Stainless steel CNC machining is widely used for high-strength, corrosion-resistant, and dimensionally stable components in industries such as medical, aerospace, energy, food processing, automotive, and instrumentation. This guide explains material features, machining methods, process parameters, design considerations, quality control, and cost structure to support technical decision-making and sourcing.

What Is Stainless Steel CNC Machining?

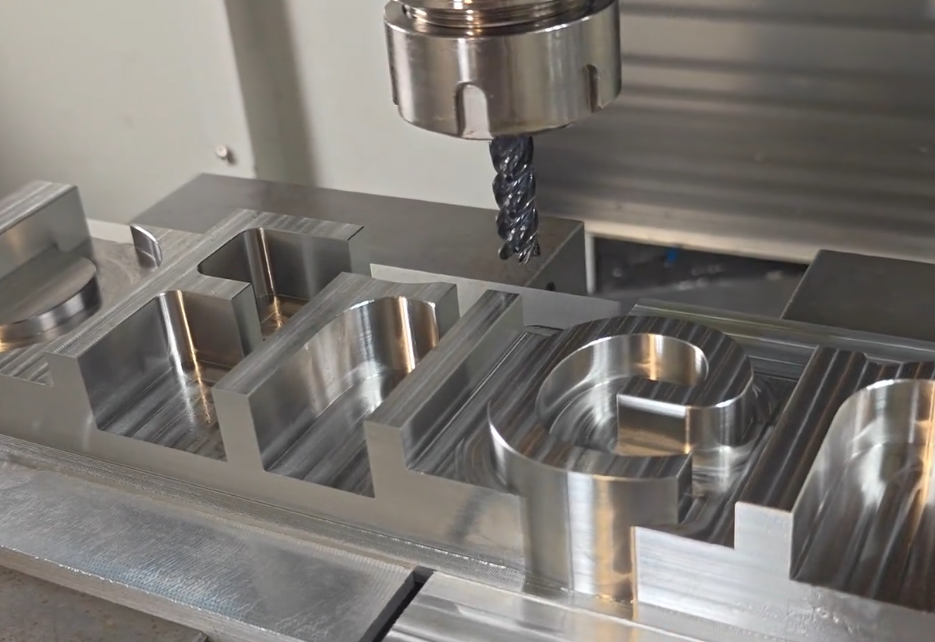

Stainless steel CNC machining is the process of removing material from stainless steel workpieces using computer numerical control (CNC) equipment such as machining centers, turning centers, and multi-axis machines. The process relies on pre-programmed toolpaths and precise machine control to achieve tight tolerances and repeatable quality.

CNC machining of stainless steel is suitable for both prototypes and series production, covers a wide range of part sizes, and supports complex geometries such as 3D contours, deep pockets, and intricate internal features. It can be combined with drilling, tapping, boring, reaming, and various secondary operations to deliver ready-to-assemble components.

Key Features of Stainless Steel for CNC Machining

Stainless steels are iron-based alloys with at least about 10.5% chromium, providing inherent corrosion resistance through a passive oxide film. Additional alloying elements such as nickel, molybdenum, manganese, titanium, and niobium modify mechanical properties and machinability. Understanding these features is essential for selecting the right grade and process.

Corrosion Resistance and Environments

Corrosion resistance depends heavily on alloy composition and surface condition. Austenitic grades (e.g., 304, 316) and duplex grades offer good resistance in many environments, while martensitic and some ferritic grades provide lower corrosion resistance but higher hardness.

- General atmospheric corrosion: Most stainless grades perform well if the passive layer is maintained and surfaces are clean.

- Chloride-containing environments: 316/316L or higher alloyed grades are preferred over 304/304L due to improved pitting and crevice corrosion resistance.

- High-temperature environments: Heat-resistant stainless steels are used to resist scaling and maintain strength.

Machining must preserve surface integrity and avoid contamination (e.g., embedded carbon steel particles) that can impair corrosion resistance.

