GH4169 is a precipitation-hardened nickel-iron-based superalloy widely used in high-temperature, high-stress structural components. It is considered the Chinese equivalent or close analogue to Inconel 718, with comparable composition and performance. This alloy combines high yield strength, fatigue resistance, and oxidation and corrosion resistance up to medium-high temperatures, along with good processability, making it a key material in aerospace, power generation, and other high-performance engineering fields.

Chemical Composition and Alloy Design

GH4169 is a nickel-iron-based superalloy strengthened mainly by γ′ (Ni3(Al,Ti)) and γ″ (Ni3Nb) precipitates. Its composition is optimized to balance strength, fabricability, and structural stability over a wide temperature range.

| Element | Content Range (wt.%) | Functional Role |

|---|---|---|

| Ni | ≈ 50–55 | Base element, forms γ matrix, ensures high-temperature strength and corrosion resistance |

| Cr | ≈ 17–21 | Improves oxidation and hot corrosion resistance by forming Cr2O3 protective films |

| Fe | ≈ 17–20 | Cost-effective balance element, contributes to matrix stability |

| Nb + Ta | ≈ 4.5–5.5 | Forms γ″ strengthening phase, key for high yield strength |

| Mo | ≈ 2.8–3.3 | Solid solution strengthening, enhances high-temperature strength and creep resistance |

| Ti | ≈ 0.6–1.2 | Participates in γ′ formation, contributes to precipitation strengthening |

| Al | ≈ 0.2–0.8 | γ′ former, improves strength and oxidation resistance |

| Co | ≤ 1 | Optional for additional solid solution strengthening and thermal stability |

| Mn | ≤ 0.35 | Deoxidation and desulfurization, improves hot workability |

| Si | ≤ 0.35 | Deoxidizer, contributes to cleanliness control |

| C | ≈ 0.02–0.08 | Forms carbides, controls grain boundaries and creep strength |

| P, S | Each ≤ 0.015 | Impurities; must be minimized to reduce hot cracking and embrittlement |

| B | ≤ 0.01 | Improves grain boundary cohesion and creep performance |

| Cu | ≤ 0.3 | Permissible residual element |

The dual-phase precipitation strengthening (γ′ + γ″) is the core of GH4169’s alloy design. γ″ phase (Ni3Nb) is especially effective in increasing yield and fatigue strength, while γ′ phase adds high-temperature structural stability. Controlled Nb and Ti levels are critical to avoid excessive δ phase (Ni<3>Nb) formation, which can affect ductility and toughness if not properly managed through heat treatment.

Physical Properties and Temperature Range

The physical properties of GH4169 are tailored for high-temperature service while maintaining dimensional stability and predictable behavior under thermal cycling.

- Service temperature range: approximately -253 °C to about 650–700 °C, depending on required mechanical properties and design criteria.

- Density: typically around 8.1–8.3 g/cm3.

- Melting range: roughly 1260–1335 °C (liquidus and solidus depending on composition and cleanliness).

- Thermal conductivity: moderate for a nickel-based alloy, increasing with temperature.

- Coefficient of thermal expansion: higher than low-alloy steels, requiring attention in assemblies with dissimilar materials.

At cryogenic temperatures, GH4169 retains high toughness and strength, which is useful for applications involving liquid hydrogen or liquid oxygen. At elevated temperatures, the balance of creep resistance, fatigue strength, and oxidation resistance determines allowable stress levels in engineering design.

Microstructure and Strengthening Mechanisms

GH4169 microstructure is based on a face-centered cubic (FCC) γ matrix with a complex population of precipitates and carbides. Microstructural control over solution and aging treatments underpins the alloy’s mechanical performance.

γ Matrix and Precipitation Phases

The γ matrix is a solid solution of Ni with Fe, Cr, and other alloying elements. Within this matrix, several phases can be present:

- γ′ (Ni3(Al,Ti)): coherent precipitates that hinder dislocation motion, providing temperature-stable strengthening.

- γ″ (Ni3Nb): disc-shaped, coherent precipitates giving strong precipitation hardening, particularly effective up to around 650 °C.

