CNC aluminum machining is a widely used manufacturing method for producing precise and complex aluminum components with high repeatability. By combining computer numerical control (CNC) with the favorable cutting characteristics of aluminum alloys, manufacturers can obtain tight tolerances, high-quality surfaces, and stable production for both prototypes and large-volume orders.

Fundamentals of CNC Aluminum Machining

CNC aluminum machining mainly includes milling, turning, drilling, boring, reaming, and tapping operations performed on aluminum and its alloys using CNC machine tools. The toolpath is generated from CAD/CAM software and executed automatically by CNC equipment, enabling precise material removal from aluminum workpieces.

Aluminum alloys exhibit high thermal conductivity, relatively low density, good machinability, and excellent corrosion resistance. These properties make them suitable for a wide range of CNC operations, especially where weight reduction, dimensional accuracy, and efficient production are important.

Key features of CNC aluminum machining include:

- High-speed material removal enabled by aluminum’s low cutting resistance

- Capability to produce complex 3D geometries and fine details

- Consistent accuracy across repeated production runs

Common Aluminum Alloys for CNC Machining

Different aluminum alloys are selected based on strength, corrosion resistance, machinability, and application requirements. Mechanical properties, heat treatability, and surface finishing behavior must be considered when planning CNC machining processes.

| Alloy | Temper (Typical) | Typical Uses | Approx. Ultimate Tensile Strength | Machinability Characteristics |

|---|---|---|---|---|

| Aluminum 6061 | T6 | General structural components, fixtures, brackets, housings | ~290 MPa | Balanced machinability, good for milling and turning |

| Aluminum 6082 | T6 | Structural parts, transportation components | ~310 MPa | Good machinability, similar to 6061 with slightly higher strength |

| Aluminum 5052 | H32 | Sheet metal, enclosures, marine applications | ~220 MPa | Good machinability for thin-walled parts, excellent corrosion resistance |

| Aluminum 2024 | T3/T4 | Aerospace structural components | ~470 MPa | Higher strength, requires careful cutting parameter control |

| Aluminum 7075 | T6/T651 | High-strength aircraft parts, performance components | ~540–570 MPa | High-strength alloy, sensitive to tool wear and heat |

| Aluminum 6063 | T5/T6 | Extrusions, frames, heat sinks | ~200–240 MPa | Good machinability, often used in extruded profiles |

Factors influencing alloy selection include:

- Required mechanical performance (strength, stiffness, fatigue resistance)

- Operating environment (corrosion, temperature, humidity)

- Surface treatment options (anodizing response, coating adhesion)

- Cost, availability, and dimensional forms (bar, plate, extrusion, forging)

Key CNC Machining Techniques for Aluminum

CNC aluminum machining employs a range of processes. Selecting the appropriate technique or combination of techniques depends on part geometry, tolerances, and production quantity.

CNC Milling for Aluminum

CNC milling is used to produce flat surfaces, pockets, slots, contours, and 3D shapes by rotating multi-point cutting tools against the workpiece. For aluminum, high-speed and high-feed milling strategies are common.

Typical considerations include:

Tool types: end mills (2-flute, 3-flute, 4-flute), face mills, ball-nose mills, and chamfer tools. For aluminum, polished carbide tools with sharp cutting edges and appropriate rake angles help reduce built-up edge and improve surface finish.

Key milling operations on aluminum:

- Roughing: high material removal using large step-over and higher feed rates

- Semi-finishing: preparing surfaces for finishing passes, refining geometry

- Finishing: small step-over and step-down to achieve final dimensions and surface quality

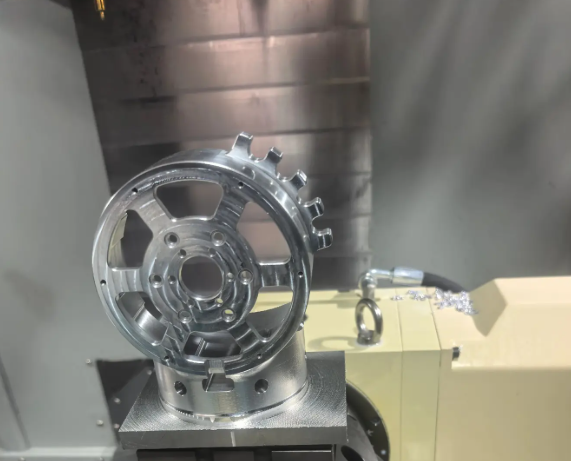

CNC Turning for Aluminum

CNC turning is used mainly for rotationally symmetric parts such as shafts, bushings, rings, and threaded components. A cutting tool moves along one or two axes while the workpiece rotates in a chuck.

