CNC machining services provide precise, repeatable, and cost-effective manufacturing of complex metal and plastic components. By combining computer-controlled machine tools with digital design data, CNC machining enables rapid prototyping, functional testing, and end-use production across multiple industries.

What Is CNC Machining Service

CNC (Computer Numerical Control) machining service is a manufacturing solution in which a service provider uses CNC-controlled machine tools to produce parts according to customer-supplied CAD and technical documentation. Toolpaths are generated via CAM (Computer-Aided Manufacturing) software, and machines execute these instructions with minimal manual intervention.

Service providers typically offer a combination of milling, turning, drilling, tapping, boring, and secondary operations, along with material sourcing, inspection, finishing, and logistics support. Parts can be produced as one-off prototypes, small batches, or large production runs.

Key attributes include dimensional accuracy, tight tolerances, good surface finish, wide material flexibility, and compatibility with complex geometries that may be difficult or impossible to make by conventional manual machining.

Core CNC Machining Processes

CNC machining services integrate different subtractive processes to cover a wide design space. The main processes are milling, turning, and drilling, supplemented by specialized techniques and secondary operations.

CNC Milling

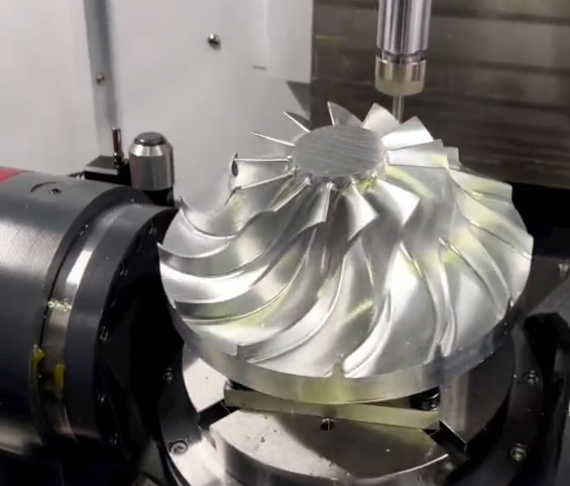

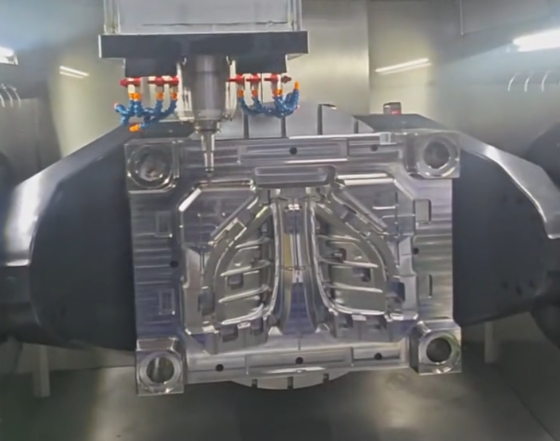

CNC milling uses a rotating cutting tool to remove material from a stationary or moving workpiece. Multi-axis milling centers allow complex 3D surfaces to be created with high precision.

Typical milling configurations include vertical machining centers (VMC), horizontal machining centers (HMC), and 3-axis, 3+2 axis, or full 5-axis machines. Milling is suitable for prismatic parts, complex contours, pockets, slots, holes, and functional surfaces.

Common milling capabilities:

- Flat, stepped, and contoured surfaces

- Pockets, slots, and keyways

- Chamfers, fillets, and deburring features

- Thread milling and interpolated holes

CNC Turning

CNC turning rotates the workpiece while a stationary cutting tool removes material. It is ideal for cylindrical, conical, and disc-shaped components. Turning centers may include live tooling and sub-spindles, combining turning and milling in a single setup.

Applications include shafts, bushings, pins, fasteners, flanges, and housings. CNC turning is often more efficient than milling for rotational symmetry and is widely used for both prototypes and high-volume production.

Drilling, Boring, and Tapping

Drilling creates round holes with rotating drill bits, boring enlarges and improves the accuracy of existing holes, and tapping cuts internal threads. These operations are often integrated into milling and turning cycles.

Service providers commonly support precise hole location, deep hole drilling with coolant, and threaded features such as UNC, UNF, metric coarse and fine, pipe threads, and custom threads based on drawings.

Multi-Axis and Complex Machining

Multi-axis CNC machines combine rotations and translations to position the tool at various angles relative to the workpiece. 4-axis and 5-axis machining reduce setups, improve accuracy over multiple faces, and enable more complex geometries such as undercuts, sculpted surfaces, and compound angles.