- δ phase (Ni3Nb): orthorhombic phase, usually formed at grain boundaries and within grains after prolonged exposure around 800–1000 °C, used in controlled amounts to refine grain size in wrought products.

- Carbides (mainly MC, M23C6): located on grain boundaries and sometimes within grains, contributing to creep strength and microstructural stability.

The targeted microstructure after standard heat treatment is a uniform distribution of fine γ′ and γ″ precipitates inside the grains, with controlled carbides at grain boundaries and limited δ phase, ensuring a combination of high strength, ductility, and long-term stability.

Grain Size and Cleanliness

Grain size significantly affects fatigue, creep, and tensile properties. For critical rotating components such as turbine disks and compressor wheels, a fine and uniform grain size is typically specified to improve low-cycle fatigue resistance. Cleanliness (low oxygen, sulfur, and non-metallic inclusions) is also crucial, since inclusions can act as crack initiation sites under cyclic loading or high-stress conditions.

Mechanical Properties and Design Data

GH4169 offers a favorable combination of tensile strength, yield strength, fatigue resistance, creep resistance, and fracture toughness across a wide temperature range. Actual values depend on product form, heat treatment, grain size, and testing standards.

| Temperature | Yield Strength (0.2% offset) | Ultimate Tensile Strength | Elongation | Notes |

|---|---|---|---|---|

| Room temperature (≈ 20 °C) | Up to roughly 1000–1200 MPa (solution + aging) | Up to roughly 1200–1400 MPa | Typically 10–25% | Depends on product and heat treatment specification |

| ≈ 650 °C | Lower than room temperature but still high relative to many steels | Moderate tensile strength retention | Moderate ductility | Common design temperature for disks and fasteners |

| Cryogenic (< -150 °C) | High yield strength | High tensile strength | Good toughness | Used for cryogenic components and vessels |

For precise design, engineers rely on material standards and proprietary datasets that provide allowable stresses, S-N curves (fatigue), creep rupture curves, and fracture toughness data. Factors such as surface condition, residual stresses, and environmental medium (air, vacuum, corrosive gas) are also considered in design to ensure reliable performance over specified service life.

Standard Grades, Specifications, and Product Forms

GH4169 is typically covered by Chinese aerospace and national standards, and its performance is generally aligned with international alloys such as Inconel 718. Depending on the application, detailed specifications can define composition limits, mechanical properties, microstructure, non-destructive testing requirements, and acceptance criteria.

Common product forms include:

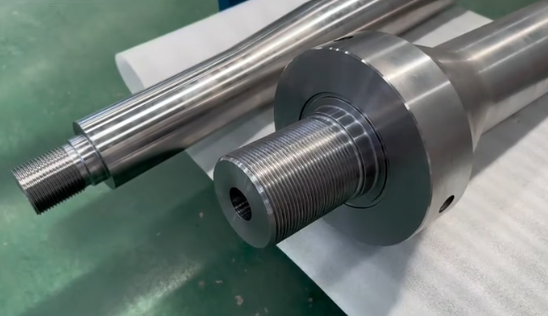

- Forgings: disks, rings, shafts, compressor and turbine components.

- Bars and rods: for machined parts, fasteners, and structural elements.

- Plates and sheets: for structural panels, spacers, and shrouds.

- Strips and foils: for seals, springs, and thin-walled high-temperature parts.

- Wires: for fasteners, springs, and welding consumables.

- Castings (for related alloy systems where applicable): complex shapes with specific processing controls.

Each product form may align with particular standards that define not only composition but also heat treatment schedules, mechanical property levels, and inspection methods such as ultrasonic testing, eddy current testing, and surface inspection.

Heat Treatment Processes

Heat treatment is central to achieving the desired balance of strength, ductility, and structural stability in GH4169. The typical heat treatment sequence involves solution treatment followed by one or multiple aging steps.

