Energy CNC machining supports the production of critical components across oil and gas, power generation, nuclear, and renewable energy applications. This guide explains processes, materials, tolerances, design practices, quality control, and cost structures specific to the energy sector.

Role of CNC Machining in the Energy Industry

CNC machining is used where dimensional accuracy, repeatability, and material performance are critical under high loads, pressures, and temperatures. Typical applications include downhole tools, turbine components, compressor parts, pump housings, manifolds, and structural hardware for renewable installations.

In energy projects, CNC machining is often applied at three stages: prototype validation of new components, low-to-medium volume production of specialized parts, and maintenance or refurbishment of high-value equipment. CNC allows tight tolerances on complex 3D geometries and ensures consistency between batches and over long service lifetimes.

Energy Segments Using CNC Machining

Different energy segments impose distinct mechanical and environmental requirements, which directly influence material choices, tolerances, and machining strategies.

Oil and Gas

Oil and gas components operate in high-pressure, corrosive, and often abrasive environments. CNC machining is widely used for:

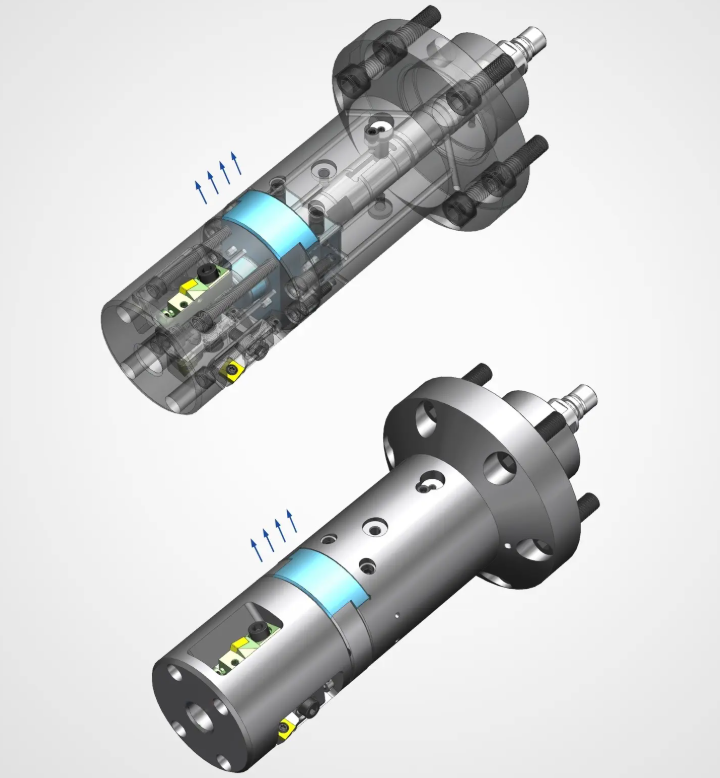

- Downhole tools: mandrels, subs, collars, stabilizers, drilling motors, and measurement-while-drilling (MWD) housings

- Wellhead and subsea equipment: valves, connectors, hubs, flanges, clamps, and tree blocks

- Surface equipment: pumps, compressor components, manifolds, actuator housings, and fittings

Parts must withstand sour service conditions (H2S), high external pressure for subsea operations, and repeated load cycles. CNC machining enables precise sealing surfaces, threaded connections (API, premium threads), and internal flow paths that minimize turbulence and erosion.

Power Generation (Conventional and Nuclear)

For thermal power and nuclear plants, CNC machining supports high-temperature, high-stress applications, including:

- Steam and gas turbine components: blades (airfoils), discs, casings, rotor shafts, and diaphragms

- Boiler and heat exchanger parts: tube sheets, headers, flanges, and support structures

- Nuclear systems: reactor internals, control rod components, pump and valve parts for primary and secondary loops

Critical considerations include creep resistance, fatigue resistance, dimensional stability at temperature, and strict quality documentation. Machining must accommodate heat-resistant superalloys and stainless steels while maintaining tight geometry and surface integrity.

Renewable Energy

Renewable energy systems integrate both metallic and non-metallic components, with CNC machining used for:

Wind energy: hubs, main shafts, bearing housings, gearbox housings, yaw and pitch components, brake components, and tower connection flanges.

Hydropower: turbine runners, guide vanes, wicket gates, shafts, and bearing components.

