Precision CNC machining is a core manufacturing process for producing high-accuracy metal and plastic components with repeatable quality. This guide explains what precision CNC machining is, its main technical features, typical tolerances and capabilities, advantages, applications, cost factors, and how to select a suitable machining supplier.

What Is Precision CNC Machining?

Precision CNC machining is the use of computer numerical control (CNC) machine tools to remove material from a solid workpiece and produce parts that meet tight dimensional and geometric tolerances. Numerical programs define the toolpaths, cutting parameters, and motions required to achieve the specified part geometry.

Compared with general CNC machining, precision CNC machining emphasizes tighter tolerances, superior surface finishes, and consistent repeatability over large production batches. It is widely used in industries where component accuracy and reliability are critical, such as aerospace, medical devices, automotive, electronics, and industrial equipment.

Typical processes within precision CNC machining include CNC milling, CNC turning, drilling, boring, reaming, tapping, and a variety of secondary and finishing processes. Parts may be produced as prototypes, small batches, or large volumes, depending on the project requirements and the chosen production approach.

Core Features of Precision CNC Machining

Precision CNC machining is characterized by a combination of machine capabilities, control systems, tooling, and process control. The following core features define its technical performance.

Multi-Axis CNC Capabilities

CNC machines for precision work commonly provide 3-axis, 4-axis, 5-axis, or even more complex motion combinations. More axes allow the tool to approach the part from additional orientations, enabling highly complex geometries and reducing the number of setups.

- 3-axis machining: Movement along X, Y, and Z axes. Suitable for many prismatic parts, pockets, and simple contours.

- 4-axis machining: Adds rotation around one axis (typically A or B). Useful for machining multiple faces without manual repositioning.

- 5-axis machining: Adds simultaneous rotation around two axes (e.g., A and B). Ideal for complex freeform surfaces, undercuts, and high-precision multi-face machining.

By minimizing setups and manual handling, multi-axis machining improves dimensional accuracy, concentricity between features, and overall process reliability.

Tight Dimensional and Geometric Tolerances

Precision CNC machining is selected when parts must conform to tight dimensional and geometric requirements. Typical shop capabilities vary, but many precision CNC environments offer:

- Linear dimensional tolerances commonly in the range of ±0.005 mm to ±0.02 mm (±0.0002 in to ±0.0008 in) for critical features, depending on material, geometry, and lot size.

- Positional tolerances for holes and features within several micrometers when required and when supported by fixturing and metrology.

- Geometric tolerances such as flatness, parallelism, perpendicularity, circularity, cylindricity, and runout controlled using GD&T (Geometric Dimensioning and Tolerancing) specifications.

In practice, achievable tolerances depend on part size, aspect ratio, material stability, cutting forces, and measurement method. Tighter tolerances generally require more controlled processes, more inspection, and higher cost.

Surface Finish and Edge Quality

Surface finish is a key characteristic in precision parts, influencing wear behavior, sealing, friction, and appearance. CNC machining can produce a wide range of surface finishes, expressed by Ra (arithmetical mean roughness):

Typical ranges include:

- General machined surfaces: Ra ≈ 1.6–3.2 μm.

- Precision machined surfaces with optimized parameters: Ra ≈ 0.4–0.8 μm.

- Fine finishing and light finishing passes: Ra down to ≈ 0.2 μm or better, depending on material and tooling.

Edge quality is controlled through deburring methods such as manual deburring, vibratory finishing, brushing, or specialized deburring tools. For components like hydraulic blocks, medical instruments, and precision gears, burr-free and consistently chamfered edges are essential.

High Repeatability and Process Stability

Precision CNC machining focuses on repeatable production of identical parts. Key technical aspects include:

- Machine positioning accuracy and repeatability typically specified by the machine builder (e.g., ±0.002 mm positioning and equal or better repeatability for high-end machines).

- Use of rigid machine structures, precision ball screws or linear motors, and high-resolution encoders.

- Thermal compensation and temperature management to reduce drift over time.

- Stable fixturing and workholding to minimize deflection and vibration.

Through controlled programming, toolpath strategies, and process monitoring, precision CNC machining maintains consistent dimensions across long runs and repeated orders.

Close Integration With CAD/CAM

Precision CNC machining relies heavily on CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing):

- CAD models define exact 3D geometry, tolerances, and critical features.

- CAM software generates optimized toolpaths, cutting parameters, and simulations to detect potential collisions or errors.

- Post-processing converts CAM data into machine-specific G-code.

This integration minimizes interpretation errors between engineering and production, supports complex geometry, and enables rapid design revisions while preserving process accuracy.