Solution Treatment

Solution treatment is conducted at a temperature suitably high to dissolve precipitates such as γ′, γ″, and δ phase into the γ matrix, while avoiding incipient melting and excessive grain growth. After holding for a specified time, the alloy is cooled at a controlled rate, often air cooling or faster, depending on the specifications.

The objectives of solution treatment are:

- Homogenize composition and dissolve coarse precipitates formed during previous processing.

- Prepare a supersaturated solid solution for subsequent precipitation during aging.

- Adjust grain size when combined with forging or thermomechanical treatments.

Aging Treatment

Aging is carried out at one or more intermediate temperatures to precipitate fine γ′ and γ″ particles. A typical aging process involves controlled temperature and time to optimize precipitate size, distribution, and volume fraction, thereby maximizing yield strength and fatigue resistance while retaining adequate ductility.

Key considerations for aging GH4169 include:

- Aging temperature selection to promote γ″ formation without excessive δ phase growth.

- Duration and number of steps (single or double aging) to control precipitate coarsening.

- Compatibility with subsequent manufacturing steps such as machining or surface treatments.

In some applications, modified heat treatments are used to emphasize particular property sets, such as improved low-cycle fatigue, increased creep resistance at specific temperatures, or enhanced dimensional stability under long-term exposure.

Hot Working and Forging Characteristics

GH4169 exhibits good hot workability when processed within the appropriate temperature window. It is commonly processed by forging, rolling, and extrusion to produce bars, rings, and other wrought forms.

Forging Temperature Range and Deformation Behavior

The typical forging temperature range for GH4169 is selected to ensure adequate plasticity while minimizing grain growth and avoiding formation of unwanted phases. During forging:

- Preheating is carried out to ensure uniform temperature distribution and reduce thermal gradients.

- Deformation is applied in multiple passes with intermediate reheating as needed.

- Forging reductions are controlled to refine grain structure and break up cast dendritic structures.

Excessive forging temperatures and overheating can cause grain coarsening and segregation, which degrade mechanical properties, especially fatigue strength. Forging at too low a temperature risks cracking and high deformation resistance.

Ring Rolling and Disk Forging

For turbine disks and compressor rings, ring rolling and disk forging processes are often used to obtain the required geometry and microstructure. These processes aim to produce a uniform radial and axial grain flow pattern, which is critical for controlling anisotropy and ensuring that the strongest directions of the material align with the principal stress directions in service.

Cold Working and Fabrication

GH4169 has higher strength and work hardening rate compared with many steels, which affects its cold formability and fabrication methods. Cold working is possible but requires appropriate tooling and process control.

Key aspects include:

- Intermediate annealing may be required during intensive cold forming operations to restore ductility.

- Forming allowances and springback must be considered due to the high strength of the material.

- Fabrication sequences typically integrate machining, drilling, and forming steps with heat treatments and surface finishing.

For complex structural parts, combined hot and cold working routes are sometimes used to achieve the required dimensions and microstructure while maintaining tight tolerances and surface quality.

Welding and Joining

GH4169 is weldable using various fusion and solid-state welding processes when proper procedures are followed. The main objectives are to maintain joint strength, avoid cracking, and control the heat-affected zone (HAZ) microstructure.

Welding Processes

Typical welding methods applied to GH4169 include:

- Gas tungsten arc welding (GTAW/TIG): commonly used for high-quality welds and precise control.

- Gas metal arc welding (GMAW/MIG): used for higher productivity in suitable geometries.

- Electron beam welding (EBW) and laser beam welding: for high-precision, low-distortion joints, often in aerospace components.

- Resistance welding or friction welding: used for specific joint configurations and production environments.

Welding consumables are usually compositionally matched or closely related to GH4169 to ensure compatible mechanical properties and corrosion resistance in the weld metal.

Heat-Affected Zone and Weldability Considerations

Welding GH4169 requires control of:

- Heat input and interpass temperature: excessive heat can promote formation of brittle phases, coarse grain growth, or segregation in the HAZ.

- Pre-weld and post-weld heat treatments: often required to restore precipitation-strengthened microstructure and relieve residual stresses.

