40Mn4 (EN 10083) and AISI 1040 (SAE 1040) are widely used medium-carbon steels offering a balanced combination of strength, toughness and cost. They are commonly specified for shafts, axles, bolts, connecting rods and other mechanical parts requiring better mechanical properties than low-carbon steels, but without the high cost of alloy grades.

Steel Designation, Standards and Equivalents

40Mn4 and 1040 belong to the same general family of 0.40% carbon steels, but they arise from different standard systems. Understanding the equivalence range is essential when substituting grades across regions.

| System / Region | Designation | Remarks |

|---|---|---|

| EN (Europe) | 40Mn4 | Standard medium-carbon steel; material number approx. 1.0516 |

| DIN (legacy) | C40E / 40Mn4 | Similar to EN; suffixes may indicate special requirements (e.g. controlled S, P) |

| AISI / SAE (USA) | 1040 | Plain carbon steel with ~0.40% C, no deliberate alloy additions |

| ISO | C40 / Ck40 | International designation; composition close to 1040 / 40Mn4 |

| BS (UK) | 080M40 | British equivalent to C40-type medium carbon steel |

Although 40Mn4 and 1040 are often used interchangeably, minor differences in manganese content, impurity control and heat-treatment practice can lead to small variations in properties. For critical components, specifications should refer explicitly to the relevant standard and property requirements rather than only the grade name.

Chemical Composition

The composition of 40Mn4 / 1040 is centered around 0.40% carbon, with limited alloying. Manganese is the main intentional alloying element used to improve hardenability and strength while maintaining reasonable toughness and machinability.

| Element | 40Mn4 (EN) typical range | 1040 (AISI/SAE) typical range |

|---|---|---|

| C | 0.37 – 0.44 | 0.37 – 0.44 |

| Mn | 0.70 – 1.00 | 0.60 – 0.90 |

| Si | 0.15 – 0.40 | ≤ 0.35 (typical) |

| P | ≤ 0.035 | ≤ 0.040 |

| S | ≤ 0.035 | ≤ 0.050 |

| Cr | ≤ 0.25 (residual) | ≤ 0.20 (residual) |

| Ni | ≤ 0.30 (residual) | ≤ 0.25 (residual) |

| Mo, V, others | Residual / not intentionally added | Residual / not intentionally added |

The relatively modest carbon content provides significantly higher strength than low-carbon steels but still allows weldability and formability if appropriate procedures are followed. Modest manganese content enhances hardenability and contributes to strength and wear resistance.

Microstructure and Metallurgical Features

The microstructure of 40Mn4 / 1040 steel depends strongly on its thermal history. In the hot-rolled or normalised condition, the structure is predominantly ferrite and pearlite. After quenching and tempering, martensite and tempered martensite dominate, potentially with some bainite depending on section size and quench severity.

Key microstructural aspects include:

- Ferrite-pearlite balance: In normalised condition, a fine ferrite-pearlite structure yields a good compromise between strength and ductility for general engineering use.

- Hardenability: Due to moderate carbon and manganese levels, 40Mn4 / 1040 has limited through-hardening capability in large cross-sections. Thin sections can achieve high hardness with oil or water quenching, while thick sections may exhibit hardness gradients.

- Carbide formation: During tempering of quenched steel, iron carbides precipitate and coarsen, leading to controlled reduction of hardness and improvement of toughness.

Controlling grain size via normalising or appropriate austenitising practice is important for achieving consistent mechanical properties and minimising brittleness.

Mechanical Properties

Mechanical properties of 40Mn4 / 1040 depend on delivery condition, heat treatment, and product form (bar, forging, plate). Typical property ranges for selected conditions are outlined below; exact values should always be confirmed with mill certificates or relevant standards.

Typical mechanical properties (indicative ranges)

- As rolled / normalised (tensile strength Rm): approximately 540 – 680 MPa

- As rolled / normalised (yield strength Re): approximately 300 – 430 MPa

- Elongation A5: around 16 – 25%

- Reduction of area Z: around 35 – 55%

- Brinell hardness (HB): approximately 140 – 210 HB in normalised state

- Quenched and tempered to higher strength: tensile strength up to about 700 – 900 MPa (depending on tempering temperature and section size)

At higher strength levels obtained by quench and temper, toughness and ductility decrease. Designers should balance the required strength with impact performance, especially for dynamically loaded parts.

Physical and Thermal Properties

40Mn4 / 1040 steel has physical properties comparable to other plain carbon steels. These parameters are important for thermal processing, dimensional stability and heat transfer calculations.

