630 stainless steel, commonly known as 17-4 PH, is a precipitation-hardening martensitic stainless steel widely used where high strength, moderate corrosion resistance and good toughness are required in a single alloy. It is used in aerospace, energy, chemical processing, pumps, valves, and precision mechanical parts that must retain performance under demanding service conditions.

Overview of 630 Stainless Steel

630 stainless steel (UNS S17400, EN 1.4542) is a chromium-nickel-copper alloy belonging to the precipitation-hardening stainless steel family. In practice, it is one of the most frequently specified PH grades because it combines:

- High tensile and yield strength after aging

- Useful corrosion resistance comparable to many 300-series grades in mild environments

- Good dimensional stability and distortion control during heat treatment

The alloy is supplied in various forms including bar, plate, sheet, forgings, castings and wire. Its microstructure and properties are mainly controlled by solution treatment followed by a low-temperature aging (precipitation hardening) process.

Standard Designations and Equivalent Grades

Multiple standards refer to 630 stainless steel using different designations. Knowing these equivalents is important when comparing data sheets or sourcing material internationally.

| System / Region | Designation | Notes |

|---|---|---|

| UNS | S17400 | Unified Numbering System |

| AISI / SAE (informal) | 630 | Often referred to as 17-4 PH |

| Common Trade Name | 17-4 PH | Indicates 17% Cr and 4% Ni nominal content |

| EN | 1.4542 | European material number |

| ASTM (plate, sheet, strip) | ASTM A693 Type 630 | Precipitation-hardening stainless steel plate etc. |

| ASTM (bar, wire, forgings) | ASTM A564 Type 630 | Hot-finished or cold-finished age-hardening stainless steel |

| ASTM (seamless pipe/tube) | ASTM A705 / A705M Grade 630 | Forgings for pressure and high-temperature parts |

| ISO | X5CrNiCuNb16-4 | Approximate nominal composition description |

Chemical Composition

The properties of 630 stainless steel are largely determined by its balanced composition of chromium, nickel, copper and niobium (or niobium plus tantalum). Typical composition limits for wrought products are:

| Element | Typical Range | Function |

|---|---|---|

| Carbon (C) | ≤ 0.07 | Controls hardness and strength; kept low for toughness and weldability |

| Chromium (Cr) | 15.0 – 17.5 | Primary corrosion resistance and martensite formation |

| Nickel (Ni) | 3.0 – 5.0 | Austenite stabilizer; improves toughness and corrosion resistance |

| Copper (Cu) | 3.0 – 5.0 | Key precipitation-hardening element; strengthens during aging |

| Niobium + Tantalum (Nb + Ta) | 0.15 – 0.45 | Carbide/precipitate former; enhances strength and pitting resistance |

| Manganese (Mn) | ≤ 1.00 | Deoxidizer; improves hot workability |

| Silicon (Si) | ≤ 1.00 | Deoxidizer; influences oxidation resistance |

| Phosphorus (P) | ≤ 0.040 | Residual; limited to maintain toughness |

| Sulfur (S) | ≤ 0.030 | Residual; low for better toughness and corrosion resistance |

| Iron (Fe) | Balance | Matrix element |

This composition enables martensitic transformation during cooling and precipitation of copper-rich phases during aging, resulting in high strength with useful toughness.

Microstructure and Strengthening Mechanism

630 stainless steel is supplied in a solution-annealed condition (often designated as condition A) and later hardened by aging. Its microstructure evolves as follows:

- After solution treatment and rapid cooling, the structure is primarily martensitic with some retained austenite.

- During aging at 480–620 °C, fine copper-rich precipitates form, producing precipitation hardening and a significant increase in yield strength.

- Niobium-containing carbides and intermetallics provide additional strengthening and contribute to the stability of the microstructure at service temperatures.

This combination of martensitic matrix and fine precipitates allows 630 stainless steel to reach high mechanical strength levels while retaining acceptable ductility and toughness in properly treated conditions.

Mechanical Properties by Heat Treatment Condition

Mechanical properties of 630 stainless steel are highly dependent on the aging temperature and time. The alloy is commonly designated by conditions such as H900, H1025, H1075, H1150 and others, where the number refers to the nominal aging temperature in °F.