- Welding sequence and joint design: optimized to minimize distortion, residual stress concentration, and potential crack initiation sites.

Stress relief and post-weld aging treatments are often used to re-precipitate γ′ and γ″ in the joint region and recover mechanical properties to levels similar to the base metal.

Machinability and Surface Finishing

GH4169 is characterized by high strength and work hardening tendency, which makes it more challenging to machine compared with conventional steels. Nevertheless, with appropriate tooling and process parameters, stable and efficient machining is achievable.

Machining Characteristics

During machining:

- Cutting forces are relatively high, and tool wear can be significant without optimized conditions.

- Work hardening in the surface layer may occur if cutting parameters and tool geometry are not properly selected.

- Heat generation at the tool-workpiece interface can be substantial, requiring effective cooling and lubrication.

To manage these factors:

- Carbide or advanced tool materials are typically used, often with specialized coatings.

- Moderate cutting speeds, appropriate feeds, and sufficient depth of cut help reduce work hardening and improve tool life.

- Coolants and cutting fluids assist in heat removal and surface finish control.

Surface Integrity and Finishing

Surface integrity is crucial in high-cycle and low-cycle fatigue-critical components such as disks and shafts. After rough machining, finishing processes such as grinding, honing, or polishing may be employed to achieve the required surface roughness and remove surface damage and tensile residual stresses. Shot peening or other surface enhancement techniques can be used to introduce beneficial compressive residual stresses and enhance fatigue performance.

Corrosion and Oxidation Resistance

GH4169 has robust oxidation and corrosion resistance in many high-temperature and aggressive environments due to its Cr and Ni content, combined with Al and other alloying elements that support stable oxide formation.

Oxidation Behavior at Elevated Temperatures

At elevated temperatures, GH4169 forms a protective oxide layer mainly composed of Cr2O3, often enhanced by other complex oxides that adhere well to the surface. This layer helps reduce further oxidation and minimizes metal loss. Oxidation resistance supports long service life for components operating in air or combustion gases within the alloy’s effective temperature range.

Corrosion Performance in Various Media

GH4169 exhibits good resistance to general corrosion, pitting, and stress corrosion cracking in many industrial environments, including certain acids, salts, and marine atmospheres, depending on concentration and temperature. In gas turbine and aero-engine applications, resistance to high-temperature hot corrosion (e.g., from sulfur and chloride-containing deposits) is also important. While GH4169 has substantial resistance to such conditions, component life and maintenance intervals are still carefully managed based on operating environments.

Creep, Fatigue, and Long-Term Stability

For high-performance rotating parts and high-temperature fasteners, creep resistance, fatigue strength, and microstructural stability over long service times are critical aspects of GH4169’s performance.

Creep and Stress Rupture

Creep and stress rupture behavior of GH4169 are influenced by temperature, applied stress, grain size, and aging condition. The dual-phase precipitation strengthening mechanism provides considerable creep resistance within the typical service temperature range. Design engineers use long-term test data to determine allowable stresses for given temperatures and service lives, and these values are codified in relevant standards and design codes.

Low-Cycle and High-Cycle Fatigue

In rotating equipment, GH4169 components often experience complex stress cycles, including thermal-mechanical loading. Low-cycle fatigue (LCF) performance is important for components subjected to high strain amplitudes and thermal transients, while high-cycle fatigue (HCF) is relevant for components exposed to vibration and long-duration cyclic loading with small strain amplitudes.

Factors impacting fatigue performance include:

- Surface finish quality and presence of notches or geometric stress concentrators.

- Microstructural uniformity, grain size, and inclusion content.

- Residual stresses from machining, heat treatment, and peening processes.

- Environmental conditions such as humidity, corrosive gases, or elevated temperature.

Optimized heat treatment, surface enhancement (such as shot peening), and careful design of transitions and fillets contribute to enhanced fatigue life in GH4169 components.

Typical Applications and Performance Requirements

GH4169 is used extensively in aerospace, power generation, and other fields where components face combined demands of high strength, corrosion resistance, and long service life at elevated temperatures.