These capabilities are valuable for aerospace, medical, and mold applications where part geometry and feature interrelationships are demanding.

Secondary and Complementary Operations

Many CNC machining services also provide secondary operations to deliver finished, ready-to-use parts. These can include deburring, knurling, reaming, broaching, basic assembly, and integration of threaded inserts or dowel pins. Coordinate measuring machine (CMM) inspection and functional testing are often available for critical components.

Materials for CNC Machining

CNC machining services support a broad spectrum of metals and plastics. Material selection affects machinability, strength, weight, cost, thermal behavior, and corrosion resistance. Selecting the right material is essential for performance, manufacturability, and cost-effectiveness.

Metals

Metallic materials dominate CNC machining due to high mechanical performance and thermal stability.

| Material | Key Properties | Typical Applications |

|---|---|---|

| Aluminum 6061 | Good strength-to-weight ratio, excellent machinability, good corrosion resistance, weldable | General housings, brackets, fixtures, prototypes, consumer electronics |

| Aluminum 7075 | Very high strength, lower corrosion resistance than 6061, good fatigue performance | Aerospace components, high-stress structural parts, performance sporting goods |

| Stainless Steel 304 | Excellent corrosion resistance, non-magnetic in annealed condition, good formability | Food processing equipment, chemical handling parts, architectural components |

| Stainless Steel 316 | Enhanced corrosion resistance, especially in chloride environments | Marine fittings, medical instruments, chemical process parts |

| Carbon Steel 1018 | Good machinability, moderate strength, readily case hardened | Shafts, gears (after heat treatment), pins, general mechanical parts |

| Alloy Steel 4140 | High strength and toughness, good fatigue resistance, hardenable | Tooling, drive components, high-load mechanical assemblies |

| Brass (e.g., C360) | Excellent machinability, good electrical conductivity, corrosion resistance | Fittings, valves, electrical connectors, decorative components |

| Copper | Very high thermal and electrical conductivity, softer material | Heat sinks, electrical bus bars, RF components |

| Titanium Grade 2 | High strength to weight, excellent corrosion resistance, biocompatible | Medical components, chemical processing parts, aerospace structures |

| Titanium 6Al-4V (Grade 5) | Very high strength, good fatigue properties, heat-resistant | Aerospace fasteners, high-performance automotive parts, implants |

Plastics

Engineering plastics are used when low weight, electrical insulation, chemical resistance, or transparency are required. They are suited for enclosures, jigs and fixtures, bearings, and fluid handling components.

| Material | Key Properties | Typical Applications |

|---|---|---|

| ABS | Good toughness, impact resistance, easy to machine, good surface finish | Prototypes, consumer products, instrument housings, brackets |

| Polycarbonate (PC) | High impact strength, transparent grade available, good dimensional stability | Protective covers, lenses (with post-processing), transparent guards |

| POM (Delrin, Acetal) | Low friction, good wear resistance, dimensional stability | Gears, bushings, bearings, precision mechanical components |

| PEEK | High temperature resistance, chemical resistance, high strength | Aerospace, medical devices, high-performance industrial parts |

| HDPE | Chemical resistance, low moisture absorption, low cost | Containers, fluid components, wear strips |

| Nylon (PA) | Good wear resistance, low friction, absorbs moisture | Gears, rollers, bushings, structural components |

| PTFE (Teflon) | Very low friction, high chemical resistance, high temperature capability | Seals, gaskets, chemical handling components |

| PMMA (Acrylic) | Excellent transparency, good surface finish | Display elements, light guides, windows, covers |

Tolerances and Dimensional Accuracy

Tolerances define the permissible variation in part dimensions. CNC machining services can achieve tight tolerances, but realistic tolerances depend on material, geometry, machine capability, and inspection method.

Typical general tolerances for CNC machining services are:

- Linear dimensions: ±0.005 in (±0.125 mm) common, tighter tolerances down to ±0.001 in (±0.025 mm) or better upon request

- Hole diameters: ±0.002 in (±0.05 mm) with standard drilling, tighter with reaming or boring

- Flatness and straightness: dependent on size and geometry, commonly 0.002–0.005 in per 10 in

Critical tolerance zones, fits between mating parts, and geometric dimensioning and tolerancing (GD&T) requirements such as position, concentricity, and parallelism should be clearly defined on technical drawings. Overly tight tolerances on non-critical features can increase machining time, scrap rate, and cost.

Surface Finish and Post-Processing

Surface finish affects part aesthetics, friction, sealing performance, and corrosion resistance. CNC machining services can deliver a range of finishes, from as-machined surfaces to polished or coated components.

