CNC machining relies on precise, repeatable removal of material using controlled cutting tools. While a wide range of metals, plastics and composites can be CNC machined, some materials are poor candidates or effectively impossible to machine with conventional CNC milling or turning. Understanding why certain materials cannot be CNC machined is crucial for design, material selection and process planning.

What It Technically Means When a Material “Cannot Be CNC Machined”

“Cannot be CNC machined” can mean several different but related things:

- Tool cannot effectively cut the material (excessive wear, edge failure, no chip formation).

- Material degrades physically or chemically under machining conditions (melting, burning, cracking, smearing, delamination).

- Dimensional accuracy and surface quality cannot be reliably achieved.

- Process becomes uneconomical or unsafe compared to alternative methods.

In practice, some materials are completely incompatible with conventional CNC cutting, while others are technically machinable but only under extremely constrained or specialized conditions, making them impractical for normal CNC shops.

Key Physical and Chemical Factors Limiting CNC Machinability

Whether a material can be CNC machined depends largely on its physical and chemical properties and how they interact with cutting mechanics.

Mechanical Properties

Critical mechanical properties include hardness, strength, toughness, ductility and abrasion behavior.

| Property | Typical “Friendly” Range for CNC Machining | Problematic Extremes |

|---|---|---|

| Hardness (Vickers) | 100–350 HV for general-purpose tooling | > 60 HRC (~700+ HV) often requires grinding or EDM instead of standard CNC cutting |

| Ultimate Tensile Strength | 200–1,000 MPa | > 1,500 MPa creates excessive cutting forces, rapid tool failure |

| Elongation at Break | 10–30 % | < 2 % → brittle fracture and chipping; > 300 % → smearing, burrs instead of clean chips |

| Abrasion Resistance | Moderate (non-loaded plastics, standard steels) | High (fiber-reinforced rubber, filled polymers, certain composites) → extreme tool wear |

Thermal Properties

Cutting generates heat in the tool and workpiece. Thermal properties that limit machinability include:

- Low melting temperature (softening or melting at cutting edge).

- High thermal expansion (dimensional instability under localized heating).

- Very low thermal conductivity (heat concentrates at cutting zone, damaging tool and surface).

Soft thermoplastics with glass transition temperature close to room temperature, or low-melting alloys, are especially sensitive to this effect.

Chemical Reactivity and Phase Stability

Chemical behavior may render materials incompatible with typical CNC cutting fluids or air machining:

- Spontaneous ignition or hazardous reactions in chip form.

- Corrosion or embrittlement in presence of coolant.

- Phase transformations (e.g., decomposition of ceramics at high temperature) altering properties during machining.

Some reactive metals, explosives, and chemically unstable materials fall into this category.

Microstructure and Internal Architecture

Microstructural features such as grain size, porosity, fiber orientation, layer bonding and internal stresses influence chip formation and surface integrity. A material can be strong in bulk but still unsuitable for CNC machining if its structure delaminates, crumbles or tears under localized cutting forces. Many foams, brittle composites and layered materials encounter this issue.

Broad Categories of Materials That Cannot Be CNC Machined Effectively

Materials incompatible with CNC machining generally fall into overlapping categories: extremely soft, extremely hard, extremely brittle, highly elastic, chemically hazardous and structurally unstable under cutting. Below are the categories that most often result in materials being deemed non-machinable in a CNC context.

Extremely Soft and Low-Melting Materials

Very soft materials deform instead of cutting. Tools plow through them, causing smearing, tearing and dimensional inaccuracies. If the melting point is low, the material may melt due to frictional heat at the cutting edge.

Typical examples include:

- Very soft thermoplastics (e.g., low-durometer TPU, some hot-melt adhesives).

- Waxes and certain low-melting fusible alloys.

- Soft food products without fixturing and specialized tooling.

Key mechanisms that prevent proper CNC machining:

1. Plastic Flow Instead of Chip Formation

Below a certain hardness and yield strength, material flows plastically around the cutting edge rather than fracturing into chips. This leads to:

- Heavy burr formation.