Aerospace and Aero-Engine Components

In aero-engines and gas turbines, GH4169 is used for:

- Turbine disks and compressor disks requiring high fatigue strength and damage tolerance.

- Rings, spacers, and shafts in rotating assemblies.

- High-temperature fasteners and bolts in hot-section components.

- Structural parts where both low-temperature toughness and high-temperature strength are required.

These components must meet strict requirements for mechanical properties, dimensional stability, and structural integrity, backed by rigorous inspection regimes including ultrasonic, radiographic, and surface inspections.

Power Generation and Industrial Equipment

In power generation and industrial environments, GH4169 is applied in:

- Gas turbine components subjected to thermal and mechanical loads.

- High-temperature springs, seals, and hardware.

- High-pressure, high-temperature bolting systems.

- Certain petrochemical and chemical process equipment parts exposed to aggressive conditions.

Engineers select GH4169 when a combination of structural strength, oxidation resistance, and processability is required, and when alternative materials such as heat-resistant steels cannot meet the full set of performance requirements.

Processing-Related Considerations and Pain Points

While GH4169 offers an excellent balance of properties, it also introduces specific considerations during material selection, processing, and component manufacturing.

Processing and Manufacturing Considerations

Typical considerations include:

- Heat treatment control: precise temperature, time, and cooling rate control are necessary to achieve the desired γ′/γ″ precipitation state and avoid excessive δ phase formation.

- Forging process sensitivity: improper forging schedules may cause inhomogeneous microstructures, undesirable grain size distribution, or residual segregation, affecting fatigue performance.

- Machining complexity: high strength and work hardening tendency can increase tool wear and machining time, requiring specialized tooling and process optimization.

- Welding process control: improper welding parameters or post-weld heat treatment can lead to cracking, softened zones, or microstructural instability in the HAZ and weld metal.

- Inspection and quality control: stringent non-destructive testing and metallographic examination are often necessary for safety-critical parts, increasing process complexity.

These considerations are usually addressed through well-established process specifications, qualified procedures, and adherence to relevant standards, ensuring consistent and reliable material performance in service.

Storage, Handling, and Quality Assurance

Proper storage and handling of GH4169 semi-finished and finished products help maintain surface quality, corrosion resistance, and overall performance characteristics.

Storage and Handling

During storage and handling:

- Products are typically kept in dry, clean environments to minimize corrosion and surface contamination.

- Contact with carbon steels and other dissimilar metals is controlled to avoid surface contamination or galvanic effects, especially prior to heat treatment and welding.

- Surface damage such as scratches, dents, or impact marks is avoided, as these can become crack initiation sites under fatigue loading.

Quality Assurance and Certification

Quality assurance for GH4169 typically includes:

- Chemical analysis verification to ensure compliance with specified composition ranges.

- Mechanical property testing (tensile, impact, hardness, and sometimes fatigue or creep tests) in accordance with relevant standards.

- Non-destructive testing such as ultrasonic testing, eddy current testing, and surface inspection for critical components.

- Metallographic examination to verify grain size, cleanliness, and presence and distribution of precipitates and carbides.

Certified material documentation, including mill test reports and process traceability records, supports engineering design and regulatory compliance, particularly in aerospace and power-generation applications.

FAQ About GH4169 Superalloy

What is GH4169 superalloy?

GH4169 is a precipitation-hardened nickel-based superalloy known for its high strength, excellent corrosion resistance, and good fatigue performance at elevated temperatures. It is widely used in aerospace, power generation, and high-temperature industrial applications.

How does GH4169 compare to Inconel 718?

GH4169 is the Chinese standard equivalent of Inconel 718, with very similar chemical composition, mechanical properties, and performance characteristics.

Is GH4169 easy to machine?

GH4169 has moderate machinability. Due to its high strength and work-hardening tendency, proper cutting tools, low cutting speeds, and sufficient cooling are recommended.

What are the typical applications of GH4169?

GH4169 is commonly used in aircraft engine components, gas turbines, fasteners, springs, pressure vessels, and high-temperature structural parts.