Typical room-temperature mechanical properties for wrought products are as follows (values are approximate and vary with product form, size, and standard):

- Condition A (solution treated): moderate strength, high ductility, easier machining than hardened conditions.

- Condition H900: very high strength, lower toughness and slightly reduced corrosion resistance compared with softer conditions.

- Condition H1025 to H1150: balanced strength and toughness; commonly used for structural components and pressure-containing parts.

Representative ranges (for guidance only):

Tensile strength (Rm): approximately 930–1310 MPa depending on condition.

Yield strength (Rp0.2): approximately 725–1170 MPa depending on condition.

Elongation (A5): approximately 10–20 %.

Hardness: approximately 28–44 HRC (lower hardness for higher aging temperatures).

For precise design, reference should be made to specific standards (such as ASTM A564 or A693) and mill certificates corresponding to the exact heat treatment condition and product form.

Physical Properties

Key physical properties of 630 stainless steel at room temperature include:

- Density: about 7.75–7.80 g/cm³

- Melting range: approximately 1400–1440 °C

- Thermal conductivity: roughly 16–18 W/(m·K), somewhat higher than austenitic stainless steels like 304

- Specific heat: about 460–500 J/(kg·K)

- Electrical resistivity: on the order of 0.9–1.0 μΩ·m

- Coefficient of thermal expansion (20–100 °C): approximately 10–11 × 10−6/K

These values can vary slightly with condition and exact composition, but they provide a useful basis for thermal and dimensional calculations.

Corrosion Resistance Characteristics

630 stainless steel provides moderate to good corrosion resistance in many environments due to its chromium content and passive film formation. Its performance can be summarized as follows:

In general atmospheric and mildly corrosive industrial environments, 630 stainless steel performs well, particularly in aged conditions such as H1025 or H1150. It resists oxidation and general corrosion in many chloride-free or low-chloride environments.

Compared with austenitic stainless steels such as 304 or 316, 630 stainless steel usually has:

- Better stress corrosion cracking resistance in many conditions due to its martensitic structure.

- Comparable pitting resistance to 304 in mild chloride environments, but often inferior to 316 in more aggressive chloride exposures.

In more demanding chloride-bearing media, careful consideration is needed. High-strength conditions (for example H900) may be more susceptible to stress corrosion cracking or pitting under tensile stress and elevated temperature.

In acidic or reducing environments, the corrosion behavior depends strongly on the specific chemistry, temperature and presence of crevices. For long-term immersion or critical pressure-containing components, qualification testing in the actual medium is advisable.

Heat Treatment and Aging Conditions

Heat treatment is the primary tool for tailoring the properties of 630 stainless steel. The usual sequence for wrought products is:

Solution Treatment

Solution treatment is typically performed at a temperature around 1020–1060 °C followed by rapid cooling (generally air cooling for standard cross-sections). This produces a solution-treated martensitic microstructure with good ductility. Condition A is the standard solution-treated condition supplied by many mills.

Precipitation Hardening (Aging)

The precipitation-hardening step is carried out at a lower temperature, usually in the range of 480–620 °C. Commonly used conditions include:

- H900 (approx. 482 °C): maximum strength and hardness, reduced toughness.

- H1025 (approx. 552 °C): high strength with improved toughness compared with H900.

- H1075 and H1100: intermediate conditions balancing strength, ductility and corrosion behavior.

- H1150 or double H1150: lower strength, higher ductility and toughness, often preferred for heavy-section components or applications where impact resistance is important.

Aging times are typically on the order of 1–4 hours, depending on the selected condition, followed by air cooling. Proper control of time and temperature is essential to achieve specified mechanical properties.

Dimensional Stability

Because aging temperatures are relatively low, dimensional changes during hardening are limited. This is a key advantage for precision components: machining can be performed in the softer condition, followed by aging to final strength with minimal distortion when the heat treatment is properly controlled.

Processing and Fabrication

Processing of 630 stainless steel covers forming, machining, welding and surface finishing. Each stage must take into account the martensitic nature and heat treatability of the alloy.

