Machining titanium and stainless steel requires significantly different approaches, even though both are categorized as difficult-to-machine materials. This guide compares them in terms of material behavior, tool selection, cutting data, coolant strategies, and process optimization so that process engineers, programmers, and machinists can set realistic parameters and control cost per part.

Fundamental Material Differences

The first step in optimizing titanium and stainless steel machining is understanding how their physical and mechanical properties affect cutting behavior.

| Property | Titanium (Ti-6Al-4V typical) | Stainless Steel (304 / 316 typical) |

|---|---|---|

| Density | ~4.4–4.5 g/cm³ | ~7.8–8.0 g/cm³ |

| Thermal conductivity | ~6–7 W/m·K (low) | ~15–20 W/m·K (higher) |

| Elastic modulus | ~110 GPa (low stiffness) | ~190–210 GPa |

| Ultimate tensile strength (common grades) | ~900–1100 MPa | ~520–750 MPa (austenitic), higher for martensitic |

| Work-hardening tendency | Moderate to high at tool–chip interface | High for austenitic grades (304, 316) |

| Chemical reactivity | High reactivity with tool materials at elevated temperature | Moderate; forms tenacious oxide films |

These properties result in distinct machining behaviors:

- Titanium keeps heat at the cutting zone, promotes rapid tool wear and notch wear, and tends to deflect due to low stiffness.

- Stainless steel, especially austenitic grades, work-hardens rapidly, generates high cutting forces, and can cause built-up edge and adhesion on cutting tools.

Machinability Characteristics

Machinability is not a single property but a combination of tool life, surface finish, achievable cutting speed, chip control, and power consumption.

Titanium Machinability

Typical characteristics when machining titanium alloys:

- Permissible cutting speeds are relatively low.

- Cutting forces are moderate but concentrated on a small contact zone.

- Heat is concentrated in both the tool and the workpiece because of low thermal conductivity.

- Tool life is dominated by crater wear, flank wear, notch wear, and chipping.

- Thin walls and long overhangs are prone to chatter and distortion.

Ti-6Al-4V is often used as a reference grade; in many machinability rating systems it is much less machinable than low-carbon steels and common stainless steels, requiring lower speeds and careful coolant delivery and toolpath strategies.

Stainless Steel Machinability

Stainless steels cover a wide family of alloys. The most common machining grades fall into three categories:

- Austenitic (e.g., 304, 316, 321): high toughness, strong work-hardening, lower thermal conductivity than carbon steels.

- Martensitic (e.g., 410, 420, 440C): harder, higher strength, can be abrasive after heat treatment.

- Ferritic / duplex (e.g., 430, 2205): higher strength and moderate work-hardening; duplex can be quite demanding.

Typical stainless steel machinability traits include:

High cutting forces, strong tendency to work-harden if cutting conditions are too light or if tools rub instead of cutting, formation of long, tough chips without optimized chipbreaker geometry, a tendency to generate built-up edge at low to moderate cutting speeds, and sensitivity to heat, which can degrade surface integrity and corrosion resistance if not controlled.

Tool Material Selection

Cutting tool material choice must reflect the thermal and mechanical behavior of the workpiece, the stability of the setup, and the required productivity.

Tool Materials for Titanium

Common choices include:

Cemented carbide: Fine-grain or submicron grades with high hot hardness and toughness are standard. Coatings typically include AlTiN, TiAlN, or AlCrN, chosen for their thermal stability and oxidation resistance at high temperatures. PVD coatings are preferred over CVD to maintain sharper cutting edges and higher toughness.

Cermets and ceramics:

In roughing of certain titanium components, advanced SiAlON ceramics can be used at high cutting speeds under rigid conditions, but this is less common in general machining because of brittleness and sensitivity to interrupted cuts.

Polycrystalline diamond (PCD): Generally not recommended for titanium due to strong chemical affinity and rapid tool wear at elevated temperatures, except in specific non-ferrous titanium matrix composites or under special conditions.

Tool Materials for Stainless Steel

Stainless steels allow a wider spectrum of tool materials:

Cemented carbide: Universal choice for turning and milling. Grades are optimized with a balance of toughness and hot hardness. CVD or PVD coatings are selected according to operation type: roughing or finishing, continuous or interrupted cuts.

Cermets: Useful for finishing austenitic stainless steels at high speeds with light cuts, especially when high surface finish is required and interruptions are minimal.

Coated HSS: Used for drilling, tapping, and reaming at lower speeds, particularly in small diameters or when machine power is limited. Cobalt-alloyed HSS improves red hardness.

Ceramics and PCBN: For some hard martensitic stainless steels, whisker-reinforced ceramics or PCBN may be used in finishing operations at higher speeds; they demand high rigidity and stable cutting conditions.