Solar and energy storage: precision mounting structures, tracking system parts, cooling plates, battery housings, and connection hardware.

Key requirements include structural stability, resistance to fatigue and corrosion in outdoor environments, and compatibility with large-scale assembly and maintenance operations.

Key CNC Processes for Energy Components

Energy components use a combination of turning, milling, drilling, grinding, and other processes. The choice depends on component size, geometry complexity, and tolerance requirements.

CNC Turning

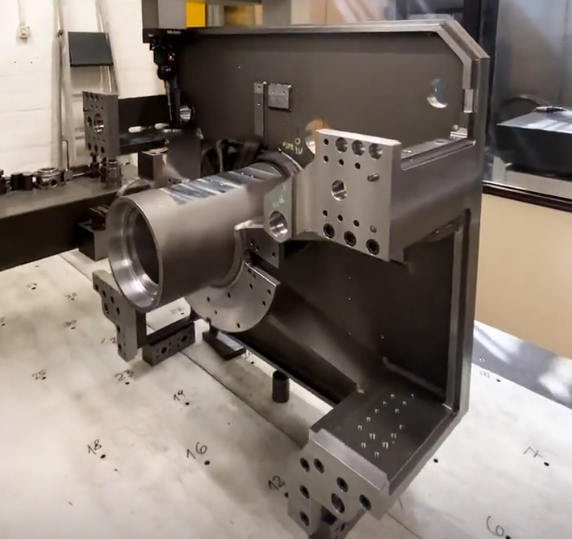

CNC turning is used for rotationally symmetric parts such as shafts, collars, rings, hubs, and tubular components. In the energy sector, many components are long and heavy, often requiring large-bore lathes and steady-rest support.

Typical capabilities include:

- Diameter ranges from below 10 mm up to over 1,000 mm on heavy-duty lathes

- Length up to several meters for shafts and tubulars

- Standard dimensional tolerances in the IT7–IT9 range, with tighter tolerances achievable when required

Turning operations commonly include API and premium thread machining, taper turning, grooving for seals, and precision facing of critical sealing surfaces.

CNC Milling

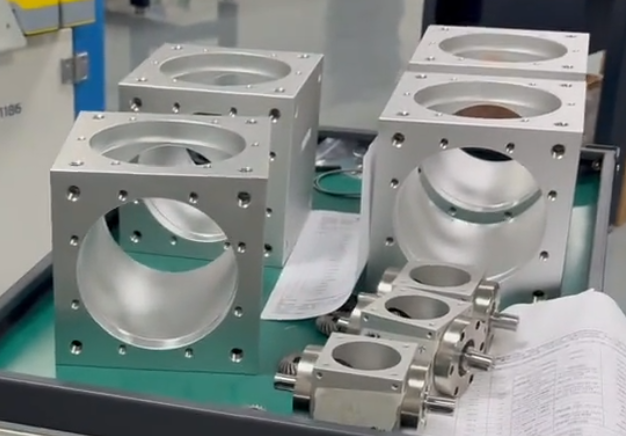

CNC milling produces complex 3D geometries and features such as pockets, slots, mounting surfaces, and bolt patterns. For energy equipment, milling is frequently used for:

Valve and pump bodies, manifolds and blocks with internal flow passages, turbine casings, mounting brackets, and structural frames. Multi-axis (3-axis, 4-axis, and 5-axis) machining centers enable contouring of complex surfaces and reduce setups. This is essential for airfoils, curved manifolds, and complex housings.

CNC Drilling, Boring, and Deep Hole Machining

Deep and accurate holes are widely used in the energy industry for flow channels, instrumentation, and internal passages. Deep hole drilling and boring operations can produce straight bores with controlled surface finish and minimal deviation, even at high length-to-diameter ratios.

Energy components often require:

- Long inner bores in downhole tools and tubular accessories

- Accurate bolt holes and stud patterns in flanges and tower joints

- Cooling, lubrication, and instrumentation passages in turbines and compressors

Grinding and Finishing

Grinding is used where tight dimensional tolerances and surface finishes are needed, especially on sealing surfaces, bearing journals, and precision shafts. In energy systems, surface finish directly affects sealing performance, wear, and fatigue behavior.

Additional finishing processes may include honing of internal bores, lapping of sealing surfaces, and deburring of flow paths to minimize turbulence and reduce the risk of crack initiation.