Turning operations for aluminum include external turning, facing, grooving, drilling on the lathe, boring, and threading. Aluminum’s good machinability allows high spindle speeds and productive turning cycles. Careful chip control and effective coolant application are important to maintain surface quality and dimensional stability.

High-Speed Machining of Aluminum

High-speed machining (HSM) refers to using elevated spindle speeds and feed rates with optimized toolpaths to improve material removal rates and surface quality. Aluminum alloys are well suited to HSM due to their low cutting resistance and good thermal conductivity.

Typical practices in high-speed aluminum machining include:

Using lighter radial cuts and deeper axial cuts, maintaining constant tool load with trochoidal or adaptive toolpaths, using balanced tooling and rigid spindle systems, and applying abundant coolant or minimum quantity lubrication to manage temperature and chip evacuation.

Drilling, Tapping, and Boring Aluminum

Holes, threads, and precision bores are common features in aluminum parts. CNC machining offers tightly controlled tool positioning and depth control for drilling and tapping operations.

Important points for these operations:

Drilling: Selecting drills with polished flutes and suitable point geometry for aluminum helps reduce burrs and built-up edges. Short peck cycles may be used for deep holes to prevent chip packing.

Tapping: Rolled or cut taps can be used, depending on thread requirements. Lubrication is essential to prevent galling and thread damage.

Boring: Precision boring tools provide tight diameter control and improved roundness for critical holes such as bearing seats or alignment features.

Cutting Parameters and Tooling for Aluminum

Optimizing cutting parameters is critical for efficient and stable CNC aluminum machining. Parameters should be adjusted according to alloy type, tool diameter, tool material, and machine capability.

| Operation | Tool Type / Material | Cutting Speed (Vc) | Feed per Tooth (fz) | Coolant / Lubrication |

|---|---|---|---|---|

| Milling (Roughing) | Carbide end mill, 3-flute for aluminum | 200–600 m/min | 0.05–0.25 mm/tooth | Flood coolant or MQL, good chip evacuation |

| Milling (Finishing) | Carbide end mill, 2–3 flute, polished | 300–800 m/min | 0.02–0.12 mm/tooth | Coolant for surface quality and tool life |

| High-Speed Milling | Balanced carbide tool, HSM grade | 400–1200 m/min | 0.03–0.18 mm/tooth | High-pressure coolant or air blast |

| Turning (Roughing) | Carbide insert, positive rake | 200–600 m/min | 0.1–0.4 mm/rev | Coolant recommended |

| Turning (Finishing) | Carbide insert, sharp edge | 300–800 m/min | 0.05–0.25 mm/rev | Coolant for better surface finish |

| Drilling | Carbide or HSS drill for aluminum | 80–250 m/min | 0.05–0.25 mm/rev | Coolant through-tool or external |

| Tapping | Coated tap for aluminum | 10–40 m/min | As per thread pitch and tap manufacturer data | Lubricant or cutting oil essential |

Values in the table are indicative ranges and must be adjusted based on actual conditions, tool manufacturer recommendations, and machine tool rigidity. Excessive cutting speed or feed may cause chatter, tool wear, surface damage, or dimensional deviations.