Cutting Parameters and Speeds

Cutting data differs significantly between titanium and stainless steel due to heat generation, tool wear mechanisms, and chip formation behavior.

| Operation | Titanium Alloy (e.g., Ti-6Al-4V) | Austenitic Stainless (e.g., 304/316) |

|---|---|---|

| Carbide turning, roughing | 30–70 m/min | 80–180 m/min |

| Carbide turning, finishing | 40–90 m/min | 120–250 m/min |

| Carbide milling, roughing | 40–90 m/min | 80–200 m/min |

| Carbide milling, finishing | 60–120 m/min | 120–260 m/min |

| Carbide drilling, Ø>10 mm | 20–60 m/min | 40–120 m/min |

| HSS drilling, Ø<10 mm | 8–18 m/min | 10–25 m/min |

These values are indicative starting points and must be adjusted to specific tool grades, coatings, coolant conditions, rigidity, and machine capability.

Feed Rates and Chip Load

For titanium, relatively high feed per tooth and moderate depths of cut are often preferred to maintain a productive chip thickness, avoid rubbing, and overcome work-hardening at the tool–material interface. However, excessive chip load leads to edge chipping and rapid wear because the tool operates in a high-temperature zone.

For stainless steel, feeds must overcome work-hardened layers but also account for higher cutting forces and machine power. A common strategy is to use robust chipbreakers and sufficient feed per revolution or tooth to ensure consistent chip formation, especially in austenitic grades.

Tool Geometry and Edge Preparation

Tool geometry is crucial in controlling cutting forces, chip flow, and heat distribution for both materials.

Geometry Considerations for Titanium

Key aspects include:

Positive rake angles: Tools for titanium typically feature high positive rake to reduce cutting forces and limit heat generation. A positive geometry promotes smooth chip flow and reduces the contact area between chip and rake face.

Edge preparation: A small, controlled hone or very light radius on the cutting edge helps prevent micro-chipping while maintaining a sharp cutting action. Excessive edge rounding increases cutting forces and heat, leading to accelerated wear.

Helix angle (milling): High-helix end mills enhance chip evacuation and provide smoother cutting, but they must be balanced against potential deflection in long overhangs.

Relief and clearance angles: Sufficient clearance is required to avoid rubbing, which quickly raises tool temperature. However, too much clearance reduces edge strength.

Geometry Considerations for Stainless Steel

For stainless steels, the goal is to manage work-hardening and avoid built-up edge:

Moderate to high positive rake: Positive rake reduces cutting forces and limits work-hardening, especially for austenitic grades. In some high-strength martensitic steels, slightly less positive or even neutral rake may be used to enhance edge strength.

Chipbreaker design: Aggressive chipbreakers are often necessary to break long, tough chips, especially in turning. Correct chipbreaker selection is critical for reliable chip evacuation and surface quality.

Edge preparation: A small hone or micro-chamfer is used to prevent edge chipping and control built-up edge formation. Excessive honing leads to more heat and higher forces.

Coolant and Lubrication Strategies

Coolant type, pressure, and application method have a decisive influence on tool life and surface integrity in both titanium and stainless steel machining.

Coolant Use in Titanium Machining

Titanium’s low thermal conductivity concentrates heat at the cutting zone, making coolant strategy critical:

High-pressure coolant (HPC): Directed high-pressure jets at the cutting edge improve chip evacuation, lower tool temperature, and reduce crater and notch wear. Pressures in the range of 20–80 bar or higher are common in modern CNC systems for titanium.

Flood cooling vs. minimum quantity lubrication (MQL): Conventional flood coolant is widely used; MQL can be applied in some high-speed finishing or slotting operations, but process windows are narrow because inadequate heat removal accelerates wear.

Coolant chemistry: Chlorine-free, sulfurized extreme-pressure additives or synthetic coolants with good lubricity help reduce friction and tool wear. Coolant must be filtered to avoid abrasive particles that damage cutting edges.

Coolant Use in Stainless Steel Machining

Stainless steels generate substantial heat and can suffer from surface integrity issues if not cooled properly:

Flood and high-pressure coolant: Effective for chip control, particularly when drilling deep holes or turning with narrow chip evacuation channels. High-pressure coolant also helps break chips in austenitic grades by inducing chip curling and segmentation.

Lubricity: Additives that improve lubricity reduce adhesion, built-up edge, and friction at the tool–chip interface. This contributes to better surface finish and longer tool life.

Threading and tapping: These operations in stainless steel benefit strongly from high-lubricity oils or concentrates, often applied in higher viscosity than general-purpose coolants.