As-Machined Surface Finish

As-machined surfaces result directly from the cutting process without additional treatment. Surface roughness (Ra) typically falls in the range of 1.6–3.2 μm depending on tool, feed, speed, and material. Visible tool marks are normal and often acceptable for functional components.

Mechanical Finishes

Mechanical finishing processes improve or alter the surface topography.

Common mechanical finishes include:

- Bead blasting for uniform matte surfaces on metals

- Grinding and lapping for precision flatness and low roughness

- Polishing and buffing for reflective finishes, often on stainless steel or plastics

Chemical and Electrochemical Finishes

These finishes modify surface chemistry or add protective layers.

Typical options:

Anodizing for aluminum provides corrosion resistance, increased hardness, and a range of colors. Type II anodizing is used for decorative and general corrosion protection, while Type III (hard anodizing) increases wear resistance.

Plating processes such as nickel plating, zinc plating, and chrome plating improve corrosion resistance, hardness, and appearance. Passivation of stainless steel removes free iron contaminants and enhances corrosion resistance.

Coatings and Painting

Paint, powder coating, and specialized coatings such as PTFE-based or ceramic coatings are applied to achieve color, additional protection, or specific surface properties like low friction or high temperature resistance.

Design Considerations for CNC Machined Parts

Design decisions strongly influence machinability, lead time, and cost. Considering machining constraints early in the design process helps ensure that parts are feasible and economical to produce.

Geometry and Feature Design

Key geometric considerations include:

Internal corners: Milling tools are cylindrical, so internal corners always have a radius. Designing with standard tool radii reduces machining time and tool wear. Extremely sharp internal corners typically require EDM or alternative methods.

Wall thickness: Very thin walls may deflect under cutting forces, causing chatter, dimensional inaccuracies, or surface defects. A practical minimum wall thickness for metals is often about 0.8–1.0 mm, and for plastics typically 1.5 mm or more, depending on part size.

Depth of pockets and holes: Deep features require longer tools or multiple setups. Deep pockets can cause tool deflection and chip evacuation issues. Limiting pocket depth relative to tool diameter helps maintain accuracy and finish.

Tolerancing and Datums

Functional features should be tied to clearly defined datums. GD&T frameworks provide a consistent way to communicate design intent for alignment, coaxiality, and fit. Applying tight tolerances selectively only where necessary helps control cost.

Threaded Features

Design for standard thread sizes and depths when possible. Through-holes are easier to machine and tap than blind holes. Adequate relief at the bottom of blind holes and space for tooling improves reliability and thread quality.

Material-Related Considerations

Harder or more abrasive materials tend to reduce tool life and may require slower feeds and speeds. Plastics with high thermal expansion may need specific clamping strategies and finishing passes to manage dimensional variation and heat buildup. Considering material machinability can reduce cycle times and improve consistency.

Typical Applications of CNC Machining Services

CNC machining services support multiple industries with both prototype and production components. Applications range from simple fixtures to highly critical aerospace and medical parts.

Aerospace and Defense

Aerospace applications rely on CNC machining for precise aluminum, titanium, and high-strength steel parts such as structural brackets, engine components, housings, and tooling. Weight reduction, fatigue resistance, and traceability are key requirements.

Automotive and Transportation

Automotive components include engine and transmission parts, suspension elements, brackets, housings, and prototypes for testing and validation. CNC machining supports short-run and specialty vehicle programs, motorsport components, and aftermarket parts.

Medical and Dental Devices

Medical applications demand high precision, biocompatible materials, and consistent surface finishes. CNC machining is used for implants, surgical instruments, diagnostic equipment components, housings, and laboratory fixtures. Documented inspection and quality control are often required.

Industrial Equipment and Automation

Industrial machinery, robotics, and automation systems rely on CNC machined parts for frames, manifold blocks, precision shafts, gears (pre- or post-heat treatment), and custom fixtures. Robustness, maintainability, and compatibility with existing assemblies are important.

Electronics, Instrumentation, and Optics

Enclosures, heat sinks, mounting plates, and precision optical mounts are commonly produced via CNC machining. Materials such as aluminum, copper, brass, and engineering plastics are used for thermal management, EMC considerations, and mechanical stability.

Tooling, Jigs, and Fixtures

CNC machining is an efficient method for producing custom jigs, fixtures, and manufacturing aids. These components support assembly lines, inspection setups, test rigs, and automated handling systems, improving repeatability and throughput.

Quality Control and Inspection

Reliable CNC machining services integrate quality control throughout the manufacturing process to ensure conformance to drawings and functional requirements.