Mechanical Properties and Strength-to-Weight Ratio

Stainless steels combine moderate to high strength with good ductility. They are denser than aluminum or titanium but provide favorable strength and excellent durability.

Austenitic grades work harden during machining, increasing local hardness. Martensitic and precipitation-hardening grades can achieve high hardness and strength after heat treatment, making them suitable for wear-resistant and high-load components.

Work Hardening and Implications for Machining

Many stainless steels, especially austenitic grades such as 304 and 316, are prone to work hardening. When heavily deformed by cutting, the surface layer hardens, increasing cutting forces and tool wear. This behavior affects virtually every aspect of process planning:

- Need for sharp tools and optimized cutting parameters to cut beneath the hardened layer.

- Avoidance of excessive rubbing, low feed rates, and dull tools that increase work hardening.

- Correct selection of tool materials and coatings to withstand higher thermal and mechanical loads.

Thermal Conductivity and Heat Generation

Stainless steels generally have lower thermal conductivity than carbon steel and some other metals. Heat tends to concentrate at the cutting zone instead of dissipating into the workpiece and chips. This leads to higher cutting temperatures, affecting tool life, dimensional stability, and surface quality. Effective coolant delivery and proper cutting data are critical.

Common Stainless Steel Grades for CNC Machining

The selection of stainless steel grade is driven by corrosion resistance requirements, mechanical properties, machinability, weldability, and cost. The table below summarizes common grades used in CNC machining.

| Grade | Type | Key Features | Typical Applications |

|---|---|---|---|

| 303 | Austenitic, free-machining | Improved machinability, lower corrosion resistance than 304; not recommended for marine or highly corrosive environments. | Fittings, fasteners, small turned parts, shafts. |

| 304 / 304L | Austenitic | Good corrosion resistance, excellent formability, weldable; work hardens; standard choice for many applications. | Food equipment, housings, brackets, consumer products. |

| 316 / 316L | Austenitic | Enhanced corrosion resistance with Mo; better pitting resistance; used in marine and chemical environments. | Marine hardware, medical components, chemical processing parts. |

| 410 | Martensitic | Can be hardened; moderate corrosion resistance; higher strength than 304 when heat treated. | Pump shafts, valves, fasteners, wear components. |

| 420 | Martensitic | High hardenability; can reach high hardness; used for cutting tools and wear-resistant parts. | Surgical instruments, knives, cutting tools. |

| 430 | Ferritic | Lower cost, magnetic; moderate corrosion resistance; limited formability compared to austenitic grades. | Appliance parts, decorative trim, automotive parts. |

| 17-4PH (1.4542) | Precipitation-hardening | High strength and hardness, good corrosion resistance, can be machined in solution-treated condition and aged later. | Aerospace components, high-strength shafts, structural parts. |

Design Considerations for CNC Machined Stainless Steel Parts

Design has a direct impact on machinability, achievable tolerances, and overall cost. When designing stainless steel parts for CNC machining, several aspects should be evaluated systematically.

Wall Thickness and Stiffness

Thin walls can deflect under cutting forces, causing chatter, dimensional inaccuracies, and poor surface finish. A minimum wall thickness of about 0.8–1.0 mm is often used as a practical lower limit for small features in stainless steel, but the optimal value depends on part size, geometry, and material grade. Uniform wall thickness reduces internal stresses and distortion.

Internal Corners and Radii

Sharp internal corners are difficult and time-consuming to machine because tool diameter limits corner radius. Where possible, add internal corner radii equal to or larger than the tool radius. Common practical guidelines include:

- Use internal radii ≥ 0.5–1.0 mm for small cavities, larger for deep pockets.

- Match corner radii to standard end mill sizes to reduce tool changes and machining time.

- Avoid extremely deep narrow slots that require long, slender tools.

Tolerances and Fits

Tight tolerances increase machining time, inspection effort, and scrap risk. Stainless steels can readily achieve tolerances in the range of ±0.01–±0.05 mm on CNC equipment for many dimensions. Tighter tolerances are possible on critical features with appropriate process control, but should be applied selectively where function demands.