- Surface smearing rather than cutting.

- Poor dimensional repeatability.

2. Heat-Driven Softening and Melting

Materials with melting temperatures below approximately 150–200 °C are very susceptible to local softening at typical cutting speeds. Continuous contact with a rotating tool can cause surface melting, welding to the tool and abrupt tool loading. This is especially visible with low-softening hot-melt resins and waxes, which may be more suitable for casting or additive processes than CNC machining.

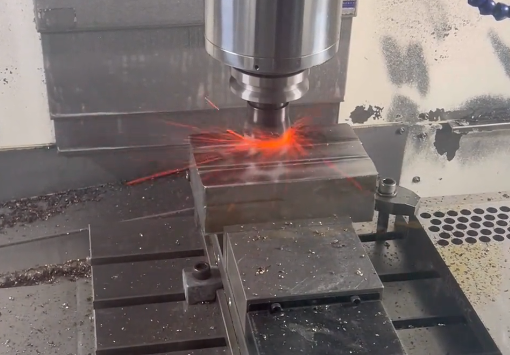

Extremely Hard or Abrasive Materials Beyond Tool Capability

At the opposite extreme, some materials are so hard or abrasive that conventional carbide or even many advanced tools cannot cut them efficiently. The cutting edge wears out so rapidly that machining becomes impractical or impossible.

Materials in this category include:

- Fully sintered tool ceramics and some advanced oxide/nitride ceramics.

- Polycrystalline diamond, cubic boron nitride (PCBN) bulk materials.

- Fully hardened steels beyond the range of available tooling (e.g., certain die steels above 65 HRC, depending on tool technology).

- Highly filled, abrasive composites (e.g., heavy mineral-filled thermosets, some concrete-like composites) without appropriate specialized tooling.

Key limitations:

- Excessive tool wear, requiring constant tool changes.

- Insufficient penetration of the cutting edge (tool simply rubs and overheats).

- Chipping or catastrophic fracture of cutting inserts.

In many cases, such materials are instead shaped by grinding, electrical discharge machining (EDM), laser cutting or other non-conventional processes rather than traditional subtractive CNC milling or turning.

Highly Brittle Materials Prone to Cracking and Chipping

Brittle materials have low fracture toughness and little plastic deformation before fracture. Under localized cutting forces, they tend to chip, crack or shatter instead of forming controlled chips. Even when technically machinable with very specific parameters, surface damage may be unacceptable.

Typical examples include:

- Glass and most glass-ceramics (in the absence of specialized grinding setups).

- Many technical ceramics (e.g., alumina, zirconia, silicon carbide) after sintering.

- Some stone types with strong anisotropy or internal microcracks.

During CNC machining, these materials can show:

- Subsurface microcracking compromising strength and reliability.

- Edge chipping and uncontrolled fracture.

- Unpredictable breakage, especially at thin sections.

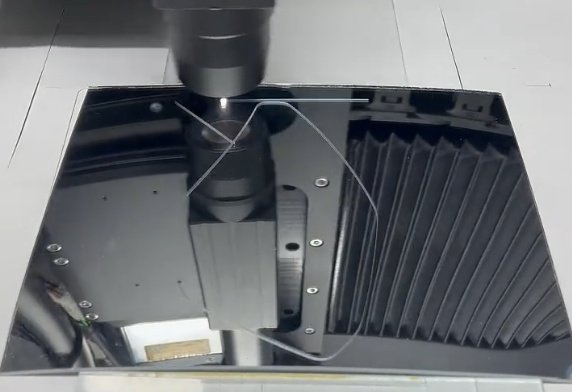

While there are niche CNC processes that use diamond grinding tools on specialized machines to shape glass and ceramics, this moves away from conventional chip-forming CNC cutting into grinding, lapping and polishing processes.

Highly Elastic, Rubber-Like and Viscoelastic Materials

Rubber-like materials present another fundamental limitation. Their high elasticity and viscoelastic behavior mean they deflect away from the cutting tool instead of being sheared cleanly.