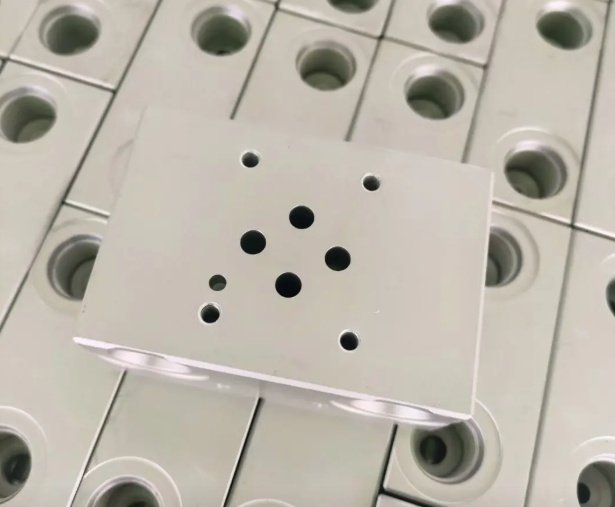

Tolerances and Surface Finish in Aluminum CNC Parts

CNC machining can achieve tight dimensional tolerances and fine surface finishes when equipment, tooling, and process parameters are properly controlled. Aluminum’s good machinability contributes to consistent quality, especially for precision components.

Typical Tolerance Ranges

Tolerance capability depends on machine accuracy, fixturing, tool wear, and inspection methods. Typical achievable tolerances for CNC aluminum parts include:

General machined dimensions: ±0.05 mm to ±0.1 mm for standard components without special requirements, tighter tolerances (such as ±0.01 mm to ±0.02 mm) for critical features with appropriate process control.

Hole diameters: ±0.02 mm to ±0.05 mm for standard tooling, tighter using precision boring or reaming operations.

Geometric tolerances: Flatness, perpendicularity, and position tolerances can be held to within 0.02–0.05 mm depending on part size and fixturing strategy.

Surface Roughness Targets

Surface finish of aluminum CNC parts is commonly expressed as Ra (arithmetical mean roughness). Typical ranges are:

Roughing operations: Ra 3.2–6.3 μm, focusing on material removal rather than finish.

Standard finishing: Ra 0.8–1.6 μm for general functional surfaces.

Fine finishing: Ra 0.2–0.8 μm for cosmetic surfaces or precision mating surfaces, achieved with fine finishing passes, sharp tools, and stable cutting conditions.

Surface Finishing and Post-Processing of Aluminum Parts

After CNC machining, aluminum parts often undergo additional processes to improve appearance, corrosion resistance, or specific functional properties. Surface finishing choice depends on the alloy, application environment, and mechanical constraints.

Deburring and Edge Treatment

Machined aluminum parts commonly exhibit burrs on edges and in holes. Deburring operations remove these to improve assembly, safety, and performance. Methods include manual deburring with tools, mechanical deburring through tumbling or vibratory finishing, and brushing or abrasive flow for internal features.

Anodizing

Anodizing is a widely used electrochemical process that increases corrosion resistance, wear resistance, and aesthetic appeal of aluminum surfaces. It forms a controlled oxide layer that can be colored and sealed.

Key points of anodizing for CNC aluminum parts:

Common anodizing thickness: approximately 5–25 μm for typical decorative or protective layers. The process slightly affects dimensions, so allowance must be considered in design and machining.

Certain alloys, such as 6061 and 6082, respond well and produce uniform anodized layers. High-copper alloys like 2024 may require careful process control for consistent appearance.

Other Surface Treatments

In addition to anodizing, CNC aluminum components may receive other finishing processes, such as conversion coatings for basic corrosion protection and paint adhesion, powder coating for thicker protective layers and color, polishing and bead blasting for specific textures and improved aesthetics, and plating or coating where special electrical or wear properties are required.

Design Considerations for CNC Machined Aluminum Parts

Design choices strongly affect the machinability, cost, and performance of aluminum components. Proper design for CNC machining helps reduce cycle times, improve stability, and reduce the risk of defects.

Wall Thickness and Structural Features

Minimum wall thickness should be set to balance weight reduction and rigidity. Very thin walls can vibrate, deform under cutting loads, or distort after machining. Practical minimum wall thicknesses for aluminum parts often range from about 0.5–1.0 mm for small features to 1.5–2.0 mm or more for larger panels and structures.

Reinforcement features such as ribs, gussets, and fillets may be used to maintain structural integrity while minimizing weight. Internal ribs should be designed with tool accessibility in mind to avoid impractical tool reach or special tooling.

