cost by:

Standardizing materials and fastener types across assemblies. Avoiding unnecessarily tight tolerances and surface finishes. Reducing the number of setups needed to complete all features. Grouping parts into larger orders where practical to spread setup cost and reduce unit cost.

Quality Requirements and Standards

Automotive CNC machined parts are often produced under structured quality management systems. Compliance ensures consistent parts across batches and alignment with vehicle-level safety and reliability requirements.

Quality Management Systems

Common frameworks applied to automotive machining suppliers include ISO 9001 and automotive-specific standards such as IATF 16949. These standards define requirements for process control, documentation, traceability, and continuous improvement.

Process Control and Traceability

Key elements in automotive CNC production:

Process control plans that identify critical features, measurement methods, and sampling frequencies. Statistical process control (SPC) where appropriate, especially for high-volume parts. Traceability of materials, especially for safety-related components, from raw material batch to finished part.

Documentation and PPAP

For many OEM and Tier 1 automotive customers, the Production Part Approval Process (PPAP) is required. This may include dimensional reports, material certificates, capability studies, and process flow documentation. CNC machining suppliers must be able to generate consistent documentation to support part approvals and ongoing production.

Selecting an Automotive CNC Machining Supplier

Choosing the right CNC machining supplier is critical when developing or producing automotive components. Evaluation should address technical capability, quality systems, capacity, and communication.

Technical Capability

Points to assess:

Machine types and axes: Ability to perform required milling, turning, and possible 5-axis operations. Material experience: Proven experience with the specific alloys and plastics used in the project. Tolerance and finish capability: Supplier’s documented track record in achieving the specified precision and surface quality.

Production Capacity and Lead Times

Automotive schedules often require tight lead times and reliable delivery. Suppliers need sufficient capacity, scheduling control, and flexibility to handle demand peaks, prototype work, and engineering changes without affecting quality.

Quality and Inspection Capability

Inspection equipment such as CMMs, surface roughness meters, and dedicated gauges is important. The supplier should be able to demonstrate calibration management, operator training, and robust measurement processes to support the required quality level.

Communication and Engineering Support

Effective communication supports clear definition of requirements, timely response to design questions, and efficient resolution of issues. Engineering support from the supplier can help refine designs for manufacturability, reduce costs, and avoid delays.

Use Cases: Prototyping, Low Volume, and Series Production

Automotive CNC machining is used throughout a vehicle development cycle.

Prototyping and Development

During concept and early design phases, CNC machining supports fast production of functional prototypes. Machined parts can be made from production-intent materials, enabling testing under realistic mechanical, thermal, and environmental conditions.

Typical activities include:

Engine and transmission prototype components for bench testing. Suspension and steering components for vehicle dynamics evaluation. Housing and bracket prototypes for packaging and assembly verification.

Pilot and Pre-Production Builds

As designs mature, CNC machining supplies parts for pilot runs and validation builds. At this stage, attention shifts toward repeatability, process capability, and alignment with series production requirements.

Series Production and Service Parts

For low to medium volume models, specialty vehicles, motorsport, and service parts, CNC machining can remain a main production method. Parts that require high precision but relatively limited volume often stay with CNC machining rather than transitioning to alternative processes.

Common Practical Considerations in Automotive CNC Projects

When planning automotive CNC machining work, several practical points often arise:

Material Availability

Lead time for specific alloys, bar sizes, or forgings can impact project schedules. Early confirmation of material availability and equivalent grades avoids delays. For global programs, ensuring consistent material specifications across regions is important.

Dimensional Stability and Distortion

Thin-walled aluminum and magnesium parts, as well as heat-treated steels, can distort during or after machining. Appropriate strategies, such as stress-relief heat treatment before final machining and balanced material removal, help maintain dimensional stability.

Tool Life and Consistency

In production, maintaining consistent tool life reduces variation and unexpected downtime. For hard materials or high-speed machining of aluminum, tool selection and monitoring are critical to achieving predictable wear behavior and stable part dimensions.