Typical physical and thermal properties at room temperature (approximate values):

- Density: about 7.85 g/cm³

- Modulus of elasticity (Young’s modulus): about 205 – 210 GPa

- Poisson’s ratio: approximately 0.29 – 0.30

- Thermal conductivity: around 45 – 52 W/(m·K)

- Specific heat capacity: about 0.45 – 0.50 kJ/(kg·K)

- Linear thermal expansion coefficient (20–100 °C): roughly 11 – 12 × 10⁻⁶ /K

Thermal expansion and thermal conductivity are important for assessing dimensional accuracy in high-temperature service or repeated heating and cooling cycles, as well as for distortion control during heat treatment.

Heat Treatment of 40Mn4 / 1040 Steel

Heat treatment is a core method to tailor the properties of 40Mn4 / 1040 steel. This steel responds well to normalising, annealing, quenching and tempering, as well as surface hardening processes such as induction hardening and flame hardening.

Normalising

Normalising refines the grain structure, relieves residual stresses from forging or rolling, and produces a more uniform ferrite-pearlite microstructure.

- Typical austenitising temperature: about 840 – 880 °C

- Holding time: sufficient to equalise temperature (commonly 30–60 minutes depending on section)

- Cooling: air cooling in still air

The resulting structure offers moderate strength and good toughness and machinability, suitable for many general engineering components.

Annealing

Annealing aims to soften the steel, improve machinability and enhance cold workability by producing a coarse pearlitic and ferritic structure with lower hardness.

- Typical full annealing temperature: approximately 800 – 840 °C

- Soaking: adequate to ensure uniform temperature throughout the section

- Cooling: slow furnace cooling to about 600 °C then air-cooling

Annealed hardness typically falls in the lower part of the 40Mn4 / 1040 range, facilitating turning, drilling and other machining operations.

Quenching and Tempering

Quenching and tempering are used to obtain higher strength and wear resistance for more demanding applications such as shafts and gears.

- Austenitising temperature for quenching: usually 830 – 870 °C

- Quenching medium: oil is common; water or polymer quench may be used with caution due to risk of cracking or excessive distortion

- Tempering temperature: typically 200 – 650 °C depending on required hardness and toughness

Lower tempering temperatures (around 200 – 250 °C) give higher hardness but lower toughness, while higher tempering temperatures (above 500 °C) produce lower hardness and improved ductility and impact resistance. Effective section size should be considered, as 40Mn4 / 1040 does not have the deep hardenability of alloy steels.

Stress Relieving

Stress-relief heat treatment reduces residual stresses from machining, cold work or welding.

- Typical stress-relief temperature: around 500 – 650 °C

- Holding time: usually 1 – 2 hours depending on section thickness

- Cooling: air cooling

This treatment helps minimise distortion in service and improves dimensional stability without drastically changing mechanical properties.

Surface Hardening and Case Hardening

Because of its carbon content and response to rapid heating, 40Mn4 / 1040 is widely used with surface hardening processes to improve wear resistance on critical surfaces while retaining a tougher core.

Induction and Flame Hardening

Surface hardening by induction or flame heating followed by rapid quenching is common for parts such as shafts, pins, gears and cam components.

- Surface heating: localized rapid heating of the surface layer to austenitising temperature (often 850 – 900 °C)

- Quenching: usually water spray or polymer solution to transform surface austenite to martensite

- Surface hardness: typically around 50 – 58 HRC depending on heating and quench parameters

- Case depth: can range from about 1 – 5 mm, depending on frequency (induction), heating time and part size

After hardening, a low-temperature temper (for example 150 – 200 °C) is frequently applied to reduce brittleness while preserving high surface hardness.

Carburising Considerations

40Mn4 / 1040 already contains about 0.4% carbon, which is higher than typical carburising steels (often ~0.15 – 0.25% C). Carburising is therefore less common for this grade. When deep hardened case with very high surface carbon is required, lower-carbon case-hardening steels usually offer better control over case depth and core toughness. For 40Mn4 / 1040, induction hardening or flame hardening are usually preferred surface-hardening options.

Machinability of 40Mn4 / 1040 Steel

Machinability is one of the important reasons for the popularity of 40Mn4 / 1040 steel in medium-duty engineering applications. In the annealed or normalised condition, it can be machined with standard high-speed steel (HSS) or carbide tools.

Machinability Rating and General Behaviour

In many machining rating systems where free-cutting low-carbon steel (such as AISI 1112) is taken as 100%, AISI 1040 typically has a machinability rating in the range of about 55 – 65%. This reflects moderate cutting forces and reasonable tool life when appropriate cutting conditions are selected.

In hardened or induction-hardened condition, machinability decreases significantly, and grinding or hard turning with appropriate carbide or CBN tools is often required for finishing.

Cutting Tool Selection and Cutting Conditions

For machining 40Mn4 / 1040 steel in annealed or normalised condition:

- Tool materials: HSS tools for low to medium cutting speeds; coated carbide tools for higher productivity and improved tool life.