Examples include:

- Natural and synthetic rubbers across a wide durometer range.

- Silicone elastomers and many elastomeric seals and gaskets.

- Soft polyurethane foam and similar cushioning materials.

Typical machining problems:

- Material deflection: part bends and rebounds, so the tool cannot define a precise dimension.

- Smearing and tearing: instead of chips, the material stretches and tears, producing ragged edges.

- Poor surface quality: cut surfaces appear rough, distorted or uneven.

For these materials, die cutting, waterjet cutting, molding or laser processing often replace CNC milling or turning for better dimensional control and edge quality.

Highly Porous, Friable and Crumbly Materials

Materials with high porosity and weak internal bonding can crumble under localized cutting forces. As the tool engages, the material may disintegrate instead of producing continuous chips.

Common examples:

- Low-density foams (especially open-cell foams with fragile cell walls).

- Some types of aerated concretes and lightweight building stones.

- Chalk-like or sintered materials with insufficient cohesion.

Problems during CNC machining include:

- Crushing of material rather than cutting.

- Excessive dust and debris instead of controlled chips.

- Dimensional inaccuracy due to local collapse of the material.

For foams and similar substrates, hot-wire cutting, die cutting or specialized abrasive waterjet may provide more predictable results than conventional CNC machining.

Materials With Unstable or Weak Internal Bonding

Some materials have layered, laminated or weakly bonded internal structures that delaminate, tear or peel under cutting loads. Even if their base constituents are machinable, the combined structure may not be.

Examples include:

- Low-quality laminates with poor adhesive bonding between layers.

- Certain printed structures with incomplete interlayer fusion.

- Weakly consolidated composites or green bodies before final curing or sintering.

Representative issues:

- Layer separation and delamination along tool paths.

- Edge fraying and fiber pull-out in loosely bound composites.

- Loss of dimensional integrity because the structure breaks apart during machining.

Many of these structures must be fully cured, sintered or otherwise consolidated before any precision machining is attempted. In the case of some laminates or poorly bonded stacks, they may be unsuitable for CNC machining altogether.

Chemically Reactive, Hazardous or Energetic Materials

CNC machining generates chips, fine particulates and heat, and usually uses cutting fluids or compressed air. Certain materials react dangerously under these conditions and are therefore unsuitable for standard CNC machining.

Examples include:

- Energetic materials (explosives, propellants) that may detonate or deflagrate when cut, heated or impacted.

- Materials that react violently with water-based coolants or oils (e.g., some reactive metals, certain metal hydrides, some strong reducing agents).

- Certain pyrophoric metals in finely divided form, where chips or dust can ignite spontaneously.

Reasons these materials are effectively non-machinable in typical CNC environments:

- Inability to control ignition risk from heat and sparks.

- Dangerous by-products when reacting with cutting fluids.

- Severe health and safety risks from toxic or explosive dust.

When these materials must be shaped, they are usually processed in specialized facilities using strictly controlled methods, often far removed from standard CNC machining practices.

Biological, Hygroscopic and Swelling Materials

Some materials absorb moisture, swell or degrade under exposure to cutting fluids or environmental conditions prevalent in CNC machining. This can make dimensional control and surface integrity difficult or impossible.

Examples include:

- Unstabilized biological tissues or biomaterials not fixed or encapsulated.

- Highly hygroscopic materials that swell significantly with humidity or liquid exposure.

- Certain water-soluble or solvent-sensitive materials that may dissolve or deform in contact with coolant.

Issues encountered:

- Dimensional changes during or after machining due to moisture uptake or loss.

- Surface softening or dissolution at the cutting interface.

- Biological contamination risks and sterility loss for medical applications.

These materials may require alternative shaping techniques such as molding, freeze-drying with post-processing or specialized dry machining conditions that are not commonly available.

Specific Material Classes Commonly Considered Non-Machinable

Beyond broad categories, the following specific material classes are often identified in practice as unsuitable or severely limited for CNC machining.