Common Materials for Precision CNC Machining

Precision CNC machining supports a broad range of metals and plastics. Material properties such as hardness, toughness, thermal expansion, and machinability influence achievable tolerances, surface finish, and cost.

| Material Category | Examples | Typical Use Cases |

|---|---|---|

| Aluminum Alloys | 6061, 6082, 7075, 2024 | Lightweight structural parts, housings, fixtures, aerospace and automotive components |

| Carbon Steels | 1018, 1045, 1215 | Shafts, brackets, machine parts, general industrial components |

| Alloy Steels | 4140, 4340, 8620 | Gears, high-strength shafts, tooling components |

| Stainless Steels | 303, 304, 316, 17-4 PH | Corrosion-resistant parts, medical components, food processing equipment |

| Tool Steels | D2, A2, O1, H13 | Molds, dies, cutting tools, wear-resistant inserts |

| Titanium Alloys | Ti-6Al-4V (Grade 5), Grade 2 | Aerospace structures, medical implants, high-strength lightweight components |

| Copper and Alloys | Copper, brass, bronze | Electrical contacts, heat transfer components, decorative elements |

| Engineering Plastics | ABS, POM (Delrin), PA (Nylon), PC, PEEK, PTFE | Insulators, bearings, medical components, prototypes, chemical-resistant parts |

Material selection should consider mechanical requirements, environmental conditions, regulatory standards, and machining behavior. Some high-performance materials (e.g., hardened steels, titanium, nickel alloys) require specialized tooling and parameters, affecting machining time and cost.

Key CNC Machining Processes in Precision Manufacturing

Precision CNC machining is not a single process but a combination of complementary operations. Selecting the right process ensures that design requirements are met efficiently.

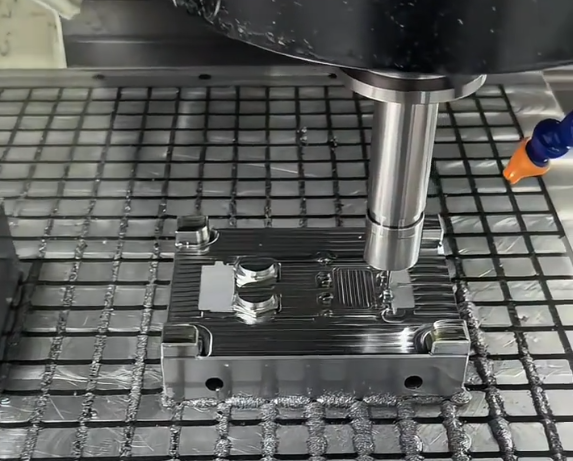

CNC Milling

CNC milling uses rotating cutting tools to remove material from a stationary or moving workpiece. It is suitable for prismatic parts, complex surfaces, and multi-face features.

Main capabilities include:

- Flat and contoured surfaces, pockets, slots, and profiles.

- 3D surfaces such as turbine blades, molds, and ergonomic shapes (often using 5-axis machines).

- Precise hole patterns, bosses, and pockets for assemblies and enclosures.

High-speed machining (HSM) with elevated spindle speeds and optimized toolpaths is frequently applied to aluminum alloys and certain steels to improve productivity and surface finish while maintaining dimensional accuracy.

CNC Turning and Turn-Milling

CNC turning rotates the workpiece while stationary or rotating tools remove material. It is designed for rotationally symmetric parts such as shafts, bushings, and rings.

Capabilities include:

- Turning of external diameters, internal bores, and complex profiles.

- Facing, grooving, threading, and parting-off operations.

- Achieving tight roundness, cylindricity, and runout tolerances.

Turn-milling centers combine turning with milling functions, allowing features such as flats, keyways, cross-holes, and complex end geometry to be machined in a single setup. This reduces concentricity errors between turned and milled features and improves overall part precision.

Drilling, Boring, and Reaming

Precision holes are critical for fasteners, fluid passages, alignment pins, and bearings. CNC machining operations for holes include:

- Drilling: Creates initial holes; tolerances and surface finish depend on drill type and parameters.

- Boring: Enlarges and refines holes; improves positional and diameter accuracy.

- Reaming: Produces very accurate diameters and fine surface finish; typical for critical fits.

With accurate fixturing and toolpath control, hole position tolerances within a few micrometers can be achieved in controlled conditions, especially on multi-axis machining centers.

Tapping and Thread Milling

Internal and external threads are produced using tapping, thread milling, or turning operations:

- Tapping is efficient for standard internal threads in high volumes. Synchronization of spindle and feed is managed by the CNC control.