Consider the functional fit (clearance, transition, interference) and specify geometric tolerances only where necessary. Over-tolerancing entire drawings often leads to unnecessary cost escalation.

Threading and Features Requiring Tapping

Internal and external threads can be produced in stainless steel by tapping, thread milling, or single-point threading. For small threads, thread milling and forming taps can provide better control and reduce risk of tap breakage. Selecting standard thread sizes and avoiding excessively deep blind threads simplifies machining and improves reliability.

Machining Allowances for Subsequent Processes

If parts will undergo heat treatment, polishing, passivation, or other finishing operations, allow sufficient stock for final machining or finishing steps. This maintains dimensional accuracy and surface quality after all processes are completed.

CNC Machining Methods for Stainless Steel

Stainless steel components can be produced using a range of CNC machining methods. Method selection depends on geometry, required accuracy, batch size, and cost targets.

CNC Milling

CNC milling removes material with rotating cutters and is suitable for prismatic and complex 3D parts. Key aspects for stainless steel milling include:

Cutting strategies: High-efficiency milling and constant chip load strategies help dissipate heat and maintain tool life. Climb milling is generally preferred for better surface finish and lower cutting forces. Avoid excessive radial engagement that increases heat generation.

Typical applications include housings, brackets, manifolds, covers, fixtures, and 3D contoured components used in medical, instrumentation, and aerospace systems.

CNC Turning

CNC turning is used for rotational parts such as shafts, rings, bushings, and fasteners. It typically provides high productivity for cylindrical features and is well suited to materials like stainless steels with proper tooling and parameters.

Considerations include stable workholding to prevent vibration, correct selection of nose radius to balance surface finish and tool pressure, and adequate coolant delivery. Turning centers can also integrate drilling, boring, grooves, and threading in a single setup.

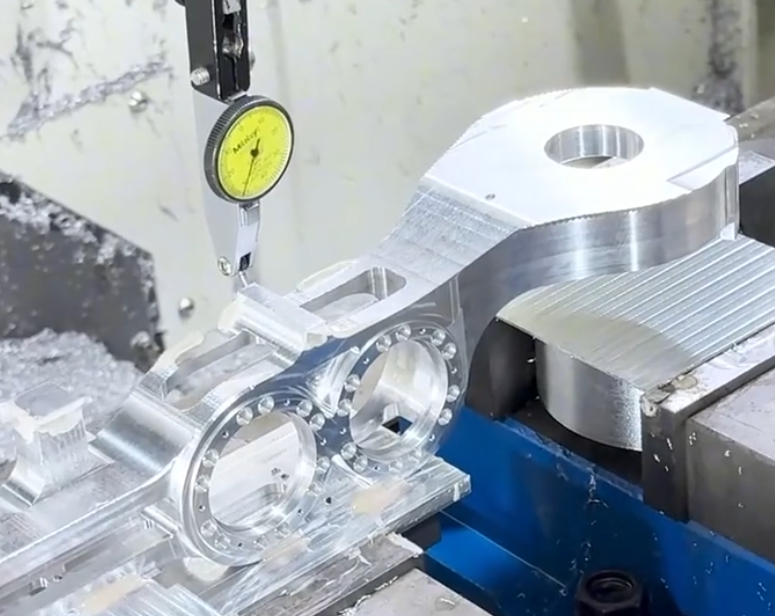

Multi-Axis and Mill-Turn Machining

Multi-axis machining (3+2 and 5-axis) and mill-turn centers enable machining of complex geometries in a reduced number of setups. Benefits include improved positional accuracy, fewer fixtures, and shortened lead times for sophisticated stainless steel parts.

Applications include medical implants, surgical instruments, aerospace brackets, and fluid control components with intersecting channels and compound angles.

Drilling, Boring, and Reaming

Stainless steels require careful drilling practices because of work hardening and high cutting temperatures:

- Use rigid setups and short overhang tools where possible.

- Apply appropriate feed to maintain chip formation and avoid rubbing.