Corner Radii and Fillets

Internal corners machined by rotating tools cannot be perfectly sharp. Corner radii should be defined to match tool diameters and avoid the need for extremely small tools that increase machining time and reduce tool life.

Recommendations include specifying internal radii equal to or larger than the tool radius used for pocketing operations and using consistent radii throughout similar features to allow the same tool to be reused, reducing tool changes and programming complexity.

Hole Design and Threading

Holes should be sized and located with consideration of standard drill sizes and thread standards. For threaded holes in aluminum, adequate thread engagement and correct tap drill size help maintain strength while avoiding stripping or cracking.

Deep holes require special attention to chip evacuation and guidance. For very deep holes, gun drilling or step drilling may be required. Threaded holes located too close to edges or thin walls may be prone to deformation during tapping or assembly.

Fixturing and Accessibility

Magining strategies depend on secure and repeatable fixturing. Designers should consider how the part will be clamped, which surfaces will be used as reference datums, and how to minimize the number of setups.

Accessibility for cutting tools is essential. Features that require extremely long tools, severe approach angles, or hidden surfaces can significantly increase machining difficulty and cost. Where possible, part geometry should allow straightforward tool access from one or a few directions.

Advantages of CNC Aluminum Machining

CNC aluminum machining offers a combination of performance characteristics that make it suitable for a wide range of applications in demanding industries.

Dimensional Accuracy and Repeatability

CNC machines with appropriate calibration and tooling can consistently produce aluminum parts within tight tolerance ranges. This reliability is important for assemblies, precision mechanisms, and components that must interface with other parts or standardized hardware.

Material Efficiency and Weight Reduction

Aluminum’s low density allows substantial weight savings compared to steel or other metals. CNC machining enables efficient removal of material from blocks, plates, or extrusions to create optimized structures with pockets, cavities, and thin walls while maintaining necessary strength. This combination is especially valuable in applications where mass is critical, such as aerospace, automotive, robotics, and portable devices.

High Productivity with Good Machinability

Aluminum alloys can be cut at higher speeds than many other metals. This allows shorter cycle times and higher throughput when correct tooling and machining parameters are used. Chips generally evacuate efficiently, and heat generated in the cutting zone is quickly dissipated.

Versatility in Geometry and Batch Size

CNC milling and turning can produce complex geometries including 3D contours, intricate internal features, and fine details. The same machinery can handle single prototypes, engineering samples, and low to medium production volumes without requiring dedicated tooling. This supports rapid design iterations and flexible manufacturing plans.

Compatibility with Multiple Surface Finishes

Aluminum accepts a wide range of surface treatments and finishes. Machined surfaces can be left as-is, lightly polished, bead blasted, anodized, coated, or painted. This flexibility allows both functional and aesthetic requirements to be fulfilled within the same material system.

Typical Issues and Practical Considerations

Although aluminum is generally easy to machine, several practical issues must be managed to ensure stable and efficient production.

Built-Up Edge and Burr Formation

Aluminum’s ductility can cause built-up edge on cutting tools and burr formation on machined edges. This affects dimensional accuracy and surface quality and may complicate assembly.

Mitigation measures include using sharp tools with suitable coatings or polished flutes for aluminum, optimizing cutting speed and feed to minimize adhesion, applying sufficient coolant or lubrication, and implementing effective deburring strategies.

Thermal Expansion and Distortion

Aluminum has a relatively high coefficient of thermal expansion. During machining, localized heating can lead to temporary dimensional changes and, in some cases, residual stresses that cause warping after machining or after removal from fixtures.

To manage this behavior, stable cutting parameters with controlled heat input, balanced material removal from both sides of a part where feasible, appropriate clamping that avoids over-constraining the component, and intermediate stress relief treatments for critical components may be used.

Tool Wear and Chip Evacuation

While aluminum does not cause excessive abrasive wear, improper chip evacuation can lead to re-cutting of chips, tool edge damage, and surface defects. In addition, alloys with hard intermetallic phases or contaminants can increase tool wear.

Practical approaches include selecting suitable flute count and chip space in tools, using air blast or high-pressure coolant to remove chips, monitoring tool condition and applying tool life management, and matching tool geometry to the specific aluminum grade being machined.