- Thread milling uses a rotating cutter that moves along a helical path; it provides better control of thread geometry, chip evacuation, and is useful for hard materials and deep threads.

- External threads on turned parts are typically produced via single-point threading on lathes.

Selection of threading method depends on thread size, material, depth, and tolerance requirements.

Tolerances and Technical Parameters

To define precision levels and ensure manufacturability, it is necessary to understand typical tolerances and process parameters in CNC machining.

Dimensional Tolerance Ranges

While exact capabilities vary, a representative range for precision CNC machining (under stable conditions) is:

- General features: ±0.05 mm (±0.002 in).

- Precision features: ±0.01 mm (±0.0004 in).

- High-precision features on suitable geometries: ±0.005 mm (±0.0002 in) or better.

Larger parts or very long features are more difficult to hold to micrometer-level tolerances due to thermal effects and machine travel limitations.

Geometric Tolerances

GD&T defines how form, orientation, and location are controlled. Common machinable ranges include:

- Flatness and parallelism: often controlled within 0.01–0.03 mm for surfaces up to several hundred millimeters, with tighter values possible under controlled conditions.

- Perpendicularity: often held within 0.01–0.05 mm relative to a datum over typical feature lengths.

- Circular runout and total runout: for rotating parts, values down to a few micrometers are achievable with suitable grinding or finishing after machining, if required.

To avoid unnecessary cost, tolerances should be specified only as tight as functionally required.

Surface Roughness Parameters

Surface finish is influenced by tool geometry, feed rate, spindle speed, depth of cut, and material. Typical Ra ranges in precision CNC machining include:

- Roughing operations: Ra ≈ 3.2–6.3 μm.

- Semi-finishing: Ra ≈ 0.8–1.6 μm.

- Finishing: Ra ≈ 0.2–0.8 μm.

When finer finishes are needed (e.g., sealing surfaces or sliding fits), additional finishing processes such as grinding, honing, or polishing may be applied after CNC machining.

Benefits of Precision CNC Machining

Precision CNC machining is widely used because it offers a combination of accuracy, flexibility, and cost-effectiveness for many part types and production volumes.

High Accuracy and Consistency

CNC control systems, rigid machine structures, high-quality tooling, and advanced metrology allow precision CNC machining to deliver closely controlled dimensions on every part. This is critical where misalignment, leaks, or vibration can cause functional failures, such as in hydraulic components, medical implants, and aerospace assemblies.

Repeatability across batches simplifies assembly, reduces fitting and adjustment work, and decreases the risk of rework or field failures.

Compatibility With Complex Geometries

Using multi-axis machining centers and advanced CAM software, precision CNC machining can produce complex geometries that would be difficult or impossible with manual methods. Examples include:

- Internal channels and intersecting bores with tight positional requirements.

- 3D surfaces and freeform curves on molds, dies, and aero components.

- Multi-face parts with precise relationships between features.

This geometric flexibility supports product designers in optimizing performance, weight, and integration of multiple functions into a single component.

Material and Process Versatility

Precision CNC machining can handle many metals and plastics, enabling selection based on performance rather than process limitations. It supports aluminum for lightweight components, stainless steels for corrosion resistance, titanium for strength and biocompatibility, and engineering plastics for electrical insulation and chemical stability.

In addition, CNC machining is compatible with a variety of secondary processes such as heat treatment, anodizing, plating, painting, and assembly. This makes it suitable for both functional prototypes and production parts.

Efficiency for Small and Medium Batches

While high-volume mass production often favors casting, forging, or molding, precision CNC machining is particularly efficient for prototypes, low volumes, and medium-scale batches. Tooling costs are relatively low compared to molds and dies, and changeovers between part numbers can be done quickly by switching fixtures and programs.

This balance of flexibility and precision is especially valuable in sectors where product lifecycles are short or where customized solutions are required.

Reduced Manual Intervention

Because CNC programs control the majority of motions and operations, human involvement is focused on setup, supervision, and inspection. This consistency minimizes human error and leads to predictable quality, especially for parts with multiple complex operations.

Typical Applications of Precision CNC Machining

Precision CNC machining is employed whenever component performance relies on exact geometry, reliable fit, and repeatable production. The following industries illustrate common applications.

Aerospace and Defense Components

Aerospace components must meet demanding requirements for strength-to-weight ratio, fatigue life, and dimensional accuracy. Precision CNC machining is used for:

- Structural components such as ribs, frames, and brackets in aluminum and titanium alloys.

- Engine components including compressor and turbine parts, housings, and fuel system elements.

