25CrMo4 and AISI 4140 represent closely related chromium‑molybdenum low alloy steels widely used for highly loaded mechanical components. This guide explains their composition, properties, processing, and selection aspects for engineering and purchasing use.

Chemical Composition of 25CrMo4 and AISI 4140

25CrMo4 (material number 1.7218) is standardized mainly in European norms, while AISI 4140 is widely used under American standards. Both belong to Cr‑Mo low alloy steels, but they have slightly different nominal compositions and carbon levels, leading to somewhat different hardenability and property ranges.

| Grade | C | Si | Mn | P (max) | S (max) | Cr | Mo | Other elements |

|---|---|---|---|---|---|---|---|---|

| 25CrMo4 (EN 1.7218) | 0.22–0.29 | ≤ 0.40 | 0.60–0.90 | ≤ 0.025 | ≤ 0.035 | 0.90–1.20 | 0.15–0.30 | Residual Cu, Ni, etc. as per EN limits |

| AISI 4140 | 0.38–0.43 | 0.15–0.35 | 0.75–1.00 | ≤ 0.035 | ≤ 0.040 | 0.80–1.10 | 0.15–0.25 | Residual Cu, Ni, etc. per ASTM/AISI practice |

The higher carbon content of AISI 4140 typically allows higher achievable hardness and strength after quenching and tempering compared with 25CrMo4, while 25CrMo4 provides good toughness and weldability for many applications in the normalized or quenched and tempered condition.

Relevant Designations and Standards

25CrMo4 and AISI 4140 are defined across different international standards systems. Understanding equivalent designations is important for global sourcing and specification control.

- European designations: 25CrMo4, 1.7218 under EN standards

- American designations: AISI 4140, UNS G41400 under ASTM standards

- Other common equivalents: JIS SCM440, GB 42CrMo (similar to 4140, not identical to 25CrMo4)

Typical standards that specify composition, delivery conditions, and mechanical properties include:

- EN 10083 series for quenched and tempered steels

- EN 10250 for open die forged steels

- EN 10269 for steels for fasteners at elevated and low temperatures (for certain conditions)

- ASTM A29/A29M for general requirements of carbon and alloy steel bars

- ASTM A322 for steel bars, alloy, standard grades

- ASTM A519 for seamless alloy steel mechanical tubing (includes 4140)

When specifying material, it is important to cite both the grade and the relevant standard (for example, 25CrMo4, 1.7218, EN 10083-3) to avoid ambiguity in composition and delivery condition.

Microstructure and Metallurgical Features

The microstructure of 25CrMo4 and AISI 4140 depends strongly on heat treatment and product form. In general:

- In the normalized condition, the microstructure consists of fine pearlite and ferrite.

- After quenching and tempering, the microstructure becomes tempered martensite, sometimes with small amounts of bainite.

- In the annealed condition, spheroidized carbides in a ferritic matrix can be present, giving improved machinability.

Chromium and molybdenum promote hardenability by slowing down transformation from austenite during cooling, enabling the formation of martensite through thicker cross-sections when properly quenched. Molybdenum also improves tempering resistance, allowing high strength with retained toughness after tempering.

Mechanical Properties

Mechanical properties for 25CrMo4 and AISI 4140 depend on the heat treatment condition, product size, and exact specification. The values below represent typical ranges and should not replace the grade-specific standard or inspection certificates.

| Grade / condition | Tensile strength Rm (MPa) | Yield strength Re/Rp0.2 (MPa) | Elongation A5 (%) | Impact toughness KV (J) at RT | Brinell hardness (HBW) |

|---|---|---|---|---|---|

| 25CrMo4, normalized | 650–800 | 450–600 | ≥ 14 | Typically > 35 | 200–260 |

| 25CrMo4, quenched and tempered (approx. 30–36 HRC) | 800–950 | 650–800 | ≥ 12 | Typically > 30 | 285–340 |

| AISI 4140, quenched and tempered (approx. 28–32 HRC) | 850–1000 | 700–850 | ≥ 13 | Application dependent; often > 35 | 277–321 |

| AISI 4140, quenched and tempered (approx. 38–44 HRC) | 1000–1250 | 850–1000 | ≥ 10 | Lower toughness; check specific requirements | 340–430 |

The balance between strength and toughness is defined predominantly by the final tempered hardness: lower hardness improves toughness and fatigue resistance, while higher hardness increases strength and wear resistance but may reduce toughness and weldability.