Hot Working

Hot working is typically carried out at temperatures around 950–1200 °C, followed by air cooling or oil quenching depending on section size and required hardness. Uniform heating and avoiding prolonged soaking at high temperature help to maintain a fine and homogeneous microstructure.

After hot working, a solution treatment is normally applied to achieve a consistent martensitic matrix prior to aging.

Cold Working and Formability

Cold formability of 630 stainless steel is more limited than that of austenitic grades. In the solution-treated condition, modest cold bending, rolling or drawing operations can be performed, but forming radii and deformation levels must be chosen carefully to avoid cracking.

Extensive cold deformation may require intermediate stress-relief treatments. In hardened conditions, cold forming is generally restricted due to increased strength and reduced ductility.

Welding Behavior

630 stainless steel can be welded by common processes such as GTAW (TIG), GMAW (MIG/MAG), SMAW and others. Welding is usually performed in the solution-treated condition, followed by a suitable aging treatment to restore or adjust properties in the heat-affected zone and weld metal.

Considerations during welding include:

- Preheating is typically not required for thin to moderate sections, but avoidance of high heat input is recommended.

- Matching or compatible filler metals (often 17-4 PH-type consumables) are preferred to maintain strength and corrosion behavior.

- Post-weld aging at the selected condition (for example H1025 or H1150) is important to achieve uniform mechanical properties.

For critical weldments, procedure qualification and impact or corrosion testing in the welded condition are often specified.

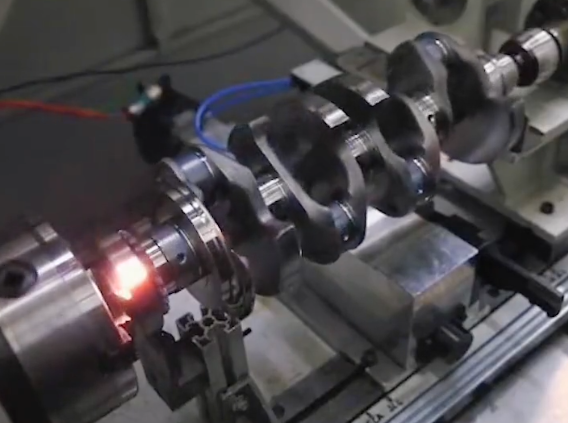

Machining Characteristics of 630 Stainless Steel

Machining is a central practical issue with 630 stainless steel, especially for high-precision components. Its behavior varies significantly with condition.

Machinability in Solution-Treated Condition

In condition A (solution treated), 630 stainless steel has machinability comparable to many other martensitic stainless steels. The material is relatively softer than in hardened states, which allows:

- Economical roughing operations with moderate tool wear.

- Higher allowable cutting speeds compared with aged conditions.

- Acceptable chip control with properly selected tooling and cutting parameters.

Many manufacturers machine components close to final dimensions in condition A and then perform the aging treatment to reach the final strength. This strategy reduces tool consumption and improves dimensional control.

Machinability in Aged Conditions

After aging (for example H900 or H1025), the hardness and strength increase markedly, which leads to:

- Higher cutting forces and heat generation.

- Accelerated tool wear and potentially shorter tool life.

- Greater risk of work hardening at the surface if cutting parameters are not optimized.

Finish machining or light operations such as grinding, honing or fine turning may still be required after aging, especially for tight-tolerance fits or critical surfaces. In these cases, use of rigid machine setups, sharp tools and carefully controlled feeds is important.

Cutting Tool Materials and Parameters

Typical guidelines for machining 630 stainless steel include:

- Carbide inserts are widely used for turning and milling; coated grades designed for stainless steels can improve tool life.

- High-speed steel tools may be used for drilling, tapping or low-speed operations, ideally with cobalt-containing grades for improved hot hardness.

- Positive rake angles and adequate clearance help reduce cutting forces and work hardening.

- Sufficient cutting fluid, preferably with good lubricity and cooling capacity, lowers temperature and surface work hardening.

Exact cutting speeds, feed rates and depth of cut depend on the hardness condition, tool material, machine rigidity and component geometry. Many shops rely on manufacturer recommendations for stainless steel machining and then refine parameters based on tool wear and surface finish observations.