Quality Control and Inspection for Aluminum CNC Parts

Quality control ensures that machined aluminum components meet dimensional, functional, and aesthetic requirements. A structured inspection process integrates measurement, documentation, and feedback to machining operations.

Dimensional Inspection Methods

Common dimensional inspection tools include calipers and micrometers for linear measurements, height gauges and surface plates for flatness and heights, plug gauges and bore gauges for holes, and coordinate measuring machines (CMM) for complex geometries and statistical process control.

For higher-precision or safety-critical parts, CMM inspection and detailed inspection reports are frequently used. Data from inspection can be linked with process parameters to refine machining programs and maintain consistent quality across batches.

Surface and Visual Inspection

Surface quality and appearance are assessed by visual inspection and, when necessary, roughness measurement instruments. For anodized or coated parts, inspection includes checking for color consistency, coverage completeness, absence of defects such as pits or stains, and verification of coating thickness when required.

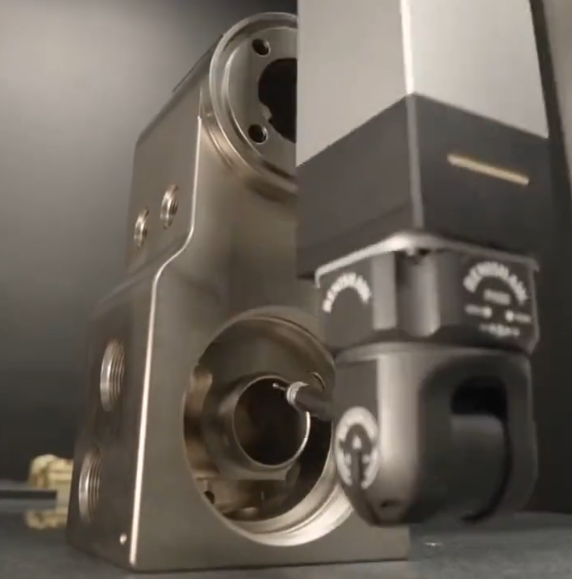

Material and Performance Verification

In applications where material properties are critical, verification may include checking material certificates, hardness testing, or other mechanical tests. For functional parts such as hydraulic components or pressure-containing housings, pressure tests or leak tests may be part of the quality process.

Application Cases of CNC Aluminum Machining

CNC aluminum machining is used across many industries where the combination of low weight, high strength, and precision geometry provides clear benefits. Below are representative cases that illustrate how the process is applied in practice.

Aerospace Structural and Functional Components

In aerospace applications, numerous components are machined from high-strength aluminum alloys such as 2024 and 7075. Typical parts include structural brackets, rib and frame elements, seat framework, avionics housings, and mounting interfaces.

Requirements often include tight tolerances for assembly, consistent mechanical properties verified by material traceability, and surface treatments such as anodizing or conversion coatings to improve corrosion resistance. Multi-axis CNC machining is commonly used to produce complex 3D geometries with optimized strength-to-weight ratios.

Automotive and Motorsport Parts

Aluminum CNC machining supports the production of lightweight components in automotive and motorsport sectors. Parts include engine brackets, suspension elements, intake manifolds, gearbox housings, and custom performance parts such as brake adapters and steering components.

Design priorities focus on reduced mass, sufficient stiffness for dynamic loads, and visually appealing surfaces for exposed parts. CNC machining allows quick iteration of prototype designs during development and efficient production of low-to-medium volume performance components.

Electronics Housings and Heat Dissipation Components

Aluminum is a favorable material for electronic housings and heat-dissipating elements due to its good thermal conductivity. CNC machining is used to produce enclosures, heat sinks, RF and microwave housings, and precision mounting plates for electronic modules.

Precision machining ensures proper fit for interface connectors, seals, and PCBs. Surface treatment may include anodizing for insulation and corrosion resistance, as well as specific finishing to improve thermal contact with thermal interface materials.