Physical Properties

Physical properties of 25CrMo4 and AISI 4140 are similar to other low alloy steels with comparable carbon content.

Typical values at room temperature:

- Density: about 7.75–7.85 g/cm³

- Elastic modulus (Young’s modulus): about 205–215 GPa

- Poisson’s ratio: approximately 0.28–0.30

- Thermal conductivity: roughly 42–46 W/(m·K)

- Specific heat capacity: about 460–500 J/(kg·K)

- Electrical resistivity: around 0.20–0.25 µΩ·m

These values vary slightly with temperature and exact composition but are adequate for most engineering calculations where detailed temperature‑dependent data are not mandatory.

Heat Treatment of 25CrMo4 / AISI 4140

Heat treatment is the key to tailoring properties for different applications. Common processes include annealing, normalizing, quenching and tempering, and stress relieving.

1) Annealing

Annealing is applied to soften the material, improve machinability, and homogenize microstructure.

Typical procedure for 25CrMo4 and AISI 4140:

- Heating to approximately 680–710 °C (subcritical spheroidizing or process annealing) or to around 800–850 °C (full annealing, depending on standard).

- Soaking time sufficient to equalize temperature through the section, often 1–2 hours for moderate cross‑sections.

- Controlled slow cooling, usually in the furnace, to avoid the formation of hard structures.

The resulting hardness is usually in the range of about 160–220 HB depending on the exact cycle and material.

2) Normalizing

Normalizing is mainly used for 25CrMo4 to refine grain size and improve toughness prior to final heat treatment or for direct use.

Typical normalizing cycle:

- Austenitizing at around 880–920 °C.

- Soaking time adjusted to section thickness.

- Cooling in still air to room temperature.

This produces a fine pearlitic‑ferritic microstructure with moderate strength and good toughness, often sufficient for many general applications.

3) Quenching and Tempering

Quenching and tempering provide the most widely used property combination for 25CrMo4 and AISI 4140.

Typical quenching parameters:

- Austenitizing temperature: approximately 830–880 °C.

- Holding time: generally 1–2 minutes per mm of effective thickness, but at least about 30 minutes for smaller sections; follow specific furnace practice.

- Quenching medium: oil quench is common; polymer or water may be used for certain sizes and shapes, with careful control to reduce risk of cracking and distortion.

Subsequent tempering is essential to reduce brittleness and adjust hardness:

- Tempering temperature: typically 450–650 °C depending on target strength.

- Higher tempering temperatures result in lower hardness and higher toughness.

- Tempering time: usually at least 1 hour, often 1 hour per 25 mm of section thickness.

For components requiring improved toughness, tempering is often performed in the 550–620 °C range. For higher strength with acceptable toughness, lower tempering temperatures in the 450–520 °C range are selected, considering potential temper embrittlement and relevant standards.

4) Stress Relieving

Stress relieving reduces residual stresses from machining, welding, or cold working without significantly changing mechanical properties.

Typical stress relieving parameters:

- Heating to 500–650 °C depending on previous treatments and required properties.

- Holding for 1–2 hours after reaching temperature.

- Cooling in the furnace or still air to avoid new stresses.

Stress relieving is often applied after rough machining of large 4140 or 25CrMo4 parts to stabilize dimensions before final machining.

Machining Characteristics

25CrMo4 and AISI 4140 exhibit moderate to good machinability depending on hardness and heat treatment condition. Generally, machinability decreases as hardness increases.

Key considerations for machining:

- Annealed condition (about 180–220 HB) provides the best machinability and is preferred for extensive machining operations.

- Quenched and tempered condition at higher hardness (300–400 HB) is more difficult to machine and may require rigid setups, lower cutting speeds, and high‑performance tooling.

- Use of appropriate cutting fluids improves tool life and surface finish, especially in drilling and tapping operations.

- Carbide tooling is commonly used for production machining, while high‑speed steel tools may be sufficient for small or low‑volume work in softer conditions.

Dimensional stability during machining can be influenced by residual stresses from prior heat treatment or from previous machining steps. Stress relieving between rough and finish machining can contribute to better dimensional control for precision components.

Weldability and Welding Recommendations

The weldability of 25CrMo4 and AISI 4140 is limited by their carbon content and hardenability but can be acceptable with proper procedures. 25CrMo4, with lower carbon, is generally easier to weld than fully hardened AISI 4140.