Materials for Energy CNC Machining

Material selection in the energy sector is closely tied to corrosion resistance, high-temperature strength, fatigue, and compatibility with media such as hydrocarbons, steam, seawater, or nuclear coolants. Machinability varies significantly among these materials and influences process planning and costs.

| Material Group | Typical Grades | Key Properties | Typical Applications |

|---|---|---|---|

| Carbon & Low-Alloy Steels | AISI 1045, 4140, 4340, 4130, low-alloy structural steels | Good strength, moderate cost, heat-treatable, reasonable machinability | Shafts, structural parts, flanges, gear components, general hardware |

| Stainless Steels | 304/304L, 316/316L, 410, 420, 17-4PH, duplex and super-duplex (e.g., UNS S31803, S32750) | Corrosion resistance, sour service capability, good strength; duplex grades for high chloride environments | Subsea hardware, valve components, manifolds, pump parts, turbine components |

| Nickel-Based Alloys | Inconel 625, Inconel 718, Hastelloy C-276, Alloy 400 (Monel) | High strength at elevated temperature, excellent corrosion and oxidation resistance, often difficult to machine | Gas turbine hot-section parts, high-temperature fasteners, sour service components, critical subsea parts |

| Titanium Alloys | Ti-6Al-4V and other alpha-beta alloys | High strength-to-weight ratio, good corrosion resistance, lower modulus, relatively difficult to machine | Offshore components where weight reduction is important, high-performance fasteners, some turbine parts |

| Copper Alloys | Copper-nickel alloys, bronzes, brasses | Good thermal and electrical conductivity, corrosion resistance in seawater (for specific copper alloys) | Heat exchangers, cooling components, bushings, some hydraulic components |

| Aluminum Alloys | 6000 and 7000 series (e.g., 6061, 6082, 7075) | Low density, good machinability, good thermal conductivity, moderate strength depending on grade and temper | Mounting structures, housings, battery and electronics enclosures, solar tracking components |

| Engineering Plastics & Composites | PEEK, PTFE, Nylon, reinforced composites | Low weight, chemical resistance, electrical insulation, specific wear properties | Seals, insulators, low-friction components, some structural parts with limited load |

Design Guidelines for Energy CNC Components

Effective design for CNC machining in energy applications reduces manufacturing time, enables reliable performance, and helps control costs. Geometric features, tolerances, and material choices should be aligned with standard tooling and machining capabilities.

Tolerances and Fits

Energy components frequently employ fits for rotating shafts, bearing seats, sealing surfaces, and bolted joints. Excessively tight tolerances may significantly increase machining costs and inspection requirements without improving performance.

Typical practice includes:

- General features: tolerances in the range of ±0.05 mm to ±0.2 mm for non-critical dimensions

- Precision fits: tighter tolerances such as ±0.01 mm or better for bearing seats and sealing surfaces

- Flatness and parallelism: defined based on sealing or alignment needs; local functional surfaces often require stricter geometric tolerances than the rest of the part

Threaded Connections

Threaded connections are central in the energy sector, particularly in oil and gas tubulars, wellhead components, and high-pressure systems. Design should respect standard thread forms (API, ASME, ISO) to simplify machining and avoid custom tooling.

Considerations include:

Adequate relief grooves and run-outs for thread tool exit, sufficient wall thickness behind threads to avoid deformation under load, and clear specification of thread class, form, and any special surface finish or coating requirements.

Wall Thickness and Structural Features

Wall thickness affects both mechanical performance and manufacturability. Very thin walls in heavy components can lead to distortion during machining and under service conditions.

Design guidelines include avoiding unnecessarily thin walls, providing uniform wall thickness when possible to reduce residual stresses, and adding ribs or gussets to reinforce high-load areas while managing weight.

Features for Assembly and Maintenance

Energy installations are often located in remote or subsea environments. Design should facilitate assembly and disassembly, considering alignment features, lifting points, and access for tools and inspection.

Machinable flats for wrench engagement, clearances for bolt insertion and tightening, and accessible measurement points for in-situ inspection improve long-term maintainability.

Dimensional Accuracy and Surface Finish Requirements

Dimensional accuracy and surface finish requirements in the energy sector are closely linked to pressure containment, flow performance, fatigue resistance, and sealing integrity. These requirements are often derived from industry standards and internal specifications.