Tool Wear Mechanisms and Tool Life

Understanding dominant wear mechanisms helps to select parameters and predict tool life for both materials.

Titanium Tool Wear

Typical wear patterns in titanium include:

Crater wear: Occurs on the rake face due to high chemical affinity and elevated temperatures at the chip–tool interface. It is accelerated by high cutting speeds and insufficient cooling.

Notch wear: Appears at the depth-of-cut line because titanium tends to harden and react at the transition between the machined and unmachined surface. This is especially pronounced in interrupted cuts and during milling with repeated entry and exit.

Flank wear and micro-chipping: Develop due to abrasion, high localized stress, and thermal cycling. Sharp yet reinforced edges and consistent cutting conditions help reduce these modes.

Stainless Steel Tool Wear

Common wear patterns in stainless steel include:

Abrasion and adhesion: Hard carbides in martensitic and duplex grades cause abrasive wear, while austenitic grades can cause adhesion and built-up edge, leading to unstable cutting forces and poor finish.

Flank wear: Often the main criterion for tool life. Wear is influenced by cutting speed, feed, and coolant effectiveness. Excessive flank wear increases cutting forces and risk of tool failure.

Chipping and breakage: Occur when tools are confronted with work-hardened layers or interrupted cuts at aggressive parameters. Correct edge preparation and stable fixturing reduce the risk.

Chip Formation and Chip Control

Chip morphology differs between titanium and stainless steels and has practical implications for safety, automation, and surface quality.

Chips in Titanium Machining

Titanium typically forms short, segmented, or curled chips due to its low thermal conductivity, high strength, and relatively lower strain to fracture at cutting temperatures. The chips often appear straw-colored to blue because of the high cutting temperature.

Pros: Shorter chips generally reduce entanglement and allow easier removal from the cutting area. This can simplify automated machining in some operations.

Considerations: Chips can be extremely hot and may ignite combustible materials under unfavorable conditions. Effective chip evacuation, enclosure cleanliness, and appropriate coolant supply are important.

Chips in Stainless Steel Machining

In austenitic stainless steels, the chips tend to be long, tough, and continuous if chipbreaker geometry and cutting conditions are not optimized. Work-hardening promotes high strength in the chip, making it more difficult to break.

Problems: Long chips can wrap around tools and workpieces, interfere with automatic bar feeders and chip conveyors, and cause surface damage by scratching the workpiece.

Control strategies: Proper chipbreaker design, sufficient feed per revolution, and high-pressure coolant can produce controlled, shorter chips. In drilling, peck cycles and optimized flute design improve chip evacuation.

Surface Finish and Dimensional Accuracy

Surface quality and dimensional stability are heavily influenced by material properties, tool condition, and cutting parameters.

Surface Finish in Titanium

Titanium’s low stiffness means that thin sections and long parts are sensitive to deflection. This can cause geometric deviations and waviness, especially in milling operations. Additionally, high cutting temperatures can modify the surface layer, causing discoloration and affecting fatigue strength if not controlled.

Key practices include using sharp tools with positive rake, stable fixturing, consistent coolant application, and avoiding excessive radial engagement. For high-precision components, finishing passes with reduced depth-of-cut and carefully controlled feeds are common.

Surface Finish in Stainless Steel

Stainless steels, particularly austenitic grades, can deliver excellent surface finishes when work-hardening and built-up edge are under control. However, if cutting parameters are too light or tools are dull, the material may smear rather than cut cleanly, resulting in a poor finish.

Using fresh, sharp inserts or tools, correct cutting speeds to minimize built-up edge, and adequate coolant greatly improves finish. In ground and polished components, control of residual stresses and surface integrity is essential for corrosion resistance and fatigue performance.

Workholding, Rigidity, and Machine Requirements

Both titanium and stainless steel require rigid setups, but the reasons differ slightly between the two materials.

Machining Titanium: Rigidity and Deflection

The low elastic modulus of titanium makes workpieces more flexible. Thin-walled parts, turbine blades, and structural aerospace components are especially prone to vibration and chatter. Rigidity at every level—machine structure, spindle, tool, and fixturing—is essential.

Long slender tools should be avoided where possible; when required, stepped tool diameters, tapered shanks, and minimized overhangs are used. Dynamic control strategies such as optimized toolpaths with constant engagement and reduced radial depth-of-cut help to limit deflection.

Machining Stainless Steel: Power and Stability

The higher cutting forces in stainless steels demand sufficient spindle power and torque, particularly in roughing operations and large-diameter drilling. Machines with robust spindles, stiff linear guides, and strong workholding are favored.

Built-up edge and vibration can be reduced by avoiding underpowered setups, ensuring toolholders are balanced and rigid, and using modern holders such as shrink-fit or hydraulic chucks for milling.