Surface Finish and Dimensional Accuracy

In high-strength conditions, 630 stainless steel may exhibit some tendency to spring-back or residual stress redistribution after machining. To maintain dimensional accuracy:

- Plan machining sequences to balance material removal and minimize asymmetric stress.

- Allow intermediate stress relief in some demanding cases (for example low-temperature temper) before final finishing.

- Apply stable clamping and avoid excessive local clamping forces that could distort thin-walled parts.

Final surface finishes in the range of Ra 0.4–1.6 μm are commonly achievable with appropriate tooling and parameters.

Cost Structure and Price Influencing Factors

The cost of 630 stainless steel is higher than that of many carbon steels and standard martensitic grades, but typically comparable to or slightly below some nickel-rich austenitic or duplex stainless steels, depending on market conditions. Price is influenced by multiple factors.

Alloy Content and Raw Material Cost

The presence of chromium, nickel, copper and niobium raises the raw material value relative to plain steels. Nickel and niobium in particular are sensitive to global commodity markets. When these alloying elements become more expensive, the per-kilogram cost of 630 stainless steel increases accordingly.

Production Route and Product Form

Manufacturing processes affect cost:

- Forged bars, rings or blocks require more energy and processing steps than hot-rolled profiles, resulting in higher prices per unit mass.

- Precision ground bars, peeled bars or centerless-ground products carry additional machining and inspection costs.

- Plates and sheets require controlled rolling and heat treatment, with cost differences between hot-rolled, cold-rolled and precision-rolled products.

Certified material for aerospace or nuclear applications may include extra inspection, testing and documentation, further raising the cost.

Heat Treatment and Machining Costs

Because 630 stainless steel must be solution-treated and often aged to the specified condition, heat treatment costs are a significant part of the total component cost. Factors include:

- Size and mass of the part, which affect furnace time and load density.

- Number of heat treatment stages, for example solution treatment plus one or more aging steps.

- Required control of atmosphere, temperature uniformity and cooling rate.

Machining costs vary according to hardness, shape complexity and tolerance requirements. Components that require finishing in the hardened condition generally incur higher tool and machining expenses than those completed mostly in the solution-treated state.

Supply Conditions and Lot Size

Commercial price also depends on supply chain factors:

- Standard diameters and thicknesses in common conditions (such as condition A) are usually more economical and readily available from stock.

- Custom dimensions, non-standard aging conditions or small order quantities can lead to surcharges for special processing and set-up.

- Lead time requirements influence pricing; urgent deliveries may involve premiums.

For project budgeting, it is typical to obtain quotations from multiple suppliers, specifying exact condition, dimensions, tolerances and certification needs to obtain comparable offers.

Typical Applications

630 stainless steel is selected where high strength and reliable corrosion performance are needed together with good dimensional stability. Typical application categories include:

Aerospace and Defense Components

In aerospace, 630 stainless steel is used for:

- Landing gear parts and structural fittings

- Engine mounts and fasteners

- Actuator components and shafts

The combination of high specific strength, reliable mechanical properties after aging and reasonable corrosion resistance is a key advantage in these applications.

Oil, Gas and Process Industry Equipment

In energy and process industries, 630 stainless steel appears in:

- Pump shafts, valve stems and seats

- Couplings and connector components

- Downhole tools and equipment subject to moderate corrosive environments

Its capacity to maintain strength at moderately elevated temperatures and under cyclic loading is often significant for these uses.

Mechanical and General Engineering Parts

In general engineering, 630 stainless steel is applied to:

- High-strength shafts, spindles and pins

- Molds and dies requiring good polishability and strength

- Precision mechanical components in marine or humid atmospheres

In many of these cases, the ability to machine in solution-treated condition and harden afterwards reduces manufacturing complexity while achieving the required final properties.

Design and Selection Considerations

When selecting 630 stainless steel for a project, several technical aspects should be considered to ensure that the alloy is appropriate for the intended service conditions and manufacturing route.