Important welding considerations:

- Preheating is usually required to reduce the risk of cold cracking, particularly for thick sections. Typical preheat ranges:

- 25CrMo4: approximately 150–250 °C depending on thickness and condition.

- AISI 4140: approximately 200–350 °C depending on hardness, thickness, and hydrogen control.

- Low‑hydrogen welding consumables and controlled welding procedures are recommended.

- Interpass temperature should be maintained to avoid excessive cooling rates between passes.

- Post‑weld heat treatment (PWHT) such as stress relieving or tempering is frequently applied to restore toughness and reduce residual stresses.

Without adequate preheating and PWHT, weld regions can form hard, brittle microstructures and suffer reduced toughness or cracking. For highly critical components, welding should be evaluated carefully or avoided by using mechanical joining methods when feasible.

Forming, Forging, and Hot Working

25CrMo4 and AISI 4140 are well suited for hot forming and forging operations.

Typical hot working range:

- Starting forging temperature: around 1150–1200 °C.

- Finishing forging temperature: not below about 850–900 °C.

- Post‑forging cooling: controlled cooling in still air or as specified to avoid excessive hardness and cracking.

After forging, normalizing or quenching and tempering is generally required to refine the grain structure and obtain the specified mechanical properties. Cold forming is more limited and usually restricted to small deformations; for major shape changes, hot forming is preferred.

Corrosion and Surface Protection

25CrMo4 and AISI 4140 are not stainless and exhibit only moderate corrosion resistance, similar to other low alloy steels. In unprotected condition and in the presence of moisture and corrosive atmospheres, they are susceptible to rusting.

Standard surface protection measures include:

- Protective coatings such as painting, powder coating, or plating (for example, zinc or nickel plating).

- Surface treatments such as phosphating or black oxide for short‑term enhanced corrosion resistance and improved oil retention.

- Use of corrosion inhibitors in lubricants and storage packaging.

For components operating in aggressive environments, design should combine suitable coatings, regular maintenance, and proper drainage to minimize crevice and galvanic corrosion. For strongly corrosive environments, stainless steels or other corrosion‑resistant materials may be preferable.

Fatigue and Wear Performance

A key advantage of 25CrMo4 and AISI 4140 is their good fatigue strength, especially when properly heat treated and surface finished.

Fatigue performance is influenced by:

- Ultimate tensile strength and hardness (higher strength often increases fatigue limit to a point).

- Surface condition and roughness: grinding and polishing reduce surface defects that initiate fatigue cracks.

- Presence of notches, keyways, and sharp transitions, which raise local stress.

- Residual compressive stresses at the surface from shot peening or surface rolling, which improve fatigue resistance.

Wear resistance increases with hardness. For 4140 and 25CrMo4 components subjected to sliding or abrasive wear, hardened and tempered conditions with hardness from about 30–45 HRC are common. Surface hardening processes like induction hardening or nitriding can further improve wear performance while maintaining tough cores.

Typical Applications

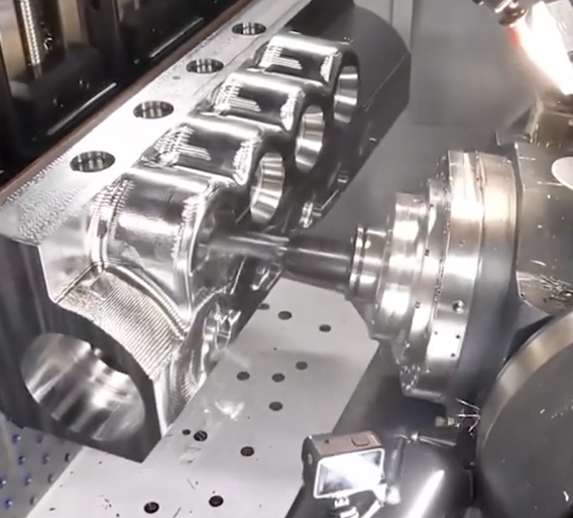

Due to their combination of strength, toughness, and hardenability, 25CrMo4 and AISI 4140 are widely used in mechanical engineering, automotive, energy, and general industrial equipment. Typical applications include:

- Shafts and axles for gearboxes, pumps, and machinery.

- Gears, pinions, and spline shafts where high strength and moderate toughness are required.

- Connecting rods, crankshafts, and other drivetrain components.

- Bolts and high‑strength fasteners (in appropriate conditions and standards).