- Landing gear parts, actuators, and hydraulic manifold blocks.

Traceability, documentation, and process validation are especially important in this sector.

Medical Devices and Implants

Medical components require biocompatibility, tight tolerances, and controlled surface finish. Precision CNC machining is used for:

- Orthopedic implants (e.g., hip and knee components) in titanium alloys and stainless steels.

- Dental implants and instruments requiring small features and smooth surfaces.

- Surgical tools, housings for diagnostic equipment, and fluid-handling components.

Cleanliness, process control, and material certification are key considerations in medical applications.

Automotive and Motorsport Parts

In automotive and motorsport applications, precision CNC machining is used for both production and high-performance parts:

- Engine components, fuel system parts, and transmission elements.

- Suspension components, brackets, and structural mounts.

- Custom performance parts and low-volume specialty components for racing.

Dimensional stability and consistent performance under dynamic loads are crucial in these applications.

Electronics, Instrumentation, and Industrial Equipment

Precision CNC machining supports enclosures, connectors, and mechanical components in instrumentation and industrial systems, such as:

- Aluminum and stainless steel housings for sensors, controllers, and power electronics.

- Precision shafts, couplings, and bearings for automation equipment.

- Fixtures and jigs for production lines and test setups.

In these cases, the combination of tight tolerances, good surface finish, and stable mechanical properties is essential for long-term reliability.

Cost Structure of Precision CNC Machining

Understanding cost drivers helps in optimizing designs for manufacturability and selecting an appropriate supplier. Precision CNC machining costs depend on material, machining time, setup, tooling, quantity, and inspection requirements.

| Cost Factor | Description | Impact on Total Cost |

|---|---|---|

| Material Type and Size | Raw material price, stock dimensions, and yield from blanks | High-density or specialty alloys and large stock sizes increase cost |

| Part Complexity | Number of features, undercuts, multi-axis requirements, thin walls | Complex geometries require longer machining time and more setups |

| Tolerance and Surface Finish | Tight dimensional and geometric tolerances, low Ra values | Stricter requirements increase cycle time, inspection, and scrap risk |

| Setup and Programming | CAM programming, fixture design, and machine setup time | Significant for prototypes and small batches; spread over larger volumes |

| Production Quantity | Number of parts in the order | Higher volumes reduce cost per part by amortizing setup and programming |

| Tooling and Tool Wear | Special tools, inserts, and wear rate in hard or abrasive materials | Increased tooling cost and machine downtime for tool changes |

| Inspection and Quality Assurance | CMM inspection, documentation, statistical process control | Additional measurement time and specialized equipment increase cost |

| Post-Processing | Heat treatment, surface coatings, assembly, packaging | Each operation adds material, labor, and lead time cost |

Material and Blank Selection

Material cost is not limited to price per kilogram; it also involves how efficiently the part can be cut from a blank. Efficient blank selection minimizes unnecessary machining and material waste. For example, near-net-shape forgings can reduce machining time for high-volume parts but add up-front tooling costs, while standard bar and plate stock are more flexible for small and medium quantities.

Impact of Complexity and Tolerance on Machining Time

Each feature (pockets, holes, threads, undercuts, grooves) adds machine time. Thin walls, deep pockets, and long tool overhangs require reduced feeds and depths of cut to control deflection and chatter, increasing cycle time. Multi-axis machining operations may be necessary for complex geometries, which can both reduce setup time and increase programming complexity.

*Tight tolerances and fine surface finishes generally demand more machining passes, slower cutting parameters, more tool changes, and additional inspection. This raises the cost per part, especially for low-volume orders.*

Setup, Programming, and Batch Size

Setup and programming costs are significant for precision CNC machining. Activities include:

- Analyzing CAD models and drawings.

- Generating CAM programs and simulating toolpaths.

- Designing and manufacturing fixtures and workholding devices.

- Setting tools and performing trial runs to validate the process.

These non-recurring engineering (NRE) costs are effectively distributed across the total number of parts produced. Thus, unit costs for prototypes and very small batches can be high, while larger batches benefit from economies of scale.

