Custom CNC machining is a core method for on-demand manufacturing, enabling rapid production of precise, repeatable parts from metals, plastics, and specialty materials. By combining digital design with computer-controlled machine tools, it supports prototypes, bridge production, and low-to-mid volume manufacturing with consistent quality and predictable lead times.

About Custom CNC Machining in On-Demand Production

Computer Numerical Control (CNC) machining uses programmed toolpaths to remove material from a workpiece and produce a finished part. In an on-demand manufacturing context, the entire workflow—from quote to shipment—is streamlined and digitally connected, allowing parts to be produced when needed and in the quantities required.

Key characteristics include:

- Digital integration from CAD/CAM to machine execution

- Repeatable accuracy and tight tolerances suitable for end-use parts

- Compatibility with a wide range of engineering materials

On-demand CNC machining is particularly suitable where dimensional control, mechanical strength, and material-specific properties are critical, and where tooling investments for processes like injection molding are not justified by volume.

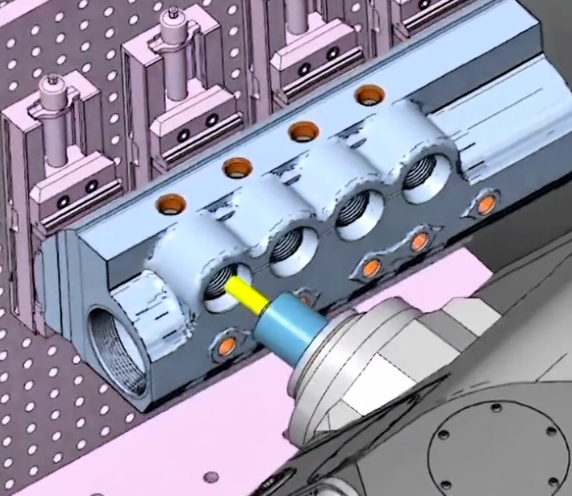

Core CNC Machining Processes

Several CNC processes are commonly used in on-demand manufacturing. These processes are often combined within a single supply chain to achieve complete parts.

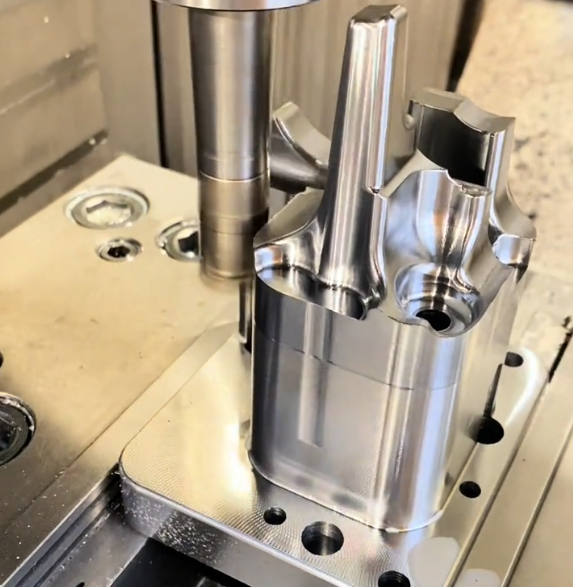

CNC Milling

CNC milling uses rotating cutting tools to remove material from a stationary or moving workpiece. Multi-axis mills can produce prismatic and complex 3D geometries.

Typical applications include:

- Flat and contoured surfaces with pockets, slots, and holes

- Enclosures, brackets, housings, and structural components

- Precision features such as sealing faces and mounting interfaces

CNC Turning

CNC turning involves rotating the workpiece while a stationary cutting tool removes material. It is well-suited for axisymmetric components.

Typical applications include:

- Shafts, bushings, pins, and spacers

- Threaded components and fittings

- Rotors, hubs, and cylindrical housings

Live Tooling and Mill-Turn Operations

Mill-turn machines combine turning with live tooling for milling, drilling, and tapping in the same setup. This reduces handling and improves positional accuracy between features.