- Cutting speeds: moderate cutting speeds depending on tool material and cooling method; lower speeds are advisable in continuous heavy-duty operations to control heat and wear.

- Feed rates: adjusted to maintain sufficient chip load for thermal stability while avoiding excessive forces that might cause vibration or tool chipping.

- Coolants: water-soluble cutting fluids or emulsions often improve surface finish and tool life by lowering interface temperature and helping chip evacuation.

Chips are usually continuous; chip breakers and appropriate feed are recommended to avoid long spiral chips in drilling and turning. For high-volume production, process optimization often focuses on balancing tool life and cycle time.

Pain Points and Practical Considerations in Machining

Several practical issues may arise when machining 40Mn4 / 1040 steel:

- Work hardening at the surface: When cutting parameters are too low or tools are dull, localized work hardening can occur, making subsequent passes more difficult and degrading surface integrity.

- Tool wear at higher hardness: If the material is in partially hardened condition (for example after improper heat treatment), cutting forces and abrasive wear can increase significantly.

- Dimensional control after heat treatment: Machining close to final dimensions before quench and temper can lead to out-of-tolerance parts due to distortion. Allowing a machining allowance for grinding or finishing after heat treatment mitigates this risk.

Planning machining sequence together with heat treatment and stress-relief steps is critical for components requiring tight tolerances and high strength.

Forming, Forging and Cold Work

40Mn4 / 1040 steel exhibits reasonable hot formability and moderate cold workability, but its 0.4% carbon content puts limits on extensive cold forming operations compared to low-carbon steels.

Hot Forging

Hot forging is frequently used for producing preforms for shafts, axles, brackets and connecting rods.

- Recommended forging temperature range: typically starting around 1150 – 1200 °C and finishing not below roughly 850 – 900 °C.

- Post-forging: air cooling or normalising is commonly applied to refine grain size and homogenise microstructure.

Forged components are often subsequently machined and heat treated to the final property profile. Control of cooling rate after forging is important to avoid excessive hardness or uneven properties in heavy sections.

Cold Forming

Cold forming operations such as bending, light drawing or upsetting are possible, but ductility is limited compared to low-carbon steels. When extensive cold deformation is required, preliminary annealing can improve formability by lowering hardness and increasing ductility.

Overly aggressive cold forming without intermediate annealing may lead to cracking or residual stress concentration, particularly in edges or sharp radii. Design for manufacturability should account for bend radii, reduction ratios and material condition.

Weldability and Joining

Because of its medium carbon content, 40Mn4 / 1040 steel is not as readily weldable as low-carbon steels, but it can be successfully welded with proper precautions. The main concern is the formation of hard and brittle heat-affected zones (HAZ) and cold cracking, especially in thick sections or highly restrained joints.

Fusion Welding

Common welding methods include shielded metal arc welding (SMAW), gas metal arc welding (GMAW / MIG/MAG), gas tungsten arc welding (GTAW / TIG), and submerged arc welding (SAW). Key recommendations typically include:

- Preheating: often in the range of about 150 – 250 °C depending on thickness, restraint and hydrogen control; this reduces cooling rate and minimises risk of martensite formation in HAZ.

- Interpass temperature control: maintaining adequate interpass temperature (often near the preheat temperature) to avoid excessive hardness and hydrogen accumulation.

- Low-hydrogen consumables: use of low-hydrogen electrodes or filler wires to reduce susceptibility to hydrogen-induced cracking.

- Post-weld heat treatment (PWHT): stress relieving or tempering can be applied to reduce residual stresses and temper hard HAZ structures, particularly for heavily loaded components.

The selection of filler metal is typically geared towards matching the strength of the base material while maintaining adequate toughness. In some cases, slightly lower-strength, more ductile filler may be chosen to improve joint toughness.

Brazing and Mechanical Joining

For components where high-strength welded joints are not strictly required, brazing or mechanical fastening (bolting, press fits) can be preferable. Brazing temperatures must be controlled to avoid undesirable microstructural transformations or significant softening, and subsequent normalising or tempering may be used when necessary.

Corrosion Resistance and Surface Protection

40Mn4 / 1040 steel has low intrinsic corrosion resistance similar to other unalloyed and low-alloy carbon steels. In most service environments where moisture, oxygen and corrosive species are present, protective measures are necessary.

Common surface protection strategies include:

- Painting or powder coating: widely used for structural and machinery parts exposed to atmospheric conditions.

- Plating: zinc plating, nickel plating or other metal coatings provide sacrificial or barrier protection against corrosion.

- Phosphating and oiling: used for temporary corrosion protection and improved lubricity in cold forming or machining.