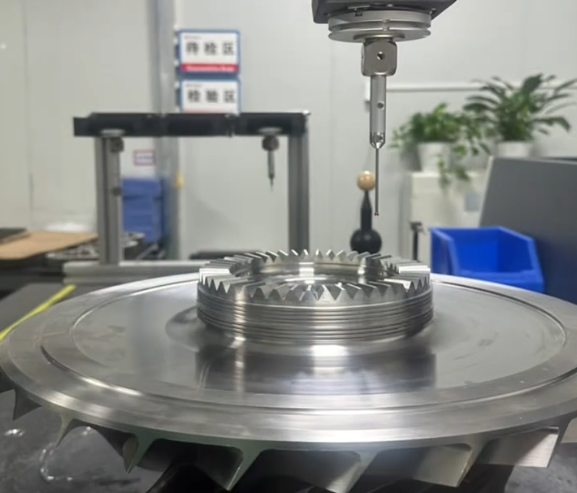

Inspection and Quality Assurance Requirements

Precision parts usually require more rigorous inspection. This may involve:

- First article inspection (FAI) with detailed dimensional reports.

- In-process inspection with gauges, micrometers, and bore gauges.

- Final inspection on coordinate measuring machines (CMMs).

Documentation and traceability requirements, such as material certificates, process records, and measurement reports, also add to total cost but are necessary in industries such as aerospace and medical.

Design Considerations for Cost-Effective Precision Machining

Thoughtful design can reduce cost and lead time while maintaining necessary precision. Key considerations include:

- Specifying tolerances only where functionally required and avoiding blanket tight tolerances on all dimensions.

- Standardizing hole sizes, threads, and radii to use readily available tools.

- Avoiding unnecessary thin walls, deep narrow pockets, or extremely slender features that are difficult to machine without distortion.

- Orienting features to reduce the number of setups and enable multi-axis machining where beneficial.

- Using materials that provide the required performance with reasonable machinability.

Working closely with machining engineers during the design stage allows potential issues to be identified early, reducing iterations and cost.

Typical Issues and How Precision CNC Addresses Them

Many users seek precision CNC machining to resolve specific issues in their existing components or manufacturing methods. Common pain points include:

- Inconsistent fit between mating parts due to poor dimensional control in previous processes.

- Leakage in hydraulic or pneumatic systems caused by inadequate surface finish or out-of-tolerance features.

- High scrap rates from manual machining processes where operator variability leads to nonconforming parts.

- Delay in development cycles when design changes require new tooling or long lead times in alternative manufacturing methods.

Precision CNC machining addresses these by providing programmable, repeatable operations, robust process control, and flexibility for design changes without major tooling modifications.

How to Choose a Precision CNC Machining Partner

Selecting the right machining supplier directly affects part quality, delivery reliability, and cost. Important evaluation criteria include:

Technical Capabilities and Equipment

Key aspects include:

- Range of CNC machines (3-axis, 4-axis, 5-axis, turning centers, mill-turn centers).

- Maximum and minimum workpiece dimensions and weight.

- Ability to process required materials, including any high-hardness alloys.

- Availability of inspection equipment such as CMMs, optical measurement, and surface roughness testers.

Assess whether the supplier’s equipment matches the tolerance, surface finish, and production volume requirements of your parts.

Process Control and Quality Management

Ask about:

- Quality management systems, including ISO standards where relevant.

- Standard procedures for first article inspection and in-process control.

- Traceability, documentation, and record-keeping practices.

Strong process control reduces variability and ensures consistent quality across multiple production batches.

Engineering Support and Communication

Effective communication and engineering support help resolve design and manufacturability issues. Consider whether the supplier can:

- Review CAD models and drawings and suggest changes for manufacturability.

- Discuss tolerance, surface finish, and material trade-offs.

- Provide clear feedback on lead times and cost implications of design decisions.

An experienced engineering team can significantly shorten development cycles and improve overall results.

Lead Time, Flexibility, and Logistics

Evaluate the supplier’s lead times for prototypes and production, their ability to handle schedule changes, and how they manage packaging, labeling, and shipping. For some industries, local availability and responsiveness may be more important than the lowest unit price.

Frequently Asked Questions (FAQ)

What is precision CNC machining?

Precision CNC machining is a manufacturing process that uses computer-controlled machines to produce parts with extremely tight tolerances and high accuracy.

How accurate is precision CNC machining?

Precision CNC machining can typically achieve tolerances as tight as ±0.005 mm, depending on the machine, material, and design complexity.

What factors influence the cost of precision CNC machining?

Costs are affected by material type, part complexity, tolerance requirements, machining time, batch size, and surface finishing needs.

Which is better for my project: CNC machining, 3D printing, or casting?

CNC machining is suitable when you need high dimensional accuracy, good mechanical properties, and parts from production-grade materials in low to medium volumes. 3D printing is attractive for highly complex shapes and rapid prototypes, often with different material and surface characteristics. Casting is efficient for high-volume production of complex shapes but requires tooling and typically involves looser tolerances, often followed by machining of critical surfaces.