- Pressure‑bearing components such as fittings, couplings, and certain hydraulic parts.

- Tool holders, mandrels, and fixtures that require good strength and dimensional stability.

- Forged parts in heavy trucks, agricultural machinery, and construction equipment.

25CrMo4 is often selected where good weldability and toughness at moderate strength levels are required, whereas AISI 4140 is frequently chosen for higher strength, wear‑resistant parts in quenched and tempered condition.

Comparison: 25CrMo4 vs AISI 4140

Although 25CrMo4 and AISI 4140 are related chromium‑molybdenum steels, they are not fully identical and should not be interchanged without verification.

Key comparative aspects:

- Carbon content: 25CrMo4 has lower carbon (about 0.22–0.29%) compared with 4140 (about 0.38–0.43%), leading to lower maximum hardness but generally better weldability and toughness at similar strength levels.

- Hardenability: AISI 4140 typically offers higher hardenability, enabling higher through‑hardness for thicker cross‑sections when quenched.

- Application focus: 25CrMo4 is often used in normalized or moderately quenched and tempered conditions, particularly where welding is involved; 4140 is widely used in high‑strength, quenched and tempered applications.

- Standards: 25CrMo4 is primarily defined in EN standards; 4140 is defined in ASTM/AISI and related standards. For international projects, equivalence must be supported by chemical and mechanical property comparisons.

In many non‑critical applications, one grade may be acceptable as a substitute for the other if it meets or exceeds the required mechanical properties, but this must be supported by engineering evaluation, customer approval, and formal documentation.

Issues and Practical Considerations

Using 25CrMo4 and AISI 4140 can involve several practical difficulties that designers, buyers, and manufacturing engineers should consider:

- Control of heat treatment: Inadequate heat treatment can lead to insufficient hardness, reduced fatigue strength, or excessive brittleness. Reliable heat treatment process control and certification are important.

- Distortion and cracking risk: During quenching, large or complex shapes may distort or crack if cooling is uneven or too rapid. Appropriate quench medium selection and fixture design are needed.

- Weld procedure complexity: For welded structures, the need for preheating and post‑weld heat treatment adds time and cost, and may not be easily implemented in all fabrication environments.

- Surface preparation: Achieving the expected fatigue and wear performance often requires proper surface finishing, which adds manufacturing steps and process control requirements.

- Material confusion: The similarity of trade names and close equivalents (25CrMo4, 42CrMo4, 4140, 4130, SCM440) can cause specification errors, making clear documentation and traceability essential.

Selection Guidelines

When selecting between 25CrMo4, AISI 4140, or related materials for a specific component, several aspects should be evaluated:

- Required mechanical properties: target tensile strength, hardness, and impact toughness.

- Component size and geometry: thicker sections may benefit from the higher hardenability of 4140.

- Welding requirements: if extensive welding is necessary, the lower carbon 25CrMo4 may be preferable or the design may involve alternative joining methods.

- Service conditions: presence of cyclic loading, shock, temperature variation, and corrosive environment.

- Availability and standards: depending on region, one grade may be more readily available with suitable certifications in required sizes and forms.

Defining the material in technical documents should include grade designation, standard reference, delivery condition (for example, quenched and tempered to specified hardness), and any special requirements such as maximum cleanliness or ultrasonic testing.

FAQ

What is 25CrMo4 / AISI 4140 steel?

25CrMo4 (EN 1.7218) / AISI 4140 is a chromium-molybdenum alloy steel known for its high strength, good toughness, and excellent wear resistance. It is widely used in high-stress mechanical and hydraulic applications.

What are the main advantages of 25CrMo4 / AISI 4140 steel?

This material offers an excellent balance of strength, toughness, and machinability. It performs well under high pressure and cyclic loading, making it ideal for components requiring long service life and reliability.

Is 25CrMo4 / AISI 4140 easy to machine?

The material has good machinability in the normalized or pre-hardened condition. Proper tooling and machining parameters ensure high precision and surface quality.

How does heat treatment affect 25CrMo4 / AISI 4140 steel?

Heat treatment such as quenching and tempering significantly improves mechanical properties, enhancing strength, hardness, and fatigue resistance while maintaining sufficient toughness for safety-critical applications.

What industries commonly use 25CrMo4 / AISI 4140 steel?

It is widely used in hydraulic systems, construction machinery, oil and gas equipment, automotive components, and heavy-duty mechanical parts.