- Implement peck drilling strategies for deep holes to break chips and improve coolant access.

Boring and reaming are often used as finishing operations to achieve tight tolerance holes and improved roundness.

Threading: Tapping and Thread Milling

Tapping stainless steel requires proper lubrication, correct hole size, and suitable tap geometry. Forming taps can provide stronger threads in ductile stainless steels and reduce chip-related problems, but require precise pre-drill diameters. Thread milling offers flexibility in thread size and pitch with a single tool and allows thread repair without removing the part from the machine.

Electrical Discharge Machining (EDM) for Stainless Steel

EDM is often used when stainless steel components have very hard conditions after heat treatment or require delicate profiles that are challenging or uneconomical to produce by conventional cutting. Wire EDM cuts through-thickness profiles, while sinker EDM creates cavities with shaped electrodes. EDM does not rely on cutting forces, which is beneficial for small or fragile features.

Tooling and Cutting Parameters for Stainless Steel CNC Machining

Proper tooling and cutting data are essential for efficient and reliable stainless steel machining. Important aspects include tool material, coating, geometry, and process parameters such as cutting speed, feed rate, and depth of cut.

Tool Materials and Coatings

Carbide tools are widely used for stainless steel due to their high hardness and hot strength. High-speed steel (HSS) tools are used where toughness is more critical than wear resistance, such as some tapping and drilling operations. Coatings such as TiAlN, AlTiN, or similar PVD coatings reduce friction and provide thermal protection, helping to extend tool life in stainless steel machining.

Cutting Speeds, Feeds, and Depth of Cut

Suitable cutting parameters depend strongly on the specific stainless steel grade, tool material, machine rigidity, and coolant delivery. Stainless steels generally require lower cutting speeds than aluminum or mild steel to control heat and wear. Feed per tooth and depth of cut must be balanced to ensure productive chip formation while avoiding excessive cutting forces or chatter.

Coolant and Chip Control

Coolant plays multiple roles: cooling, lubrication, and chip evacuation. For stainless steels, continuous coolant flow directly at the cutting zone is important for temperature control and for preventing built-up edge and work hardening. High-pressure coolant systems are often used in turning and deep-hole drilling to improve chip evacuation and tool life. Chip breakers on inserts and optimized tool geometries help avoid long, stringy chips that can entangle tools or parts.

Tolerances, Surface Finish, and Dimensional Stability

CNC machining of stainless steel can achieve high dimensional accuracy and good surface finish, provided that process planning and machine capability are aligned with part requirements.

Typical Tolerance Ranges

Standard CNC processes commonly achieve tolerances within ±0.05 mm for general dimensions. With careful control, stable fixturing, and good machine calibration, tighter tolerances such as ±0.01 mm can be held on critical features. Ultra-precision tolerances require specialized equipment and process flows.

Surface Roughness and Finishing Levels

Surface roughness (Ra) is a key indicator of machining quality and function. Stainless steel machined surfaces typically achieve:

- Ra ≈ 3.2–1.6 μm for standard roughing and semi-finishing passes.

- Ra ≈ 1.6–0.8 μm for typical finishing operations with appropriate tool geometry and parameters.

- Ra < 0.8 μm if fine finishing or polishing is applied, depending on material and tooling.

Lapped, ground, or polished surfaces can reach lower roughness values when required for sealing surfaces, bearing fits, or optical components.

Residual Stress and Distortion

Stainless steel machining may introduce residual stresses, especially in long, slender, or thin-walled parts. Subsequent stress relief heat treatment or finish machining steps may be required for critical components. Clamping methods and sequence of operations should minimize distortion by avoiding excessive localized forces and heat buildup.

Surface Finishes and Post-Processing for Stainless Steel CNC Parts

Surface finishing enhances appearance, cleanliness, corrosion resistance, and functional performance. Stainless steel components machined by CNC often undergo one or more post-processing steps.