Suitable use cases include parts with a dominant cylindrical form but requiring flats, keyways, cross-holes, or complex end faces.

Secondary and Auxiliary Operations

For fully finished components, CNC machining is frequently complemented by:

Common secondary operations include:

- Reaming and honing for precise holes

- Thread rolling or forming where required

- Surface treatments such as anodizing, plating, and heat treatment

Materials for Custom CNC Machining

CNC machining supports a broad set of engineering materials. Material selection affects machinability, achievable tolerances, surface finish, mechanical properties, and total cost.

| Material Category | Common Grades | Key Properties | Typical Applications |

|---|---|---|---|

| Aluminum Alloys | 6061-T6, 7075-T6, 6082, 2024 | Good strength-to-weight, excellent machinability, good corrosion resistance (with or without anodizing) | Aerospace and automotive components, enclosures, jigs and fixtures, heat sinks |

| Carbon & Alloy Steels | 1018, 1045, 4140, 4340 | High strength and toughness, can be heat treated, good wear resistance | Powertrain parts, shafts, gears (post-processing), structural components |

| Stainless Steels | 304, 316, 17-4 PH | Excellent corrosion resistance, high strength at elevated temperatures (grade-dependent) | Medical components, food-processing equipment, marine parts, instrumentation |

| Copper & Copper Alloys | C110, C360 brass, bronze grades | High electrical and thermal conductivity (copper), good machinability (brass) | Electrical contacts, connectors, plumbing components, decorative hardware |

| Titanium Alloys | Ti-6Al-4V (Grade 5) | High strength-to-weight ratio, excellent corrosion resistance, biocompatible | Aerospace hardware, medical implants, high-performance components |

| Engineering Plastics | ABS, POM (Delrin), Nylon, PC, PEEK | Low weight, electrical insulation, chemical resistance (grade-dependent) | Insulators, manifolds, wear components, test fixtures, housings |

| Other Materials | Tool steels, zinc alloys, composites (limited) | Wear resistance, hardness, specialty performance | Molds and dies, cutting tools, specific high-duty components |

Dimensional Capabilities and Tolerances

On-demand CNC machining can achieve high dimensional accuracy when supported by appropriate design and process control. Typical general tolerances for many shops are around ±0.10 mm, but much tighter limits are feasible on critical features.

Common capability ranges (actual values depend on equipment, material, and part geometry) include:

- Linear tolerances: from ±0.10 mm down to ±0.005 mm on precision features

- Hole diameters: typically ±0.05 mm, down to ±0.01 mm with reaming or boring

- Flatness and parallelism: often controlled within 0.05–0.02 mm for small parts

- Position tolerances: typically managed via true position GD&T based on functional requirements

Designs for on-demand machining benefit from using standard fits (e.g., H7/g6) and specifying tolerances only where they are functionally necessary. Over-tolerancing increases cost, cycle time, and inspection effort without improving performance.

Surface Finish and Post-Processing

Surface roughness and post-processing significantly influence performance, aesthetics, and compliance requirements. CNC machining delivers functional surfaces directly off the machine, but many applications call for additional finishing or treatment.

Surface Roughness for Machined Parts

Typical ranges of arithmetic average roughness (Ra) include:

- Standard milling and turning: Ra ≈ 3.2–6.3 μm

- Fine finishing passes: Ra ≈ 0.8–1.6 μm

- Polished surfaces (additional manual or automated finishing): Ra below 0.4 μm

Surface roughness should be specified only on critical interfaces, such as sealing faces, sliding surfaces, optical interfaces, or bonding surfaces.