Certain Thermoplastics and Elastomers

Not all plastics are problematic; many engineering plastics machine well. However, some classes are commonly considered non-machinable or difficult to machine with standard CNC settings:

- Ultra-soft thermoplastic elastomers (TPEs and TPUs with very low hardness).

- Thermoplastics with very low heat deflection temperature, leading to immediate softening near the cutting zone.

- Highly filled and abrasive plastics (e.g., heavy mineral or glass-filled formulations) when appropriate tooling is unavailable.

Key difficulties:

- Elastic recovery, causing machined dimensions to spring out of tolerance.

- Melting and chip welding to tools, leaving poor surface finish and requiring frequent cleaning.

- Excessive tool wear due to hard fillers in certain compounds.

In some cases, temperature control, specialized tool geometries and very sharp cutting edges can improve results, but the process may remain impractical at scale.

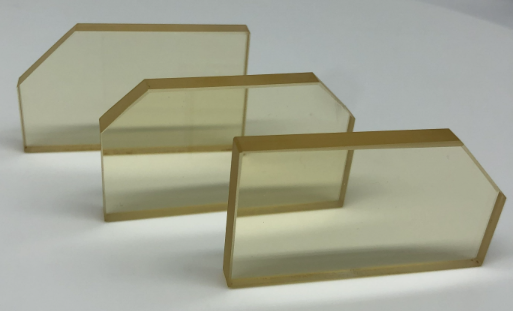

Fully Sintered Technical Ceramics Without Grinding

Technical ceramics such as alumina, zirconia, silicon nitride and silicon carbide are widely used in high-performance applications. Once fully sintered, they are extremely hard and brittle. Conventional chip-forming CNC milling or turning with typical carbide tools is usually not feasible.

Common limitations:

- Hardness significantly exceeding carbide tool capability.

- Severe brittleness, leading to edge chipping and crack initiation under contact stress.

- Ineffective chip formation, resulting in surface damage and tool failure.

Machining of such ceramics generally relies on diamond grinding, ultrasonic machining or green machining (shaping the material before full sintering), not conventional CNC cutting.

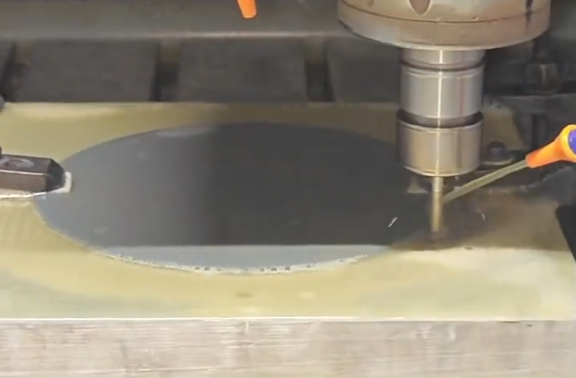

Glass and Most Glass-Like Materials

Glass combines high hardness, low fracture toughness and a tendency to crack. Standard CNC milling and turning are rarely appropriate for glass shaping, especially when fine features and surface integrity are required.

Common outcomes under conventional machining:

- Random cracking and breakage in thin or delicate sections.

- Extensive chipping at edges, damaging optical or sealing surfaces.

- Subsurface damage that is not visible but degrades mechanical strength.

Instead, glass processing typically uses grinding, polishing, laser cutting or abrasive waterjet in controlled setups.

Foams and Highly Cellular Materials

Although some rigid foams can be machined using specialized CNC routers, many very low-density or highly elastic foams are effectively non-machinable with conventional tooling. The cellular structure collapses, tears or melts instead of cutting cleanly.

Typical observations include:

- Deformation and compression under tool pressure, preventing accurate depth control.

- Cell wall tearing, producing ragged surfaces and dust.

- Localized melting or fusing in thermoplastic foams, causing rough surfaces.

Hot-wire cutting, die cutting and waterjet methods often provide better control for such materials.