Deburring and Edge Finishing

Machining can leave burrs, especially at drilled holes, threads, and intersecting features. Deburring is critical to ensure safe handling, reliable assembly, and correct function. Methods include manual deburring, mechanical tumbling, brushes, and specialized deburring tools applied on the CNC machine.

Passivation and Cleaning

Passivation enhances stainless steel corrosion resistance by removing free iron and promoting a uniform passive oxide layer. Typically, parts are cleaned and then immersed in a chemical solution. Proper passivation restores corrosion resistance that may be reduced by machining operations or contamination.

Mechanical Finishes: Polishing, Brushing, and Bead Blasting

Mechanical finishing processes modify the surface texture and appearance:

- Polishing: Produces smooth, reflective surfaces; often used for decorative, medical, or food-contact components.

- Brushing: Creates directional satin finish; useful for visible surfaces where uniform appearance is required.

- Bead blasting: Creates matte, non-reflective surfaces, helpful for hiding minor machining marks and creating a uniform look.

Heat Treatment and Hardening

Martensitic and precipitation-hardening stainless steels can be heat-treated to increase hardness and strength. For example, 17-4PH can be machined in the solution-annealed condition and then precipitation hardened to the desired strength level. Heat treatment sequences must be planned alongside machining operations to ensure final dimensions are within tolerance after all processes.

Applications of CNC Machined Stainless Steel Components

Stainless steel CNC machining supports a wide spectrum of industries where corrosion resistance, hygiene, or mechanical strength are essential.

Medical and Dental Devices

Applications include surgical instruments, orthopedic components, dental implants, hospital equipment, and fluid control components. The requirements often include biocompatibility, high corrosion resistance, precise tolerances, and traceable quality control.

Food Processing and Pharmaceutical Equipment

Stainless steels are widely used in food-grade components, packaging machinery, mixing and dosing systems, and sanitary piping. CNC machined parts such as valves, fittings, connectors, nozzles, and housings must meet hygiene standards and be easy to clean and sterilize.

Aerospace, Defense, and Energy

In aerospace and energy, stainless steel CNC machining is used for structural brackets, actuator components, fluid system elements, turbine and engine parts, and various high-strength fasteners. Components must withstand demanding environmental and mechanical conditions, requiring precise machining and rigorous inspection.

Industrial Machinery and Automation

Stainless steel machined parts serve in conveyors, pumps, robotics, measurement equipment, and control systems. They combine resistance to wear and corrosion with dimensional stability, providing long service life and reliable performance in industrial environments.

Calculate Your CNC Machining Cost for Stainless Steel

Stainless Steel CNC Machining Cost CalculatorThis is a simple estimator for CNC machining costs focused on stainless steel parts (e.g., 304/316 grades). Actual costs vary by shop, location, part complexity, and market rates.

Note: This is a rough estimator. Real quotes depend on design complexity, tolerances, tool wear (higher for stainless), location (e.g., higher in USA/Europe), and supplier. For accurate pricing, please contact us.

Cost Factors in Stainless Steel CNC Machining

The total cost of CNC machined stainless steel parts is determined by a combination of material, machining time, tooling, labor, overhead, and quality-related activities. Understanding these factors helps engineers and buyers identify cost-effective solutions while maintaining technical requirements.

Material Costs

Stainless steel raw material typically has a higher price than carbon steel or some aluminum alloys. Cost varies across grades (for example, 316 generally costs more than 304, and precipitation-hardening grades more than standard austenitic). Material cost is directly related to part volume, yield from stock size, and waste due to machining. Optimizing stock selection and near-net shapes can significantly impact cost.

Machining Time and Cycle Time

Stainless steel is generally more time-consuming to machine than free-machining steels or aluminum due to lower cutting speeds and greater tool wear. Machining time is influenced by:

- Part geometry and complexity (pockets, undercuts, deep holes, threads).

- Required tolerances and surface finish levels.

- Number of setups and tool changes.

- Use of multi-axis or mill-turn strategies to reduce repositioning.

Cycle time reductions can yield considerable cost savings for medium and high-volume production.