Common Post-Processing Options

Post-processing options are selected based on mechanical, environmental, or regulatory requirements.

| Process | Applicable Materials | Purpose | Typical Use Cases |

|---|---|---|---|

| Anodizing (Type II / Type III) | Aluminum alloys | Corrosion resistance, color coding, improved surface hardness | Consumer enclosures, structural components, outdoor hardware |

| Plating (Ni, Zn, Cr, etc.) | Steels, brass, copper alloys | Corrosion protection, wear resistance, conductivity control, appearance | Fasteners, connectors, decorative parts, mechanical assemblies |

| Heat Treatment | Carbon steels, alloy steels, tool steels, some stainless grades | Hardness, strength, wear resistance, dimensional stability | Gears, shafts, dies, structural parts with high load requirements |

| Bead Blasting | Metals, some plastics | Uniform matte finish, surface preparation, removal of minor marks | Visible housings, aesthetic panels, grip surfaces |

| Powder Coating / Painting | Metals | Durable color finish, corrosion protection, branding | Industrial equipment, consumer products, enclosures |

| Polishing and Buffing | Metals, some plastics | Low roughness, improved aesthetics, optical clarity for transparent plastics | Decorative hardware, medical instruments, optical components |

Design for Manufacturability in CNC Machining

Design for manufacturability (DFM) ensures that parts can be produced accurately, quickly, and at reasonable cost. In on-demand manufacturing, DFM directly affects lead time, pricing, and reliability.

Geometry Considerations

Some geometric features impact machining time and setup complexity:

- Deep cavities and thin walls increase tool deflection and may require multiple passes and specialized tooling.

- Very small radii and narrow slots require small tools, which reduce feed rates and increase cycle time.

- Undercuts and internal features that are not accessible from standard orientations may need custom tooling or multiple setups.

Whenever possible, parts can be designed with accessible features, consistent wall thicknesses, and fillets that match available tool diameters.

Tolerancing and GD&T

Applying geometric dimensioning and tolerancing (GD&T) allows functional requirements to be captured without unnecessarily restricting non-critical areas. This supports cost-effective production while ensuring that assemblies function correctly.

Common practices include:

- Using datums that reflect how the part is assembled or constrained in service.

- Applying position tolerances to hole patterns, bearing bores, and critical alignment features.

- Limiting tight tolerances to fits, sealing faces, and functional interfaces.

Material and Thickness Selection

Material choice and section thickness are closely linked. For metallic parts, excessive thickness increases material cost and cycle time; overly thin features can lead to distortion during machining or use. For plastics, stiffness, creep resistance, and thermal expansion need to be considered to maintain dimensional stability.

Digital Workflow and On-Demand Ordering

On-demand CNC services typically operate on a digital workflow that shortens time between design and physical parts.

From CAD to CAM and NC Code

The typical data flow includes:

- CAD model creation by the customer, often accompanied by a 2D drawing for critical dimensions and tolerances.

- CAM programming to generate toolpaths based on geometry, tools, and machine constraints.

- Post-processing to convert CAM data into NC code specific to the machining center.

This workflow allows quick iteration if design changes are needed, especially for prototypes and low-volume production runs.

Quoting and Order Management

Online CNC platforms often provide automated or semi-automated quoting. Inputs typically include:

- 3D CAD files (e.g., STEP, IGES, Parasolid)

- Drawings specifying tolerances, threads, and finishes

- Material, quantity, and delivery requirements

Automated analysis can flag non-manufacturable features and suggest adjustments, reducing the number of design cycles and manual reviews.

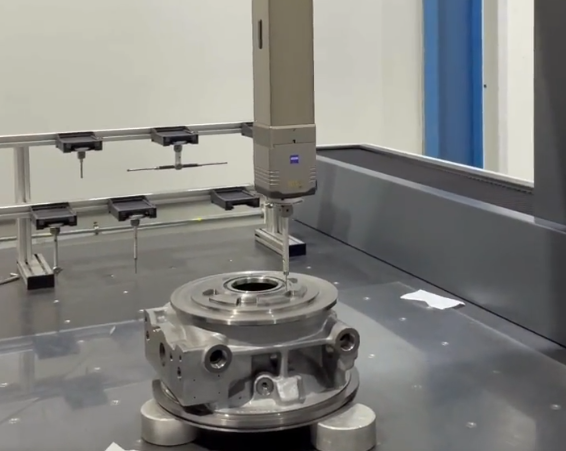

Quality Assurance and Inspection

Consistent quality is central to custom CNC machining. Inspection and process control ensure that parts meet dimensional and functional requirements.