Robotics, Automation, and Machinery Components

In robotics and factory automation, aluminum CNC parts include arm structures, joints, end effectors, brackets, linear motion supports, and various machine frames. Low weight reduces inertia and improves dynamic performance, while high dimensional accuracy ensures smooth motion and reliable positioning.

CNC machining of aluminum enables tailored designs for new automation cells, special-purpose machines, and customized fixtures. Parts can be optimized for stiffness and accessibility, with integrated mounting features for sensors, actuators, and cable management.

Medical and Laboratory Equipment Components

Medical devices and laboratory equipment often use aluminum components in frames, holders, instrumentation housings, and motion systems. Requirements include cleanability, corrosion resistance, and high precision. CNC machining offers the ability to integrate multiple functions in a single component, such as mounting features, channels, and positioning elements.

Cost and Production Considerations

Cost-effectiveness of CNC aluminum machining depends on multiple factors. Appropriate process planning can significantly reduce overall cost while maintaining quality.

Material Utilization and Blank Selection

Using stock shapes that are close to final geometry reduces machining time and material waste. For example, extrusions may be used for long sections with repeated cross-sections, while plates and blocks are chosen for more complex shapes.

Nesting multiple parts within a single stock piece or standardizing blank sizes can improve material utilization. For large parts with deep pockets, the weight of removed material should be considered, as it affects both cost and handling requirements.

Setup Optimization and Batch Size

Setup time, including programming, fixture design, and machine preparation, constitutes a significant portion of total cost for small batches. Consolidating features to reduce the number of setups and using modular fixturing systems help improve efficiency.

For repeated production, investment in dedicated fixtures and optimized toolpaths can reduce cycle time per part and improve overall cost competitiveness.

Tooling Strategy and Tool Life Management

Tool selection and life management influence both productivity and surface quality. Using standardized tool libraries, balanced tool assemblies for high-speed operations, and appropriate tool coatings for aluminum contribute to reliable performance.

Monitoring tool wear through inspection or tool life counters allows timely replacement before dimensional or surface issues occur. Stable processes reduce scrap and rework, improving overall cost structure.

Integration of CNC Aluminum Machining in Production Chains

CNC aluminum machining often forms part of a broader manufacturing and supply chain, from material procurement to final assembly and packaging. Understanding its role helps coordinate scheduling, quality control, and logistics.

From Prototype to Production

During product development, CNC machining is used to produce prototypes and engineering test parts. The same or similar CNC programs and fixtures can frequently be adapted for initial production, ensuring consistency between prototypes and final components.

Process documentation, including setup sheets and inspection records, helps gradually refine processes as volumes increase. For some products, CNC machining remains the primary method even at higher quantities, especially where flexibility and complexity outweigh the advantages of dedicated tooling.

Combination with Other Manufacturing Processes

CNC aluminum machining is often combined with other processes. Cast or forged aluminum blanks might be machined to final tolerances and surface finish. Extruded profiles are cut to length and machined with features such as holes, slots, and pockets. Sheet metal aluminum parts may be formed and then undergo localized machining.

This combination allows designers to exploit the strengths of multiple processes, using CNC machining for precision features and critical interfaces while relying on forming or casting for cost-effective bulk shaping.

FAQs about CNC Aluminum Machining

What is CNC aluminum machining?

CNC aluminum machining is a computer-controlled manufacturing process that precisely removes material from aluminum workpieces to produce accurate and repeatable parts.

What CNC techniques are commonly used for aluminum machining?

Common techniques include CNC milling, CNC turning, drilling, tapping, and multi-axis machining for complex aluminum components.

Why is aluminum ideal for CNC machining?

Aluminum offers excellent machinability, lightweight properties, corrosion resistance, and high strength-to-weight ratio, making it ideal for CNC machining.

What are the main advantages of CNC aluminum machining?

Key advantages include high precision, fast machining speeds, consistent quality, lower tooling wear, and cost-effective production.

How does CNC aluminum machining compare to other manufacturing methods?

Compared to casting or extrusion, CNC machining offers higher accuracy, better surface finish, and greater design flexibility.

Which aluminum alloys are commonly used in CNC machining?

Frequently used alloys include aluminum 6061, 7075, 5052, and 2024, selected based on strength, corrosion resistance, and application needs.