Tooling Costs and Tool Life

Cutting tools for stainless steel (carbide inserts, drills, end mills, taps) are exposed to higher mechanical and thermal loads. Tool life is a critical economic factor: short life increases tool consumption and machine downtime. Proper selection of tool materials, coatings, geometry, and cutting parameters can substantially reduce tooling cost per part.

Setup, Programming, and Fixturing

Complex stainless steel parts may require specialized fixtures, multiple setups, or detailed CAM programming to ensure accessibility and stability. The cost of setup and programming is amortized over the production quantity. For small batches and prototypes, minimizing setups and using flexible fixturing concepts can be cost-effective.

Quality Control and Inspection

Inspection requirements influence overall cost. Dimensional measurement with calipers and micrometers for basic features is relatively low cost, while comprehensive CMM inspection, surface roughness measurement, and material certification add to the price. Critical applications such as aerospace and medical devices often require additional documentation, traceability, and statistical process control.

Batch Size and Economies of Scale

Batch size significantly impacts unit cost. Non-recurring costs such as programming, fixture design, and first article inspection represent a larger portion of total cost for small batches. For larger volume production, these costs are spread across more parts, and tooling and process optimization investments become economically beneficial.

Typical Issues in Stainless Steel CNC Machining

Stainless steel CNC machining presents several recurring practical difficulties that impact both production and cost if not addressed adequately.

Tool Wear and Breakage

Due to work hardening and low thermal conductivity, stainless steel tends to accelerate tool wear. Inadequate cutting parameters or coolant delivery can lead to premature edge chipping or tool breakage, causing machine downtime and potential scrap.

Surface Quality and Burr Formation

Without optimized machining strategies, machined surfaces may show tearing, built-up edge marks, or inconsistent roughness. Burrs are common on cross-holes and threads, especially with austenitic grades. Deburring operations then become time-consuming and costly if not considered during design and process planning.

Dimensional Stability for Thin-Walled Parts

Thin-walled or high-aspect-ratio stainless parts are prone to distortion from cutting forces and residual stresses, requiring careful fixturing and process sequencing. Achieving tight tolerances on such geometries often demands additional machining passes and intermediate stress relief, increasing cost.

| Cost Driver | Impact on Cost | Typical Mitigation |

|---|---|---|

| Material grade and stock size | Higher alloy content and oversized stock increase material expense. | Select appropriate grade; optimize stock dimensions; use near-net profiles. |

| Geometry complexity | More complex shapes increase cycle time and setup requirements. | Simplify features where function allows; use multi-axis machining. |

| Tolerance and surface finish | Tighter tolerances and fine finishes increase machining and inspection time. | Apply tight tolerances only to critical features; standardize finish requirements. |

| Tooling and tool life | Frequent tool changes raise tool cost and downtime. | Use optimized tools and parameters; implement tool monitoring strategies. |

| Batch size | Small batches carry higher unit cost due to setup and programming overhead. | Group orders; plan repeat runs; consider flexible fixturing. |

| Quality and documentation | Extensive inspection and reporting increase labor and equipment utilization. | Align inspection scope with application criticality; standardize documentation. |

FAQ About Stainless Steel CNC Machining

What is stainless steel CNC machining?

Stainless steel CNC machining is a precision manufacturing process that uses computer-controlled machines to produce custom parts from stainless steel with high accuracy, strength, and corrosion resistance.

Which stainless steel grades are commonly used for CNC machining?

Commonly used grades include 304, 316, 303, 410, and 420 stainless steel. Each grade offers different machinability, corrosion resistance, and mechanical properties depending on the application.

How much does stainless steel CNC machining cost?

Costs depend on material grade, part complexity, tolerance, surface finish, machining time, and order quantity. Stainless steel generally costs more than aluminum due to longer machining time and tool wear.

How can I reduce the cost of stainless steel CNC machining?

Cost can be reduced by optimizing part design, avoiding unnecessary tight tolerances, selecting machinable grades (such as 303), and increasing order quantity.