Process Planning and Cost per Part

Process planners must weigh material removal rate, tool life, and machine availability when choosing strategies for titanium and stainless steel.

Process Planning for Titanium

In titanium, the limiting factor is often tool life and heat management, not machine power. Process planning focuses on:

Moderate cutting speeds with careful feed and depth-of-cut selection to balance chip load and thermal load, high-pressure coolant and optimized toolpaths to reduce heat and preserve tool edges, and minimizing air cuts, re-entries, and unnecessary tool engagement to reduce thermal cycling and notch wear.

Cycle time can be relatively long compared with aluminum or low-carbon steels, but aggressive attempts to increase speed often result in steep increases in tool costs and unstable processes.

Process Planning for Stainless Steel

In stainless steel, process planning concentrates on managing work-hardening and high cutting forces, while still achieving competitive cycle times. Major considerations include:

Choosing robust roughing strategies that maintain adequate chip thickness, using chipbreaker geometries and coolant delivery optimized for each operation, and selecting machines and tooling systems capable of sustained high-load cutting without excessive vibration.

When machining high volumes, small improvements in chip control and tool life can significantly reduce downtime and tool consumption.

Typical Applications and Material Selection Impact

The application context often dictates whether titanium or stainless steel is used, which in turn defines machining priorities.

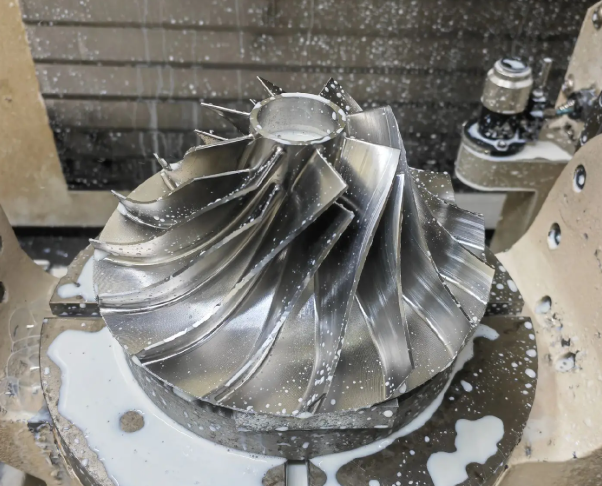

Titanium Applications and Machining Priorities

Titanium is widely used in aerospace structures, jet engine components, medical implants, high-performance automotive parts, and marine applications where corrosion resistance combined with low density is critical.

Machining priorities include maintaining dimensional accuracy in thin-walled structures, controlling surface integrity for fatigue performance in critical components, and ensuring traceable and consistent processes for regulated industries such as aerospace and medical.

Stainless Steel Applications and Machining Priorities

Stainless steels are omnipresent in food and beverage processing equipment, chemical plants, pumps and valves, fasteners, medical instruments, energy and power generation components, and consumer products and architecture.

In these applications, machining priorities typically include maintaining corrosion-resistant surface condition, achieving tight tolerances in seals and mating surfaces, and balancing tool cost with production rate for high-volume components.

Comparative Summary: When to Treat Them Differently

Although both titanium and stainless steel are classified as difficult-to-machine, they require different priorities and parameter windows.

In titanium, thermal management, sharp positive geometry, and high-pressure coolant are central. The process is typically limited by tool life and stability of thin features rather than by machine power.

In stainless steel, combating work-hardening, controlling chip formation, and managing cutting forces dominate. Machine power, tool rigidity, and chip evacuation are often the main constraints, especially in austenitic and duplex grades.

In practice, these differences must be reflected in CAM strategies, tool selection, coolant systems, and inspection methods. Treating titanium exactly like stainless steel, or vice versa, generally results in poor tool life, inadequate surface finish, and increased overall cost per part.

FAQ

What are the main differences between machining titanium and stainless steel?

Titanium is stronger, lighter, and more heat-resistant, but harder to machine due to low thermal conductivity, while stainless steel is easier to machine and more forgiving during cutting.

Which material is more difficult to machine, titanium or stainless steel?

Titanium is generally more difficult to machine because it generates higher cutting temperatures and causes faster tool wear.

Does titanium machining cost more than stainless steel machining?

Yes, titanium machining typically costs more due to higher material prices, slower machining speeds, and increased tooling costs.

Which industries typically choose titanium over stainless steel?

Aerospace, medical, and high-performance automotive industries often choose titanium, while stainless steel is widely used in industrial and commercial applications.

When should stainless steel be selected instead of titanium?

Stainless steel is preferred when cost efficiency, ease of machining, and corrosion resistance are required without strict weight constraints.