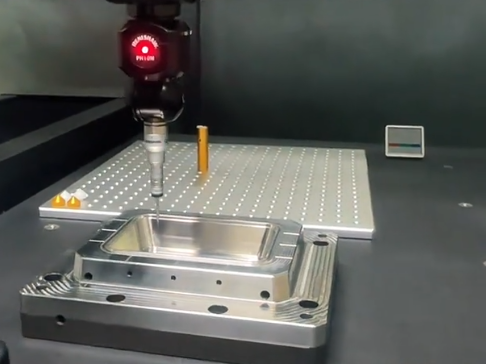

Inspection Methods

Common inspection tools and methods include:

Hand tools such as calipers, micrometers, height gauges, and plug gauges for quick checks and general tolerances.

Coordinate measuring machines (CMM) for complex geometries, tight tolerances, and GD&T features. CMMs provide high-accuracy measurements and can generate detailed inspection reports.

Optical and vision systems for small parts, intricate features, or when contact measurement is difficult. Surface roughness testers measure Ra and other parameters when surface finish is critical.

Documentation and Traceability

For regulated industries or high-reliability applications, CNC machining services may provide material certificates, process records, and inspection reports. Serial numbering and lot tracking support traceability from raw material to finished components.

How CNC Machining Services Operate

Understanding the typical workflow of a CNC machining service provider helps customers plan projects, communicate requirements, and evaluate quotations.

From RFQ to Quotation

The process often begins with an RFQ containing 3D models (STEP, IGES, or native CAD), 2D drawings with dimensions and tolerances, material specifications, quantities, and required finishes. The service provider reviews manufacturability, identifies potential issues, selects processes and machines, and estimates material usage and machining time. A quotation is then supplied, including price, lead time, and any assumptions or clarifications.

Programming and Setup

Once the order is confirmed, CAM programmers generate toolpaths based on the CAD model and machining strategy. Post-processors convert toolpaths into machine-specific G-code. Setup technicians prepare fixtures, select and load tools, set work offsets, and perform trial runs to verify the program before full production.

Production Machining and Inspection

During production, operators monitor tool wear, chip evacuation, coolant flow, and dimensional stability. In-process inspection checks ensure parts remain within tolerance. For larger batches, statistical sampling may be used alongside first-article and final inspections.

Pain Points and Typical Issues

Common practical issues that arise in CNC machining projects include:

Incomplete or ambiguous drawings: Missing dimensions, undefined tolerances, or unclear datums can cause delays or misinterpretation. Providing complete documentation reduces back-and-forth clarification.

Non-standard material specifications: Specifying rare alloys or unusual plastic grades can extend lead times due to sourcing and may increase cost. Using commonly stocked materials where feasible improves responsiveness.

Unoptimized designs for machining: Geometries with unnecessarily deep pockets, extremely tight tolerances on non-critical features, or inaccessible undercuts may require specialized tooling or multi-step setups. Early design reviews can identify and correct these constraints.

Cost Factors in CNC Machining Services

Multiple factors influence the cost of CNC machined components. Understanding these elements assists in making informed trade-offs between design, quantity, lead time, and budget.

Material and Stock Utilization

Material cost is affected by material type, stock form (plate, bar, block), and yield from the raw stock. Efficient nesting and selection of appropriate stock dimensions reduce waste. High-value materials such as titanium and specialty alloys significantly impact total cost.

Setup and Programming Time

Setup and programming represent a fixed cost distributed over the order quantity. Complex multi-operation parts or those requiring custom fixtures and detailed CAM programming have higher non-recurring costs. Larger batch sizes help amortize these efforts.

Machining Time and Tooling

Cycle time per part and tooling consumption affect variable cost. Hard materials, intricate shapes, and tight tolerances generally require slower feeds, more passes, and more frequent tool changes. Special tools or small-diameter cutters for fine features add to both time and tooling expenses.

Finishing, Inspection, and Logistics

Additional processes such as anodizing, plating, heat treatment, and precision inspection introduce extra steps, lead time, and cost. Packaging, labeling, and shipping requirements, especially for delicate or high-precision parts, also influence overall project cost.

When to Choose CNC Machining Services

CNC machining is appropriate when parts require high precision, functional mechanical properties, and a wide range of materials. It is suitable for both early-stage prototypes and low-to-medium volume production.

Compared to additive manufacturing, CNC machining typically offers better surface finish, dimensional accuracy, and material performance for metals. Compared to casting or molding, CNC machining is more flexible for design changes and lower volumes.