Typical Dimensional Accuracy Ranges

General-machined features may use standard tolerances based on ISO 2768 or similar frameworks. Precision areas such as bearing journals, sealing diameters, and mating surfaces typically require individually specified tolerances.

In many power and oil and gas applications, critical components demand tight runout and concentricity specifications to ensure stable rotation, uniform load distribution, and correct sealing.

Surface Finish Targets

Surface finish directly impacts friction, wear, corrosion initiation, and performance of seals. Common ranges include:

- General surfaces: moderate roughness values suitable for structural and non-sealing features

- Sealing surfaces and bearing seats: finer finishes achieved via grinding, honing, or lapping

- Flow-contact surfaces: controlled finish to balance pressure drop, erosion resistance, and cost

Typical Energy Components and Their Machining Requirements

Energy components have specific sizing, material, and tolerance requirements that influence process selection and cost. The following table provides representative examples.

| Component Type | Typical Size Range | Common Materials | Key Machining Requirements |

|---|---|---|---|

| Downhole tool body | Outer diameter often 50–200 mm; length up to several meters | High-strength steels, nickel alloys, non-magnetic stainless for specific tools | Deep hole drilling, precision threads, impact-resistant features, controlled straightness |

| Subsea valve body | Block or body up to hundreds of kilograms | Duplex/super-duplex stainless steel, nickel alloys | Complex internal flow paths, tight sealing surfaces, corrosion-resistant surface condition |

| Steam turbine blade root and dovetail | Blade lengths from tens of millimeters to over one meter | Stainless steels, nickel alloys | Accurate root profile, smooth surface finish, controlled fillet radii to manage stress |

| Wind turbine hub | Diameter often over 1 m, large mass castings | Cast steels or iron with machined interfaces | High-accuracy bolt circles, bearing seat machining, large-scale fixturing and alignment |

| Heat exchanger tube sheet | Thickness from tens to hundreds of millimeters; diameter from under 1 m to several meters | Carbon steel, stainless steel, copper alloys, nickel alloys | Large arrays of precision-drilled holes, flatness control, deburring for clean flow |

| Gearbox housing (wind or hydro) | Medium to large castings | Cast iron, cast steel | Boring of bearing seats, alignment of shaft axes, surface preparation for sealing |

Quality Control, Standards, and Documentation

Energy components are often classified as safety-related or critical, requiring rigorous quality control, traceability, and adherence to international standards. Quality assurance covers raw materials, machining processes, inspection, and documentation.

Inspection and Measurement

Inspection methods commonly used include coordinate measuring machine (CMM) checks for complex geometries and critical dimensions, surface roughness measurement with contact or non-contact instruments, thread gauges for standard and premium threads, and non-destructive testing (NDT) such as ultrasonic, magnetic particle, dye penetrant, and radiographic inspection for critical pressure-containing parts.

Relevant Standards and Specifications

While detailed standards differ between segments and regions, energy CNC machining commonly references:

- Dimensional and geometric tolerances: ISO and ASME standards for tolerancing and fits

- Pressure equipment: international codes for pressure vessels and piping

- Oil and gas: API specifications and relevant standards for materials and equipment

- Nuclear: industry and regulatory standards governing materials, fabrication, and quality assurance

Suppliers often implement documented quality management systems, material traceability, and process controls to meet these requirements.

Energy CNC Machining Costs: Structure and Drivers

Cost estimation for CNC machining in the energy sector requires a structured view of all contributors: material, machining time, tooling, inspection, and overhead. Large part sizes, hard-to-machine materials, and stringent quality demands are major cost drivers.

Material Costs

Material cost is influenced by alloy type, stock form, and required certifications. Nickel alloys, duplex stainless steels, and titanium are significantly more expensive than carbon steels and common stainless grades. Heavy forgings and large-diameter bars increase total material cost and may require special logistics.

Material utilization also affects cost. Complex parts machined from solid blocks may generate high scrap volumes. Near-net-shape forgings or castings can reduce machining time and material waste but may increase raw part cost and lead time.

Machine Time and Hourly Rates

Machining time is strongly influenced by part geometry, tolerances, and material machinability. Harder materials and heat-resistant alloys typically require lower cutting speeds, more passes, and more frequent tool changes, increasing total time.

Hourly machine rates vary based on machine size and complexity. Large horizontal boring mills, heavy-duty lathes for long shafts, or multi-axis machining centers typically command higher hourly rates than standard machines due to higher investment and operating costs.