Energetic and Pyrophoric Materials

Energetic materials (explosives, propellants, pyrotechnics) and some pyrophoric metals cannot be safely subjected to CNC machining with conventional cutting tools.

Key reasons:

- Spark generation from tool-workpiece interaction may initiate combustion or detonation.

- Heat buildup may trigger exothermic reaction in energetic compounds.

- Fine chips or dust may have much lower ignition thresholds than bulk material.

Processing such materials often involves casting, pressing, controlled chemical synthesis into near-net shapes or specialized non-sparking manual methods, not general-purpose CNC equipment.

Typical Difficulties When Attempting to Machine Non-Compatible Materials

When engineers or machinists attempt to use CNC machining on materials outside its practical range, several recurring issues arise.

Dimensional Inaccuracy and Poor Tolerances

Soft, elastic or swelling materials rarely hold tight tolerances under typical clamping and cutting forces. The workpiece may deflect or change size during and after machining. As a result, parts can fall outside tolerance despite apparently correct toolpaths and offsets.

Unacceptable Surface Finish and Edge Quality

Instead of clean cuts, non-compatible materials often show ragged or smeared surfaces and heavily burred edges. For applications where sealing, mating, optical performance or fatigue life depend on surface quality, this alone can render a CNC process unusable.

Accelerated Tool Wear and Process Instability

Abrasive or extremely hard materials can destroy cutting tools very quickly. Frequent tool changes, variable tool wear and unpredictable tool life make process control difficult and raise costs. In severe cases, tools may chip or fail catastrophically, creating safety risks and damaging machine spindles or fixtures.

Safety and Contamination Risks

Certain materials generate hazardous dusts, fumes or chips when machined. Others may react with coolants or ignite. These effects can exceed the safety controls of typical CNC shops, requiring specialized ventilation, containment and process design that goes beyond standard practice.

How to Assess Whether a Material Can Be CNC Machined

Before committing to CNC machining for a new material, it is useful to evaluate several technical aspects.

Review Fundamental Material Properties

Key data to examine include:

- Hardness and tensile strength (to estimate cutting forces and tool requirements).

- Fracture toughness and elongation (to judge brittleness versus ductility).

- Melting point, glass transition temperature and heat deflection temperature (to anticipate softening or melting).

- Thermal conductivity and expansion (to assess local heating and dimension changes).

- Chemical stability with air, coolant and expected cutting temperatures.

Where data points to extremes (very soft, very hard, very brittle, highly reactive), CNC machining may be impractical or require specialized capabilities.

Analyze Microstructure and Construction

For composites, laminates and foams, microstructural features are as important as bulk properties. Consider:

- Fiber orientation, matrix ductility and interfacial bonding.

- Porosity and cell structure for foams.

- Layer bonding quality and orientation in laminates.

Delamination or crumbling under localized loading is a sign the material may not be suitable for conventional machining without modification.

Evaluate Safety and Environmental Aspects

For any material with potential hazards, review:

- Combustibility and ignition temperature of bulk and dust.

- Potential reactions with coolant or air at elevated temperature.

- Toxicity of dusts, vapors or chips.

Where risks cannot be effectively mitigated within typical CNC shop infrastructure, alternative manufacturing methods should be considered.

Alternative Processes for Materials Unsuitable for CNC Machining

When a material cannot be CNC machined effectively, several other manufacturing methods may be more appropriate.

| Material Type | Typical Alternative Processes | Key Advantages vs. CNC Machining |

|---|---|---|

| Soft elastomers, rubber | Injection molding, compression molding, die cutting, waterjet cutting | Better edge definition, no elastic deflection issues, higher productivity in volume |

| Foams and cellular materials | Hot-wire cutting, die cutting, abrasive waterjet, molding | Reduced crushing, smoother surfaces, feasible for low-density structures |

| Glass and technical ceramics | Grinding, lapping, polishing, laser cutting, green machining | Controlled material removal with minimal cracking and surface damage |

| Extremely hard alloys and carbides | EDM, grinding, near-net shape forming, powder metallurgy | Reduced tool wear, ability to shape very hard materials |

| Energetic or reactive materials | Casting, pressing, controlled chemical synthesis, non-sparking manual methods | Improved safety, controlled environment for hazardous materials |

| Hydrophilic or swelling materials | Dry cutting with specialized tools, molding, additive manufacturing | Minimized moisture-induced distortion and surface degradation |