Strength vs. Toughness Balance

Higher aging temperatures generally yield lower strength but improved toughness and ductility. For components subjected to impact, bending or cyclic loads, designers often prefer intermediate or higher aging temperatures (such as H1025 or H1150) rather than the highest-strength H900 condition, to avoid brittle behavior under service stresses.

Corrosion Environment Assessment

For chloride-containing or otherwise aggressive environments, it is important to:

- Evaluate whether the corrosion resistance of 630 stainless steel is sufficient, especially relative to alternatives such as 316 or duplex grades.

- Consider potential stress corrosion cracking risk under combined stress and temperature.

- Analyze crevice geometry, stagnant zones and cleaning methods that could influence localized corrosion.

In borderline cases, corrosion testing in simulated or actual process media can provide useful data.

Heat Treatment Capability and Control

Achieving the specified mechanical properties relies on correct solution treatment and aging. Designers and buyers should confirm:

- Availability of qualified heat treatment facilities capable of controlling time, temperature and cooling conditions for the part size.

- Appropriate heat treatment cycles in drawings and specifications, including target conditions such as H900 or H1150.

- Inspection requirements (tensile testing, hardness, impact testing) to verify heat treatment results.

Sufficient process control reduces the risk of under- or over-aging, which can respectively lower strength or reduce toughness.

Welded vs. Non-Welded Designs

Where welding is necessary, attention is needed to:

- Design joints that allow uniform post-weld heat treatment of the entire component where feasible.

- Specify compatible filler metals and welding procedures that limit dilution and avoid harmful phases or defects.

- Assess the effect of welding on dimensional accuracy, residual stresses and mechanical properties.

In some designs, using bolted or mechanically joined assemblies may simplify fabrication and avoid complex post-weld aging treatments.

Common Practical Issues and Considerations

Several practical topics often arise when working with 630 stainless steel in production and service.

Work Hardening During Machining

Like other stainless steels, 630 can exhibit work hardening near the machined surface, especially if cutting tools are dull or cutting parameters are not optimized. This can lead to:

- Increased cutting forces in subsequent passes

- Potential surface microcracks or residual tensile stresses

- Reduced tool life

Using sharp tools, appropriate feeds and adequate coolant flow minimizes work hardening and supports consistent machining.

Distortion Control

Although precipitation hardening at low temperature reduces distortion compared with quench and temper processes, some dimensional change can still occur, particularly for asymmetrical or thin-walled components. Designers often mitigate this by:

- Providing machining allowances to permit final finishing after aging.

- Using symmetric cross-sections and balanced material removal.

- Performing trial runs or prototype heat treatments to evaluate size changes.

Inspection and Quality Assurance

For critical components, comprehensive inspection is common, including:

- Chemical analysis to confirm compliance with 630 stainless steel composition limits.

- Mechanical testing in the specified condition to verify tensile strength, yield strength, elongation and hardness.

- Nondestructive testing such as ultrasonic or magnetic particle inspection for forged or machined parts.

These measures help ensure that the alloy has been processed correctly and that internal defects or surface imperfections are within acceptable limits.

FAQ About 630 Stainless Steel

What is 630 stainless steel?

630 stainless steel, also known as 17-4PH stainless steel, is a precipitation-hardening martensitic stainless steel. It offers a unique combination of high strength, good corrosion resistance, and excellent dimensional stability after heat treatment.

What are the equivalent grades of 630 stainless steel?

630 stainless steel is equivalent to:

17-4PH (ASTM / AISI)

UNS S17400

SUS630 (JIS)

EN 1.4542 / X5CrNiCuNb16-4

All these grades refer to the same material with comparable chemical composition and properties.

How does 630 stainless steel compare to 304 or 316 stainless steel?

Compared to 304 or 316, 630 stainless steel offers significantly higher strength but slightly lower corrosion resistance. It is preferred when mechanical strength is more critical than maximum corrosion resistance.

What are common applications of 630 stainless steel?

Typical applications include:

Valves and pump components

Aerospace and automotive parts

Shafts, fasteners, and gears

CNC machined precision components

Is 630 stainless steel magnetic?

Yes. Due to its martensitic structure, 630 stainless steel is magnetic, especially after heat treatment.