Tooling and Consumables

Tooling costs increase with difficult-to-machine materials and complex geometries. In nickel alloys and duplex steels, cutting tools wear faster, and special tool grades or coatings are often required. Tooling costs include inserts, drills, end mills, reamers, and specialized form tools, as well as fixtures and clamping systems tailored to specific components.

Setup, Programming, and Fixturing

Energy components may require complex fixturing because of size, weight, and geometric requirements. Initial design and manufacture of custom fixtures represent a one-time cost but must be considered for low-volume production.

Programming time for multi-axis machining or complex internal flow paths can be significant. Process planning and simulation may be needed to ensure collision-free tool paths and optimized cutting strategies.

Inspection and Testing Costs

High-level inspection requirements can be a significant portion of total part cost. Activities include detailed dimensional inspections, surface roughness measurements, NDT, and pressure or functional testing. Documentation preparation, such as inspection reports, material traceability records, and certification packages, also adds time and cost.

Batch Size and Repetition

Batch size strongly affects unit cost. Larger production runs spread programming and fixture costs over more parts, enabling more aggressive process optimization. For one-off or small batch energy components, per-piece costs are higher due to the proportionally larger impact of setup, programming, and qualification.

Cost Estimation Approach for Energy CNC Parts

To estimate CNC machining cost for an energy component, it is useful to follow a structured approach that considers all major elements. While specific numeric values depend on region, supplier, and material markets, the structure of the calculation is relatively consistent.

1) Define Requirements and Scope

Accurate cost estimation begins with a clear definition of requirements. This includes 3D models and fully dimensioned drawings, material specifications and certification requirements, quantity and delivery schedules, inspection and testing scope, and any special requirements (surface treatments, coatings, documentation format).

2) Estimate Material Cost

Material cost is calculated based on the volume of raw stock required, material density, and market price per unit weight. For large forgings or castings, supplier quotations are typically required. The estimator considers cutting allowances and extra stock for fixturing and potential distortions.

3) Calculate Machining Time

Machining time is estimated from process plans that break the part down into operations. For each operation, expected machine time per pass, number of passes, tool changes, and handling time are evaluated. CAM software can provide time estimates, which are then adjusted based on experience, allowance for interrupts, and machine utilization.

4) Add Tooling, Setup, and Programming

Tooling costs are estimated based on expected tool life, number of inserts or tools consumed, and any special tooling or fixtures that must be designed and manufactured. Setup and programming time are converted to cost using engineering and setup labor rates, then distributed across the batch size.

5) Include Inspection, Testing, and Documentation

Inspection plans specify which features are measured and by what methods. Time for CMM programs, manual gauging, NDT, and report generation is estimated and converted to cost. For pressure-containing parts or safety-class components, additional testing (e.g., hydrostatic testing) is included.

6) Apply Overhead and Margin

Suppliers apply overhead to cover facility costs, equipment depreciation, quality systems, and administration. A margin is then added to ensure sustainable operation. The final quotation reflects all cost elements plus risk allowances aligned with project complexity.

Considerations When Selecting an Energy CNC Machining Partner

Choosing a machining supplier for energy components involves more than price. Capability, experience, and control systems strongly influence reliability and total lifecycle cost of equipment.

Capacity and Equipment Range

Energy components can be extremely large or long. Suppliers must have machines capable of handling the required dimensions, weights, and tolerances. This may include long-bed lathes for tubulars and shafts, large vertical or horizontal machining centers for housings and hubs, and lifting and handling systems for heavy workpieces.

Experience with Energy Alloys

Suppliers should demonstrate experience machining materials used in energy applications, such as duplex stainless, nickel alloys, and high-strength steels. Evidence of robust cutting data, tool management, and distortion control improves confidence in the supplier's ability to deliver consistent quality.

Quality Systems and Traceability

Effective quality management systems are essential. Suppliers should maintain material traceability with mill certificates and heat numbers, documented process controls with controlled work instructions and inspection plans, calibrated measurement equipment, and complete documentation packages aligned with customer and regulatory expectations.

Delivery, Logistics, and After-Sales Support

Energy projects often operate on tight schedules. Suppliers must plan production to meet delivery windows and handle shipping of large or heavy parts. For long-term programs, the ability to sustain consistent production and support spare parts and refurbishment is valuable.