- Surface hardening plus lubrication: in wear-critical components, hardened surfaces combined with lubrication can mitigate both wear and corrosion to some degree.

For environments requiring high intrinsic corrosion resistance (e.g. marine, chemical processing), alloy steels or stainless steels are usually selected instead of 40Mn4 / 1040.

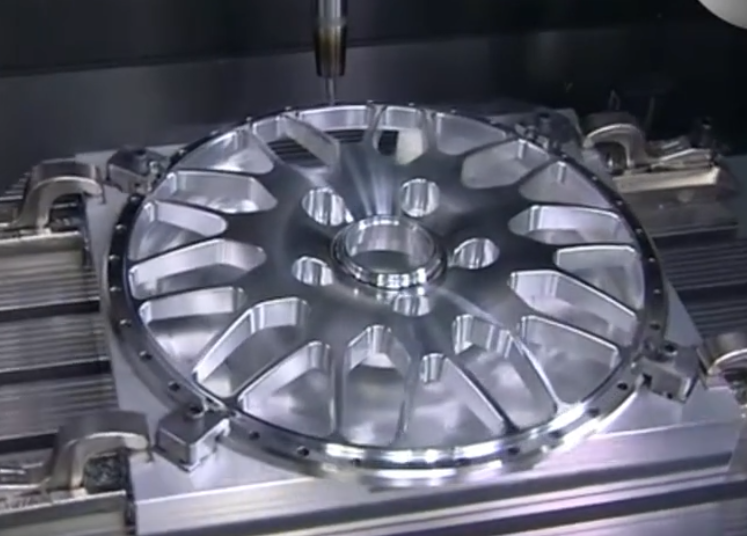

Applications of 40Mn4 / 1040 Steel

Due to its balanced mechanical properties and cost-effectiveness, 40Mn4 / 1040 steel is widely used in general engineering applications, automotive components, agricultural machinery and machine-building sectors.

General Engineering Components

In normalised or quenched-and-tempered condition, 40Mn4 / 1040 is used for many rotating and static components, including:

- Shafts and axles for industrial machinery, conveyors and transmission systems.

- Couplings, flanges, sleeves and hubs requiring moderate strength and toughness.

- Bolts, studs, pins and fasteners when higher strength than mild steel is required.

- Connecting rods, levers, brackets and linkages in mechanical assemblies.

The grade’s ability to be machined, heat treated and locally surface hardened allows designers to tailor performance without resorting to higher-alloy steels in many cases.

Automotive and Transportation Parts

In vehicles and transportation equipment, 40Mn4 / 1040 steel finds use in:

- Crankshafts and camshafts for small and medium power engines (often using induction-hardened journals and lobes).

- Steering shafts, gear shafts, axle components and transmission elements.

- Suspension and chassis parts requiring medium strength and fatigue resistance.

Induction hardening of bearing surfaces and splines on 1040 shafts is a common solution to achieve high surface wear resistance combined with a tough core resistant to impact loads.

Power Transmission and Machine-Building

In power transmission and machine-building industries, typical applications include:

- Gears, sprockets and toothed parts where surface hardening provides wear resistance.

- Spindles, rollers and guide rails subjected to friction and moderate loads.

- Keys, wedges, couplings and bushings requiring good machinability and reliable mechanical strength.

For heavy-duty gears and highly stressed power transmission components in large cross-sections, alloy steels with higher hardenability are often selected, whereas 40Mn4 / 1040 is well suited to small and medium-sized components.

Mechanical and Agricultural Equipment

In agricultural machinery, construction equipment and industrial tools, 40Mn4 / 1040 is used for:

- Drive shafts, PTO components, connecting elements and linkages.

- Wear parts with local hardening such as pins and bushings.

- Hydraulic system components requiring turned or ground surfaces and moderate pressure resistance.

The availability in a wide range of bar sizes and shapes makes 40Mn4 / 1040 convenient for maintenance and replacement parts as well as OEM production.

Standards, Delivery Conditions and Quality Considerations

40Mn4 / 1040 steels are supplied according to national and international standards that define chemical composition, mechanical properties, dimensional tolerances and inspection requirements. Common delivery conditions include as-rolled, normalised, quenched and tempered, and sometimes spheroidised-annealed for improved machinability.

When specifying 40Mn4 / 1040, key aspects to consider include:

- Required mechanical property range (tensile strength, hardness, impact energy) and corresponding heat treatment condition.

- Dimensional tolerances and straightness requirements, especially for long shafts and bars.

- Ultrasonic or other non-destructive testing requirements for critical components in safety-relevant applications.

- Surface quality specifications (decaburization limits, scale removal, surface roughness) depending on downstream processes.

Close coordination between design, procurement and heat treatment providers is essential to ensure that finished parts meet both standard requirements and application-specific performance criteria.