Design Considerations When Material Choice Conflicts With CNC Machining

When designers select materials without considering machinability, conflicts can arise later in production. There are several strategies to align design intent with manufacturing capabilities.

Material Substitution With Similar Performance

In many applications, a problematic material can be replaced with a more machinable alternative while retaining necessary performance characteristics, such as:

- Switching from extremely soft elastomer to a slightly harder grade that remains machinable but still provides adequate flexibility.

- Using a machinable ceramic or composite instead of a fully sintered ultra-hard ceramic.

- Replacing a highly filled abrasive polymer with a formulation that balances machinability and mechanical properties.

Data sheets and application engineering support from material suppliers can guide such substitutions.

Hybrid Manufacturing and Near-Net Shape Processes

In some cases, it is effective to combine methods:

- Form a near-net shape using casting, molding or powder processes.

- Apply CNC machining only to secondary features on more machinable regions or inserts.

- Integrate mechanical interfaces via separate, machinable components bonded to or embedded in the primary material.

This approach reduces or eliminates the need to cut the non-machinable material directly.

Component Redesign to Minimize Sensitive Features

Geometry can amplify machining challenges. Features such as thin walls, sharp internal corners and deep pockets are especially difficult in materials near the limits of machinability. Redesigning components to reduce such features or accommodate alternative processing steps can make manufacturing feasible without compromising overall function.

Summary

Not all materials are compatible with CNC machining. Extremely soft, hard, brittle, elastic, porous, chemically reactive or structurally unstable materials often fall outside the practical range of conventional milling and turning. Limitations arise from fundamental interactions among mechanical, thermal, chemical and microstructural properties and the demands of chip-forming cutting.

By understanding the reasons certain materials cannot be CNC machined, engineers and manufacturers can make informed choices about material selection, process planning and part design. Where CNC machining is unsuitable, alternative methods such as molding, grinding, EDM, waterjet or additive processes may provide more reliable and economical paths to achieving the required part geometry and performance.

FAQ

Are all metals suitable for CNC machining?

No. While most metals can be machined, extremely hard or brittle metals like tungsten carbide, hardened tool steels, or some ceramics are difficult or impossible to machine on standard CNC equipment. Their hardness can cause excessive tool wear, breakage, or even damage the machine.

Can plastics be CNC machined?

Many plastics are CNC-friendly, but some soft, sticky, or highly flexible plastics (like very soft polyethylene or silicone) can be problematic. They may deform, melt, or chatter during machining, resulting in poor tolerances and surface finish.

Are composites hard to machine with CNC?

Some composites, especially carbon fiber or fiberglass, can be machined, but they are abrasive and can quickly wear out tools. In addition, improper tooling can lead to delamination or rough edges, making CNC machining challenging without the right setup.

Are there any materials that are completely impossible to CNC machine?

Yes. Materials that are extremely hard, brittle, or have unusual physical properties (like hardened ceramics, diamond, or certain glass types) cannot be machined with conventional CNC mills or lathes. They require specialized processes like EDM (Electrical Discharge Machining), waterjet cutting, or laser machining.

What should I do if my chosen material is difficult or impossible to CNC machine?

First, review whether a similar but more machinable material can satisfy your design requirements. If not, consider alternative manufacturing processes such as molding, casting, grinding, EDM, waterjet or additive manufacturing. Hybrid approaches are also common: use near-net shaping for the primary material and restrict CNC machining to inserts or secondary features made from machinable materials. Consulting both material suppliers and experienced machinists can help identify viable alternatives.