Inspection Methods

Common inspection tools and methods include:

- Hand tools such as calipers, micrometers, height gauges, and plug gauges.

- Coordinate Measuring Machines (CMM) for complex geometries and tight tolerances.

- Optical measurement systems for small features and delicate components.

For serialized production, sampling plans and statistical process control (SPC) may be used to maintain consistency without 100% measurement of every dimension on every part.

Documentation and Traceability

On-demand manufacturing services often provide quality documentation aligned with customer requirements.

- Inspection reports listing measured dimensions and tolerances.

- Material certificates confirming grade and composition.

- Process records for heat treatment, surface treatments, and special operations.

For industries with regulatory obligations, additional traceability such as batch numbers and serialization can be integrated into the CNC workflow using engraving or marking.

Production Volumes and Use Cases

CNC machining supports a wide volume range, from single prototypes to ongoing batches.

Prototyping and Pre-Production

For prototypes and engineering validation, CNC machining offers:

- Use of end-use materials, enabling direct mechanical and environmental testing.

- Accurate representation of final geometry, including tight tolerances and surface finishes.

- Rapid iteration; design updates can be implemented between short production runs.

This is useful for functional testing, pilot builds, and validating assembly behavior before committing to higher-volume processes.

Bridge and Low-to-Medium Volume Production

When initial demand is uncertain or product life cycles are short, CNC machining can serve as a bridge between prototyping and high-volume manufacturing. Benefits include:

- No dedicated hard tooling required, avoiding upfront mold costs.

- Ability to adjust design between batches without scrap of legacy tooling.

- Consistent part quality across repeated orders due to digital process control.

Common Issues When Sourcing CNC Machined Parts

Buyers and engineers sometimes encounter recurring difficulties when working with custom CNC machining services. Recognizing these helps in specifying requirements more effectively.

- Ambiguous or incomplete drawings, leading to inconsistent interpretations of tolerances or finishes.

- Over-constrained tolerances that increase costs and delivery times without functional benefit.

- Insufficient information on critical surfaces, leading to incompatibility in assembly.

- Unclear requirements for material certificates, inspection reports, or regulatory compliance.

Clear engineering documentation, defined acceptance criteria, and early communication between designers and manufacturing engineers help reduce these issues.

When CNC Machining Is a Good Fit for On-Demand Manufacturing

CNC machining is particularly suitable for on-demand scenarios when:

- Parts require tight tolerances, stable mechanical properties, or specific surface finishes.

- Material properties are critical, such as strength, thermal performance, or chemical resistance.

- Designs are expected to evolve, and flexibility is needed between iterations.

- Volumes do not justify dedicated tooling-based processes.

By aligning design choices, material selection, tolerances, and quality expectations with the capabilities of CNC machining, on-demand manufacturing can provide reliable parts in lead times compatible with modern development cycles.

FAQ

What is on-demand custom CNC machining?

On-demand custom CNC machining is a flexible manufacturing approach that produces parts only when needed, allowing customers to order custom components without long-term inventory commitments.

How does on-demand CNC machining support agile manufacturing?

It enables fast production, rapid design changes, and scalable order quantities, helping manufacturers respond quickly to market demand and product updates.

What tolerances can be achieved with on-demand CNC machining?

Precision tolerances as tight as ±0.001 mm can be achieved, depending on design and material.

Is on-demand CNC machining suitable for end-use parts?

Yes, CNC machining produces production-quality components suitable for functional testing and end-use applications.